Blogs

Revolutionizing Material Science with DOMADIA™ Clad Metals: Stronger, Smarter, Cheaper

What if you could combine the corrosion resistance of nickel, the conductivity of copper, and the strength of steel all in one engineered sheet?

Clad metals make it possible, and DOMADIA™ Clad Metals make it scalable.

Clad metals are not just alloys or coatings. They are layered composites that unite the strengths of different metals into a single high-performance material. From EVs to cookware, aerospace to electronics, this smart fusion solves the age-old problem of choosing between performance and cost.

DOMADIA™ Clad Metals deliver exactly what today’s industries demand: durability, conductivity, corrosion resistance, and the freedom to customize every layer.

What is Clad Metals?

Clad metals are layered composites of two or more dissimilar metals. These materials have remarkable potential to combine the desirable properties and/or characteristics of individual metals and alloys into composites that provide improved characteristics over the individual metals.

Imagine having the performance of a premium metal like nickel or titanium on the outside, with the cost-efficiency and strength of steel or copper as the base. That’s the power of cladding.

Cladding can be customized in many ways. It may be done on one side or both sides of the base metal, and with different thicknesses and material variations, depending on performance requirements and cost considerations.

Cladding Process: How Are Metals Cladded?

There are various methods to clad metals, depending on the application and material types:

Common Cladding Techniques:

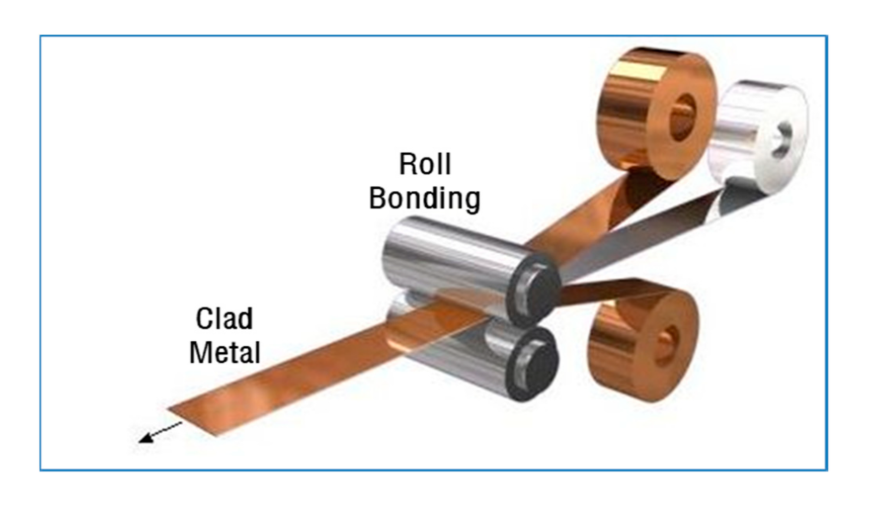

- Roll Bonding – Metals are passed through rollers under heat and pressure to fuse them together.

- Explosive Bonding – A controlled explosion presses the metals together instantly.

- Laser Cladding – A laser melts one metal onto the surface of another.

- Diffusion Bonding – Metals are joined by applying pressure at high temperature over time.

- Hot Pressure Cladding – Heat and compression bond layers in a furnace or press.

Common Metals Used in Cladding

Clad combinations are chosen based on end-use requirements — conductivity, corrosion resistance, thermal properties, and cost.

| Cladding Material | Purpose / Benefit |

| Nickel Alloys | Corrosion, heat resistance |

| Copper Alloys | Conductivity, ductility |

| Stainless Steel | Strength, corrosion resistance |

| Titanium | Lightweight & strong |

| Beryllium Copper | Conductive, spring-like, non-sparking |

Advantages of Metal Cladding

- Best technique for coating complex or irregular shapes, which increases the lifespan of wearing parts.

- Enables repair of damaged parts, especially when moulds no longer exist or are too time-consuming to reproduce.

- Most suitable for graded material applications, where properties vary layer by layer.

- Supports near-net-shape manufacturing, reducing waste and machining effort.

- Ensures low dilution between cladding and base material – unlike traditional welding – while achieving a strong metallurgical bond.

- Minimizes deformation and creates a small heat-affected zone (HAZ), preserving substrate integrity.

- High cooling rate during the process leads to a fine microstructure with improved mechanical properties.

- Offers material flexibility – works with metals, ceramics, and even some polymers.

- Produces parts that are free from cracks and porosity, ensuring durability and strength.

- Uses compact technology that is easy to integrate into modern production environments.

Applications of Clad Metals

Clad metals are used across various industries where highperformance, costsavings, and materialefficiency are crucial. Their layered structure allows combining the strengths of multiple metals while minimizing material costs.

Electrical & Electronics

Used in electricalconnectors, busbars, and switchgear components.

Example: Copper + Steel – Combines electrical conductivity with mechanical strength.

Automotive Industry

Ideal for heatshields, enginegaskets, and brakecomponents.

Example: Aluminum + Steel – Lightweight yet durable for thermal applications.

Cookware Manufacturing

Widely used in multi-layer cookware like frying pans and saucepots.

Example: Copper + Stainless Steel – Excellent heat conduction and food safety.

Aerospace & Defense

Used in aircraft skin panels, fuel systems, and armor plating.

Benefit: Lightweight materials like titanium are clad over strong core metals.

Battery & EV Industry

DOMADIA™ Clad metals help in making battery terminals, connectors, and busbars for electric vehicles.

Need: High conductivity with mechanical reliability.

Minting & Currency

Used in coins, commemorative medals, and token manufacturing.

Example: Nickel-clad steel or copper-clad steel – Cost-effective and durable.

Conclusion

DOMADIA™ Clad metals are not just an innovation—they are a strategic advantage. Whether you’re producing components for electric vehicles, industrial tools, or cookware, cladding offers a way to improve product performance, reduce costs, and expand design flexibility. And with the ability to customize layer thickness, side configurations, and material combinations, metal cladding is an essential solution for any forward-thinking manufacturer.

💬 Got Questions? Want a Custom Clad Combo?

Contact our experts today!

Learn more on: https://domadia.net/contact/

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia