Blogs

How to Use the Beryllium Copper Hardness Chart for Your Projects

Introduction

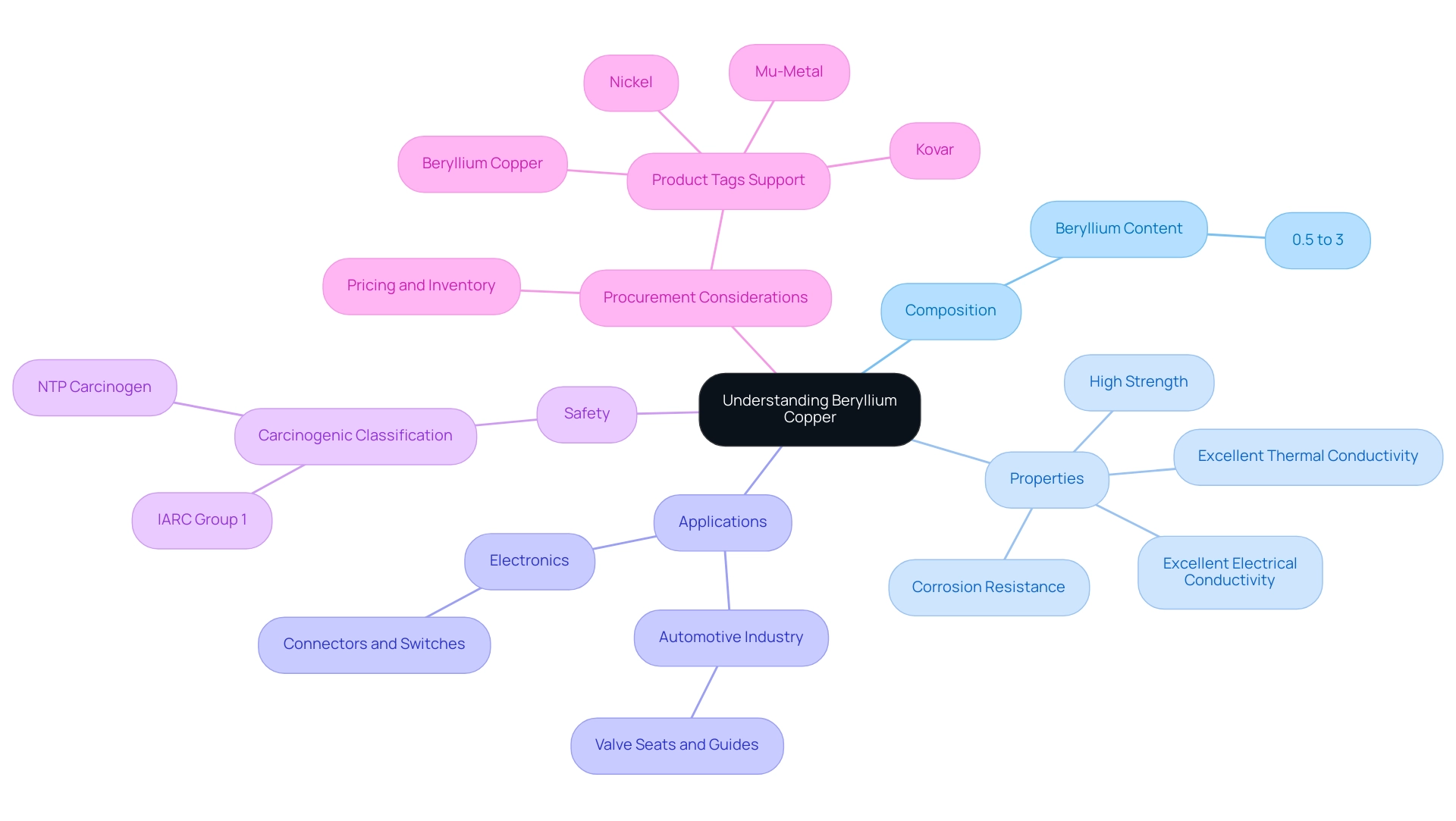

In the realm of advanced materials, beryllium copper emerges as a standout alloy, revered for its unique blend of strength, conductivity, and corrosion resistance. With a beryllium content ranging from 0.5% to 3%, this versatile material is indispensable across various industries, particularly in automotive and electronics applications.

However, procurement managers must navigate not only its impressive properties but also critical safety considerations, given the carcinogenic nature of beryllium.

This article delves into the intricacies of beryllium copper, from understanding its composition and hardness characteristics to exploring its diverse applications and best practices for hardness testing. By equipping procurement professionals with the knowledge needed to make informed decisions, this comprehensive guide aims to enhance project outcomes and ensure the safe and effective use of this remarkable alloy.

Understanding Beryllium Copper: Composition and Properties

Copper alloyed with a content ranging from 0.5% to 3% of beryllium is renowned for its exceptional properties. This alloy stands out due to its high strength, excellent thermal and electrical conductivity, and notable corrosion resistance, making it an ideal choice for high-performance applications across various industries, particularly automotive and electronics. Importantly, DOMADIA Beryllium Copper complies with international standards such as UNS and ASTM, ensuring quality and reliability for procurement managers.

It is crucial to note that this element is classified as a Group 1 human carcinogen by the International Agency for Research on Cancer (IARC), and the National Toxicology Program (NTP) also lists this substance as a carcinogen, highlighting essential safety considerations. In the automotive industry, alloys valve seats and guides are incorporated into high-performance four-stroke engines, providing superior heat dissipation compared to conventional steel or iron parts. In electronics, its conductivity and strength make it a preferred material for connectors and switches.

Understanding these characteristics is essential for procurement managers, as they directly correlate with the hardness levels reflected in the beryllium copper hardness chart. The adaptability of this alloy is further emphasized by its extensive product assortment, including non-sparking wrenches, which are crucial for uses necessitating safety in explosive settings. Additionally, procurement managers can inquire about pricing and inventory details to make informed purchasing decisions.

Support for customer inquiries regarding product tags for Beryllium Copper, Kovar, Mu-Metal, and Nickel materials is also available, ensuring a complete understanding of the product offerings.

How to Interpret the Beryllium Copper Hardness Chart for Your Projects

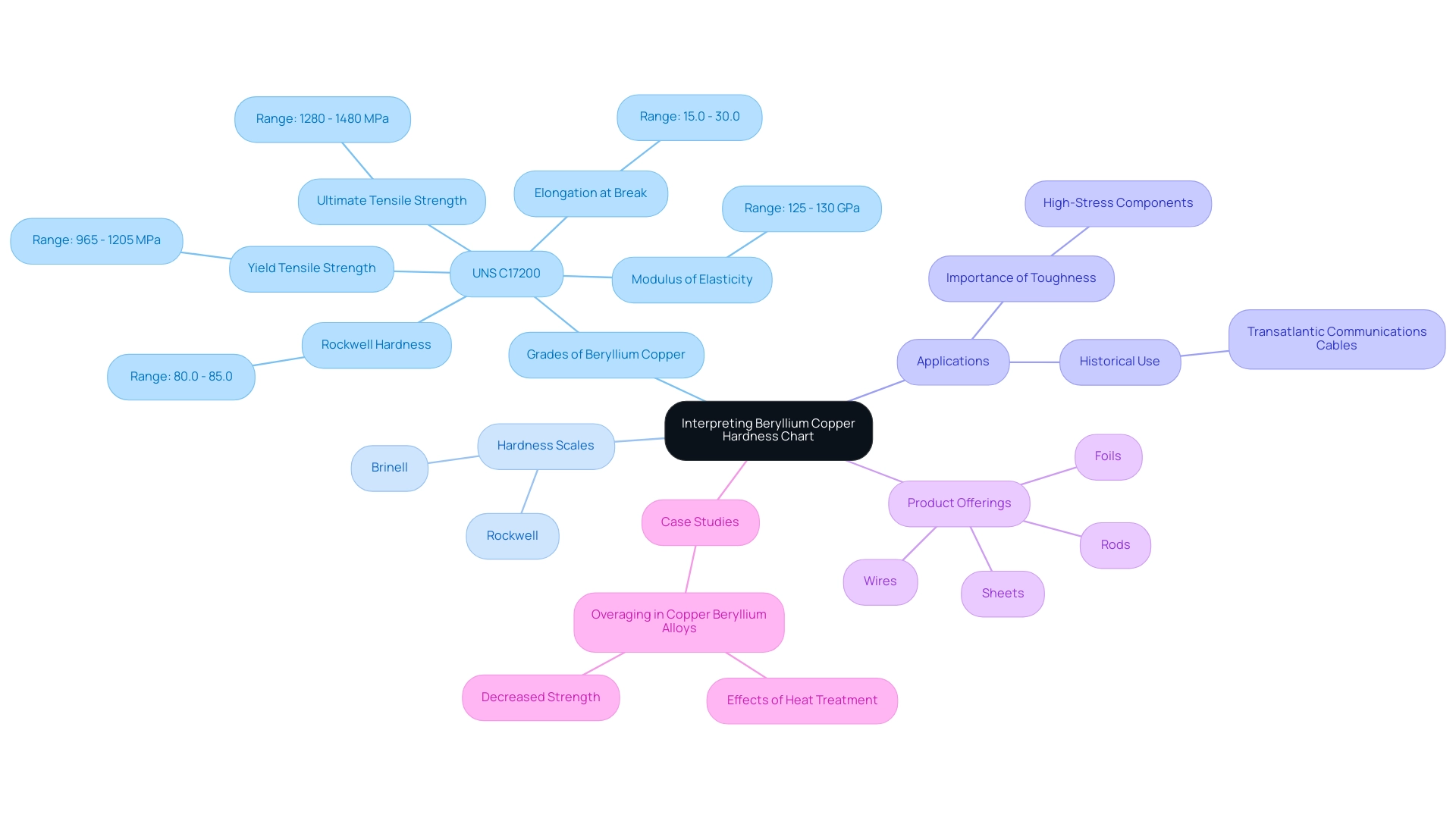

Understanding the alloy durability chart is essential for choosing the appropriate material for your projects. Start by identifying the particular grade of beryllium alloy you plan to utilize, as each grade displays unique toughness levels. The chart typically presents toughness values measured on the Rockwell or Brinell scales, which are essential for assessing material suitability.

For example, the hardness values for UNS C17200 metal range significantly, with a Rockwell hardness between 80.0 and 85.0, indicative of its robust mechanical properties. Copper alloy has historically been utilized for connectors in transatlantic underground communications cables between Europe and the US, showcasing its importance in critical applications. At Domadia, your trusted partner for Beryllium Copper solutions, we offer an extensive range of Beryllium Copper products, including:

- Foils

- Sheets

- Rods

- Wires

All available from ready stock to meet diverse needs.

When assessing your application requirements, especially for high-stress components, it is wise to choose a grade that displays elevated toughness values. Moreover, our custom fabrication options ensure tailored solutions, enhancing project outcomes. Additionally, it is imperative to cross-reference these toughness values with the necessary mechanical properties to ensure optimal performance in your application.

Understanding these parameters will not only guide your material selection but also support the success of your project outcomes. As noted by Z.W., ‘Writing—review and editing’ plays a crucial role in ensuring the accuracy of such technical discussions. Additionally, the case study named ‘Overaging in Copper Alloys’ demonstrates the effects of extended heat treatment on mechanical characteristics, elucidating its significance to strength values and the necessity of regulating aging processes.

Our Copper Non-Sparking Wrench exemplifies the safety features crucial for high-stakes environments, ensuring that you can trust our products in demanding applications.

Key Properties Influencing Hardness in Beryllium Copper

The toughness of C17200 Copper, especially the C17200 grade, is greatly affected by various key aspects, including the alloy’s content of the element, specific heat treatment methods, and the presence of other alloying components. Research indicates that higher concentrations of beryllium within the alloy correlate with increased hardness, as shown in the beryllium copper hardness chart, making it a critical factor in material selection for demanding applications. At Domadia, our dedication to offering high-quality Copper solutions is evident through our innovative manufacturing practices and rigorous quality control measures.

Our copper plates, known for their exceptional strength and conductivity, are ideal for various industrial applications, including aerospace and precision tools. Various heat treatment methods, such as aging, play a pivotal role in enhancing hardness by modifying the alloy’s microstructure, which is essential for applications requiring exceptional durability, such as electrical connectors and precision tools. As noted by materials scientists, the interplay between these factors is vital for procurement managers to consider when using the beryllium copper hardness chart to assess the appropriate grade of Beryllium Copper for specific operational demands.

For instance, the melting temperatures of beryllides such as:

1. ZnBe (2200 K)

2. TaBe (2250 K)

3. Mobe (1970 K)

provide a technical reference point for understanding the thermal properties of these materials. Additionally, the health implications of beryllium exposure are highlighted by Cezary Palczynski, who states that the beryllium blood lymphocyte proliferation test (BLPT) is essential for assessing individuals at risk for chronic beryllium disease. Recent studies have also shown that heat treatment not only affects the hardness indicated in the beryllium copper hardness chart but can also influence the electrochemical and tribological properties of the alloy.

Additionally, a case study on the hot deformation behavior of Zr–1.0 Be alloy demonstrates how heat treatment processes can affect material performance, thus highlighting the complexity of Copper behavior under varying conditions. For procurement managers, understanding the pricing and inventory details of Copper Strips, currently priced at $1,050.00 per unit, is also crucial for making informed purchasing decisions.

Applications of Beryllium Copper and the Relevance of Hardness

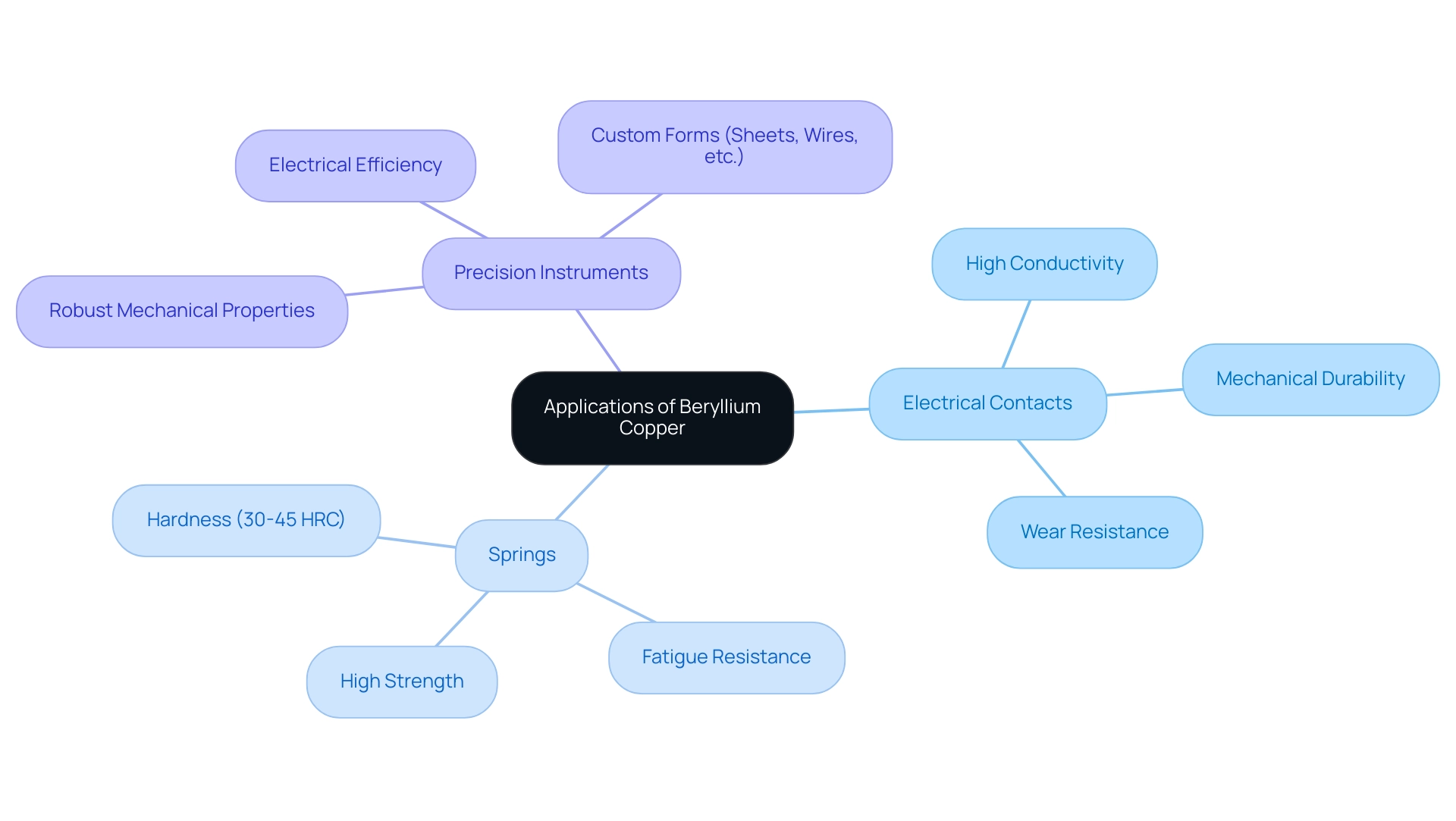

Beryllium alloy is renowned for its exceptional strength and electrical conductivity, making it a preferred choice in various high-performance applications, including:

- Electrical contacts

- Springs

- Precision instruments

With a conductivity rating that can reach up to 96% IACS, this alloy stands out for its ability to combine electrical efficiency with robust mechanical properties. Unlike standard alloys, this metal exhibits superior rigidity and strength, which are critical in demanding applications.

In the automotive sector, beryllium copper is commonly employed in connectors and switches, where both high conductivity and mechanical durability are essential. The material’s durability plays a vital role in determining its wear resistance and capability to endure mechanical stress. Specifying the appropriate hardness grade—typically within the range of 30 to 45 HRC—according to the beryllium copper hardness chart is essential for optimizing performance and longevity in automotive applications.

Furthermore, at Domadia, we are dedicated to providing high-quality Copper Plates that are tailored to your specifications, supported by our expert assistance. Our offerings are not only tailored to meet your unique project needs but also include critical applications like non-sparking tools, which are vital in explosive environments. Selecting the correct type of beryllium copper not only enhances operational efficiency but also extends the lifecycle of components, ensuring reliability in demanding environments.

As one satisfied customer stated, ‘Domadia’s Copper Plates surpassed our expectations in both quality and service.’ Additionally, we provide competitive pricing on our Copper Strips, ensuring you receive the best value for your investment. Experience the difference quality and expertise can make in your next project with our Beryllium Copper solutions.

Testing Hardness: Methods and Best Practices for Beryllium Copper

Precise hardness evaluation of alloys is vital for guaranteeing material performance in diverse applications, including important uses such as mirrors in meteorological satellites, where low weight and long-term dimensional stability are essential. Domadia, your reliable partner for metal solutions, offers a wide variety of products, such as foils, sheets, rods, and wires, customized to fulfill your specific needs. Additionally, we offer non-sparking wrenches, designed with safety in mind for use in explosive environments, ensuring that you have the right tools for your projects.

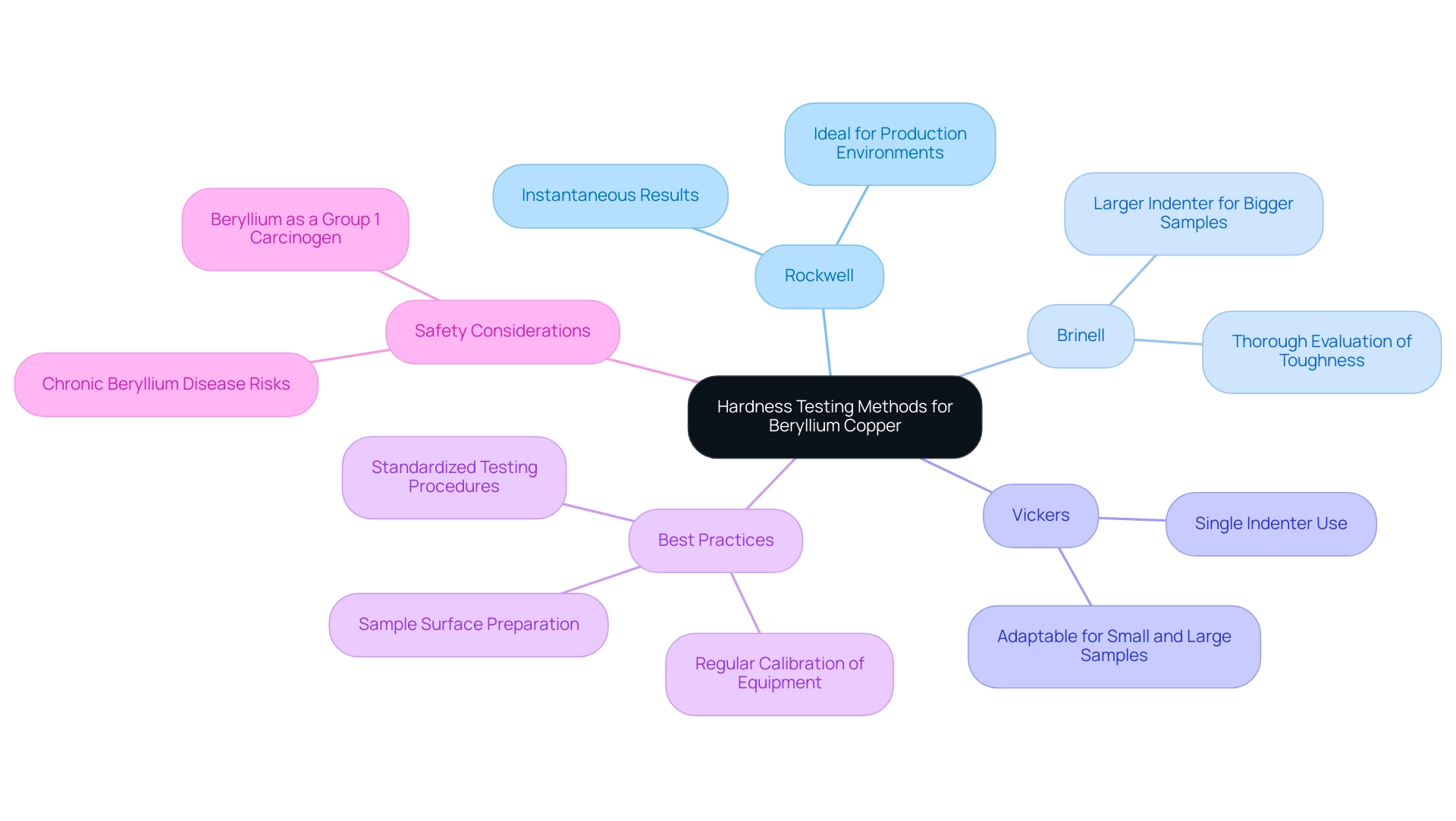

Our ready stock and custom fabrication options further demonstrate our commitment to providing high-quality beryllium copper wire and exceptional customer service for project success. The most commonly employed methods for material testing include:

- Rockwell

- Brinell

- Vickers

Each offering distinct advantages tailored to specific needs. The Rockwell test is favored for its experience, delivering instantaneous results beneficial in fast-paced production environments.

Conversely, the Brinell test, which employs a larger indenter, excels in examining larger samples and offers a thorough evaluation of material toughness across a broader area. The Vickers test, recognized for its adaptability, permits evaluation on both small and large samples with a single indenter.

To attain accurate and dependable measurement results, adherence to best practices is essential. This includes ensuring that the sample surface is meticulously prepared—clean and flat—to facilitate accurate testing. Regular calibration of testing equipment is also critical, as it guarantees consistency and reliability in the results.

Standardized testing procedures should be followed rigorously to maintain uniformity across measurements. According to industry experts, best practices in measurement of durability are instrumental in aligning results with project specifications. Furthermore, it is essential to consider the safety implications of beryllium; as noted by Joseph, while the generation of reactive oxygen species (ROS) and the associated oxidative stress are not involved in beryllium-induced cell transformation and tumorigenesis, understanding these aspects is crucial for safe handling.

Moreover, fracture surfaces of aged alloys exhibit shallower toughness nests and larger deconvolution surfaces, correlating with decreased elongation, emphasizing the significance of material properties in relation to testing. By implementing these strategies, procurement managers can ensure that they obtain trustworthy hardness data from the beryllium copper hardness chart, which is critical for informed decision-making and effective material selection in their projects. Partner with Domadia to leverage our expertise and comprehensive product offerings for your beryllium copper needs.

Conclusion

Beryllium copper stands out as a premier alloy, combining exceptional strength, conductivity, and corrosion resistance, making it invaluable in industries such as automotive and electronics. Understanding its composition and the implications of its hardness is crucial for procurement managers tasked with selecting the right materials for high-performance applications. The unique properties of beryllium copper, influenced by its beryllium content and heat treatment processes, underscore the importance of meticulous material selection based on specific project requirements.

The article has elucidated the significance of interpreting hardness charts and selecting appropriate grades of beryllium copper to ensure optimal performance in demanding environments. With hardness values that play a pivotal role in wear resistance and mechanical durability, the right choice can enhance operational efficiency and extend the lifecycle of components. Moreover, it is essential for procurement managers to stay informed about the safety considerations associated with beryllium, as its carcinogenic nature necessitates careful handling and compliance with health regulations.

In conclusion, the insights provided serve not merely as a guide but as a strategic resource for procurement professionals. By equipping themselves with knowledge about beryllium copper’s properties, applications, and testing methodologies, managers can make informed decisions that lead to successful project outcomes. Engaging with trusted suppliers like Domadia ensures access to high-quality beryllium copper products and expert support, ultimately fostering reliability and excellence in material procurement.