Blogs

How to Buy Inconel 625 Tubing for Sale: A Step-by-Step Guide

Overview:

The article titled “How to Buy Inconel 625 Tubing for Sale: A Step-by-Step Guide” focuses on providing a comprehensive process for procuring Inconel 625 tubing, highlighting essential factors such as supplier selection, pricing considerations, and customization options. The content supports this by detailing the importance of reputable suppliers, current market trends, and logistical factors, all of which are crucial for making informed purchasing decisions in the high-performance alloys market.

Introduction

Inconel 625 stands out as a premier nickel-chromium alloy, celebrated for its exceptional performance in extreme environments. As industries increasingly demand materials that can withstand both high temperatures and corrosive conditions, understanding the properties and specifications of Inconel 625 becomes essential for procurement managers.

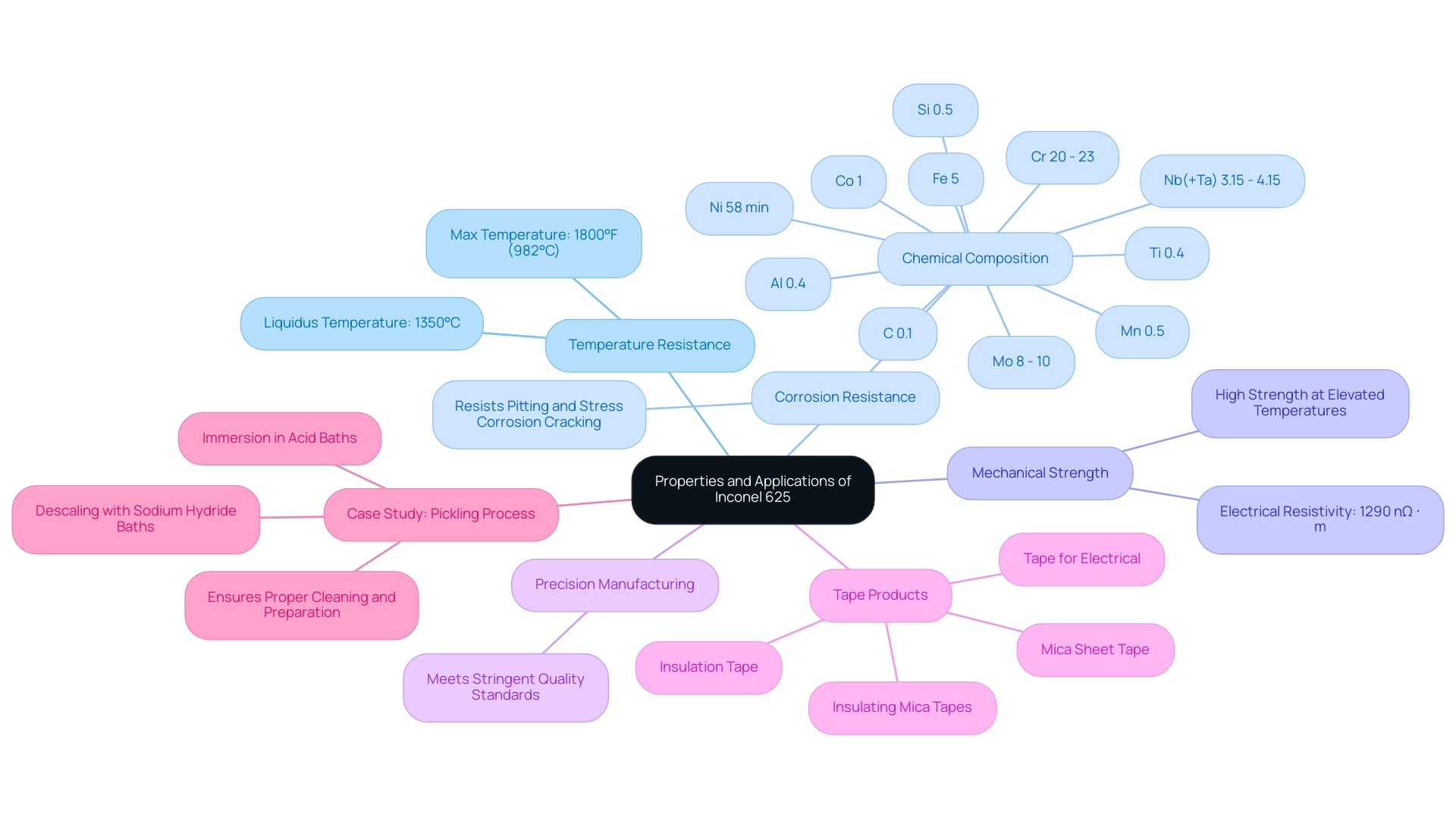

This article delves into the alloy’s remarkable features, including:

- Temperature resistance

- Corrosion resistance

- Mechanical strength

- Precision manufacturing capabilities

Additionally, it explores practical applications, sourcing strategies, and the nuances of pricing and customization options, providing a comprehensive guide for making informed procurement decisions in a competitive market.

With the right insights, organizations can leverage Inconel 625 to enhance their operational efficiency and ensure the longevity of critical components.

Understanding Inconel 625: Properties and Specifications

Alloy 625 is a high-performance nickel-chromium mixture renowned for its remarkable resistance to oxidation and corrosion, particularly in extreme environments. Its key properties include:

- Temperature Resistance: Capable of withstanding temperatures up to 1800°F (982°C), this alloy is ideal for uses demanding high thermal stability. The alloy’s liquidus temperature is noted at 1350 °C, emphasizing its capability to sustain integrity under extreme heat.

- Corrosion Resistance: This material excels in resisting pitting, stress corrosion cracking, and oxidation. This characteristic is vital for components that operate in aggressive chemical environments, ensuring longevity and reliability. Its corrosion resistance is a significant factor that improves its appropriateness for various uses. Typical analysis in percent for Alloy 625 includes:

- Ni 58 min

- Cr 20 – 23

- Fe 5

- Co 1

- Mo 8 – 10

- Nb(+Ta) 3.15 – 4.15

- Ti 0.4

- Al 0.4

- C 0.1

- MN 0.5

- Si 0.5, which contributes to its exceptional performance in corrosive conditions.

- Mechanical Strength: The alloy retains high strength and toughness even at elevated temperatures, making it a durable choice for demanding uses. With an electrical resistivity of 1290 nΩ ⋅ m, this alloy demonstrates exceptional performance in high-stress conditions.

- Precision Manufacturing: Crafted with precision, this material meets the most stringent quality standards, ensuring reliability and performance in critical uses.

Furthermore, our tape products provide essential solutions for high-temperature resistance and electrical insulation across diverse uses. These consist of:

- Insulation Tape, created for essential electrical engineering uses, ensuring reliability and durability.

- Tape for Electrical, which provides excellent flame resistance and dielectric strength.

- Mica Sheet Tape, especially suitable for insulating extensive flat areas, perfect for aerospace and automotive sectors.

- Insulating Mica Tapes, essential in the fabrication of coils and capacitors, ensuring safety and efficiency.

A practical instance of the use of 625 is the pickling process, which involves descaling with sodium hydride baths followed by immersion in sulfuric and nitric-hydrofluoric acid baths at designated temperatures and durations. This process guarantees proper cleaning and preparation of the alloy for further uses, utilizing specific acid concentrations and conditions for effective treatment.

Before proceeding with procurement, it is essential to verify specific parameters such as diameter, wall thickness, and length to ensure the alloy meets the precise requirements of your project.

Where to Buy Inconel 625 Tubing: A Guide to Suppliers and Market Trends

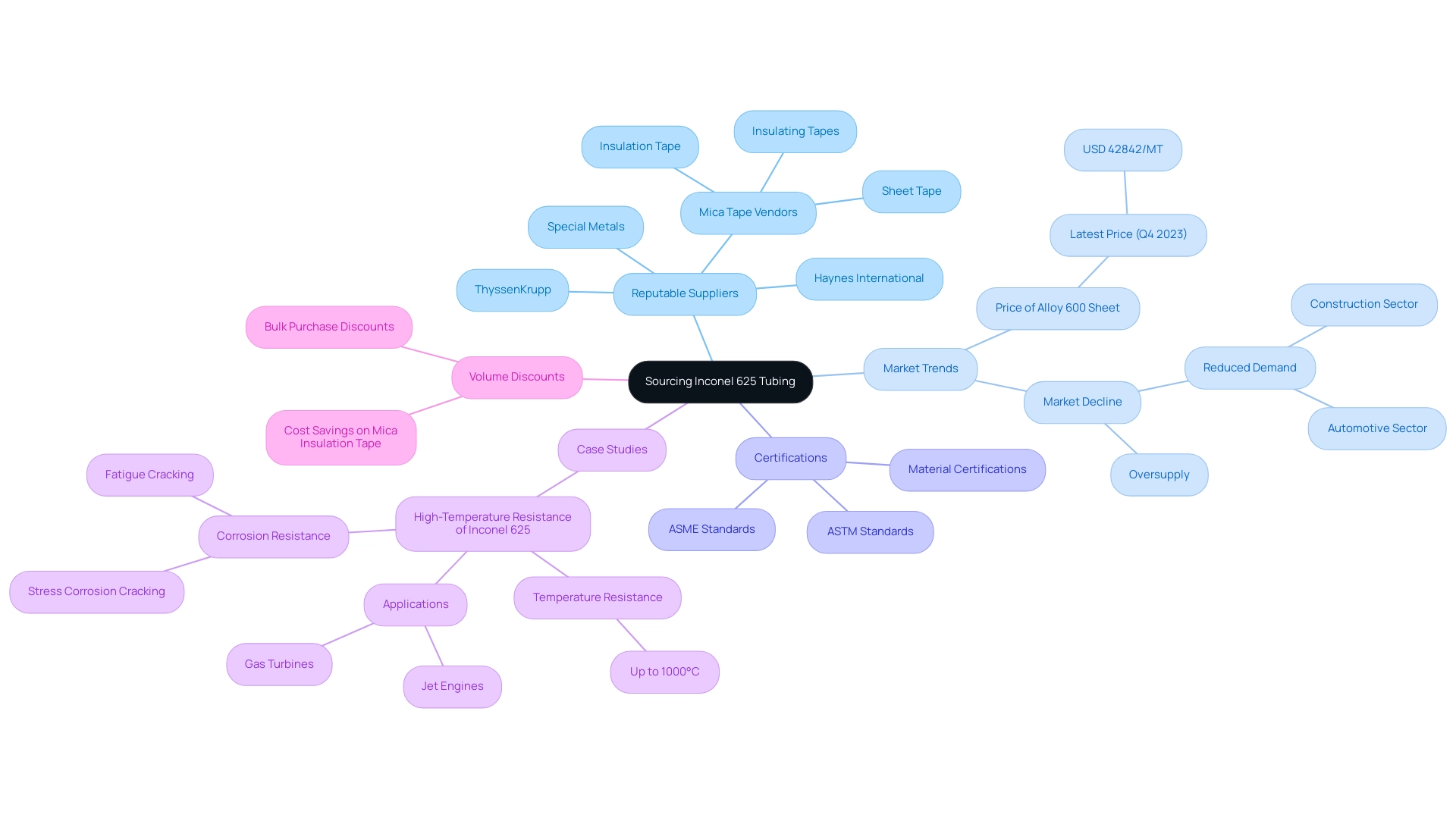

When sourcing 625 tubing, it is crucial to consider the following factors:

Reputable Suppliers: Partnering with suppliers who have established their credibility in the high-performance alloys market is essential. Notable companies such as Haynes International, Special Metals, and ThyssenKrupp stand out for their commitment to quality and reliability, making them top choices for procurement managers. Furthermore, consider vendors of high-temperature materials such as tape products made from Mica, including Insulation Tape, Sheet Tape, and Insulating Tapes, which are intended for essential uses needing outstanding electrical insulation and thermal resistance.

Market Trends: Staying informed about current market trends is crucial, particularly due to the recent drop in pricing for a certain alloy in the MEA region, affected by oversupply and decreased demand in industries like construction and automotive. The latest price for Alloy 600 Sheet Ex Dubai in the UAE was USD 42842/MT, which serves as a concrete reference point for procurement decisions. Understanding these fluctuations can directly impact pricing and availability, allowing for more informed purchasing decisions. Utilizing industry reports and trade publications will provide valuable insights into these dynamics.

Certifications: It is imperative to ensure that your suppliers meet international standards such as ASTM and ASME. Requesting material certifications is a best practice that ensures the quality and performance of the alloys you are acquiring, along with the Mica tape products that may enhance your uses.

Case Studies: A notable example of this alloy’s capabilities is its use in high-temperature environments, particularly in the aerospace sector. Alloy 625 pipes can withstand temperatures up to 1000°C, making them ideal for jet engines and gas turbines. Their resistance to stress corrosion cracking and fatigue cracking increases their worth in challenging uses. Likewise, Mica tape, comprising Mica Sheet Tape and Insulating Mica Tapes, is extensively utilized in electrical engineering due to its high-temperature resistance and dependability in numerous applications, ranging from household appliances to industrial machinery.

Volume Discounts: Consider the availability of discounts for bulk purchases, which can greatly enhance costs for procurement managers aiming to secure favorable deals on both alloy 625 tubing and complementary materials like this tape. For instance, bulk orders of Mica Insulation Tape can lead to substantial savings, making it a cost-effective choice for large projects.

Conducting thorough research and cultivating strong relationships with suppliers will empower you to secure the most advantageous deals on inconel 625 tubing for sale as well as high-temperature insulation materials, enhancing both operational efficiency and cost-effectiveness.

Navigating Pricing: Understanding Costs of Inconel 625 Tubing

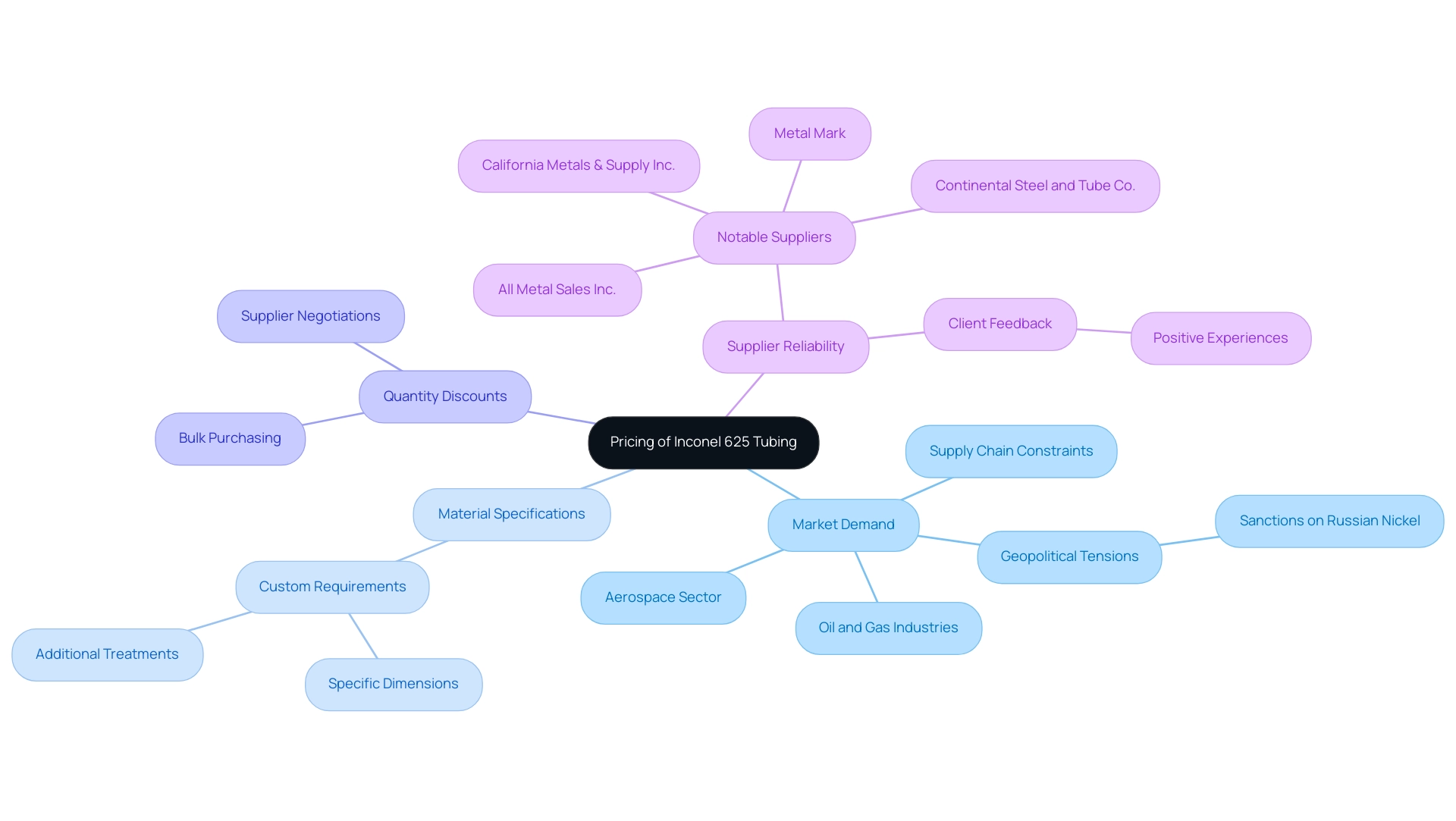

The pricing of alloy 625 tubing is subject to considerable variation, driven by multiple influential factors:

- Market Demand: Fluctuations in prices are intricately tied to supply and demand dynamics. For instance, the aerospace sector and oil and gas industries exert considerable influence, often leading to upward pricing pressure during periods of heightened demand. Recent developments in Q2 2024, such as supply chain constraints and geopolitical tensions, particularly sanctions on Russian nickel, have further complicated these dynamics, impacting availability and pricing.

- Material Specifications: Custom requirements—such as specific dimensions or additional treatments—can significantly alter costs. It is imperative to communicate your exact specifications with suppliers to obtain precise quotations.

- Quantity Discounts: Bulk purchasing frequently results in cost efficiencies. Interacting with suppliers to talk about possible discounts for larger orders can result in significant savings.

As a benchmark, current pricing for inconel 625 tubing for sale generally ranges from $50 to $150 per foot, affected by the previously mentioned factors. Notable suppliers such as All Metal Sales Inc. and Continental Steel and Tube Co. can be considered for sourcing inconel 625 tubing for sale. Furthermore, it is crucial to take into account Mica Tape products, which are engineered for high-temperature resistance and electrical insulation, making them appropriate for uses alongside a nickel-chromium alloy.

These tapes are essential in environments requiring reliable insulation, such as in aerospace and automotive industries. To navigate the complexities of these price fluctuations, procurement managers should regularly consult updated market reports, particularly in light of recent supply chain constraints and geopolitical tensions affecting the industry. Furthermore, our proven execution of small and large batch orders ensures that we can meet diverse procurement needs efficiently.

As one client noted, ‘We were really happy with the final deliverable, and the takeaways from the report,’ highlighting the importance of reliable suppliers in making informed purchasing decisions.

Customization Options for Inconel 625 Tubing: What You Need to Know

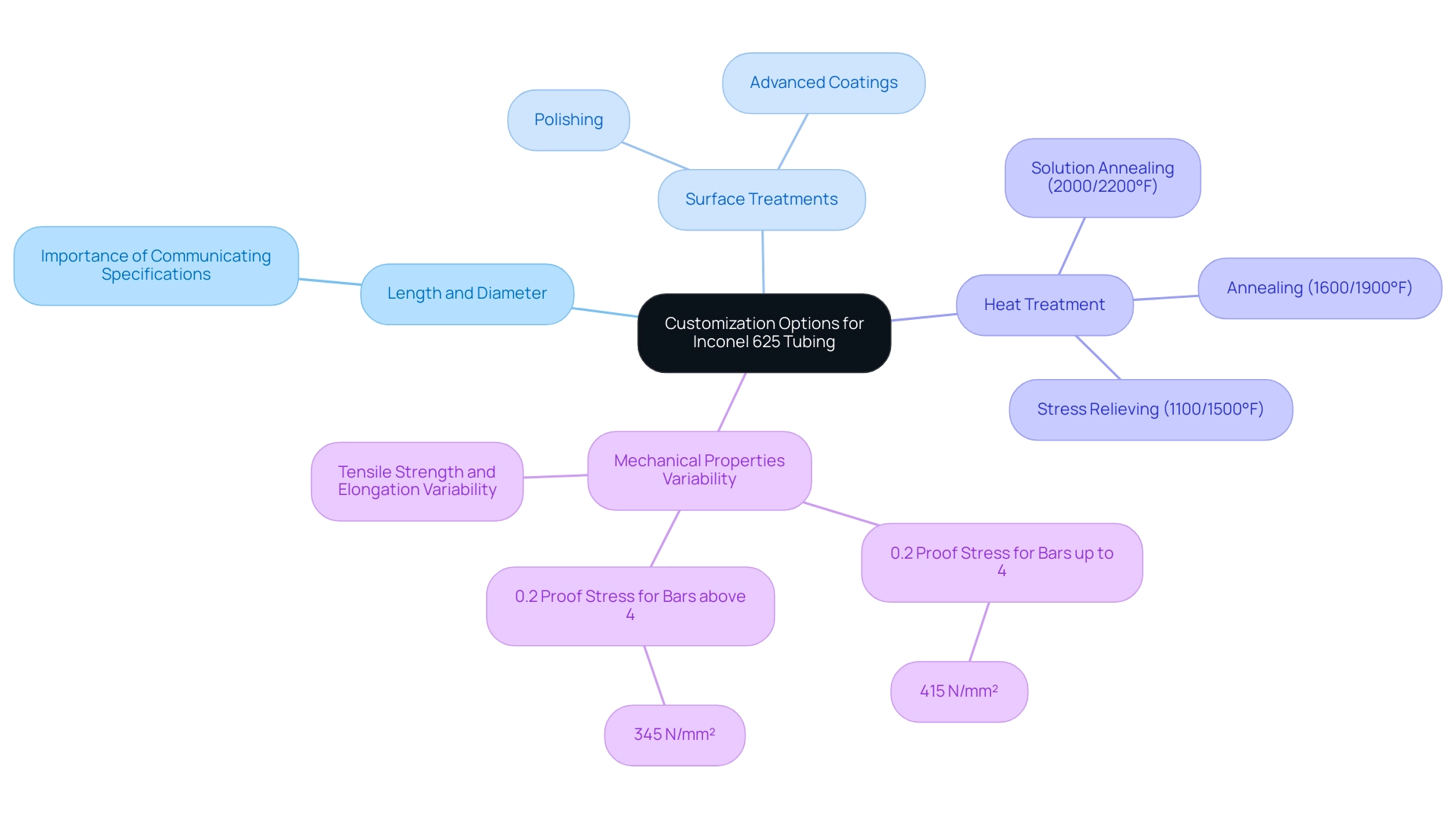

When considering inconel 625 tubing for sale, various customization options are available to ensure that it meets specific project requirements. Key areas of customization include:

- Length and Diameter: Tubing can be tailored to particular lengths and diameters, accommodating the unique needs of your project. It is essential to communicate your specifications clearly to suppliers to facilitate precise manufacturing.

- Surface Treatments: Implementing surface treatments such as polishing or advanced coatings significantly enhances both corrosion resistance and the visual appeal of the tubing. Engaging in discussions with suppliers about these options is crucial to determine the most suitable treatment for your particular use.

- Heat Treatment: Custom heat treatments are paramount for improving the mechanical properties of inconel 625 tubing for sale. Depending on the usage, these treatments can enhance the alloy’s performance in high-stress environments. The three heat treatment options for Alloy 625 include solution annealing at 2000/2200°F, annealing at 1600/1900°F, and stress relieving at 1100/1500°F, which are vital in optimizing the material’s integrity.

Additionally, the reduction of area for both bar sizes is 35%, underscoring the significance of customization in achieving desired mechanical properties. Early engagement with your supplier regarding customization possibilities ensures that all specifications are meticulously met, facilitating a more efficient procurement process. Recent studies, particularly the case study titled “Mechanical Properties of Alloy 625,” indicate that the mechanical properties of Alloy 625 vary notably with bar diameter; for bars up to 4” in diameter, the 0.2% proof stress is recorded at 415 N/mm², while for larger diameters, it drops to 345 N/mm².

This variability underscores the need for precise customization in applications where high-stress performance is critical.

Logistics of Buying Inconel 625 Tubing: Shipping and Delivery Considerations

When procuring Inconel 625 tubing, several logistical factors warrant careful consideration to ensure efficiency and compliance:

- Shipping Methods: The choice of shipping method can significantly impact timelines and costs. Depending on your supplier and geographical location, viable options may include air freight for expedited delivery, sea freight for cost-effective bulk shipments, or ground transportation for local deliveries. Assess the urgency of your project to select the most suitable method.

- Lead Times: Understanding lead times is critical. Production and delivery timelines can vary, especially for custom orders, which may necessitate longer wait periods. Inquire about average lead times, as current orders for this material typically experience lead times ranging from several weeks to a few months, depending on the supplier’s workload.

- Import Regulations: For international sourcing, it is imperative to navigate import regulations proficiently. Adhering to the correct HSN Code (84841090), which has an import statistic of 14,078, is essential as it influences duty rates and import benefits. Non-compliance can lead to unexpected delays and additional costs, impacting your overall procurement strategy. A case study titled “Regulatory Compliance for Alloy Imports” illustrates the importance of using the correct HSN Code to ensure adherence to regulatory requirements and to avoid complications during import operations.

Additionally, it is advisable to consider service expectations when engaging suppliers. As stated by Volza, “If our service does not meet your expectations, we offer a 3-day 100% money-back guarantee, applicable within the first 300 points of consumption.” This perspective can provide reassurance when selecting a supplier.

By proactively addressing these logistical considerations, procurement managers can significantly streamline the acquisition process, ensuring the timely delivery of inconel 625 tubing for sale while remaining compliant with regulatory requirements.

Conclusion

Inconel 625 is undeniably a standout choice for industries requiring materials that can endure extreme conditions. The alloy’s remarkable temperature and corrosion resistance, coupled with its mechanical strength and precision manufacturing capabilities, make it a vital asset for procurement managers aiming to enhance operational efficiency and longevity of critical components.

As discussed, selecting reputable suppliers and staying informed about market trends are essential steps in the procurement process. The recent fluctuations in pricing, influenced by supply and demand dynamics, underscore the importance of strategic sourcing to secure the best deals. Additionally, the customization options available for Inconel 625 tubing allow for tailored solutions that meet specific project requirements, ensuring optimal performance in high-stress environments.

Logistical considerations, from shipping methods to compliance with import regulations, further highlight the complexity of procuring Inconel 625. By addressing these factors proactively, organizations can streamline their acquisition process, ensuring timely delivery and adherence to necessary standards.

Ultimately, leveraging the unique properties of Inconel 625 while navigating the intricacies of procurement will empower organizations to achieve superior results in their operations. With informed decisions and strategic partnerships, the potential for enhanced performance and reliability in demanding applications is vast.