Blogs

How to Implement Anti-Shoplifting Device Shielding with Super Mumetal: A Step-by-Step Guide

Introduction

In the realm of retail security, the battle against shoplifting has taken on new dimensions, with procurement managers seeking innovative solutions to safeguard their assets. At the forefront of this endeavor is Mumetal, a specialized soft magnetic alloy renowned for its exceptional shielding capabilities.

This article delves into the multifaceted applications of Mumetal, exploring its role in:

- Anti-shoplifting technologies

- The strategic implementation of shielding solutions

- The critical evaluation of suppliers

As the landscape of retail security evolves, understanding the nuances of material selection, cost considerations, and emerging trends becomes essential for those tasked with fortifying their operations. By leveraging expert insights and practical guidance, procurement professionals can navigate the complexities of magnetic shielding and enhance the effectiveness of their anti-theft strategies.

Understanding Mumetal: The Soft Magnetic Alloy for Anti-Shoplifting

This specialized soft alloy, primarily made of nickel, iron, and molybdenum, is noted for its exceptional properties related to magnetism. Its high permeability allows efficient channeling of fields, making it an optimal choice for various shielding applications. With a low coercivity, this alloy can be easily magnetized and demagnetized, a crucial feature in environments where interference poses a risk to electronic equipment performance.

In the realm of anti-shoplifting devices, anti-shoplifting device shielding with super mumetal serves a vital role by providing a protective shield for sensitive components against external fields, significantly enhancing the reliability and effectiveness of such devices. Recent statistics suggest that the East-West element at right angles to true North measures 6,479 nT, highlighting the need for strong protective solutions to reduce interference. However, it is crucial to recognize the constraints of the material; while effective against static or slowly changing fields, its effectiveness diminishes at both low and high field strengths due to saturation.

To address this, specialized shields are often designed with multiple enclosures, and alternative methods like Faraday shields or superconducting materials are employed for higher frequency magnetic fields. Additionally, mechanical magnetometers are utilized to test metal for residual magnetism and can be calibrated using Helmholtz coils, further ensuring the integrity of protective solutions. As Stuart J Stoliar aptly noted, ‘Motor rotates glass plate,’ highlighting the practical application of a specific alloy in complex systems.

For companies pursuing thorough electromagnetic protection solutions, incorporating substances like Beryllium Copper and Kovar can improve the efficiency of soft iron, particularly in elevated temperature settings. Suppliers and manufacturers of these materials, along with high-temperature insulation products, can offer invaluable resources for procurement managers aiming to enhance their applications. Compared to other magnetic alloys, Mumetal’s unique properties provide a distinct advantage, particularly in applications requiring high sensitivity and precision.

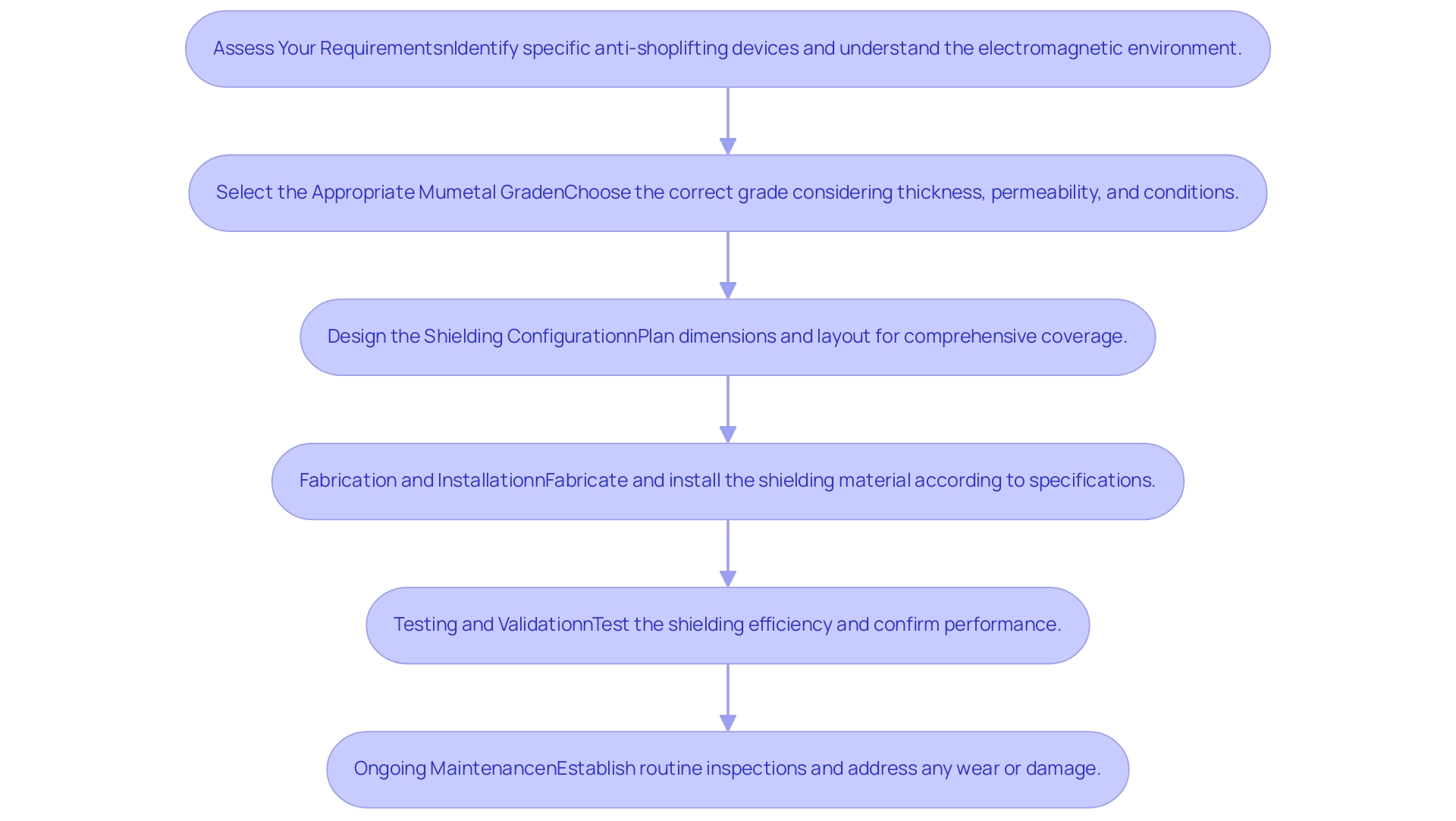

Step-by-Step Guide to Implementing Mumetal Shielding

Assess Your Requirements: Initiate the process by identifying the specific anti-shoplifting devices that require protection. A thorough understanding of the electromagnetic environment in which the anti-shoplifting device shielding with super mumetal will operate is crucial, as it influences the design and effectiveness of the protection. According to recent reviews, various materials, including metals and conducting polymers, are essential for controlling electromagnetic radiations, highlighting the relevance of Mumetal.

Select the Appropriate Mumetal Grade: Choosing the correct grade of Mumetal is pivotal for optimal protection. Consider critical factors such as thickness, permeability, and environmental conditions. The correct choice of an anti-shoplifting device shielding with super mumetal improves the barrier’s efficacy against electromagnetic interference, ensuring robust protection. As highlighted by industry specialists, the theoretical evaluation of a magnetic protection system integrating active and passive modes emphasizes the significance of choosing the appropriate substances for optimal performance.

Procurement of Mumetal: Source your Mumetal from reputable suppliers who specialize in high-performance alloys, including Electrical Insulation Paper Manufacturers and other related products like Kapton Tapes and Silica Yarn. Ensure that the substance complies with international quality and performance standards, which is crucial for ensuring effectiveness in protection applications. This procurement process may also encompass other essential materials, such as Beryllium Copper, Kovar, and Nickel, to provide comprehensive solutions.

Design the Shielding Configuration: Thoughtful planning of your shielding design is imperative. This involves determining the dimensions and layout of the material to ensure comprehensive coverage of the required components within the anti-shoplifting device shielding with super mumetal. A well-designed configuration will mitigate potential electromagnetic interference effectively.

Fabrication and Installation: Upon planning, proceed with fabricating the specified material to the required dimensions and install it according to your design specifications. It is essential that the barrier be firmly connected, with no openings that could allow interference, to sustain optimal performance.

Testing and Validation: After installation, perform thorough testing to confirm the efficiency of the metal protection. Measure the reduction in electromagnetic interference and ensure that the device functions as intended. Insights from the case study titled ‘OPM Data Collection in the Light MuRoom’ illustrate the significance of effective protective structures, showing a change in the magnetic field of approximately 300 pT, confirming good performance suitable for sensitive applications.

- Ongoing Maintenance: Establish a routine for regular inspections and upkeep of the magnetic protection. This practice is vital for ensuring its continued effectiveness over time. Promptly address any wear or damage to maintain optimal performance levels, as neglect can lead to diminished shielding capabilities.

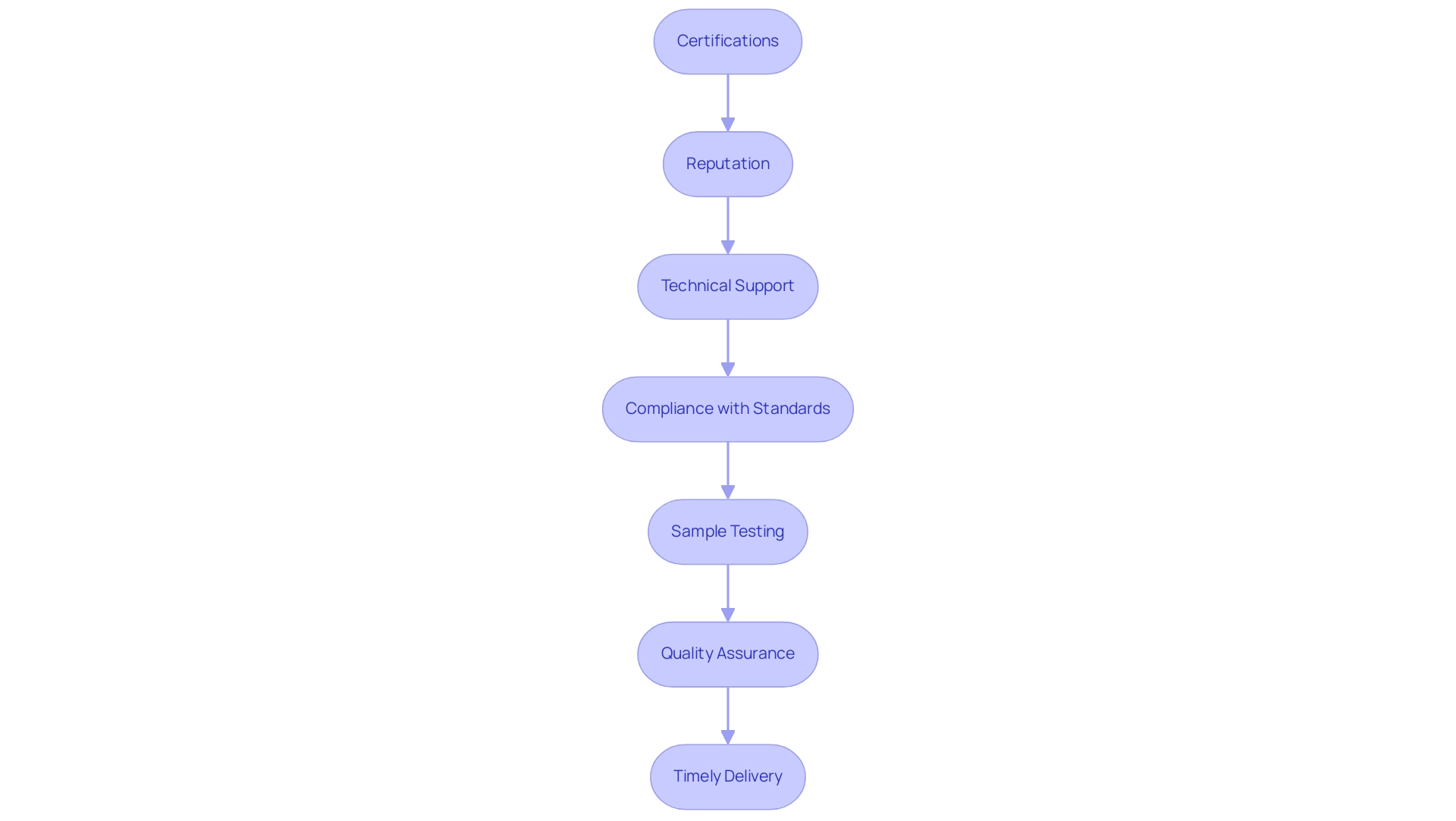

Evaluating Supplier Quality and Compliance

When evaluating suppliers for the material, a strategic approach is essential. Consider the following critical criteria:

Certifications: Confirm that suppliers possess relevant certifications, such as ISO 9001, which reflect their commitment to maintaining quality management systems.

Such certifications are indicative of a supplier’s dedication to consistent quality.Reputation: Investigate the supplier’s standing in the industry. Look for reviews, testimonials, and relevant case studies, such as Domadia’s exceptional track record in supplying Mica Tape and other high-quality products.

A well-regarded supplier often has a proven history of delivering exceptional products and fostering strong client relationships through reliable and sincere service.Technical Support: Opt for suppliers that provide robust technical support. This assistance is invaluable in guiding your selection of the appropriate metal grades tailored to your specific applications, ensuring optimal performance.

Domadia, for instance, leverages years of industry expertise to recommend the perfect solutions for your technical challenges.Compliance with Standards: Ensure that the materials supplied adhere to international standards for electromagnetic shielding and safety regulations applicable to your sector. Compliance not only safeguards your operations but also enhances the credibility of your supply chain.

For instance, significant disparities in mitochondrial calcium levels were evident across the range of 300–600 µT, underscoring the importance of quality in procurement of the alloy.Sample Testing: Prior to committing to bulk orders, request samples of the material for rigorous testing. This step allows you to evaluate whether the material meets your specifications and performance standards, mitigating risks associated with procurement.

Quality Assurance: Domadia ensures that every batch of Mica Tape undergoes rigorous testing to maintain high standards. This commitment to quality is essential for procurement managers seeking reliable materials.

Timely Delivery: With efficient logistics and supply chain management, Domadia guarantees timely delivery of products, enabling smooth operations without disruptions.

By applying these criteria, procurement managers can enhance their decision-making processes, ensuring they partner with suppliers like Domadia who align with their quality and compliance objectives, and who are dedicated to supporting their business growth.

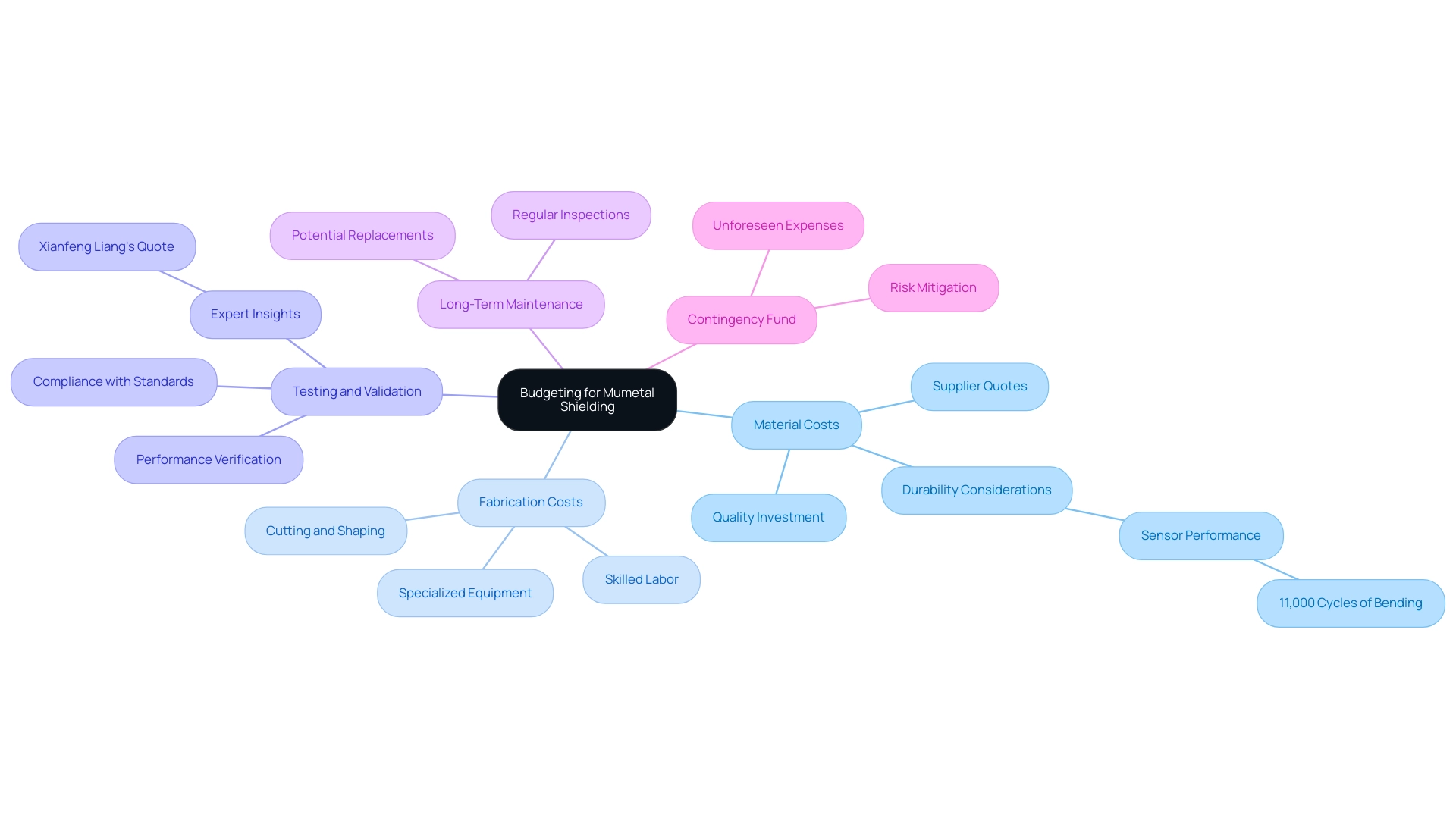

Cost Considerations and Budgeting for Mumetal Shielding

When developing a budget for Mumetal shielding projects, it is vital to consider several key factors to ensure both effectiveness and cost-efficiency:

Material Costs: Begin by obtaining quotes from multiple suppliers, such as electrical insulation paper manufacturers, high-temperature fabrics suppliers, and those specializing in Beryllium copper and Nickel. This benchmarking will help establish competitive pricing. While higher-quality substances may incur increased costs, investing in quality is crucial for achieving optimal shielding performance. Notably, the durability of this alloy is exemplified by sensors that can withstand 11,000 cycles of bending, highlighting the importance of selecting robust materials.

Fabrication Costs: Include the expenses related to cutting, shaping, and installing Mumetal. This process often necessitates specialized equipment and skilled labor, which can significantly influence overall costs.

Testing and Validation: Allocate a portion of your budget for testing the effectiveness of the barrier. This step is essential to ensure compliance with industry standards and to verify performance, safeguarding your investment. As mentioned by Xianfeng Liang from the State Grid Smart Grid Research Institute, thorough testing is critical to validate the performance of protective materials in practical applications.

Long-Term Maintenance: Consider ongoing maintenance costs, which may encompass regular inspections and potential replacements of the Mumetal protection over its lifecycle. Planning for these expenses in advance can prevent budget overruns.

Contingency Fund: Establish a contingency fund to address unforeseen expenses that might arise during the project implementation phase. This proactive measure can mitigate risks associated with unexpected challenges.

By referencing the case study titled ‘Theoretical Analysis of a Magnetic Protection System Combining Active and Passive Modes,’ procurement managers can gain insights into effective budgeting strategies and the practical implications of performance. Furthermore, exploring partnerships with reputable suppliers and manufacturers of electrical insulation and high-temperature materials, such as PTFE coated yarn suppliers, can further enhance project success. By carefully analyzing these factors, procurement managers can develop a realistic budget that supports the successful implementation of Mumetal protective solutions while maximizing the project’s overall value.

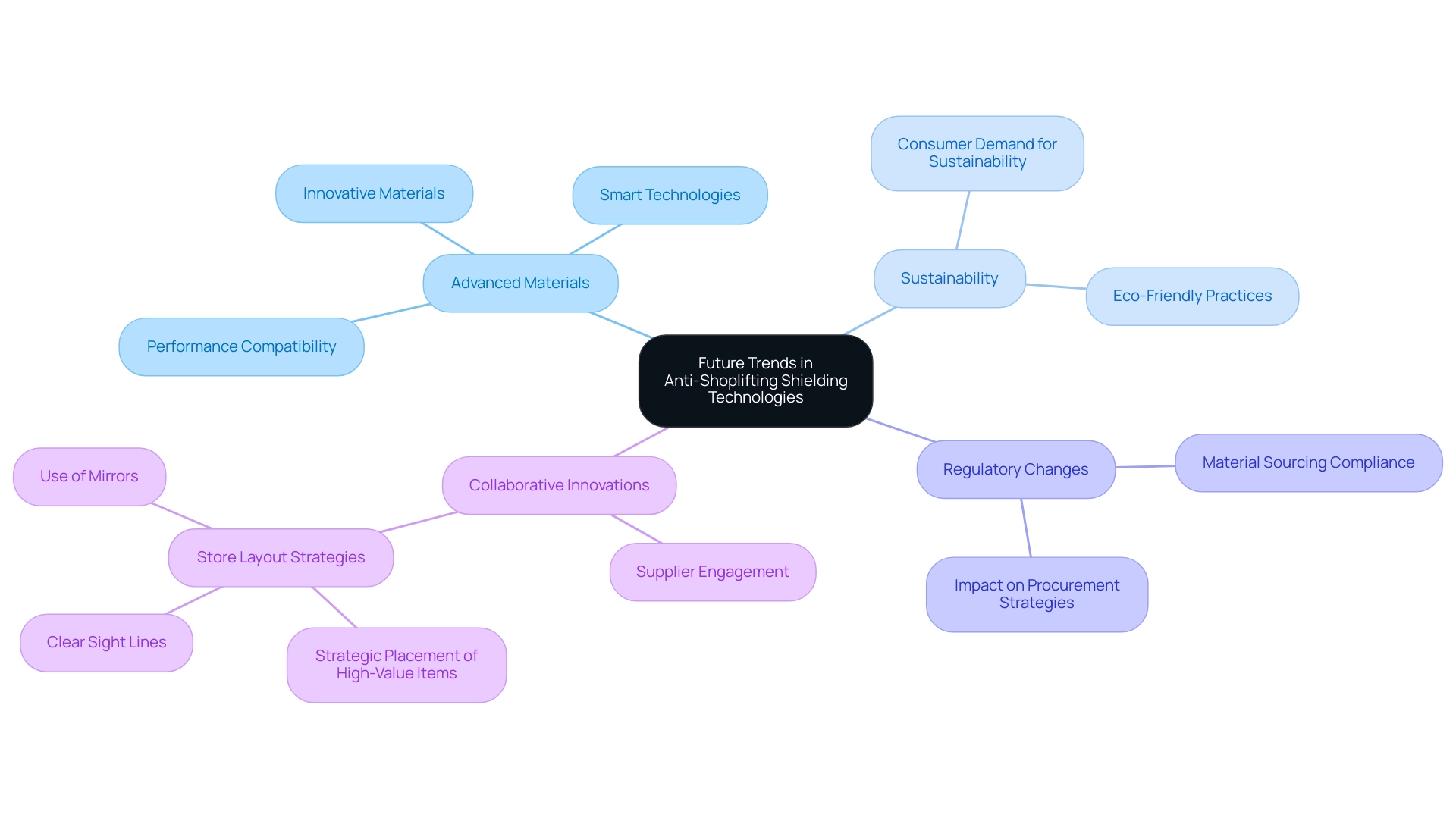

Future Trends in Anti-Shoplifting Shielding Technologies

The landscape of anti-shoplifting protection technologies is rapidly evolving, influenced by several key trends that procurement managers should closely monitor:

Advanced Materials: Ongoing research is yielding innovative materials that enhance magnetic properties while minimizing weight. Such advancements not only enhance protective effectiveness but also provide cost-reduction opportunities, making them appealing choices for procurement strategies. The incorporation of smart technologies, including IoT sensors, into anti-shoplifting systems necessitates the development of protective solutions, specifically an anti-shoplifting device shielding with super mumetal, to accommodate these electronic components. Ensuring compatibility without compromising performance is essential for enhancing operational effectiveness.

Sustainability: As sustainability gains traction, manufacturers are increasingly focusing on eco-friendly substances and practices in the production of protective solutions. This shift not only aligns with corporate social responsibility goals but also meets the growing consumer demand for sustainable products.

Regulatory Changes: Staying abreast of potential regulatory changes impacting material sourcing and compliance is critical. Such changes can significantly influence procurement strategies, requiring proactive adjustments to maintain compliance and optimize supply chains.

Collaborative Innovations: Engaging with suppliers and technology developers fosters collaborative innovations that can lead to cutting-edge shielding solutions. For instance, strategic placement of high-value items and clear sight lines, as highlighted in a recent case study on store layout and design for theft prevention, can enhance visibility and monitoring in stores. These partnerships can drive enhancements in security measures and overall performance, providing a competitive edge in the retail environment, especially with the implementation of anti-shoplifting device shielding with super mumetal. The key drivers for the growth of the anti-shoplifting systems market include increasing retail theft, stringent government regulations, and technological advancements in anti-theft solutions. These trends underscore the importance of strategic foresight in procurement, enabling decision-makers to adapt and thrive in a dynamic market. Moreover, the future growth prospects for the anti-shoplifting systems market are promising, driven by the increasing adoption of advanced security solutions and the rising awareness of the impact of retail theft on businesses.

Conclusion

Mumetal stands out as a pivotal component in the ongoing battle against shoplifting, offering procurement managers a sophisticated solution for enhancing retail security. Its unique properties, such as high permeability and low coercivity, make it an ideal choice for shielding sensitive anti-shoplifting devices from electromagnetic interference, thereby improving their reliability and effectiveness. The implementation of Mumetal requires careful consideration of material selection, design configuration, and rigorous testing to ensure optimal performance, highlighting the need for a systematic approach in its application.

Furthermore, the article underscores the importance of evaluating suppliers not only based on material quality but also their compliance with industry standards and their capacity for technical support. By partnering with reputable suppliers, procurement managers can secure the necessary resources for effective shielding solutions, ultimately safeguarding their operations against theft while optimizing costs.

Looking ahead, the retail landscape is poised for continuous evolution, driven by advancements in materials, smart technology integration, and a growing emphasis on sustainability. Staying abreast of these trends will empower procurement professionals to make informed decisions that align with both current needs and future challenges. By embracing innovative shielding solutions and fostering collaborative relationships with suppliers, businesses can enhance their anti-shoplifting strategies and bolster their overall security measures, ensuring a robust defense against retail theft in an increasingly competitive environment.