Blogs

Understanding Beryllium Copper Young’s Modulus: An In-Depth Tutorial

Introduction

In the realm of advanced materials, Beryllium Copper stands out for its exceptional mechanical properties, particularly its Young’s modulus, which plays a pivotal role in determining the material’s stiffness and load-bearing capabilities. With a modulus of approximately 120 GPa, this alloy is engineered for high-performance applications, making it indispensable in industries such as aerospace, automotive, and electronics.

As procurement managers navigate the complexities of material selection, understanding the intricacies of Young’s modulus becomes essential for ensuring the safety and reliability of components used in critical applications.

This article delves into the significance of Young’s modulus in Beryllium Copper, exploring its mechanical properties, calculation methods, and diverse applications, while also addressing the challenges faced in sourcing and processing this remarkable material.

Introduction to Young’s Modulus in Beryllium Copper

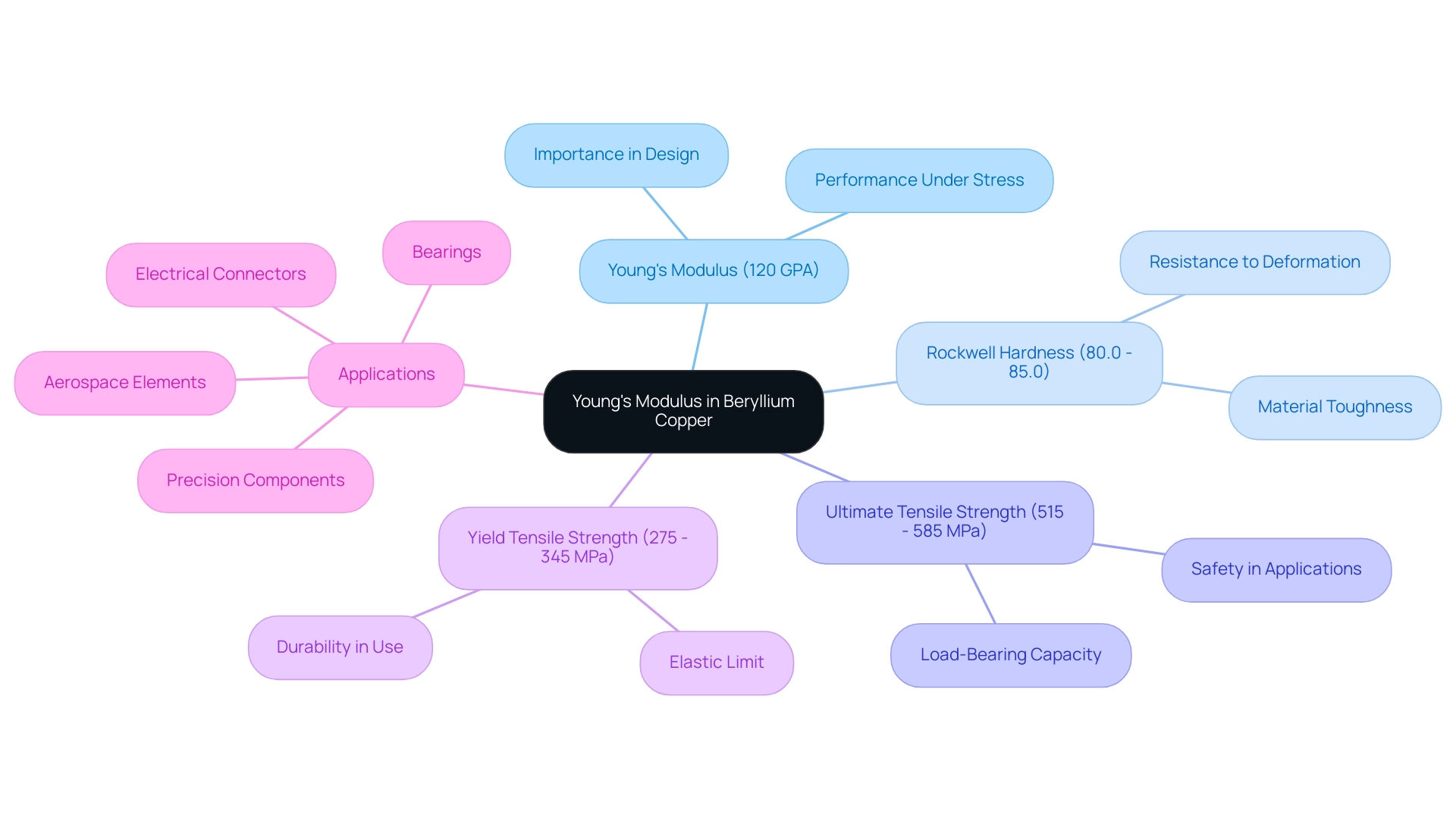

Young’s elasticity, or elastic parameter, is a critical factor in assessing the stiffness of materials, particularly for beryllium copper Young’s modulus, which demonstrates exceptional load-bearing capacity essential for aerospace and precision applications. With a beryllium copper Young’s modulus of approximately 120 GPA (gigapascals), beryllium copper showcases remarkable strength and rigidity, making it ideal for high-performance environments. The mechanical properties of UNS C172 copper alloys further highlight its utility, featuring:

- Rockwell hardness of 80.0 – 85.0

- Ultimate tensile strength ranging from 515 – 585 MPa

- Yield tensile strength between 275 – 345 MPa

Grasping beryllium copper Young’s modulus is crucial for engineers, as it allows them to anticipate the performance of beryllium copper parts under operational stresses, thus ensuring safety and dependability in uses like:

- Bearings

- Precision screw machined components

- Electrical connectors

- Various aerospace elements

As noted by Prof. Bo Chen, ‘Learn how additive manufacturing is revolutionizing structural integrity in safety-critical industries.’ This insight emphasizes the strategic significance of beryllium copper Young’s modulus not only in design but also in preserving the integrity of industrial applications.

Furthermore, DOMADIA’s commitment to delivering high-quality Beryllium Copper solutions is reflected in our innovative manufacturing processes and tailored solutions that comply with international standards, ensuring customer satisfaction and meeting the diverse needs of our clients.

Mechanical Properties of Beryllium Copper: A Closer Look

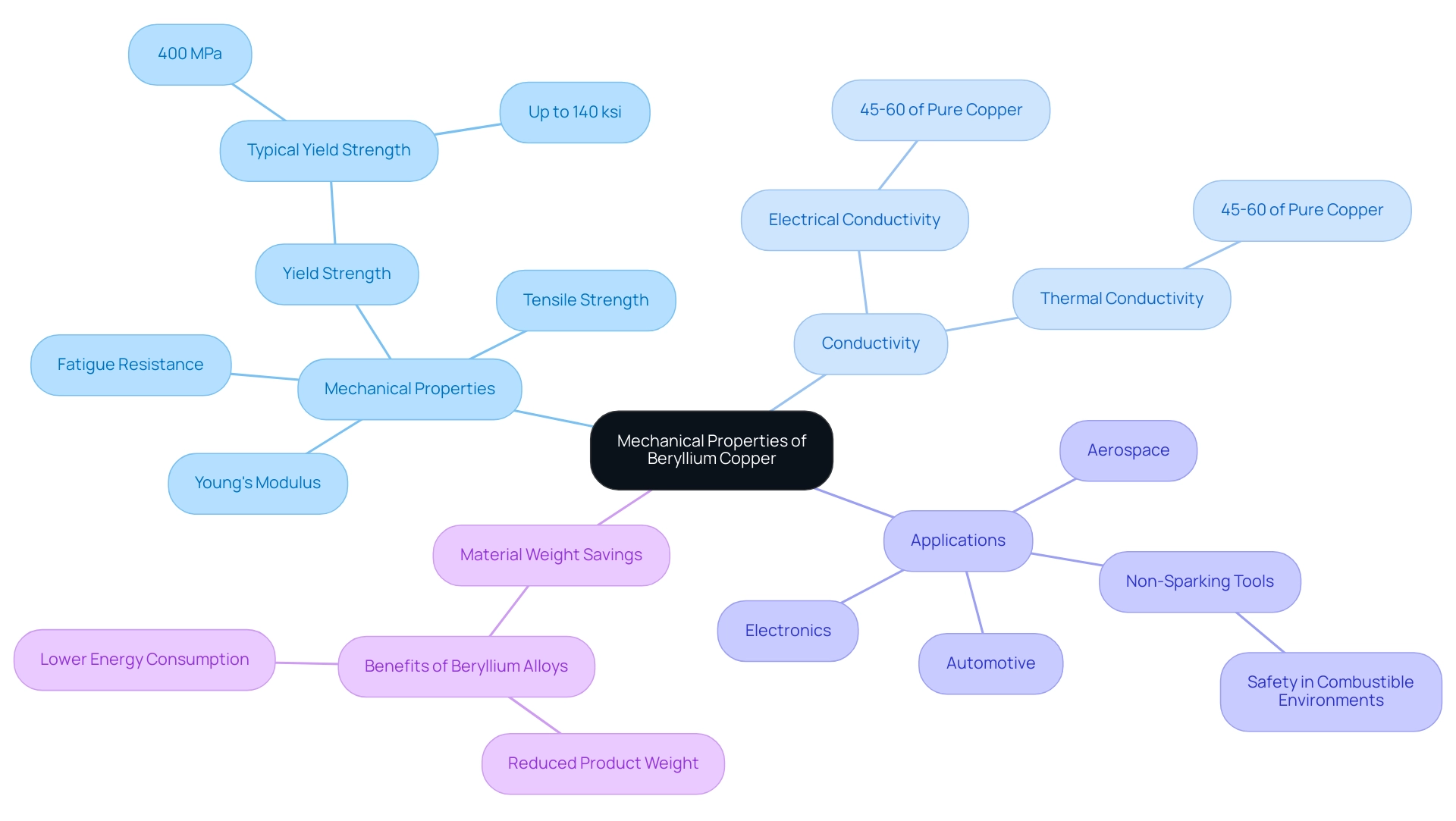

Beryllium alloy is distinguished by its superior mechanical properties, which encompass not only beryllium copper Young’s modulus but also other critical metrics such as yield strength, tensile strength, and fatigue resistance. Significantly, this element is four times more rigid than composites, highlighting its exceptional strength-to-weight ratio. Typically, certain alloys made from a combination of beryllium and other metals demonstrate a yield strength of around 400 MPa, with specific alloys providing yield strengths up to 140 ksi.

Additionally, these alloys exhibit electrical and thermal conductivity ranging from 45 to 60 percent of pure metal, enhancing their utility in various applications. These strong mechanical properties make this alloy especially beneficial in high-performance industries, such as aerospace, automotive, and electronics, where the requirements for both strength and durability are essential. The non-sparking characteristics of alloy wrenches further highlight safety in settings where combustible substances are present, making them suitable for application in sectors such as oil and gas, mining, and chemical processing.

As demonstrated in a case study on material weight savings, the use of beryllium-containing alloys allows for significant reductions in material weight compared to other common connector materials, benefiting overall product weight and energy consumption. Domadia is dedicated to providing high-quality, customized Beryllium Copper Plates, ensuring that project specifications are met with expert support. As articulated by Prof. Bo Chen, ‘Learn how additive manufacturing is revolutionizing structural integrity in safety-critical industries.’

This statement emphasizes ongoing progress that improves the efficiency of elements crafted from a specific alloy. Engineers must comprehend these mechanical properties, particularly beryllium copper Young’s modulus, to design components capable of enduring significant stresses. Recent developments within the field continue to push the boundaries of beryllium copper’s uses, confirming its role as a material of choice for addressing modern engineering challenges with beryllium copper Young’s modulus.

For additional details on the benefits and uses of non-sparking tools, please learn more about our non-sparking offerings.

Calculating Young’s Modulus: Methods and Techniques

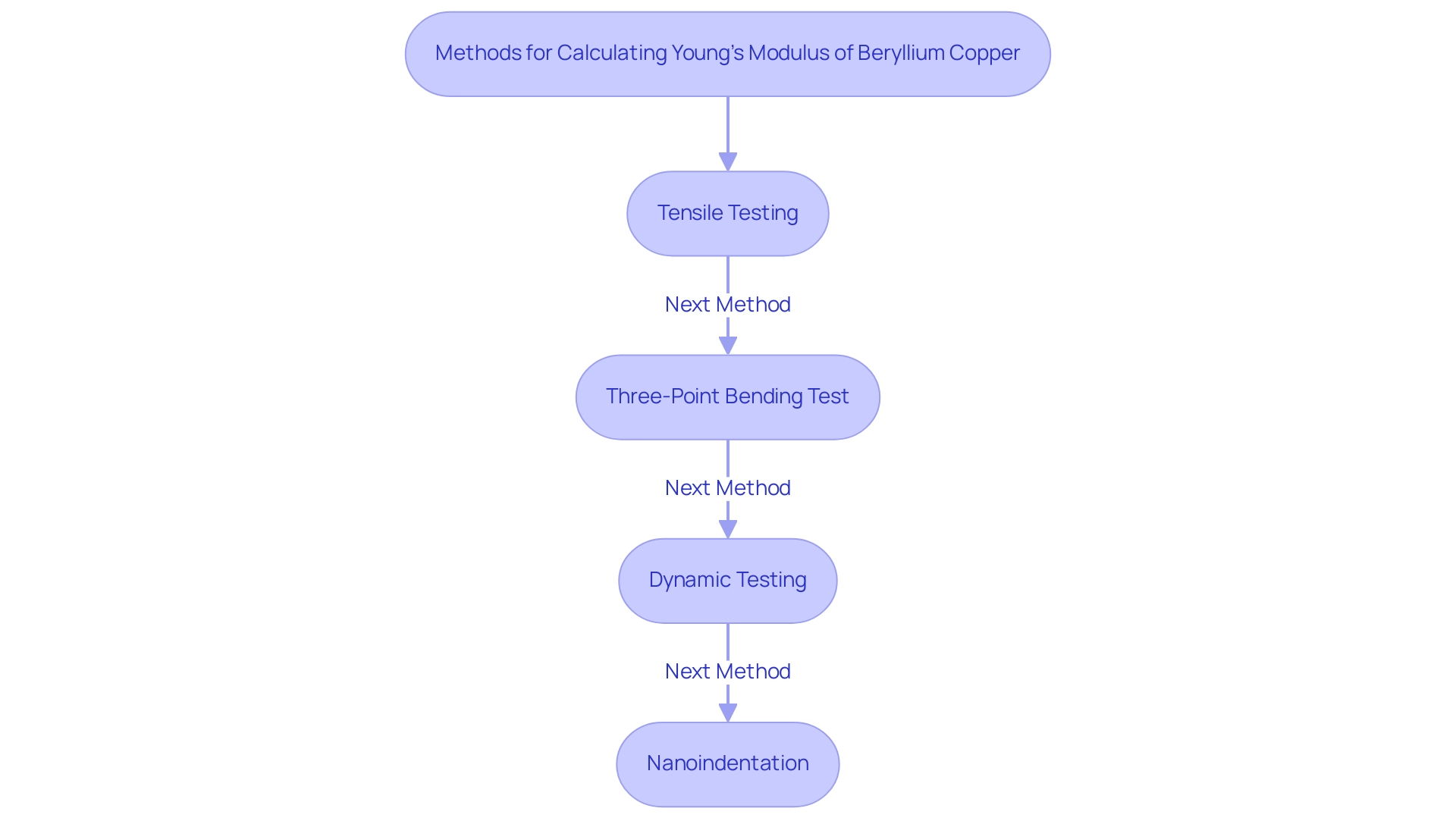

The calculation of beryllium copper Young’s modulus, measured at 4.098 GPA, can be approached through various methods, each offering unique insights into the elastic properties of beryllium copper, which is critical for procurement managers when considering product applications. One common method is tensile testing, where a sample is subjected to uniaxial stress until failure, allowing for the determination of Young’s stiffness via the stress-strain curve’s elastic region. Another effective method is the three-point bending test, where a known force is applied to a beam of Beryllium Copper, measuring its deflection to determine the beryllium copper Young’s modulus.

For dynamic testing, resonance frequency techniques utilize the material’s vibrational characteristics to ascertain beryllium copper Young’s modulus, thereby highlighting the relationship between the material’s behavior and its suitability for use. As highlighted by Thierno Ly, complexities can arise when transitioning from theoretical calculations to practical uses, underscoring the importance of partnering with a supplier like Domadia, who provides extensive Beryllium Copper solutions, including:

- Ready stock

- Custom fabrication options such as:

- Foils

- Sheets

- Rods

- Wires

Furthermore, the Beryllium Copper Non-Sparking Wrench represents a product that emphasizes safety features in scenarios where spark generation is a concern.

Advanced techniques like nanoindentation offer high-resolution measurements of beryllium copper Young’s modulus at the nanoscale. While these insights are invaluable, they may not accurately reflect bulk behavior, emphasizing the need to understand material properties across different scales. This knowledge is essential for procurement managers aiming to choose the most suitable options for Beryllium Copper, ensuring safety and performance in each use case.

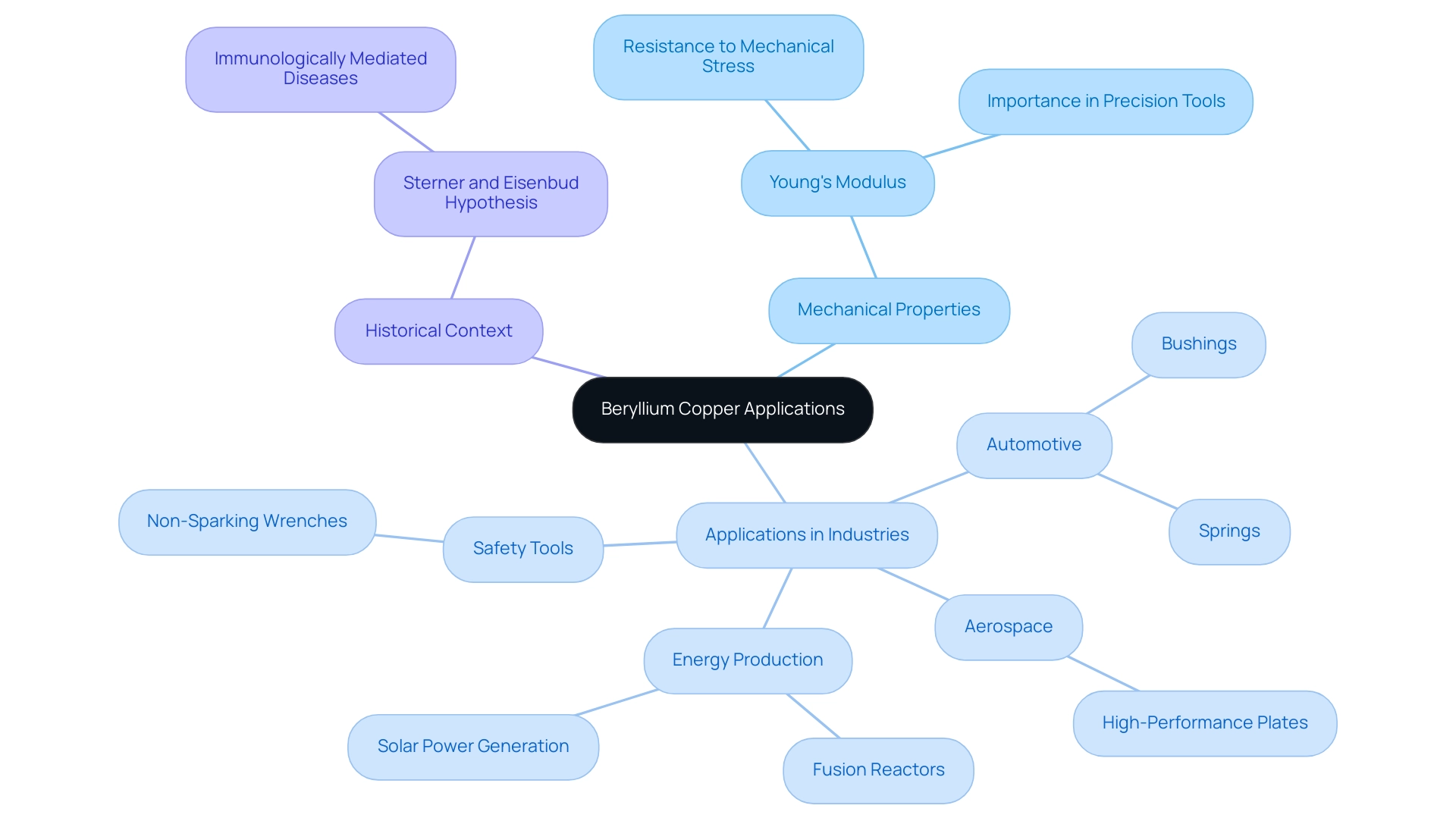

Applications of Beryllium Copper and the Importance of Young’s Modulus

Beryllium alloy, particularly the C17200 variety, is a crucial material in various applications, especially in the creation of precision tools, electrical contacts, and components that require outstanding thermal and electrical conductivity, along with corrosion resistance. Its remarkable beryllium copper Young’s modulus is crucial in these contexts, as it determines the alloy’s resistance to mechanical stress without permanent deformation. For example, within the automotive sector, a specific alloy is frequently utilized in springs and bushings, where maintaining shape and functionality under fluctuating loads is essential.

Domadia proudly leads in supplying and manufacturing high-performance Beryllium Alloy Plates, ensuring that engineers have access to the strongest metal blend with exceptional load-bearing capacity for aerospace and other precision uses. Our commitment to quality and customer satisfaction drives us to provide tailored solutions that meet the specific needs of our clients. A thorough grasp of beryllium copper Young’s modulus enables engineers to select the suitable type of alloy that meets the exact mechanical specifications of their projects.

Notably, this element is also employed in fusion reactors and has qualified for use in the International Thermonuclear Experimental Reactor (ITER) project, showcasing its broader significance in advanced applications. Additionally, the importance of Non-Sparking Tools, especially Beryllium Copper Non-Sparking Wrenches, in explosive environments cannot be overstated, as they combine safety features with high performance, reducing the risk of ignition in hazardous settings. Furthermore, Sterner and Eisenbud (1951) hypothesized that beryllium-related diseases were immunologically mediated, providing important historical context regarding safety and material handling.

Recent advancements have showcased its use in automotive components and energy production, particularly in sustainable energy solutions, where beryllium-containing alloys are fundamental. This reinforces the alloy’s reputation as a cornerstone in engineering solutions.

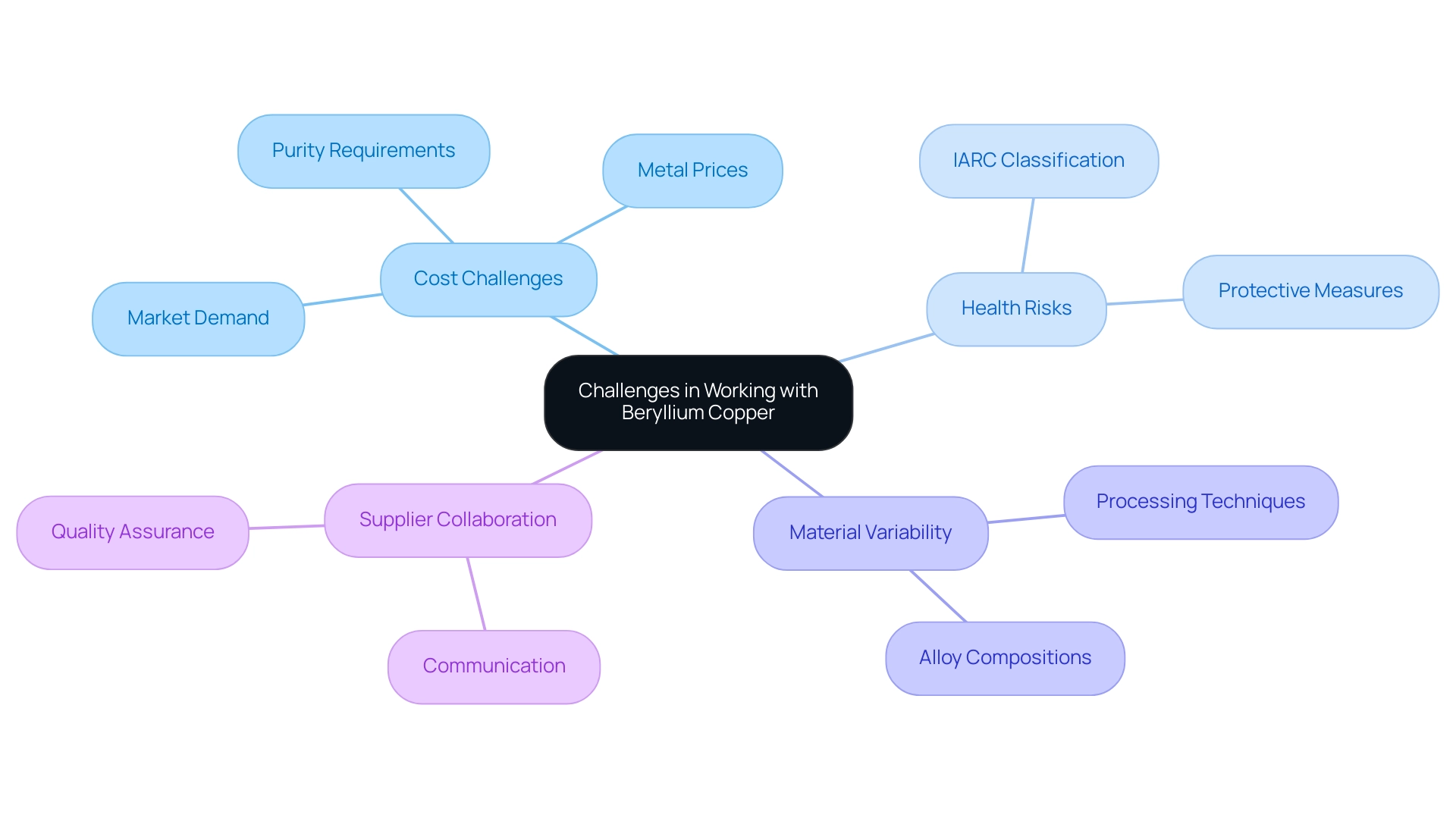

Challenges in Working with Beryllium Copper: Insights on Young’s Modulus

While the beneficial characteristics of the alloy are well-documented, especially its capacity to surpass the strength of nearly any copper-based alloy, procurement managers must navigate several challenges related to its handling and processing. A significant issue is the increased expense of beryllium-containing alloys in comparison to other metal blends, affected by elements like market demand, purity, and prevailing metal prices. Domadia is dedicated to providing fair and transparent pricing for all copper scrap transactions, ensuring competitive rates by staying informed about market trends and nurturing strong supplier relationships.

Furthermore, the inclusion of this metal in the alloy introduces substantial health risks, as the International Agency for Research on Cancer (IARC) has classified it as a human carcinogen. Domadia addresses these concerns by implementing stringent safety measures and providing products that comply with health regulations. A relevant case study highlights that approximately 25 years ago, specialized machining of beryllium components was conducted in a clean room environment to manage exposure risks, emphasizing the need for protective measures.

Additionally, the variability in beryllium copper young’s modulus due to differing alloy compositions and processing techniques can complicate material selection. It is crucial for procurement managers to maintain close collaboration with suppliers to ensure that the specified materials consistently meet required mechanical properties, including the beryllium copper Young’s modulus. Domadia’s extensive inventory—from alloy plates, rods, sheets, and wires to foil and specialized tools—supports procurement managers in sourcing the right solutions for diverse applications in aerospace, automotive, electrical, oil and gas, and defense sectors.

By understanding these challenges and engaging in discussions at international and regional forums for CNC enthusiasts, procurement professionals can enhance their planning and decision-making processes when sourcing materials, including the beryllium copper Young’s modulus.

Conclusion

The exploration of Young’s modulus in Beryllium Copper reveals its crucial role in determining the mechanical performance of this exceptional alloy. With a modulus of approximately 120 GPa, Beryllium Copper demonstrates remarkable stiffness and load-bearing capabilities, making it indispensable in high-performance sectors such as aerospace, automotive, and electronics. The detailed examination of its mechanical properties, including yield strength and fatigue resistance, underscores the material’s versatility and suitability for applications that demand both strength and reliability.

In addition to its impressive mechanical characteristics, the various methods for calculating Young’s modulus provide procurement managers with essential insights for material selection. Understanding the nuances of tensile testing, bending tests, and advanced techniques like nanoindentation empowers professionals to make informed decisions that align with their specific operational requirements. However, the challenges associated with sourcing and processing Beryllium Copper, including cost considerations and health risks, necessitate a strategic partnership with knowledgeable suppliers to ensure compliance with safety standards and consistent quality.

Ultimately, recognizing the significance of Young’s modulus in Beryllium Copper not only enhances component design and application but also contributes to the overall safety and performance of critical systems. As industries continue to evolve, the demand for high-quality Beryllium Copper solutions will remain paramount, reinforcing its status as a cornerstone in modern engineering applications. Engaging with expert suppliers who offer tailored solutions will be essential for procurement managers aiming to leverage the full potential of this remarkable material in their projects.