Blogs

Understanding the Beryllium Copper Phase Diagram: An In-Depth Tutorial

Introduction

Understanding the intricate relationship between material properties and performance is paramount in the world of Beryllium-Copper alloys. The Beryllium-Copper phase diagram serves as an essential roadmap for procurement managers and engineers, illuminating how variations in temperature and composition can significantly influence the alloy’s characteristics. This diagram not only delineates the various phases and transformations that occur during processing but also provides critical insights into optimizing the material for high-performance applications across diverse industries, including:

- Aerospace

- Automotive

- Oil and gas

As the demand for advanced materials continues to rise, grasping the complexities of the phase diagram becomes crucial for making informed decisions that enhance product reliability and performance. In this article, key strategies for leveraging the Beryllium-Copper phase diagram will be explored, along with practical considerations for procurement that ensure alignment with industry standards and operational excellence.

Introduction to the Beryllium-Copper Phase Diagram

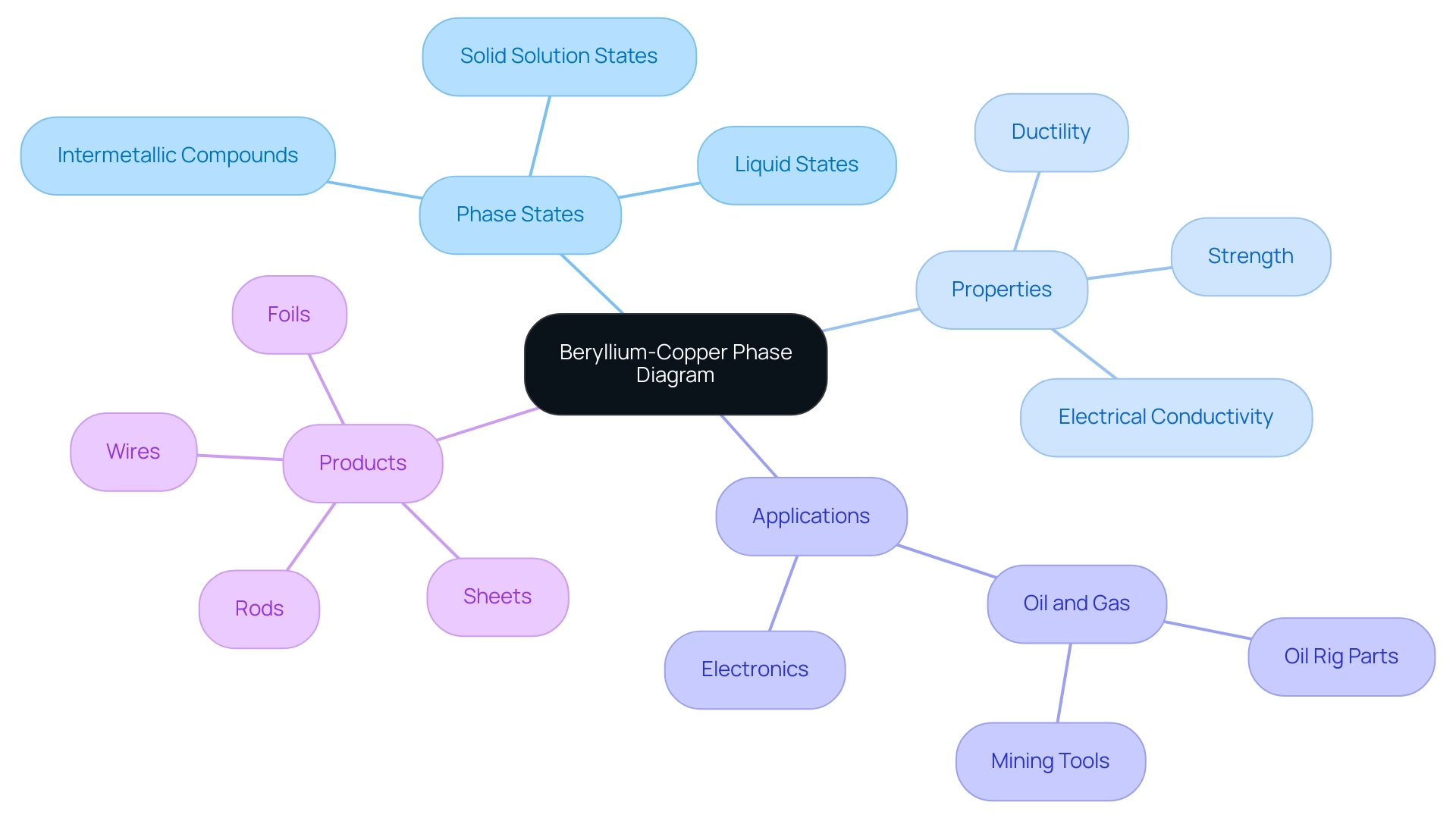

The beryllium copper phase diagram is a critical tool for understanding the stability of the alloy across a range of temperatures and compositions, particularly for high-performance applications. As emphasized by Cezary Palczynski in the Handbook on the Toxicology of Metals, the importance of the beryllium copper phase diagram cannot be overstated, as it outlines solid solution states, liquid states, and various intermetallic compounds that influence the overall performance of the substance. By examining the beryllium copper phase diagram, procurement managers can gain insights into how variations in composition and temperature affect key properties such as strength, ductility, and electrical conductivity.

Domadia, a premier supplier of high-quality Beryllium Copper solutions since 1952, offers an extensive product range including:

- Foils

- Sheets

- Rods

- Wires

This ensures that you have access to the best solutions tailored to your specific requirements. The beryllium copper phase diagram features axes that represent temperature and composition, with phase boundaries clearly marked, allowing for accurate predictions of substance behavior during processing and application. This understanding is essential for selecting the most appropriate resources, ensuring optimal performance and reliability in high-tech products, including electronics and aerospace components.

Moreover, Beryllium Copper is utilized across multiple industries, notably in the oil and gas sector for components such as:

- Oil rig parts

- Mining tools

Despite its high cost and toxicity, Beryllium’s exceptional strength and conductivity, along with its non-sparking and corrosion-resistant characteristics, continue to make it a relevant choice for demanding applications, underscoring the importance of careful selection. Additionally, Domadia provides customization options for Beryllium Copper solutions, allowing procurement managers to meet their unique project specifications effectively.

Applications and Importance of the Beryllium-Copper Phase Diagram

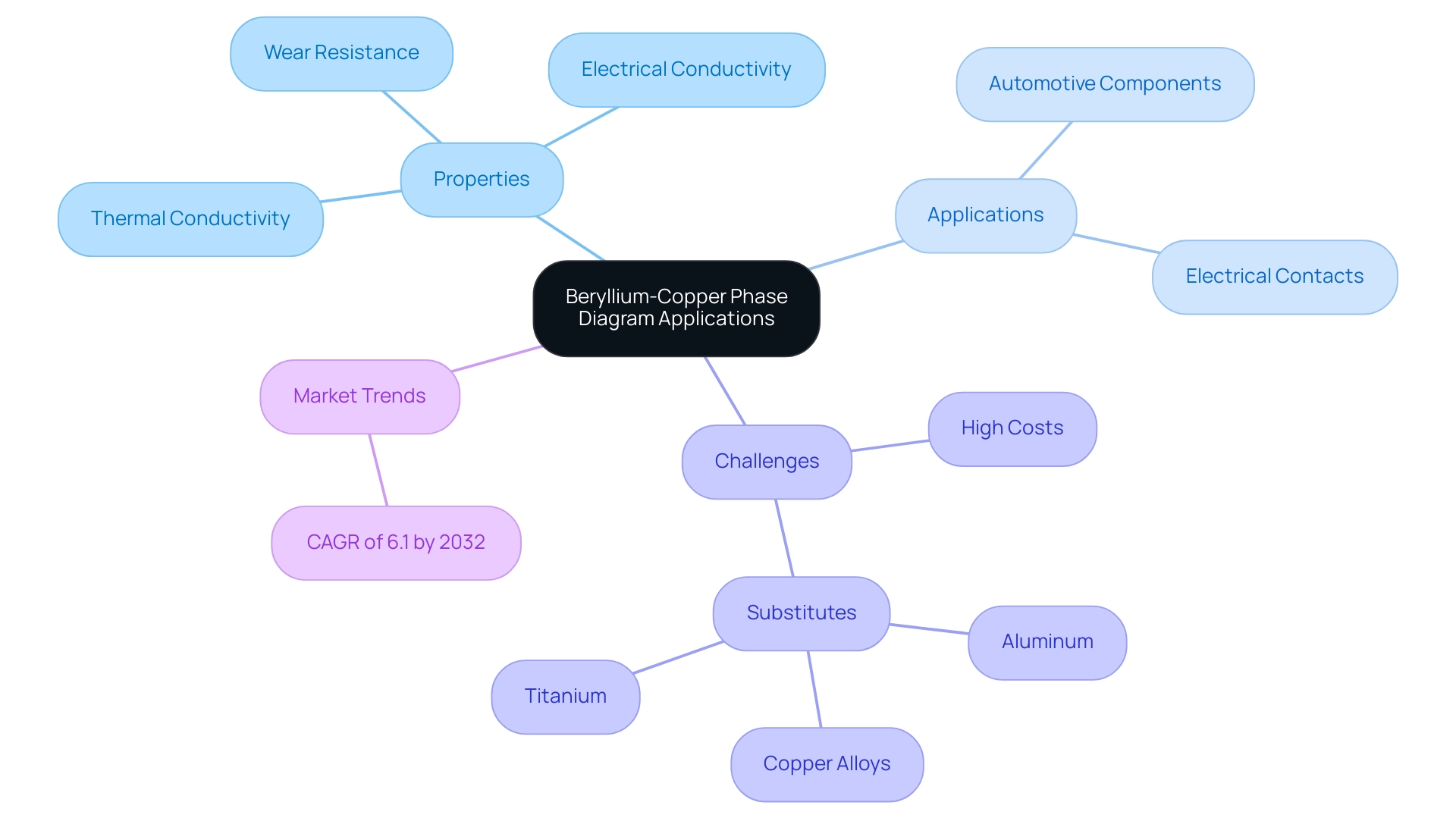

The combination of beryllium and copper is renowned for its exceptional thermal and electrical conductivity, coupled with remarkable wear and corrosion resistance. These unique properties make it a preferred choice in specialized industries such as automotive, where it is employed in critical components like connectors, springs, and electrical contacts. The durability and performance of these components are paramount, directly influencing the efficiency of automotive systems.

However, the high expenses related to these composites, along with the presence of substitute materials such as aluminum, copper mixtures, and titanium, present challenges for wider utilization. A comprehensive understanding of the Beryllium-Copper diagram is essential for engineers and procurement managers. This diagram provides insights into the optimal processing conditions necessary to enhance the alloy’s inherent properties.

For instance, by precisely forecasting transformations during heat treatment, manufacturers can greatly enhance mechanical properties, ensuring that components meet the strict requirements of their applications. A deep understanding of the phase diagram not only informs selection of substances but also cultivates robust relationships with suppliers who provide high-performance products tailored to meet these exacting specifications. Notably, procurement managers should consider pricing and inventory details for Beryllium Copper strips, as these factors are crucial for effective decision-making.

Various suppliers, including those focusing on electrical insulation and high-temperature substances, offer a diverse range of options, including Kapton tapes and high-temperature fabrics. As the market for these composites is expected to expand at a CAGR of 6.1% by 2032, strategic decision-making in procurement will be crucial for utilizing the full capacity of these advanced resources.

Understanding Phase Transitions in Beryllium-Copper

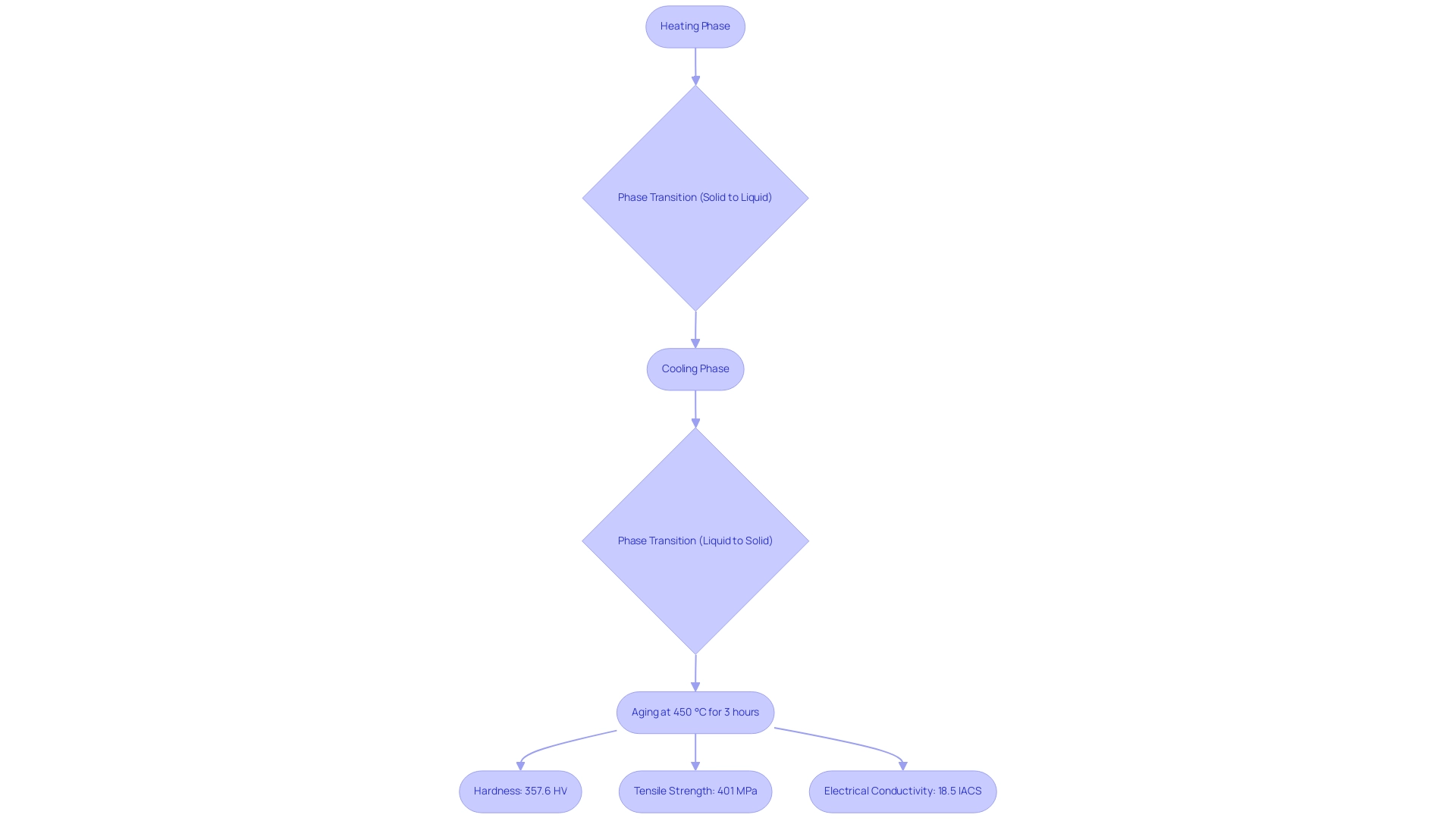

The beryllium copper phase diagram illustrates that phase transitions in Beryllium-Copper mixtures are critical processes occurring primarily between solid and liquid states during heating and cooling, significantly impacting their properties. At Domadia, we pride ourselves on being at the forefront of supplying high-performance Beryllium Copper Plates, a material indispensable in various industrial applications due to its unique combination of strength, conductivity, and corrosion resistance. Recent studies indicate that controlling cooling rates and composition can optimize the microstructure of the material—essential for enhancing mechanical attributes such as hardness and tensile strength.

Notably, after 70% deformation and aging at 450 °C for three hours, copper-beryllium alloys achieve a maximum hardness of 357.6 HV and a tensile strength of 401 MPa, along with an electrical conductivity of 18.5 %IACS. Grasping these transition processes is essential for engineers and procurement managers alike as they directly affect the required temperature ranges for effective heat treatment, aging, and other thermal processing. The beryllium copper phase diagram acts as a valuable resource, highlighting how these insights can assist in material selection and processing strategies to meet specific performance requirements.

Furthermore, the Cu–2Be alloy’s coarse-grained structure and the high density of dark particles after aging highlight the implications of solidification processes on microstructural features. As William C. Giessen noted, ‘The beryllium copper phase diagram is fundamental in metallurgy, particularly in understanding the nuances of phase transitions in the Be-Cu system.’ Keeping up with the latest findings allows us to utilize the full potential of this alloy in various applications, ensuring our clients receive the best solutions tailored to their needs.

Additionally, we provide competitive pricing and inventory details for our Beryllium Copper Strips to support informed purchasing decisions.

Strategies for Optimizing Beryllium-Copper Material Properties

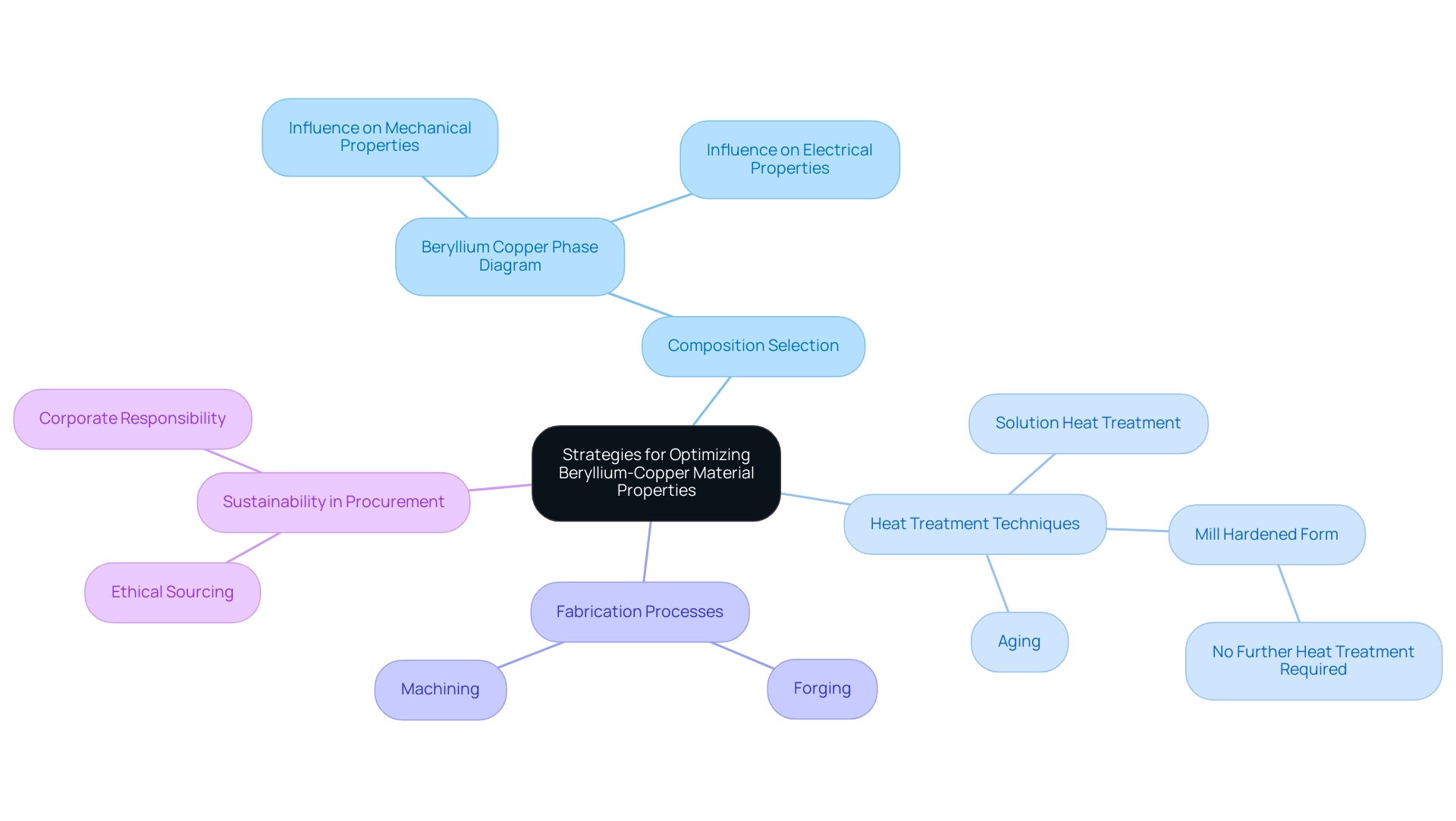

To effectively enhance the characteristics of these metal composites, a multifaceted approach is essential. The careful selection of composition, as illustrated by the beryllium copper phase diagram, stands out as a fundamental strategy; variations in beryllium content can markedly influence both mechanical and electrical properties, which is crucial for applications demanding high performance. Notably, with 52% of copper used in China utilized in electrical applications, the relevance of the beryllium copper phase diagram in this sector cannot be overstated.

Implementing targeted heat treatment techniques, such as solution heat treatment followed by aging, significantly enhances the strength and hardness of the material. As Mike Gedeon, Customer Technical Services Manager, notes,

In the mill hardened form, the material is age hardened at the mill, so no further heat treatment is required,

illustrating the efficiency of this method.

Additionally, controlling fabrication processes—such as forging and machining—is vital to preserve the desired characteristics of the material. Regular testing and characterization throughout these stages ensure compliance with industry standards and bolster product reliability.

The mechanical characteristics of UNS C172 copper materials, which are detailed in the beryllium copper phase diagram, include a Rockwell hardness range of 80.0 – 85.0 and tensile strength from 515 – 585 MPa, further emphasizing their suitability for demanding applications. Domadia’s extensive inventory features a comprehensive range of Beryllium Copper products, including:

- Plates

- Rods

- Sheets

- Wires

- Foil

- EMI finger strips

- Specialized tools

This provides procurement managers with tailored solutions for industries such as aerospace, automotive, electrical, oil and gas, and defense. Notably, our Beryllium Copper non-sparking wrench offers enhanced safety features, making it ideal for hazardous environments.

By integrating sustainability into procurement strategies, managers can align with corporate responsibility and address market demands for ethical sourcing. By adopting these strategies, procurement managers can ensure that these materials not only meet but exceed the performance expectations of their specific applications.

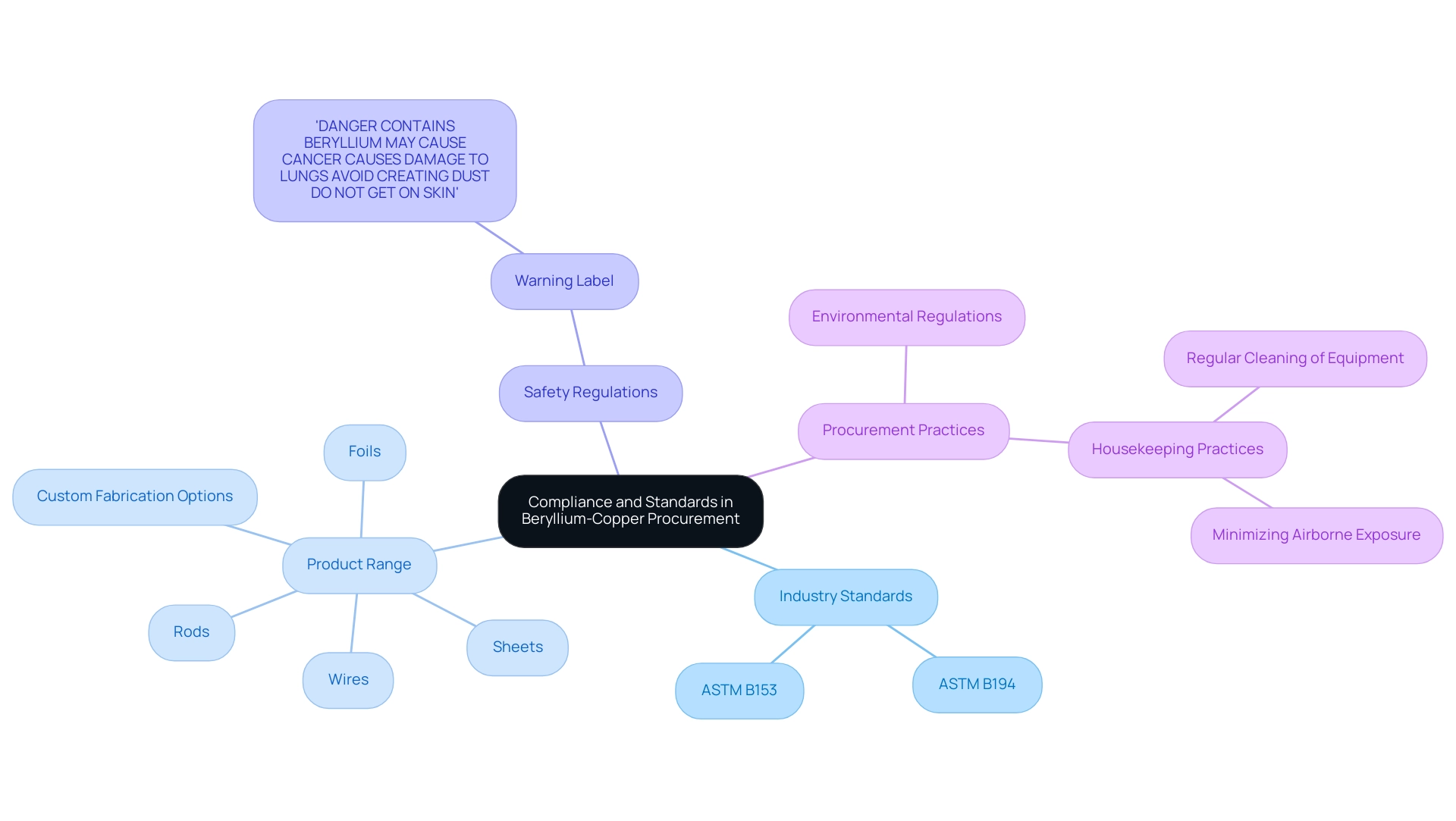

Compliance and Standards in Beryllium-Copper Procurement

In the acquisition of specific metal composites, strict adherence to industry standards such as ASTM B194 and ASTM B153 is essential for ensuring quality and performance. At Domadia, we pride ourselves on being your trusted partner, offering an extensive product range that includes:

- Foils

- Sheets

- Rods

- Wires

- Custom fabrication options tailored to meet your specific requirements.

These standards delineate the specifications for various Beryllium-Copper alloy products, providing critical criteria for composition, mechanical properties, and processing techniques as outlined in the beryllium copper phase diagram.

Additionally, labels for containers of clothing, equipment, and substances contaminated with beryllium must include the wording:

‘DANGER CONTAINS BERYLLIUM MAY CAUSE CANCER CAUSES DAMAGE TO LUNGS AVOID CREATING DUST DO NOT GET ON SKIN’,

emphasizing the hazards associated with beryllium handling. Adherence to environmental regulations regarding beryllium handling is crucial, considering its classification as a hazardous substance. As stated by Materion,

‘the evidence in the record is insufficient to conclude that dermal contact alone is sufficient to create a significant risk of CBD or even beryllium sensitization.’

Procurement managers must remain vigilant regarding these regulations to mitigate legal liabilities and safeguard their workforce. Furthermore, regular cleaning of Beryllium processing equipment and work areas is essential to prevent the accumulation of beryllium-containing materials, as effective housekeeping practices minimize the risk of airborne beryllium exposure. By aligning procurement practices with these established standards and leveraging Domadia’s comprehensive Beryllium Copper solutions, including guidance from user manuals on safe handling and maintenance, organizations can bolster their credibility and ensure that their products not only meet but also align with the requirements outlined in the beryllium copper phase diagram for their respective applications.

Conclusion

Understanding the Beryllium-Copper phase diagram is essential for procurement managers and engineers aiming to optimize material performance across various high-tech applications. This article has explored the intricate relationship between temperature, composition, and the resultant properties of Beryllium-Copper alloys, emphasizing the diagram’s role as a critical tool for informed decision-making. By leveraging insights from the phase diagram, professionals can enhance the strength, ductility, and electrical conductivity of these alloys, ensuring they meet stringent industry requirements.

Moreover, the practical strategies discussed, including careful alloy composition selection and targeted heat treatment processes, highlight the importance of a comprehensive approach to material optimization. As industries such as aerospace, automotive, and oil and gas continue to evolve, understanding and applying the principles of the phase diagram will be vital in maintaining competitive advantages and ensuring product reliability.

In conclusion, the ongoing demand for high-performance materials underscores the necessity of mastering the complexities of the Beryllium-Copper phase diagram. By aligning procurement practices with industry standards and leveraging expert insights, organizations can not only enhance their material selection processes but also contribute to the broader goal of operational excellence in their respective fields.