Blogs

Why Thermostatic Bimetals Rule Thermal Control

Thermostatic bimetals might not look flashy, but they quietly power the most critical thermal systems in industries, homes, and vehicles. They bend when heated, reset when cooled, and operate without electricity, software, or motors.

In this final blog of our series, we dive into the features that make bimetals mechanically brilliant and the advantages that make them the go-to choice for engineers designing with thermal control in mind.

FEATURES OF THERMOSTATIC BIMETALS

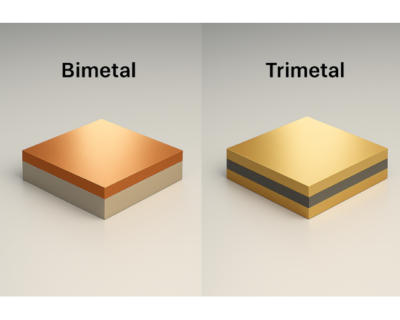

1. Bimetallic Composition

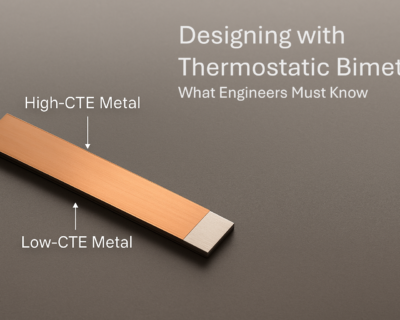

Thermostatic bimetals are composed of two or more layers of dissimilar metals or metal alloys bonded together. Each metal has a different coefficient of thermal expansion (CTE)—the rate at which it expands or contracts with temperature.

- Example pairings: Copper (high CTE) + Invar (low CTE), or Brass + Steel.

- These layers are bonded using methods like hot rolling, cold bonding, or brazing.

Why it matters: This layered composition is the basis for all the motion and function in thermostatic bimetals.

2. Temperature-Dependent Bending

When heated, the metal with the higher CTE expands more, causing the strip to bend toward the metal with the lower CTE.

- This motion is predictable and repeatable.

- The curvature is directly proportional to the temperature change.

Why it matters: This is how thermostatic bimetals convert temperature into movement—without sensors or power.

3. Mechanical Displacement

The bending force of the strip is used to:

- Open or close electrical contacts

- Rotate dials or needles

- Trigger relays, valves, or latches

Depending on the geometry (flat, spiral, snap-disc), the displacement can be linear, rotational, or bi-stable (snap-action).

Why it matters: This movement becomes the basis for temperature switches, timers, regulators, and alarms.

4. Wide Range of Alloy Combinations

Engineers can select metal pairs to:

- Match specific temperature sensitivity

- Adjust response speed and curvature

- Optimize for environmental resistance

Why it matters: It allows for custom-engineered thermal responses in both consumer and industrial applications.

5. Customization Options

Designers can specify:

- Strip thickness

- Dial size, stem length

- Protective sheath and pointer design

- Snap-point temperature thresholds

Why it matters: These options enable perfect integration into existing systems across HVAC, automotive, electronics, and more.

ADVANTAGES OF THERMOSTATIC BIMETALS

1. Power-Free Operation

Thermostatic bimetals require no external power supply. They operate solely based on ambient or system temperature.

Benefit: Reduces design complexity, eliminates battery or wiring needs, and improves energy efficiency.

2. High Reliability and Durability

- No fragile electronics

- Few mechanical parts

- Low wear and tear over time

- Immune to EMI (electromagnetic interference)

Benefit: Suitable for critical systems where failure is not an option—like fire alarms, circuit breakers, and aerospace instruments.

3. Cost-Effectiveness

- Low production cost

- Minimal maintenance

- Long service life (millions of cycles)

- Fewer parts = fewer failure points

Benefit: Offers an affordable alternative to electronic thermal systems, especially in price-sensitive products.

4. Simple Design and Operation

- Operates purely on material physics

- Easy to model and simulate

- Simple to install and replace

Benefit: Accelerates product development and reduces the need for complex calibration or software.

5. Wide Operating Temperature Range

- Effective from −70°C to +600°C depending on alloy choice.

- Withstands extreme cold, heat, and rapid cycling.

Benefit: One of the few technologies that can operate reliably in ovens, freezers, vehicles, and even spacecraft.

6. Minimal Maintenance

- No lubrication, charging, or cleaning required

- Durable even in dusty, humid, or corrosive environments

- Long cycle life with minimal deflection loss

Benefit: Perfect for hard-to-reach or unmanned systems like industrial boilers, rooftop HVAC units, or remote sensors.

7. High Accuracy and Reproducibility

- Deflection curves are highly consistent

- Snap-point bimetals provide repeatable activation thresholds

- Precision manufacturing = reliable control

Benefit: Ensures system behavior stays predictable over time, critical in sensitive controls and safety systems.

8. Vibration and Impact Resistance

- The solid-metal construction is resistant to:

- Mechanical vibration

- Sudden shocks

- Temperature cycling

Benefit: Enables use in automotive, aerospace, railway, and heavy machinery where electronics may fail.

9. Design Versatility

- Flat strips for linear motion

- Coiled strips for rotational output

- Snap-discs for quick switching

- Multi-layer composites for tailored behavior

Benefit: Allows custom fit and function in devices of all shapes and sizes.

10. Environmentally Friendly

- No rare earth materials

- Energy-efficient

- Easily recyclable

- Long operational life reduces waste

Benefit: Supports sustainability initiatives and reduces lifecycle environmental impact.

🧾 Quick Comparison: Thermostatic Bimetals vs. Electronic Sensors

| Factor | Thermostatic Bimetals | Electronic Sensors |

| Power Required | No | Yes (battery or circuit) |

| Sensitivity | High | Very High |

| Complexity | Low | Medium–High |

| Cost | Low | Moderate to High |

| Temperature Range | Very Wide | Often Narrower |

| Maintenance | Minimal | May require recalibration |

| Durability (Vibration) | Excellent | Variable |

🔚 Final Thought: Small Strip, Big Power

Thermostatic bimetals offer a unique combination of simplicity, strength, and smart behavior. They’re silent workers in everything from thermostats and fire alarms to spacecraft instruments and circuit breakers.

Whether you’re designing a low-cost appliance or a mission-critical thermal control system, thermostatic bimetals remain one of the most dependable tools in any engineer’s arsenal.

Got questions? or got an ideas—we’re always ready to dive deeper!

Contact our experts today!

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia

Read our previous blog on https://domadia.net/thermostatic-bimetal/domadia-designing-with-thermostatic-bimetals/