Blogs

Understanding Monel Water Heaters: An In-Depth Tutorial on Features and Maintenance

Introduction

In the realm of water heater technology, Monel alloys are emerging as a game-changer, particularly for those operating in demanding environments. With their remarkable corrosion resistance and durability, these nickel-copper alloys are not just a material choice but a strategic asset for procurement managers looking to enhance operational reliability.

As water heating systems face the challenges of harsh conditions, Monel proves its mettle, showcasing exceptional performance that extends beyond mere functionality. This article delves into the unique properties of Monel, essential maintenance practices, comparisons with alternative materials, and the long-term cost benefits, while also highlighting its environmental advantages and future technological trends.

Understanding these facets is crucial for professionals aiming to make informed decisions that ensure both efficiency and sustainability in their procurement strategies.

Exploring the Unique Properties of Monel in Water Heaters

Nickel-copper mixtures are renowned for their exceptional resistance to corrosion, especially in seawater and acidic conditions. This trait makes them remarkably suitable for heating devices such as the monel water heater that function under difficult conditions, as well as for boat components and marine fixtures, including hot liquid appliances, gas tanks, and pumps. Recent studies indicate that Monel-400 exhibits a polarization resistance (R_p) of 32.59 Ω·cm² in deaerated 3.5% NaCl solutions, highlighting its robustness against both uniform and pitting corrosion.

Such properties not only ensure reliability but also extend the longevity of these systems in harsh environments. Furthermore, certain alloys demonstrate excellent mechanical properties, allowing them to endure high temperatures essential for effective fluid heating. Their inherent resistance to pitting and stress-corrosion cracking further solidifies monel water heater’s position as a preferred choice for water heater applications.

Additionally, this material’s compatibility with various welding processes facilitates straightforward installation and maintenance, making it an advantageous option for procurement managers. As El-Sayed M. Sherif observes, the rigorous testing of alloys such as this one reveals their superior performance characteristics, especially in demanding applications. Therefore, the inclusion of this alloy in a monel water heater is not merely a selection but a calculated choice for maximum efficiency and longevity.

Recent studies also conclude that the deaeration process significantly decreases both uniform and pitting corrosion of Monel-400 in Arabian Gulf environments and 3.5% NaCl solutions, further emphasizing its effectiveness in harsh conditions.

Essential Maintenance Tips for Monel Water Heaters

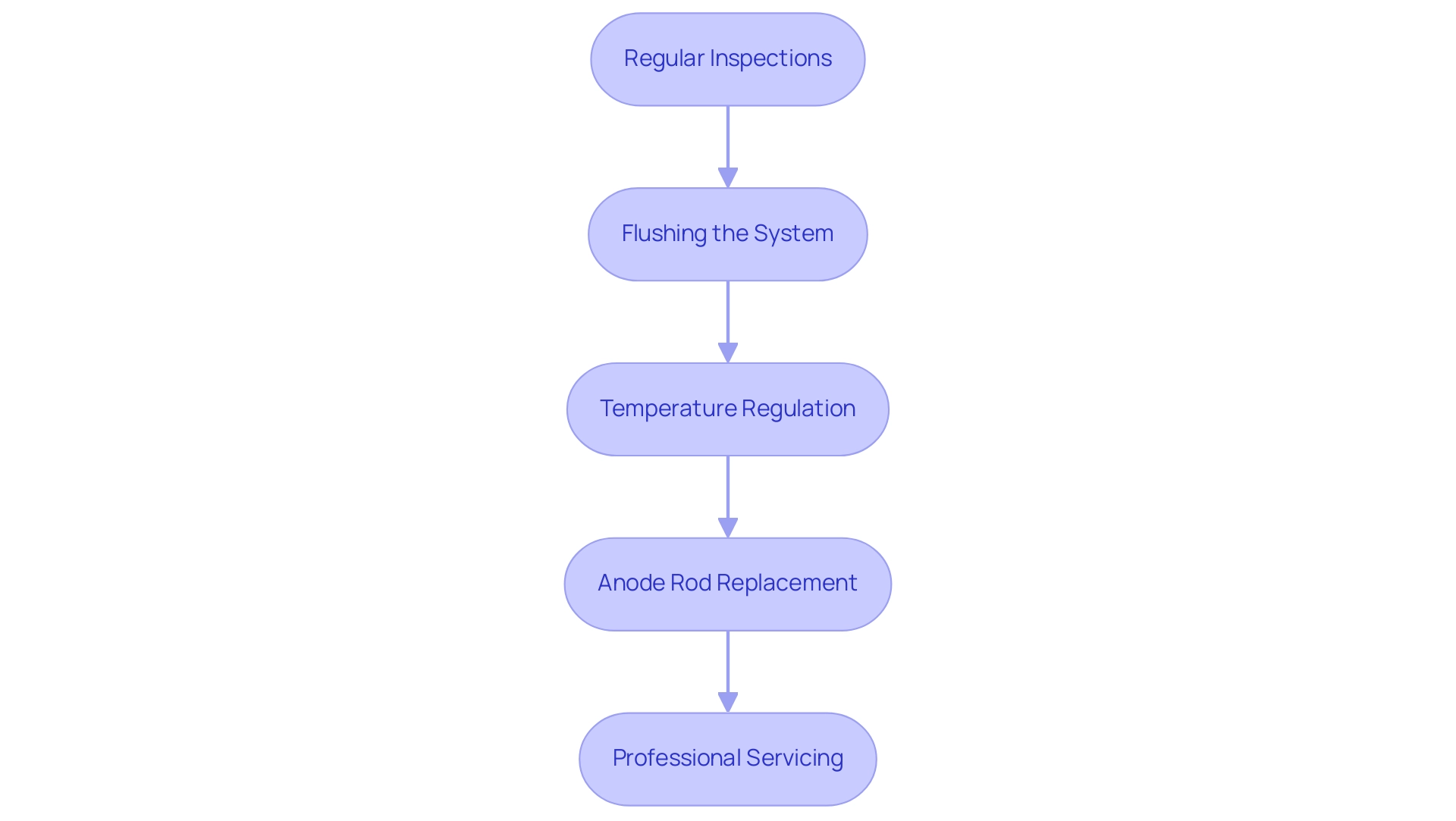

To maximize the longevity and efficiency of Monel water heaters, it is essential to follow a structured maintenance routine that includes the following steps:

Regular Inspections: Conduct annual inspections to identify signs of corrosion or wear. Pay close attention to connections and joints for any leaks, as these can lead to significant issues over time. As noted, one of the most common causes of premature failure of a tank system is rust, making inspections critical.

Flushing the System: Periodically clearing the tank is crucial to eliminate sediment buildup. This buildup can not only hinder efficiency but also contribute to corrosion, thereby shortening the lifespan of the unit. Tankless heaters have an average lifespan of about 20 years, highlighting the necessity for proper maintenance to attain this longevity.

Temperature Regulation: Maintain the liquid temperature at a maximum of 120°F (49°C). This practice not only reduces scaling but also lowers energy consumption, enhancing overall efficiency.

Anode Rod Replacement: While this alloy is known for its corrosion resistance, it is advisable to regularly inspect and replace the anode rod. This proactive measure protects the tank and significantly extends its service life.

Professional Servicing: Schedule professional maintenance every few years to ensure all components are functioning optimally. This routine checkup can help identify and address potential issues before they escalate, ensuring the system operates at peak performance. A case study titled ‘Improving Energy Efficiency’ illustrates that after proper installation and maintenance of a demand system, additional energy-saving options can help reduce heating expenses, reinforcing the value of regular servicing.

Following these maintenance practices will help maintain your Monel water heater in optimal condition, significantly prolonging its service life and improving energy efficiency. Regular inspections and maintenance align with best practices that have been shown to improve the reliability of these systems, ultimately contributing to cost savings and improved performance.

Comparing Monel with Other Materials in Water Heater Manufacturing

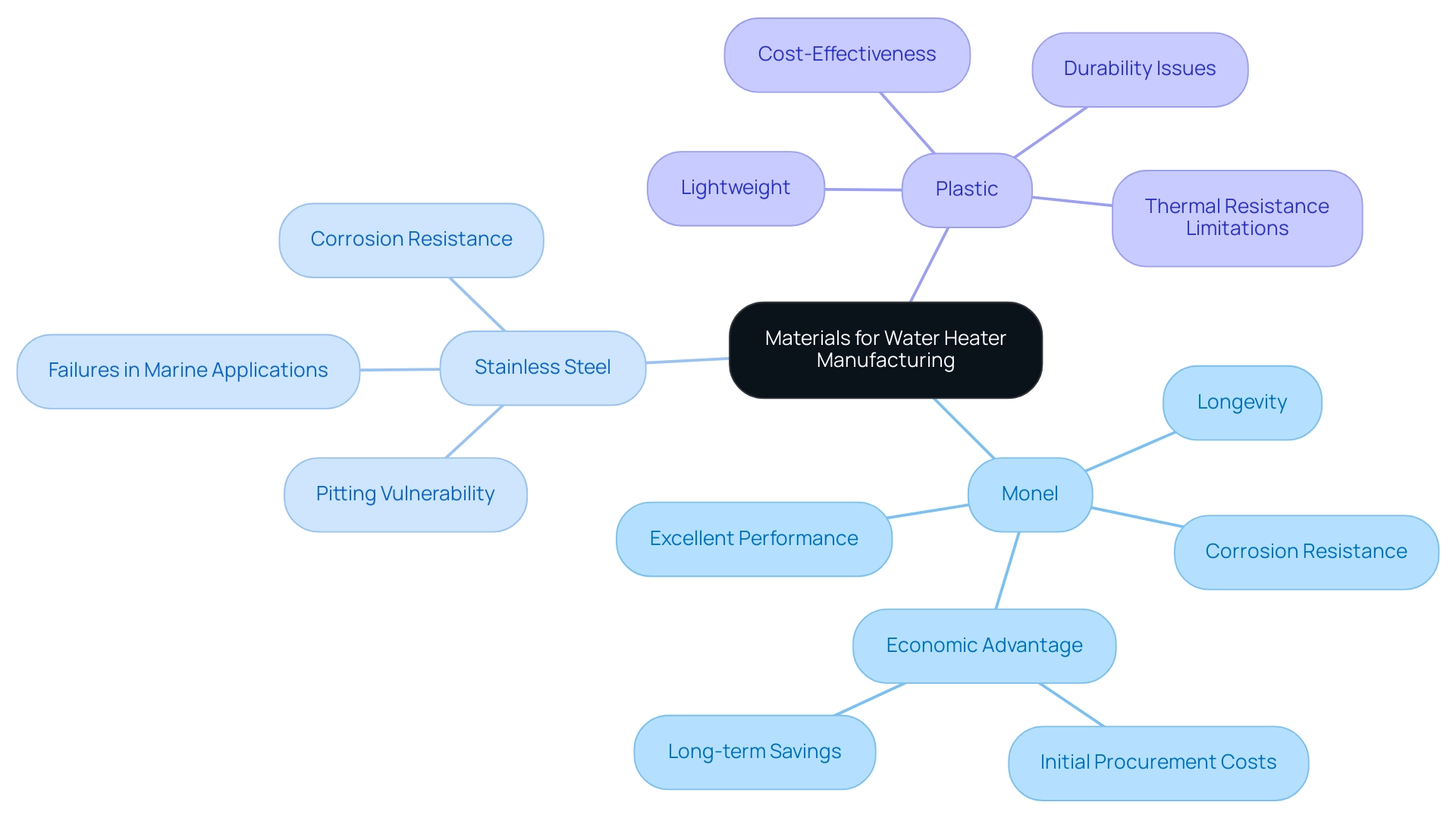

When assessing materials for water heater production, nickel-copper alloys, especially type 404, appear as a better option compared to both stainless steel and plastic. All spar manufacturers suggest using a specific type of wire due to extensive experience with small boats, emphasizing its reliability in marine environments. While stainless steel is known for its corrosion resistance, it has a notable vulnerability to pitting, especially in saline environments, which can pose significant risks in marine settings.

In contrast, this material is specifically designed to thrive under such harsh conditions, making it a reliable choice for marine applications. Plastic may offer a lightweight and cost-effective solution; however, it falls short in terms of durability and thermal resistance, particularly in high-temperature scenarios common in heating systems.

Monel’s exceptional performance characteristics contribute to its extended lifespan, which can ultimately balance out its initial procurement costs. For example, alloy 404, with its composition of 42 to 47 percent copper, is utilized extensively in marine fixtures, including monel water heaters, gas tanks, and pumps, as well as electronic components. The resilience of this mixture ensures consistent operation and longevity, providing an economic advantage over time.

Furthermore, industry experts note that we’ve seen stainless cotter pin failures on props, but not in the rigging, which underscores the reliability of this material in marine applications. Overall, the excellent performance and longevity of materials like the monel water heater justify their choice over stainless steel and plastic, making them the favored option in the competitive field of manufacturing hot systems.

Cost-Benefit Analysis of Using Monel for Water Heaters

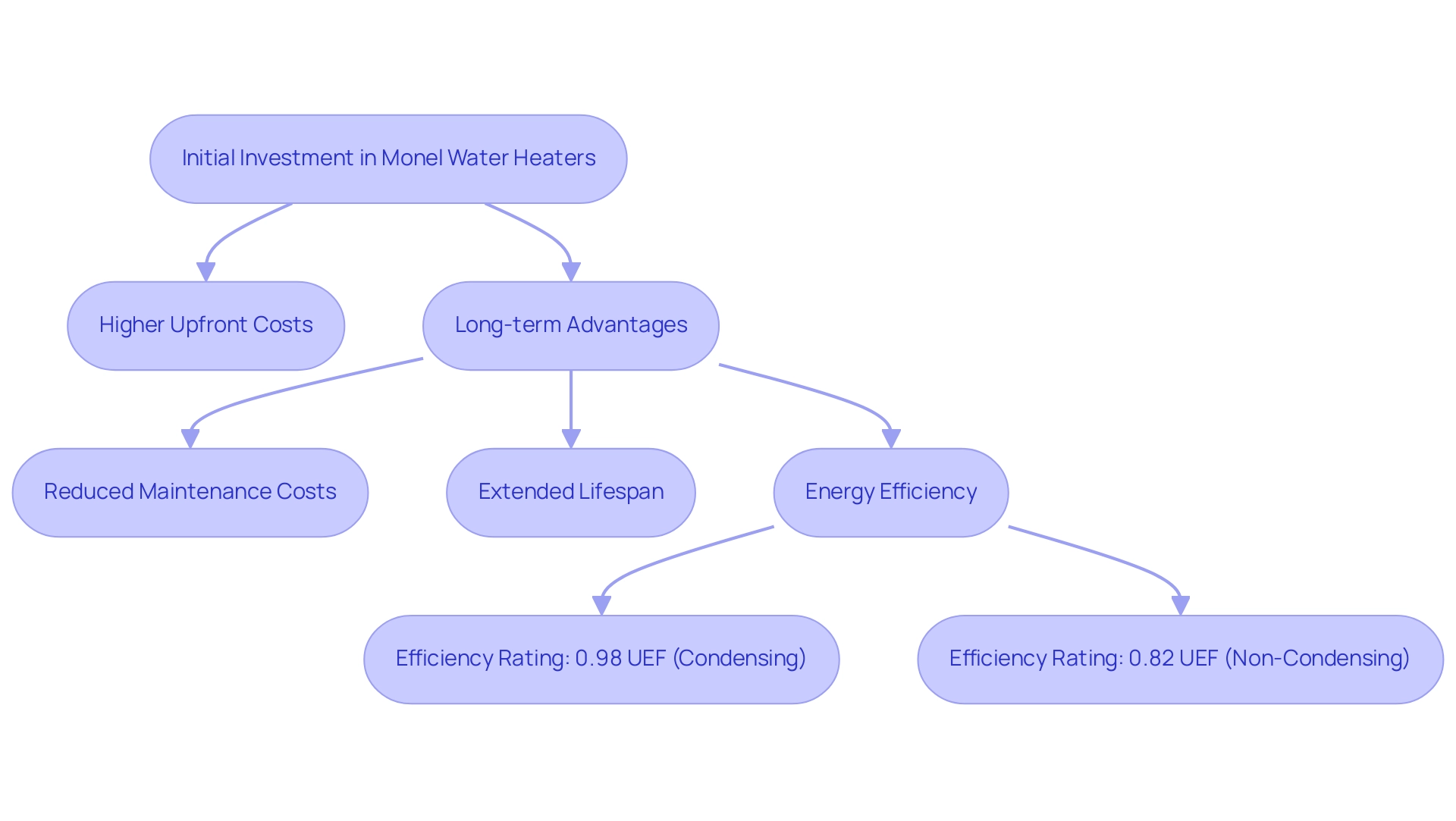

While the initial investment in specialized water devices may exceed that of standard materials, the long-term advantages often justify the higher upfront expenses. Certain alloys are renowned for their exceptional durability, which significantly reduces maintenance expenses and the frequency of replacements over time. This characteristic ultimately leads to a lower total cost of ownership.

Furthermore, the natural efficiency of this alloy in challenging conditions guarantees that these devices function effectively while using less energy. For instance, tankless heaters can achieve efficiency ratings of up to 0.98 UEF in condensing models and up to 0.82 UEF in non-condensing models, highlighting the potential for energy savings. A comprehensive cost-benefit analysis must encompass both direct expenditures and the anticipated savings stemming from decreased repair needs and an extended lifespan.

Many businesses discover that opting for a monel water heater translates into substantial dividends, resulting in enhanced reliability and reduced operational costs. This is further supported by a case study on induction heating systems, which demonstrated high efficiency and low-cost operation and maintenance, making it a viable market solution. Additionally, recent news from Apollo emphasizes the importance of reliable and cost-efficient service, as they assist residents in Akron, OH, with water heater replacement or repair.

As noted by Halil Murat Ünver from Kırıkkale University, the goal is to develop efficient heating systems that offer low-cost operation and maintenance, a vision underpinned by advancements in this technology that are applicable in the market.

Understanding the Environmental Impact of Monel

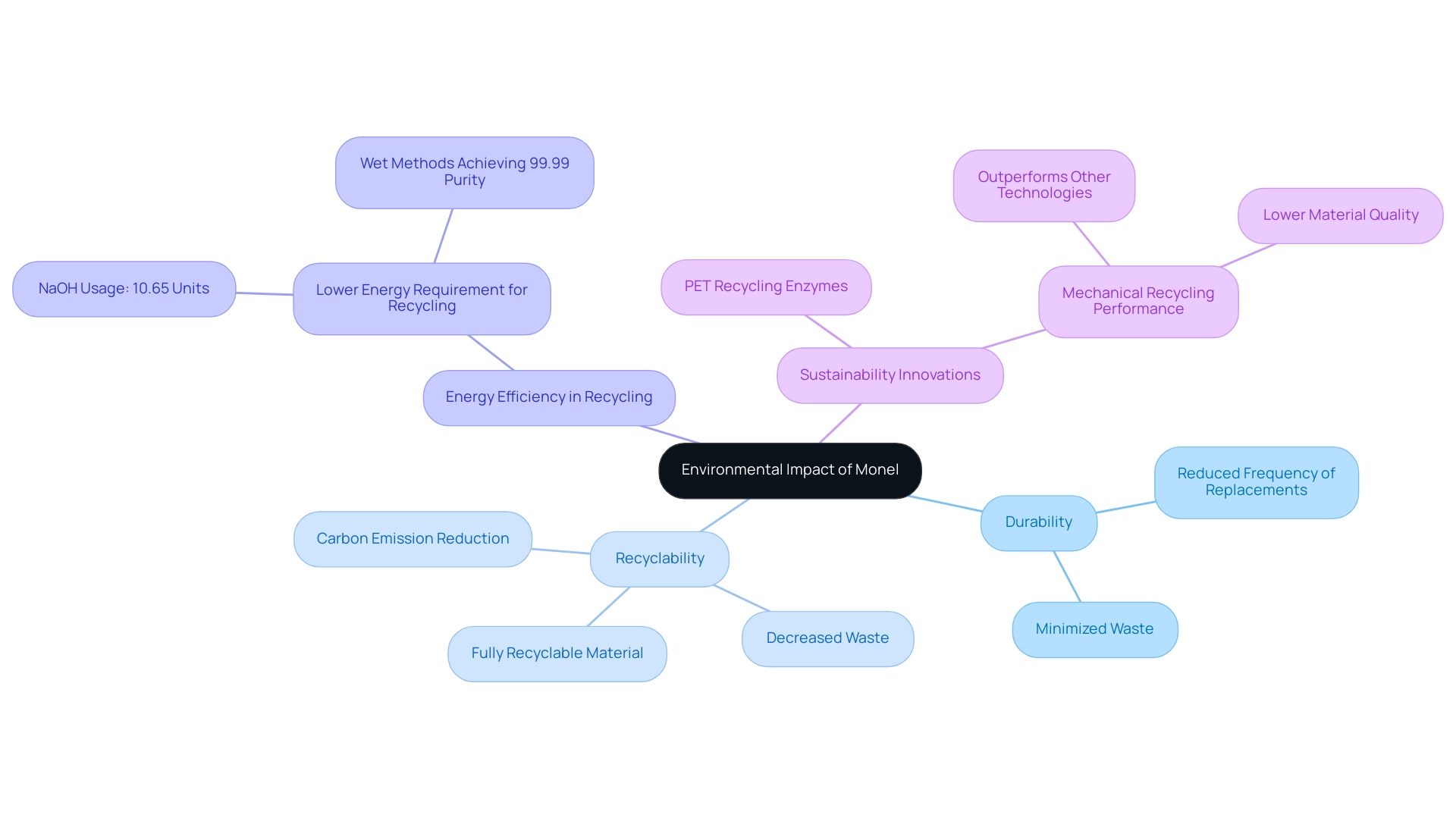

These alloys stand out not only for their exceptional performance but also for their significant environmental benefits. Their inherent durability translates to reduced frequency of replacements, which effectively minimizes waste. Furthermore, this material is fully recyclable, a characteristic that substantially decreases the ecological footprint throughout its lifecycle.

Notably, the energy required for recycling this alloy is considerably lower than that needed for the production of new materials, leading to a reduction in carbon emissions. For instance, the energy needed for NaOH usage in platinum recycling is 10.65 units, while wet methods can achieve a purity of up to 99.99%. This emphasizes the efficiency of this type of recycling in comparison.

As noted by environmental expert Nalini Chauhan, the escalating production of municipal and industrial wastewaters, alongside heightened metal emissions, underscores the urgent need for sustainable material solutions. Considering these factors, incorporating monel water heater into procurement strategies aligns seamlessly with sustainability objectives while ensuring high performance in water heating applications. Additionally, the case study titled ‘Performance Analysis of Plastic Recycling Technologies’ demonstrates that mechanical recycling outperforms other technologies economically and environmentally, suggesting that this recycling potential could similarly yield beneficial outcomes.

Furthermore, the ongoing innovations in PET recycling enzymes reflect the broader movement towards sustainability in materials, indicating that this entity’s role in eco-friendly manufacturing could be pivotal.

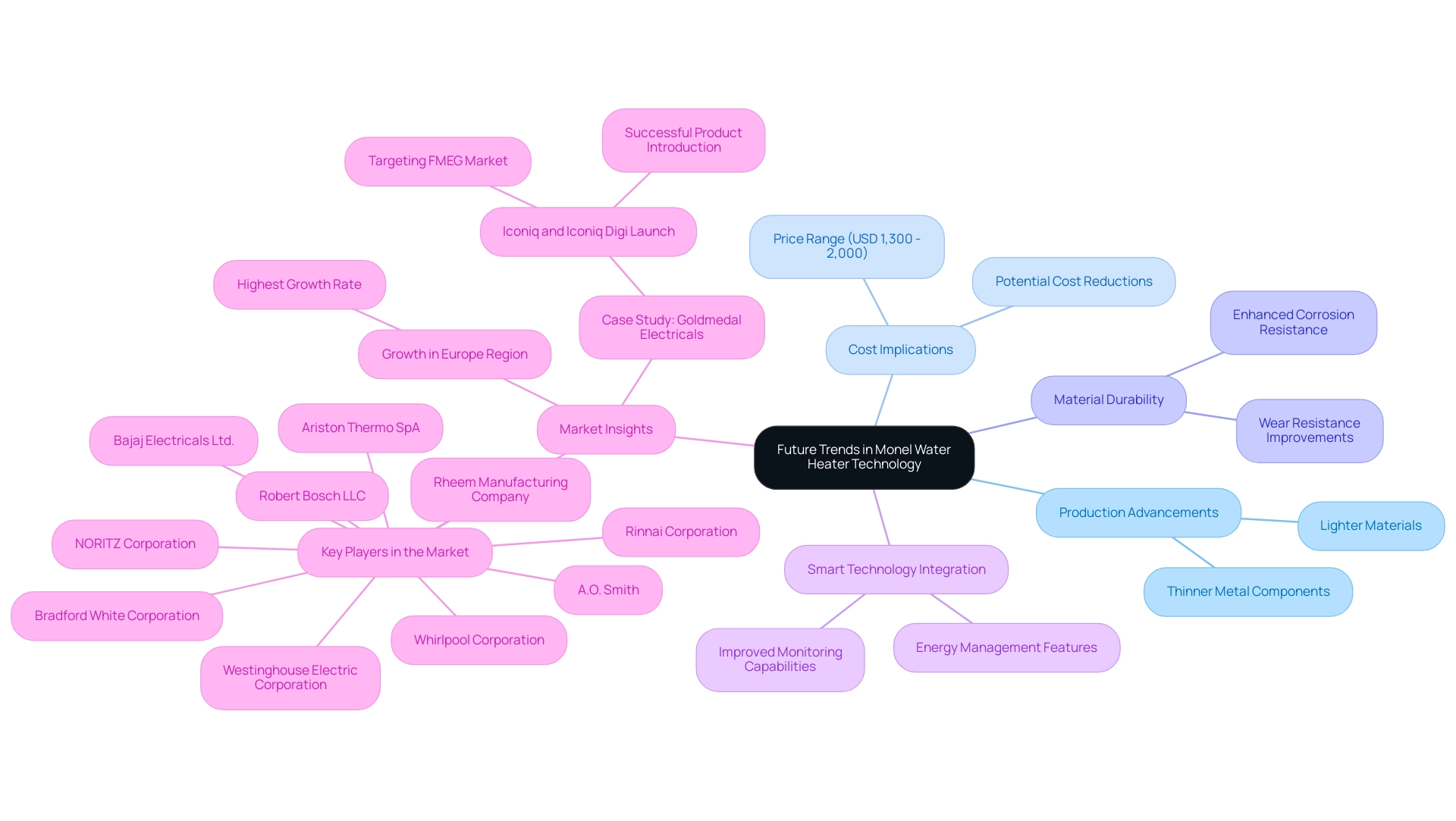

Future Trends in Monel Water Heater Technology

The scenery of thermal units is changing swiftly, propelled by considerable technological progress in both design and production. Recent advancements in production methods are allowing the development of thinner and lighter metal components, all while preserving the durability that this material is recognized for. This shift not only improves efficiency but also has the capacity to reduce costs, which is especially significant considering that the price of a brand-new tank-type appliance in the U.S. varies from USD 1,300 to USD 2,000—a crucial factor for procurement managers.

Furthermore, ongoing research into alloy compositions is poised to enhance Monel’s resistance to corrosion and wear, building on its already impressive durability. Notably, the integration of smart technology in Monel water heaters is transforming how they function, offering improved monitoring and control capabilities that facilitate better energy management. As highlighted by industry experts, including Straits Research, which noted that the Europe region has experienced the highest growth rate in the Water Heater Market, staying abreast of these trends is essential for procurement professionals aiming to harness the latest advancements and optimize the solutions available to their organizations.

A practical example of these innovations can be seen in Goldmedal Electricals’ recent launch of the Iconiq and Iconiq Digi Storage Water Heaters, which successfully entered the competitive Fast Moving Electrical Goods market in India. Embracing these innovations will undoubtedly position procurement managers to drive operational efficiency and cost-effectiveness in their respective sectors.

Conclusion

The exploration of Monel alloys in water heater technology reveals a compelling case for integrating these materials into procurement strategies. With their remarkable corrosion resistance and durability, Monel alloys, particularly the nickel-copper variants, stand out as an optimal choice for environments where conventional materials may falter. From their superior mechanical properties to their ability to withstand high temperatures, Monel not only enhances the performance of water heating systems but also extends their lifespan significantly.

Implementing a structured maintenance routine is crucial for maximizing the benefits of Monel water heaters. Regular inspections, system flushing, and professional servicing ensure that these systems operate efficiently, minimizing potential issues that could arise from neglect. The comparison of Monel with other materials further underscores its advantages, as its long-term performance and durability often outweigh initial investment costs, leading to substantial savings over time.

Moreover, the environmental impact of Monel cannot be overlooked. Its recyclability and reduced replacement frequency contribute to sustainability goals, making it an attractive option for organizations committed to reducing their ecological footprint. As the market evolves with advancements in technology and design, procurement managers must remain informed about these trends to leverage the full potential of Monel alloys.

In summary, the strategic adoption of Monel in water heater applications not only enhances operational reliability and efficiency but also aligns with broader sustainability objectives. By prioritizing these innovative materials, organizations can achieve significant long-term benefits, ensuring they remain at the forefront of industry advancements while optimizing their procurement strategies.