Blogs

How to Perform Beryllium Copper Heat Treatment: A Step-by-Step Guide

Introduction

In the realm of advanced materials, Beryllium Copper C17200, often known as Alloy 25, emerges as a standout choice for industries demanding both strength and conductivity. This high-performance alloy, with its unique composition and exceptional mechanical properties, has secured its place in critical applications ranging from aerospace components to precision tools.

As procurement managers navigate the complexities of material selection, understanding the intricacies of Beryllium Copper—its heat treatment processes, safety practices, and diverse industrial applications—becomes imperative.

This article delves into the essential characteristics of C17200, illuminating its advantages and guiding professionals in making informed decisions that enhance operational efficiency and safety in their respective fields.

Understanding Beryllium Copper C17200: Properties and Applications

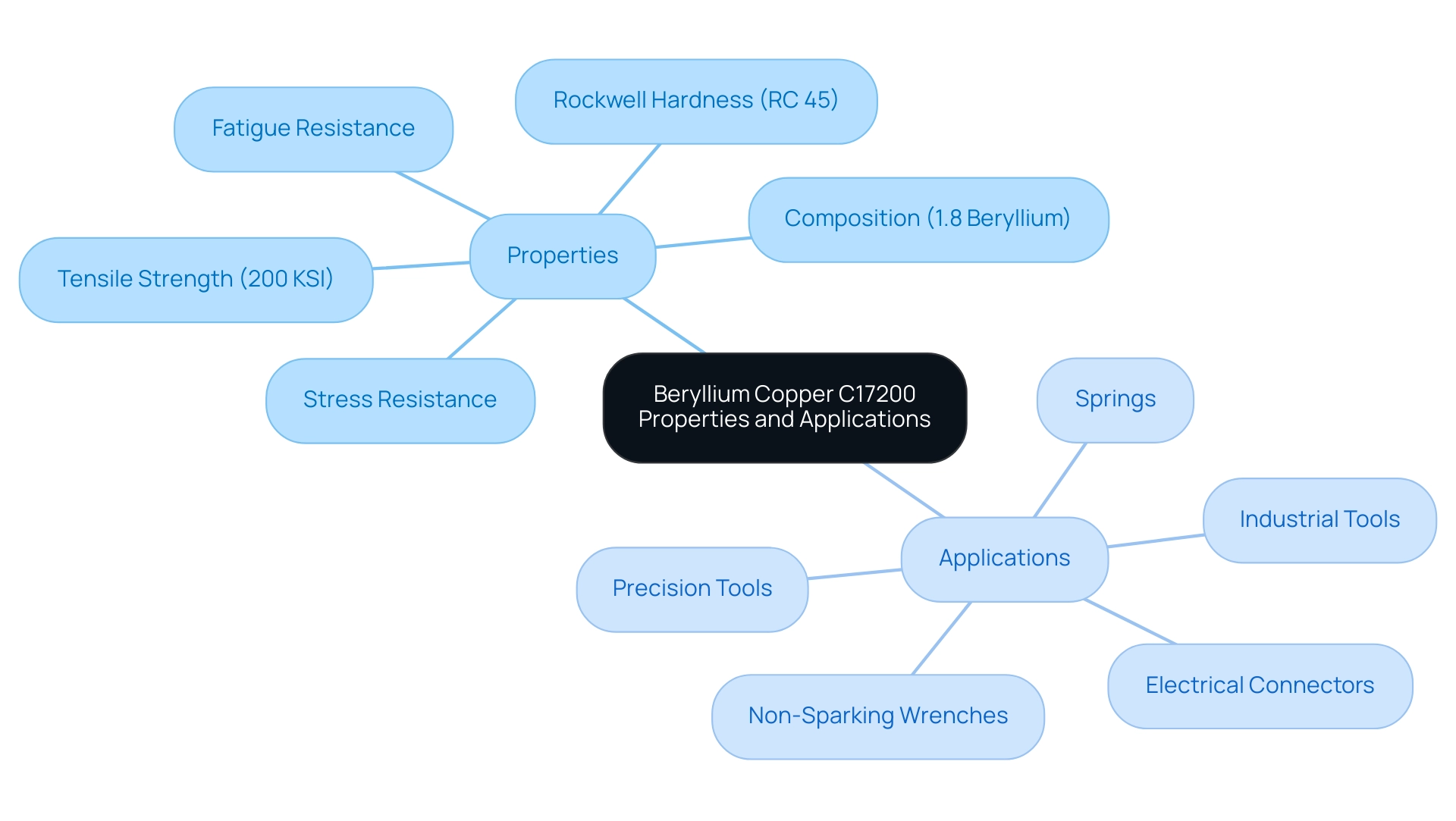

Beryllium copper C17200, commonly referred to as Alloy 25, stands out as a high-strength alloy celebrated for its remarkable electrical and thermal conductivity. This alloy’s composition typically includes approximately 1.8% beryllium, a critical element that significantly enhances its hardness and strength characteristics. Notably, in its peak aged condition, C17200 achieves an ultimate tensile strength in the vicinity of 200 KSI and Rockwell hardness values reaching RC 45, making it comparable to steel in performance.

Its exceptional traits make it highly suitable for a diverse range of uses, including:

- Electrical connectors

- Springs

- Precision tools

The alloy’s ability to withstand stress and resist fatigue is crucial, especially in demanding environments where reliability is paramount. Procurement managers should consider that DOMADIA Beryllium Copper adheres to international standards such as UNS and ASTM, ensuring quality and consistency in performance.

As you assess material choices, understanding these characteristics is crucial, as they directly influence the beryllium copper heat treatment processes and the final performance of C17200 in its designated uses. It is important to note that technical specifications are subject to change without notice, which underscores the need for constant vigilance. Recent discussions, including comments from Tom Chandler, have suggested that the hardness and tensile strength values for C17200 may have been understated, highlighting the importance of staying informed about these specifications.

Furthermore, the versatility and reliability of C17200 have been demonstrated across various uses, as outlined in case studies that showcase its effective implementation in demanding industrial environments. Additionally, DOMADIA Beryllium Copper offers competitive pricing and maintains a robust inventory to meet procurement needs. Safety characteristics of the Beryllium Copper non-sparking wrench encompass its capacity to avoid sparks in flammable settings, rendering it a crucial instrument for safety in industrial use.

Step-by-Step Guide to Heat Treatment of Beryllium Copper

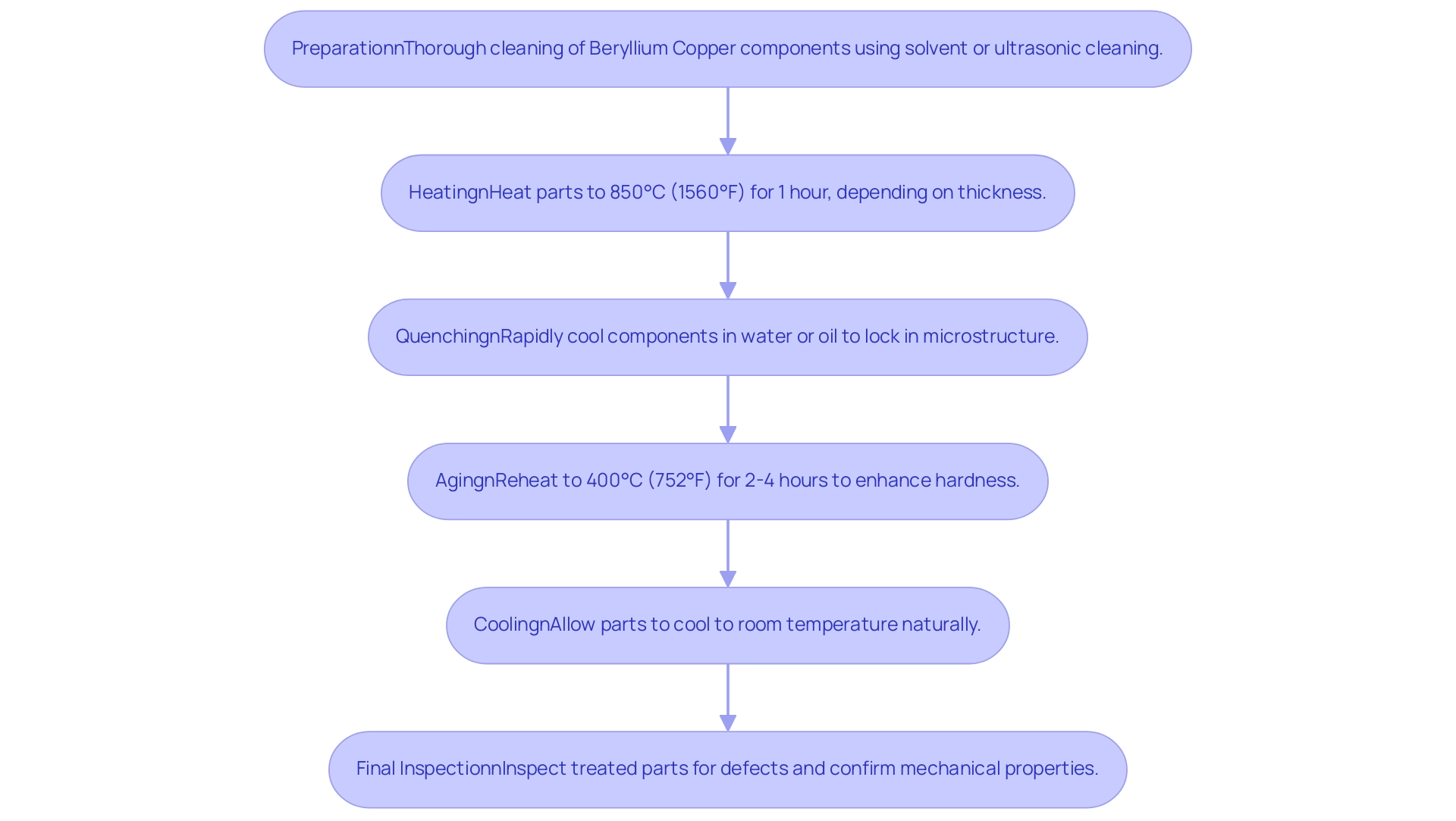

Preparation: Begin with a thorough cleaning of the Beryllium Copper components to eliminate any surface contaminants. This can be effectively achieved using a suitable solvent or through ultrasonic cleaning, ensuring a pristine surface for subsequent processing. As your trusted partner, Domadia ensures that you have access to high-quality Beryllium Copper solutions, including foils, sheets, rods, and wires, along with beryllium copper heat treatment tailored to your projects.

Heating: After cleaning, place the parts in a furnace and heat them to the solution annealing temperature, which typically hovers around 850°C (1560°F). It is essential to maintain this temperature for approximately one hour; however, the exact duration may vary based on the thickness of the material. It’s essential to recognize that beryllium copper heat treatment of C17200 results in an electrical conductivity of 19-28% Copper IACS at 68°F, which is a beneficial characteristic in numerous uses.

Quenching: Following the heating phase, rapidly cool the components by immersing them in water or oil. This quenching process is critical for locking in the microstructure and enhancing the material’s mechanical properties. The machinability of UNS C17200 is rated at 20% compared to UNS C36000, indicating that while it is workable, care must be taken during machining. At Domadia, we assist with your questions regarding beryllium copper heat treatment and its applications, ensuring you have the insights needed for successful procurement.

Aging: Once quenched, reheat the parts to an aging temperature of approximately 400°C (752°F). Hold at this temperature for a duration of 2 to 4 hours to achieve the desired hardness, significantly enhancing the alloy’s performance in demanding applications. The mechanical characteristics of UNS C17200, which include a Rockwell hardness of 80.0 – 85.0 and a tensile strength ranging from 515 – 585 MPa, underscore the significance of beryllium copper heat treatment.

Cooling: Allow the treated parts to cool to room temperature naturally after the aging process. This step is crucial for stabilizing the material’s characteristics.

Final Inspection: Conduct a thorough inspection of the treated parts to identify any defects and confirm that the desired mechanical properties have been attained. This final check ensures that the components are prepared for their intended purposes, thereby guaranteeing structural integrity and reliability in use. Domadia’s extensive range of Beryllium Copper products, including non-sparking wrenches, reflects our commitment to high-quality service and safety features designed for various industrial uses, all benefiting from beryllium copper heat treatment to enhance your operational efficiency.

Key Techniques in Beryllium Copper Heat Treatment

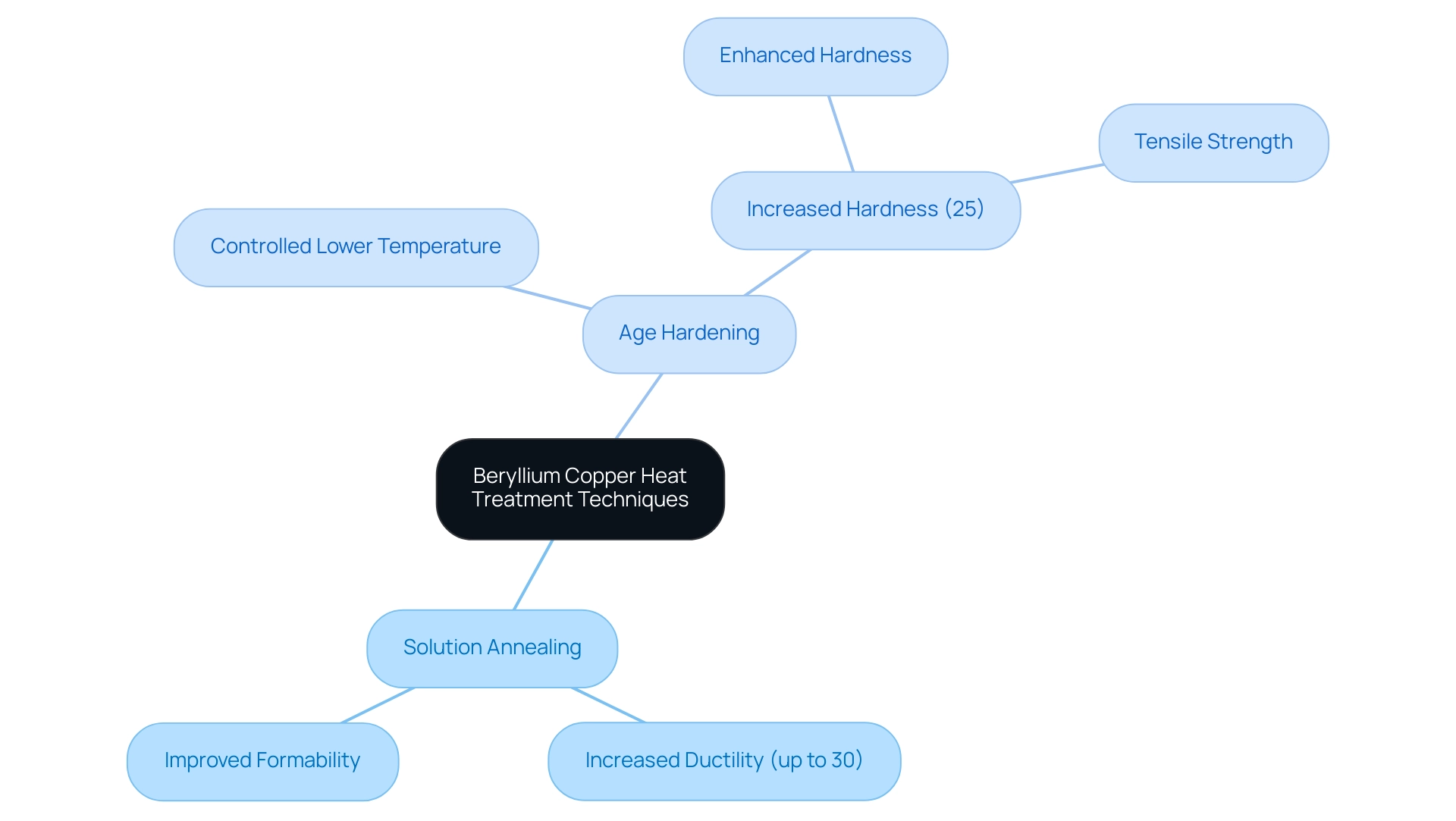

At Domadia, we are committed to supplying and manufacturing high-quality Beryllium Copper Plates, leveraging pivotal beryllium copper heat treatment techniques, such as solution annealing and age hardening, to significantly enhance the alloy’s performance for industrial applications. This step is crucial for subsequent processing, laying the groundwork for effective aging and ultimately superior mechanical properties. Recent studies indicate that effective solution annealing can increase ductility by up to 30%, improving formability for various uses, which is essential for procurement managers seeking optimal performance.

- Age Hardening: Building on the results of solution annealing, age hardening entails reheating the alloy to a controlled lower temperature, where specific precipitates form to enhance both hardness and tensile strength. These attributes are essential for systems requiring high performance and reliability under stress. The unique combination of strength, conductivity, and corrosion resistance of Beryllium Copper makes it an ideal choice for demanding environments. Grasping these fundamental techniques is crucial for procurement managers like you, who seek to choose the best-performing materials for particular uses. A pertinent case study on surface coatings optimization demonstrated that the application of age hardening techniques resulted in a 25% increase in hardness for Beryllium Copper components, highlighting the importance of precise control over the heat treatment process as part of Domadia’s innovative approach.

Safety Practices for Handling Beryllium Copper

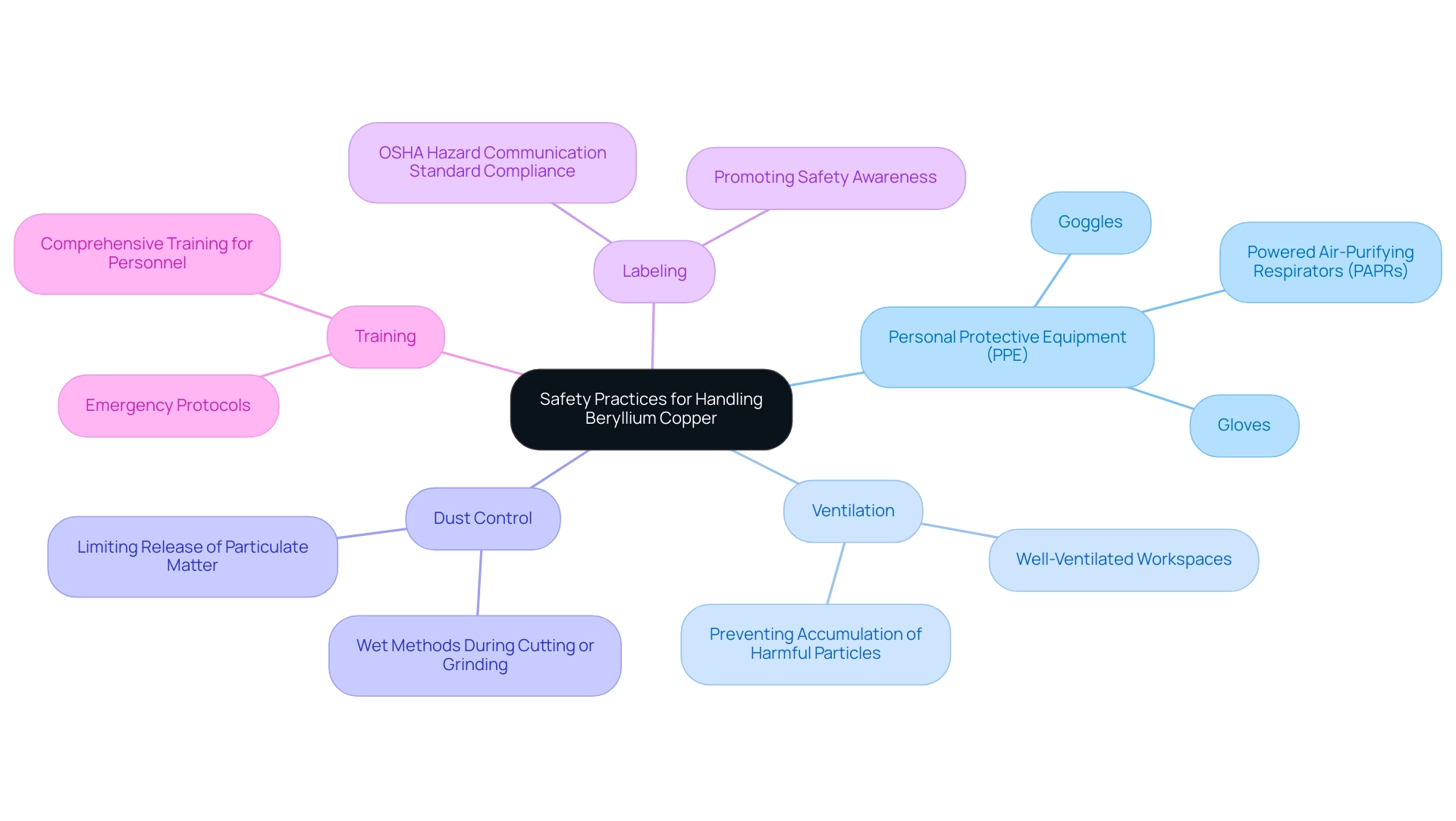

When working with a specific alloy and utilizing Non-Sparking Tools, adhering to stringent safety practices is crucial to ensuring a safe environment, particularly in explosive potential settings. Non-Sparking Tools are essential as they significantly reduce the risk of igniting flammable materials. The following measures are essential:

Personal Protective Equipment (PPE): Employers must provide appropriate PPE, including gloves, goggles, and when necessary, powered air-purifying respirators (PAPRs), as mandated when respiratory protection is required. This significantly reduces exposure risk. Skin irritation from the metal can indicate potential vulnerability to chronic beryllium disease (CBD), as noted by safety expert Frank: “If the metal irritates your skin, that can be a sign that you are susceptible to CBD.”

Ventilation: Maintain well-ventilated workspaces to mitigate inhalation hazards associated with dust and fumes. Adequate airflow is vital in preventing the accumulation of harmful airborne particles.

Dust Control: Employ effective dust control strategies, such as utilizing wet methods during cutting or grinding processes, to limit the release of harmful particulate matter into the air.

Labeling: Ensure that all containers of beryllium-contaminated materials are labeled according to OSHA’s Hazard Communication Standard to promote safety awareness and compliance.

Training: Ensure comprehensive training for all personnel involved in handling specific alloys and using Non-Sparking Tools. This training should cover the associated risks, proper handling procedures, and emergency protocols.

By implementing these safety measures, including the strategic use of Non-Sparking Tools, organizations can create a protective work environment and comply with current regulations concerning exposure to harmful substances, safeguarding the health of all employees.

Applications of Heat-Treated Beryllium Copper in Industry

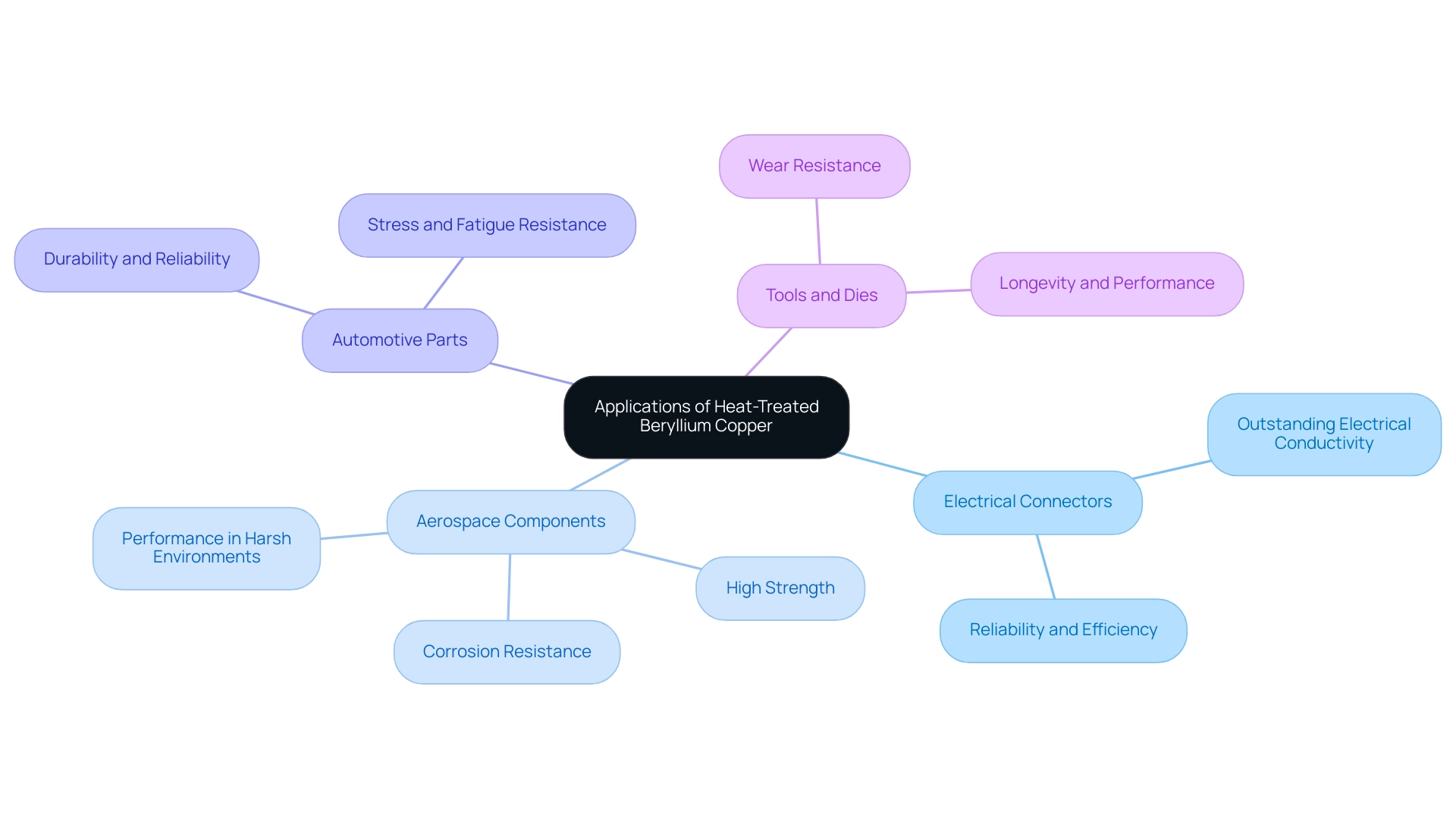

Heat-treated alloy is increasingly acknowledged for its exceptional characteristics, making it a vital material in various high-demand sectors. Its applications span various sectors, each benefiting from its unique characteristics:

Electrical Connectors: With outstanding electrical conductivity, heat-treated beryllium copper is an optimal choice for high-performance electrical connections, crucial in advanced electronic devices that require reliability and efficiency.

Aerospace Components: In the aerospace sector, this alloy is utilized in components that require both high strength and corrosion resistance. Its performance in harsh environments is critical for safety and durability, particularly in applications involving aircraft structures and systems.

Automotive Parts: The automotive sector utilizes heat-treated metal alloy in components that must endure considerable stress and fatigue. Its durability and reliability are essential in components such as connectors and sensors, where performance can directly influence vehicle safety and efficiency.

Tools and Dies: The wear resistance of heat-treated alloy makes it ideal for the manufacturing of precision tools and dies. This asset ensures longevity and performance under rigorous conditions, which is vital for maintaining production efficiency.

The beryllium copper heat treatment process significantly enhances the mechanical and physical properties of copper, making it a preferred material for demanding applications across these industries. Notably, the demand for beryllium-copper alloy strips and non-sparking wrenches is anticipated to rise due to the increasing use of advanced electronic devices, growth in the automotive industry, and expansion of the telecommunications market. As Aditya Joshi, a market research analyst, states, “Proficient in delivering research findings, I specialize in providing reports in various formats, whether customized or syndicated.”

This underscores the importance of informed procurement decisions.

Furthermore, regional insights reveal that North America dominates the market for this metal with a 35.8% share, driven by defense spending and established producers, while Asia Pacific is the fastest-growing market due to rising manufacturing and urbanization. China’s emphasis on electronics and energy industries is rising demand for the metal, bolstered by investments in refining capabilities. As demand continues to increase, especially because of progress in electronics, automotive expansion, and aerospace innovations, procurement managers should contemplate the strategic benefits of integrating beryllium copper heat treatment alloys into their supply chains.

Pricing and Inventory Details: Current pricing for beryllium metal strips typically ranges from $XX to $YY per pound, depending on the grade and quantity ordered. Inventory levels are stable, with major suppliers maintaining sufficient stock to meet demand fluctuations.

Safety Features of Non-Sparking Wrenches: Beryllium copper non-sparking wrenches are designed to minimize the risk of igniting flammable materials, making them essential in hazardous environments such as oil rigs and chemical plants. Their unique properties ensure that they can withstand high torque applications without producing sparks, thereby enhancing workplace safety.

Conclusion

Beryllium Copper C17200, or Alloy 25, stands out as a premier choice for industries seeking a combination of strength, conductivity, and reliability. The alloy’s impressive mechanical properties, including high tensile strength and Rockwell hardness, make it suitable for a wide array of applications, from aerospace components to precision tools. The heat treatment processes, particularly solution annealing and age hardening, are critical in maximizing the performance of this material, allowing it to meet the rigorous demands of various industrial environments.

Safety remains a paramount concern when handling Beryllium Copper. Implementing strict safety practices, including the use of personal protective equipment and effective ventilation, is essential to mitigate health risks associated with beryllium exposure. By adhering to these guidelines, organizations can foster a safe working environment while capitalizing on the unique advantages of this alloy.

As demand for heat-treated Beryllium Copper continues to grow across multiple sectors, procurement managers must remain informed about its properties, applications, and safety protocols. Understanding the strategic benefits of incorporating this high-performance material into supply chains will not only enhance operational efficiency but also ensure compliance with safety standards. Ultimately, leveraging the exceptional qualities of Beryllium Copper C17200 positions organizations to excel in their respective industries.