Blogs

What Are Monel Hardened Stirrups? Understanding Their Importance in Equestrian Gear

Overview

Monel hardened stirrups are essential in equestrian gear due to their exceptional strength, corrosion resistance, and lightweight design, making them ideal for the demanding conditions of horseback riding. The article emphasizes that these stirrups enhance rider safety and performance by maintaining structural integrity under stress and offering superior comfort, thus establishing their importance in high-performance equestrian equipment.

Introduction

In the realm of equestrian gear, the choice of materials can significantly influence performance, safety, and durability. Monel hardened stirrups, crafted from a specialized nickel-copper alloy, have emerged as a standout option for riders seeking reliable equipment that can withstand the rigors of various environments. Renowned for their impressive tensile strength and exceptional corrosion resistance, these stirrups not only enhance rider comfort but also ensure longevity, making them a preferred choice among equestrian professionals.

As advancements in design continue to evolve, integrating features that optimize functionality, it becomes crucial for procurement managers to understand the unique benefits that Monel offers. This article delves into the following topics:

- Material properties

- Comparative advantages

- Maintenance strategies

- Future trends surrounding Monel stirrups

Offering valuable insights for those committed to elevating their equestrian gear investments.

Introduction to Monel Hardened Stirrups: Material and Design

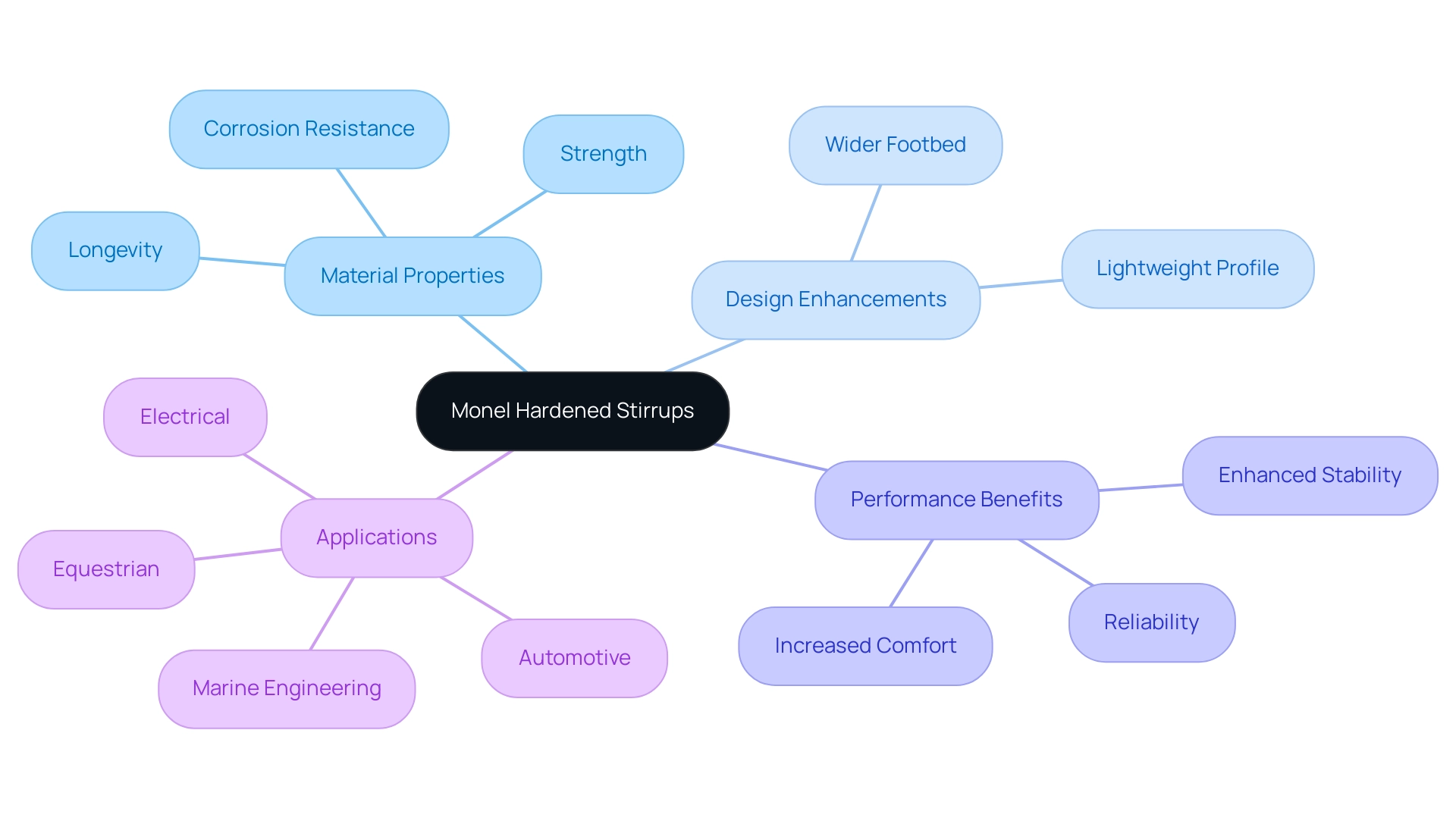

Monel hardened stirrups, made from a strong nickel-copper alloy, are renowned for their remarkable strength, corrosion resistance, and longevity. With a tensile strength of approximately 70,000 psi, this alloy’s properties make it particularly advantageous for equestrian activities, especially when using monel hardened stirrups, in environments where exposure to moisture and fluctuating conditions is prevalent. Recent advancements in saddle design have utilized the unique properties of this alloy, integrating features such as a wider footbed to enhance stability and comfort while maintaining a lightweight profile that does not compromise strength.

This thoughtful combination of material properties and design enhancements significantly boosts the performance of monel hardened stirrups, making them a preferred choice for riders who prioritize reliability and longevity in their equipment. As noted by industry experts, ‘Monel hardened stirrups offer excellent corrosion resistance and strength, making them an ideal choice for high-performance horse riding equipment.’ Additionally, this material’s exceptional properties extend beyond equestrian equipment, finding applications in marine engineering, automotive, and electrical industries.

The cold working process applied to the alloy enhances its hardness and resistance to deformation, as demonstrated in the case study ‘Cold Working Effects,’ which highlights the increase in hardness produced by cold working processes. This leads to supports that not only endure the demands of use but also provide enhanced longevity over time, making this material a versatile solution for various applications. For a comprehensive view of our offerings, including a diverse range of copper nickel alloys suitable for multiple industries, we invite procurement managers to explore our extensive product catalog at Domadia.

The Importance of Monel Hardened Stirrups in Equestrian Gear

Monel hardened stirrups are indispensable supports in equestrian gear, renowned for their exceptional durability and functionality. Priced starting from $459.00, Ophena safety supports serve as a benchmark for the cost of durable equipment in the market. These monel hardened stirrups excel in withstanding the rigorous demands riders face, primarily due to their impressive corrosion resistance, which surpasses that of many alternative materials.

This characteristic is vital, as it ensures that the supports maintain their structural integrity even under significant stress. Furthermore, the lightweight design of monel hardened stirrups supports not only ease of use but also encourages superior control and comfort during rides. Equestrian experts emphasize that a well-designed foot support significantly contributes to rider safety, as it minimizes the risk of breakage during intense activities.

Nicholas, an experienced rider, emphasizes this point, stating, Many individuals don’t consider the weight of their footrests, which highlights the surprising effect lightweight footrests can have on performance. Additionally, the case study titled “Customization for Optimal Fit and Comfort” illustrates how properly fitting safety supports can prevent accidents and enhance rider comfort, accommodating the rider’s natural heel position. As prominent experts advocate for these supports, they recognize that monel hardened stirrups play an essential role in enhancing both performance and safety across different horseback riding disciplines.

Recent research has indicated that utilizing robust supports similar to those crafted from a specific alloy can significantly decrease accident rates, further highlighting the significance of this material in equestrian safety.

Comparison with Other Materials Used in Stirrups

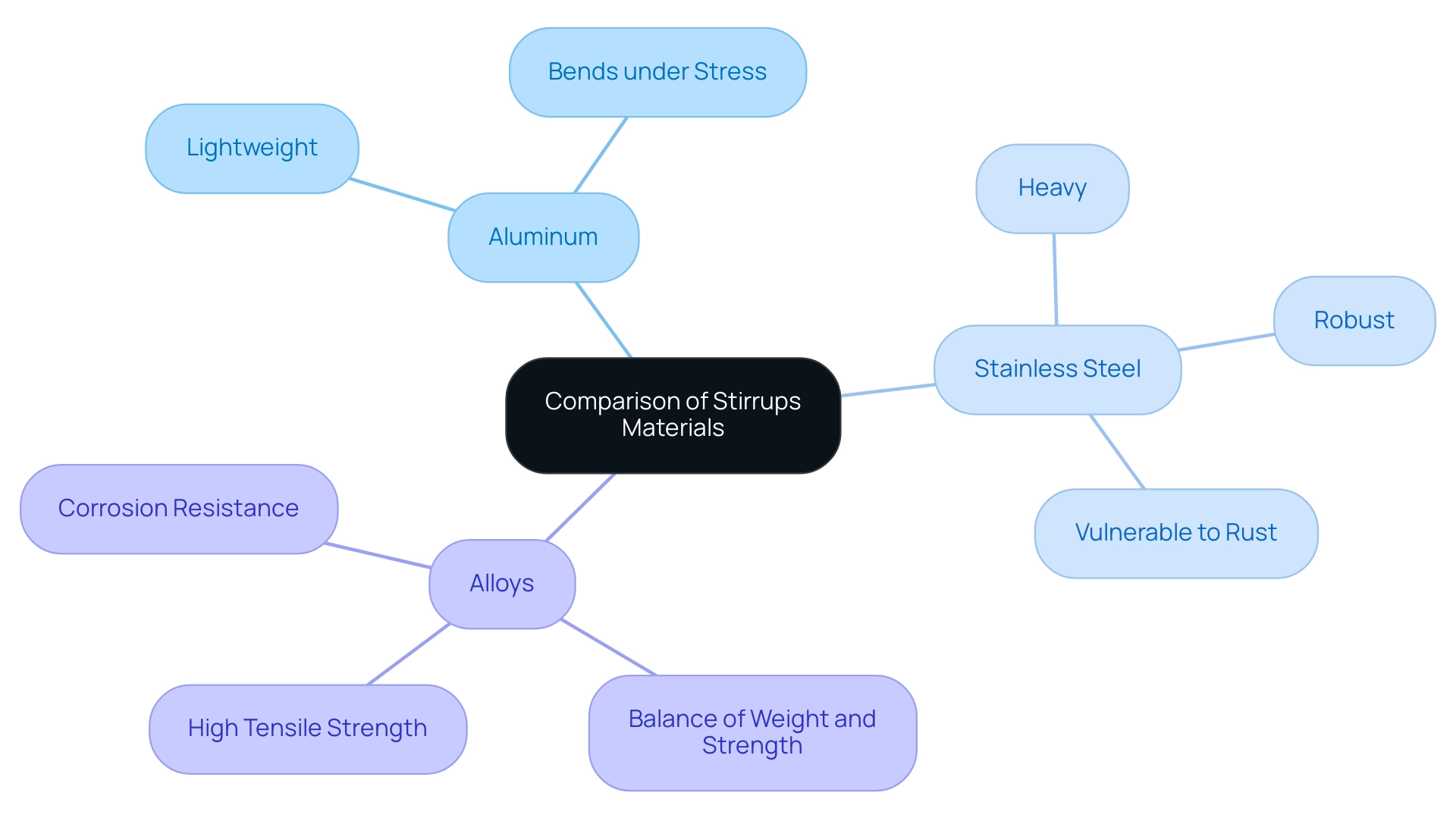

When assessing supports crafted from various metals, including aluminum and stainless steel, clear distinctions become apparent. Aluminum stirrups are notably lighter, enhancing maneuverability; however, they often bend under significant stress, limiting their durability. Stainless steel, with a density of 7.85 g/cm³, is recognized for its robustness but tends to be heavier and can be vulnerable to rust, especially in harsh environments.

In contrast, these alloys provide an exemplary balance between weight and strength, making them particularly well-suited for the demanding conditions of equestrian activities. A case study titled ‘Strength Comparison of Two Alloys’ illustrates that while both substances are strong, one provides high tensile strength and toughness in extreme temperatures, which is crucial for performance. Furthermore, this material’s inherent corrosion resistance allows for innovative, refined designs that do not compromise on strength, positioning it as a favored option among riders who prioritize high-performance gear.

As Kat de Naoum observes, the benefits of this alloy in equestrian gear are becoming more widely acknowledged, particularly as material performance keeps advancing in 2024. For specialized alloys and other material requirements, consulting with Wieland Diversified is highly recommended.

Maintenance and Care for Monel Hardened Stirrups

Maintaining the quality and performance of Monel hardened stirrups necessitates a disciplined approach to regular cleaning and inspection, similar to the resource management strategies employed in mining. Industries such as oil and gas, aerospace, electronics, mining, and medical significantly benefit from the use of specialized tools like Beryllium Copper due to their unique properties. For instance, after two hours of farming Platinum Ore, a total yield of 1056 underscores the importance of efficiency and care in resource use.

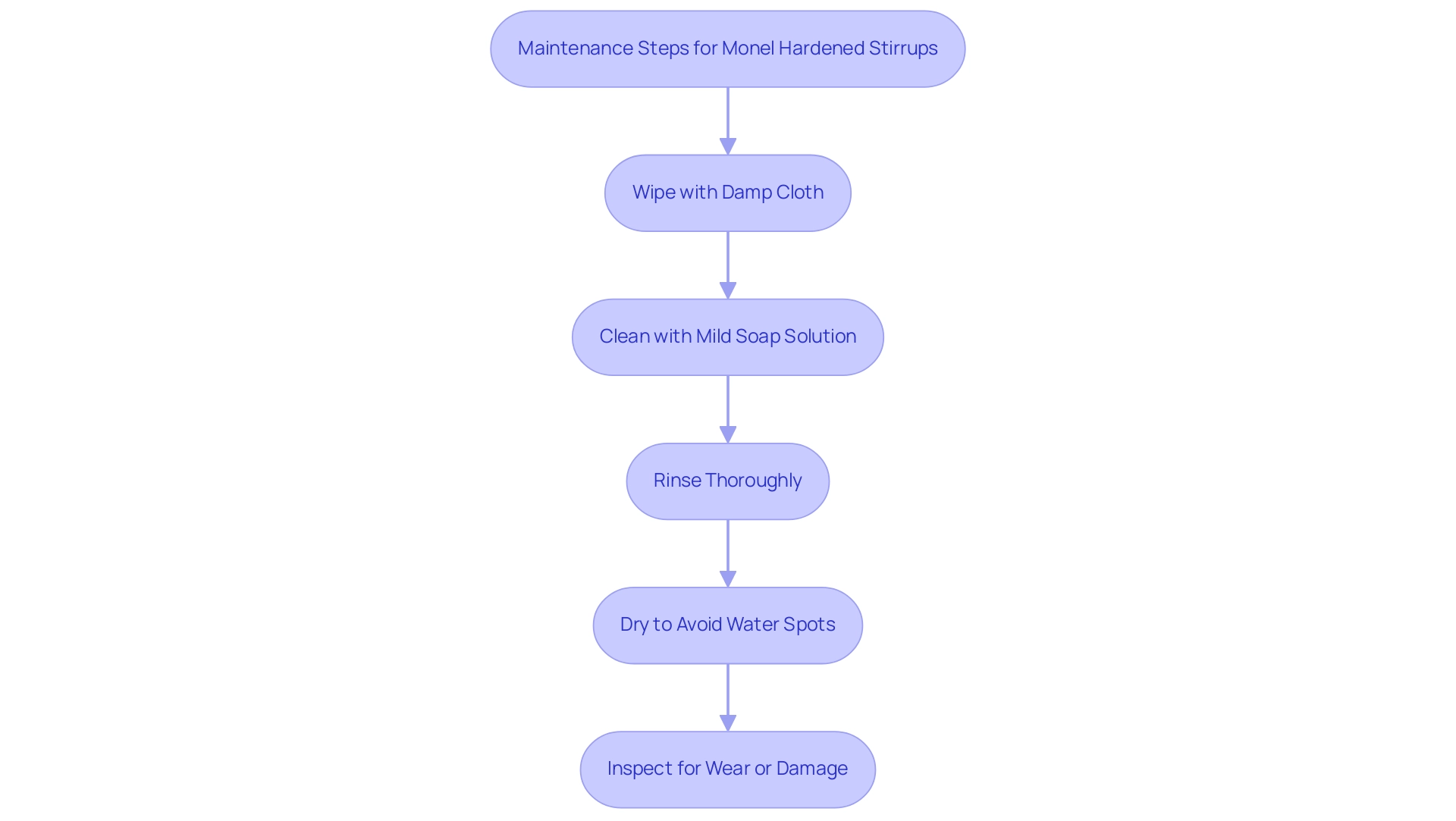

Similarly, after each use of the supports, it is essential to:

- Wipe them down with a damp cloth to remove dirt and sweat, which can accelerate corrosion over time.

- For a more thorough cleaning, a mild soap solution is recommended, followed by extensive rinsing and drying to avert water spots.

- Avoid exposure to harsh chemicals that could affect the material properties.

Periodic inspections for any signs of wear or damage are vital, akin to optimizing mining skills for better yield. These inspections ensure that the supports remain in peak condition for riding, ultimately safeguarding their reliability and performance. Just as investing in a Magnetic Mining Pick enables passive ore farming, investing in quality Monel hardened stirrups extends their lifespan, ensuring consistent quality and durability in riding gear.

Future Trends in Equestrian Gear: The Role of Monel

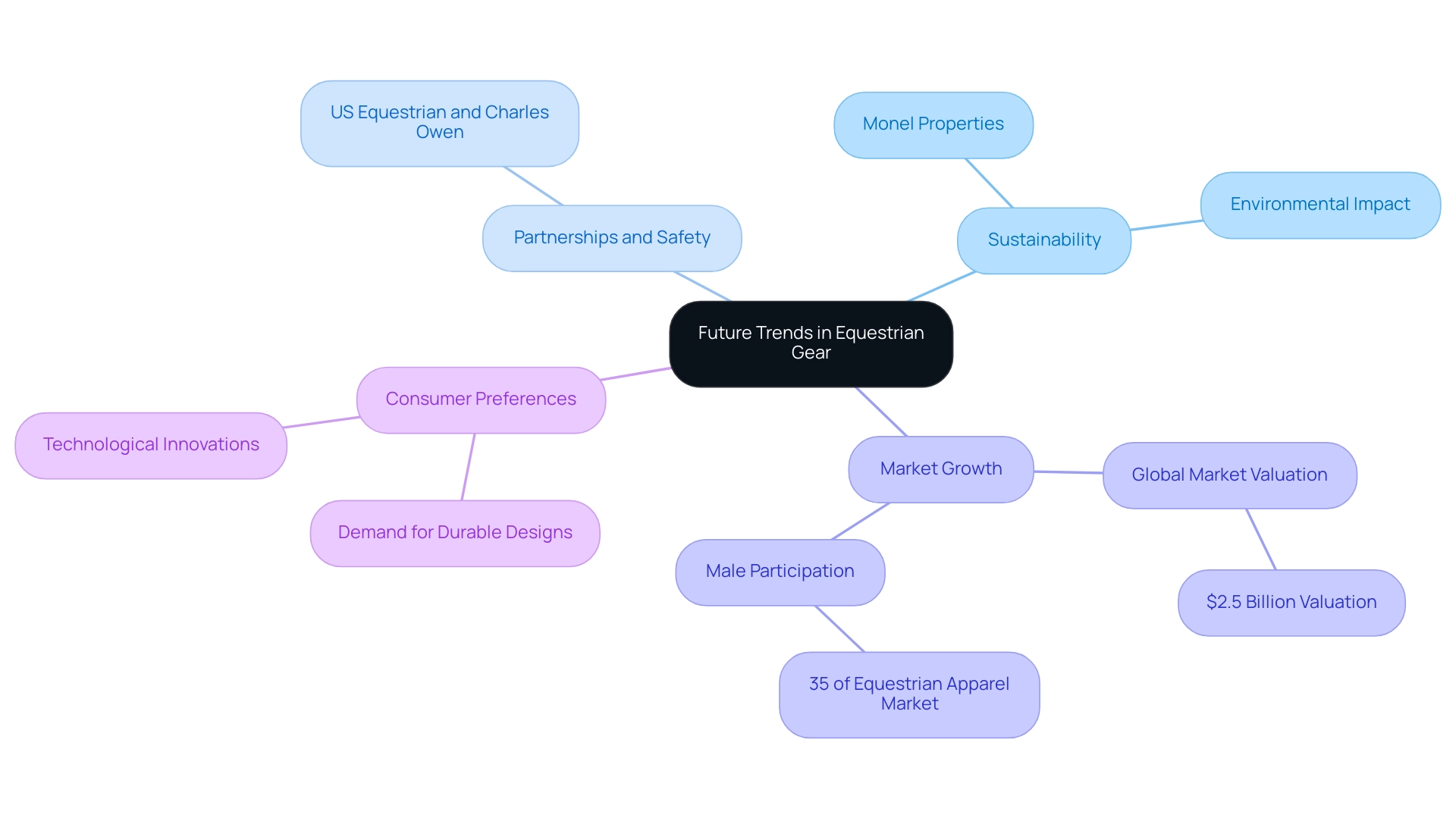

The horseback riding market is experiencing a notable change, marked by a heightened emphasis on sustainability and high-performance substances. These alloys, known for their exceptional durability and resistance to corrosion, are well-suited to address these evolving demands. As producers search for substances that not only endure the demands of equestrian activities but also encourage environmental sustainability, this alloy stands out as a viable choice.

The partnership between US Equestrian and Charles Owen as the official helmet supplier underscores the industry’s commitment to quality and safety, aligning with the discussion on high-performance materials. Additionally, the global horseback riding apparel market, valued at an estimated $2.5 billion, highlights the substantial growth potential in this sector, reinforcing the significance of certain alloys. Innovations in design and technology are expected to further enhance the capabilities of these supports, with potential integrations of smart features that monitor rider performance or improve safety.

Moreover, with male riders accounting for about 35% of the riding apparel market, there is a clear demand for durable designs that Monel’s properties can fulfill. As consumer preferences evolve towards sustainable and technologically advanced products, the future landscape of equestrian gear is poised to be shaped by monel hardened stirrups. This shift not only reflects changing rider expectations but also aligns with broader trends in the industry towards responsible consumption and innovation.

Conclusion

The exploration of Monel hardened stirrups reveals their significant advantages in the equestrian industry. With exceptional tensile strength and corrosion resistance, these stirrups excel in durability and performance, making them a reliable choice for riders facing varying environmental challenges. The thoughtful integration of design features, such as a wider footbed, enhances rider comfort and stability, further solidifying Monel’s position as a premier material in equestrian gear.

When compared to alternatives like aluminum and stainless steel, Monel stands out as a balanced solution, offering both lightweight design and remarkable strength. This combination not only promotes ease of use but also minimizes the risk of equipment failure, which is paramount for rider safety. Additionally, effective maintenance strategies ensure that Monel stirrups remain in optimal condition, extending their lifespan and performance.

Looking ahead, the trends in equestrian gear are increasingly favoring materials like Monel that align with sustainability and high-performance expectations. As the industry evolves, the demand for innovative, durable, and environmentally conscious products will likely propel Monel stirrups to the forefront of equestrian equipment. This ongoing commitment to quality and performance underscores the essential role that Monel alloys will continue to play in shaping the future of equestrian gear, ultimately enhancing both rider safety and experience.