Blogs

DOMADIA™ NiMn4Si (DIN 2.4190) – The Spark Inside Every Engine

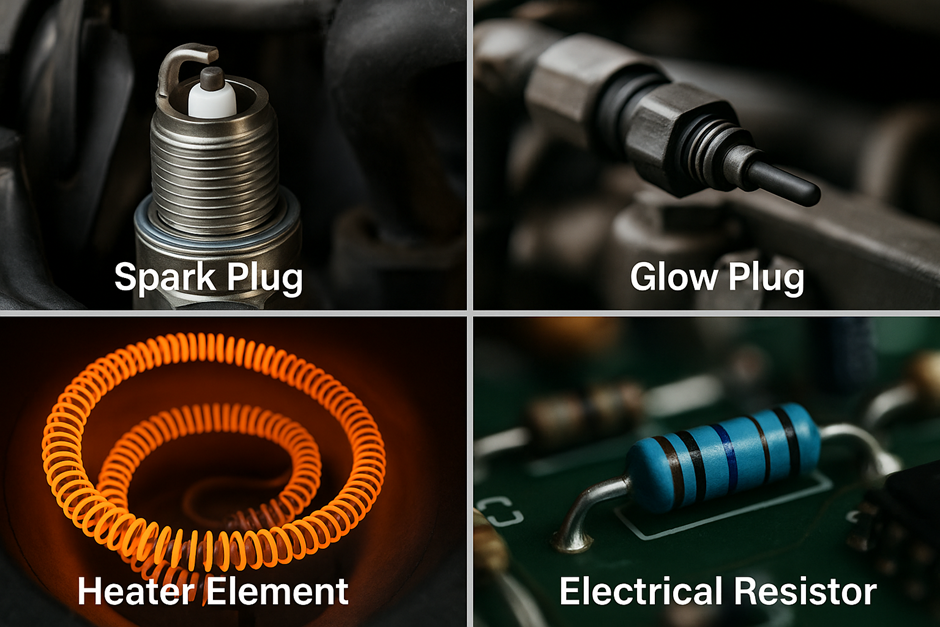

Have you ever wondered what breathes life into a cold engine with just a spark? Behind that ignition lies a small component built from a mighty alloy — one that survives heat, pressure, and time. Enter DOMADIA™ NiMn4Si, the unsung hero behind flawless spark plugs and glow plugs.

🔬 What is DOMADIA™ NiMn4Si?

DOMADIA™ NiMn4Si is a high-performance spark plug and glow plug alloy based on Nickel-Manganese-Silicon, designed for consistent conductivity and corrosion resistance. Designated as DIN 2.4190, it’s ideal for applications

🧪 Chemical Composition: NiMn4Si

The typical composition of NiMn4Si includes:

- Nickel (Ni) – Balance (approx. 90–94%)

- Manganese (Mn) – ~4%

- Silicon (Si) – ~1–1.5%

- Trace additions may include Chromium, Titanium, Zirconium in related versions (e.g., NiMn2CrSiTiZr).

These elements create a metallurgical synergy offering both electrical conductivity and oxidation resistance.

🛠️ Applications of NiMn4Si Alloy

DOMADIA™ NiMn4Si is extensively used in:

- Automotive Engines: Spark plugs are essential in gasoline-powered vehicles to ignite the air-fuel mixture.

- Motorcycles: Spark plugs are vital for efficient combustion in motorcycle engines.

- Small Engines: From lawnmowers to generators, small engines rely on spark plugs.

- Aircraft Engines: Spark plugs are used in some aircraft engines for ignition.

- Marine Engines: Spark plugs are used in outboard motors and other marine engines.

- Furnaces and Other Applications: In certain industrial and domestic applications, spark plugs are used to ignite combustible mixtures.

- Spark Plugs – Ensures reliable ignition in gasoline engines

- Glow Plugs – Assists in diesel engine starting under low temperatures

- Heater Elements – Where fast heating and durability are needed

- Electrical Resistors – Due to stable resistance over temperature

🏛 Standards and Equivalents

MATERIAL-No.: DIN 2.4190

Related Products: Ferrochronin 600, NiMn2CrSiTiZr, BR-Ni 99.9

Industry Names: Sometimes classified under spark plug / glow plug materials in ASTM standards (referenced indirectly)

💡 Key Properties

| Property | Value |

| Electrical Resistivity | Medium – stable over temperature |

| Thermal Conductivity | High – essential for plug heat dissipation |

| Oxidation Resistance | Excellent |

| Thermal Shock Resistance | Very High |

| Machinability | Moderate (suitable for precision parts) |

| Magnetic Behavior | Non-magnetic / weakly magnetic |

🧾 Technical Specifications

- Working Temperature: ~800–1000°C

- Melting Point: ~1430°C

- Tensile Strength: >400 MPa (varies by form)

- Density: ~8.5 g/cm³

- Expansion Coefficient: Optimized for plug-ceramic bonding

🧱 Shapes & Forms Available

DOMADIA™ NiMn4Si is offered in a wide range of processed formats:

- Foils

- Strips

- Plates

- Bars

- Rods

- Sheets

These customizable forms ensure compatibility with both manual and automated plug production systems.

🚗 Why It Matters

Whether you’re starting your car on a frosty morning or pushing it to its limits on a racetrack, DOMADIA™ NiMn4Si spark plug alloy ensures that ignition is never compromised. It’s not just metal—it’s performance you can trust.

🔚 Conclusion

In a world driven by reliability, DOMADIA™ NiMn4Si (DIN 2.4190) doesn’t just perform — it ignites. Trusted in the toughest environments and tailored for exacting tolerances, this alloy is your go-to solution for high-efficiency spark and glow plug systems.

Looking for thermal reliability in harsh engine conditions? Choose DOMADIA™ NiMn4Si.

👉 Contact Us Now | 🌐 Visit: www.domadia.net

Talk to us: Kairav Domadia | Aadil Domadia | Er.Pankaj Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia