Blogs

DOMADIA™ CuNi10 – The Ultimate Copper-Nickel Alloy for Marine and Industrial Use

🧭 Introduction

In industries where corrosion, heat, and mechanical stress are constant challenges, finding a reliable, long-lasting material is critical. This is where DOMADIA™ CuNi10 makes all the difference.

CuNi10, a Copper-Nickel alloy composed of roughly 90% Copper and 10% Nickel, is trusted by engineers and manufacturers worldwide. Classified under DIN 2.0811 / UNS C70700 and produced according to DIN 17471, this alloy is specifically engineered to withstand harsh marine environments, chemical exposure, and high-pressure systems.

From deep-sea pipelines to automotive brake systems and defense technologies, CuNi10 offers unmatched performance, durability, and fabrication versatility—making it a true workhorse alloy across multiple sectors.

🔎 What is CuNi10?

DOMADIA™ CuNi10 is a high-quality Copper-Nickel alloy containing approximately 90% Copper and 10% Nickel. Classified under DIN 2.0811 / UNS C70700, this alloy is manufactured according to DIN 17471 standards.

CuNi10 is specially designed to deliver exceptional resistance to corrosion, high mechanical strength, and thermal stability—making it an ideal material for critical applications across marine, chemical, offshore, automotive, and industrial sectors.

⚗️ Chemical Composition of CuNi10

| Element | Symbol | Content (%) |

| Copper | Cu | Balance (~88.7 – 90%) |

| Nickel | Ni | 9.0 – 11.0 |

| Iron | Fe | ≤ 1.8 |

| Manganese | Mn | ≤ 1.0 |

| Zinc | Zn | ≤ 1.0 |

| Lead | Pb | ≤ 0.05 |

| Phosphorus | P | ≤ 0.02 |

| Carbon | C | ≤ 0.05 |

| Sulphur | S | ≤ 0.02 |

🧪 Note: Exact composition may vary slightly based on manufacturing specifications and intended application.

🛠️ Key Features & Benefits

Corrosion Resistance

Performs exceptionally in seawater, brine, and humid environments. It naturally resists rust and degradation, even after long-term exposure.

High Strength & Ductility

Maintains strength under pressure while allowing cold-forming and fabrication. Perfect for complex parts and structural components.

Excellent Weldability

Compatible with all major welding techniques: TIG, MIG, and arc welding.

Anti-Fouling Properties

Discourages marine growth such as algae, barnacles, and biofilm, extending equipment life in seawater environments.

Stable Thermal & Electrical Conductivity

Reliable performance in heat exchangers, condensers, and electrical systems.

Non-Magnetic & Non-Sparking

Ideal for explosive environments, submarines, and sensitive instrumentation.

📊 Technical Specifications of CuNi10 (DIN 2.0811 / UNS C70700)

| Property | Value |

| Standard | DIN 17471 |

| Material Number | 2.0811 (DIN) |

| UNS Designation | C70700 |

| Copper (Cu) | ~89–90% |

| Nickel (Ni) | ~9–11% |

| Density | 8.9 g/cm³ |

| Melting Range | 1100°C – 1150°C |

| Tensile Strength | 300 – 500 MPa |

| Yield Strength | 80 – 150 MPa |

| Elongation | ≥20% |

| Electrical Conductivity | 5–6% IACS |

| Thermal Conductivity | 40 – 50 W/m.K |

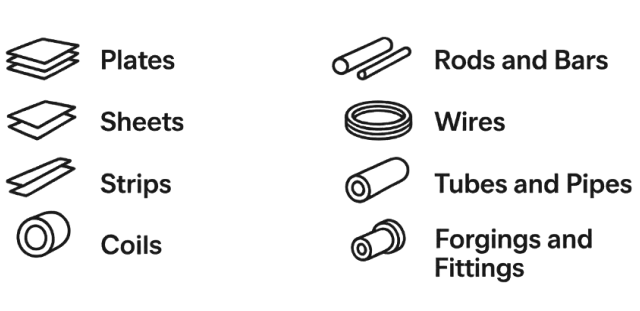

🧩 Available Shapes & Forms

AMW offers CuNi10 in a wide range of shapes to suit diverse applications:

Custom sizes and finishes are available upon request to meet project-specific requirements.

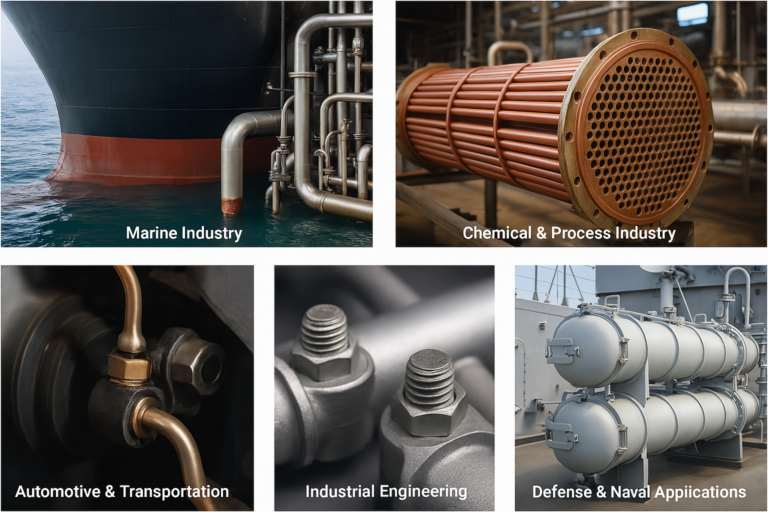

🛳️ Applications of CuNi10 Across Industries

CuNi10 is incredibly versatile. Its durability and performance make it the material of choice across industries that demand strength, safety, and reliability.

🏅 Quality & Compliance

DOMADIA™ CuNi10 is produced under strict adherence to DIN 17471, ensuring:

- Consistent chemical composition

- Verified mechanical properties

- Dimensional tolerances

- Global traceability (DIN 2.0811 / UNS C70700)

🌐 Why Choose DOMADIA™ CuNi10 from AMW?

- Engineered for demanding environments

- Backed by international quality standards

- Excellent workability and custom options

- Available for worldwide delivery

- Supported by a team of technical experts

📣 Final Thoughts

CuNi10 is more than just an alloy—it’s your ally in performance.

From deep-sea pipelines to chemical plants and naval submarines, DOMADIA™ CuNi10 provides the strength, stability, and safety your projects demand.

📬 Ready to upgrade your system with CuNi10?

Contact us now : https://domadia.net/contact/