Blogs

Designing with Thermostatic Bimetals: What Engineers Must Know

Designing with thermostatic bimetals isn’t just about selecting two metals and hoping for a bend. It’s a precise science of curvature control, material matching, and mechanical optimization—where every degree matters.

In this post, we explore the core design considerations every engineer must know when working with thermostatic bimetals—from material choice to deflection tuning and mounting techniques. And as a bonus, we also share creative design inspiration using metal cladding—showcasing how smart metalwork blends science and aesthetics.

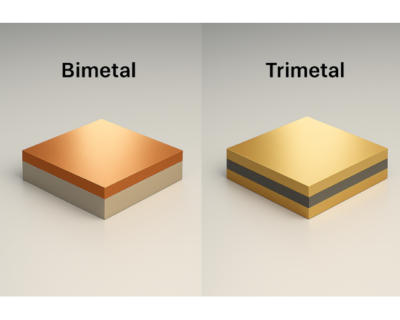

1. Material Selection & Thickness Ratios

The performance of a bimetal strip begins with the right metal pair, chosen for:

- Contrast in CTE (Coefficient of Thermal Expansion)

- Bonding compatibility

- Corrosion resistance

🔹 General Guideline:

- Use a high-CTE metal (like copper or nickel alloys) with a low-CTE base (like Invar or stainless steel).

🔸 Thickness Consideration:

- Thicker active layer = greater force, less deflection

- Thinner active layer = higher deflection, faster response

- Balance the ratio (e.g., 1:2 or 1:3) based on thermal curve requirements.

🎯 Engineering Tip: Small thickness changes have a large impact on deflection sensitivity.

2. Curvature Planning: Predicting the Bend

Engineers use curvature equations and deflection curves to model the behavior of the strip under temperature change.

Consider:

- Target actuation temperature

- Expected temperature gradient

- Desired displacement

Use this to:

- Choose snap-action vs. linear response

- Control the degree of curvature per °C

- Avoid over-bending that leads to material fatigue

🔍 CAD modeling and FEA (Finite Element Analysis) are often used in precision applications.

3. Mounting and Mechanical Constraints

How you mount the bimetal strip affects its deflection and service life.

Mounting Styles:

- Fixed-Fixed: Both ends anchored — results in arching

- Fixed-Free: One end anchored — produces a sweeping bend

- Coil Mount: Allows rotational motion — ideal for thermostats and dials

Mechanical Constraints to Plan For:

- Space limitations in enclosures

- Allowance for free expansion

- Avoiding mechanical interference with contacts or frames

⚠️ Poor mounting = dampened performance or false triggering.

4. Custom Deflection Tuning

Tuning a bimetal’s behavior for specific temperatures or movements can be done by adjusting:

- Layer material combination

- Bonding pressure during rolling

- Heat treatment profile (to fix mechanical memory)

- Pre-curving or shaping (especially in snap-discs)

You can also add coatings or surface treatments to reduce oxidation or enhance fatigue resistance.

⚙️ Some bimetals are pre-calibrated during manufacturing for specific temperature triggers (±1°C accuracy).

Design Inspiration: Creative Uses of Metal Cladding

While thermostatic bimetals are all about motion and precision, the idea of layered metals has also inspired stunning architectural applications. Here’s how the same material mindset creates visual impact through metal cladding.

1. Geometric Patterns

Use angular and repetitive patterns to create a dynamic, futuristic façade—perfect for museums, innovation labs, and cultural centres.

2. Textured Finishes

Embossed and 3D surfaces bring depth and tactile appeal to modern exteriors while maintaining sleekness.

3. Bold Colour Accents

Powder-coated aluminium panels in vibrant hues help buildings pop and define brand identity.

4. Mixed Material Combinations

Pair metal with wood, glass, or stone to add warmth and contrast—especially effective in hospitality and residential spaces.

️5. Custom Aluminium Cladding by Vulcan Cladding Systems

Explore bespoke aluminium finishes from Vulcan—including brushed, perforated, matte, or patterned options that align function with architectural flair.

🌍 Metal cladding proves: good engineering is beautiful, too.

Summary: Engineering Bimetals with Precision

| Design Factor | Why It Matters |

| Metal Selection | Drives thermal response & reliability |

| Thickness Ratios | Affects force vs. deflection |

| Curvature Planning | Ensures predictable movement and safety |

| Mounting Style | Influences shape, range, and consistency |

| Custom Tuning | Tailors function to temperature and device needs |

🔗 Up Next: Blog 7 – Applications of Thermostatic Bimetals

From home appliances to aerospace systems, we’ll explore how thermostatic bimetals power real-world innovations.

Got questions? or got an ideas—we’re always ready to dive deeper!

Contact our experts today!

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia

Read our previous blog on https://domadia.net/thermostatic-bimetal/domadia-properties-of-thermostatic-bimetals/