Blogs

Understanding Beryllium Copper’s Electrical Conductivity: A Complete Tutorial for Telecommunication Applications

Introduction

In the realm of advanced materials, beryllium copper emerges as a key player, particularly in the fields of telecommunications and aerospace. Renowned for its exceptional electrical conductivity, remarkable strength, and resistance to corrosion, this alloy is increasingly becoming indispensable for a variety of critical applications.

From fiber optic connectors that facilitate seamless communication to non-sparking tools designed for hazardous environments, the versatility of beryllium copper cannot be overstated. As industries evolve and demand for high-performance materials surges, understanding the properties, manufacturing processes, and procurement strategies associated with beryllium copper is essential for procurement managers seeking to enhance operational efficiency and ensure product reliability.

This article delves into the multifaceted advantages of beryllium copper, highlighting its applications, compliance standards, cost considerations, and future trends, offering valuable insights for informed sourcing decisions in an ever-changing market landscape.

Key Properties of Beryllium Copper: Electrical Conductivity and Beyond

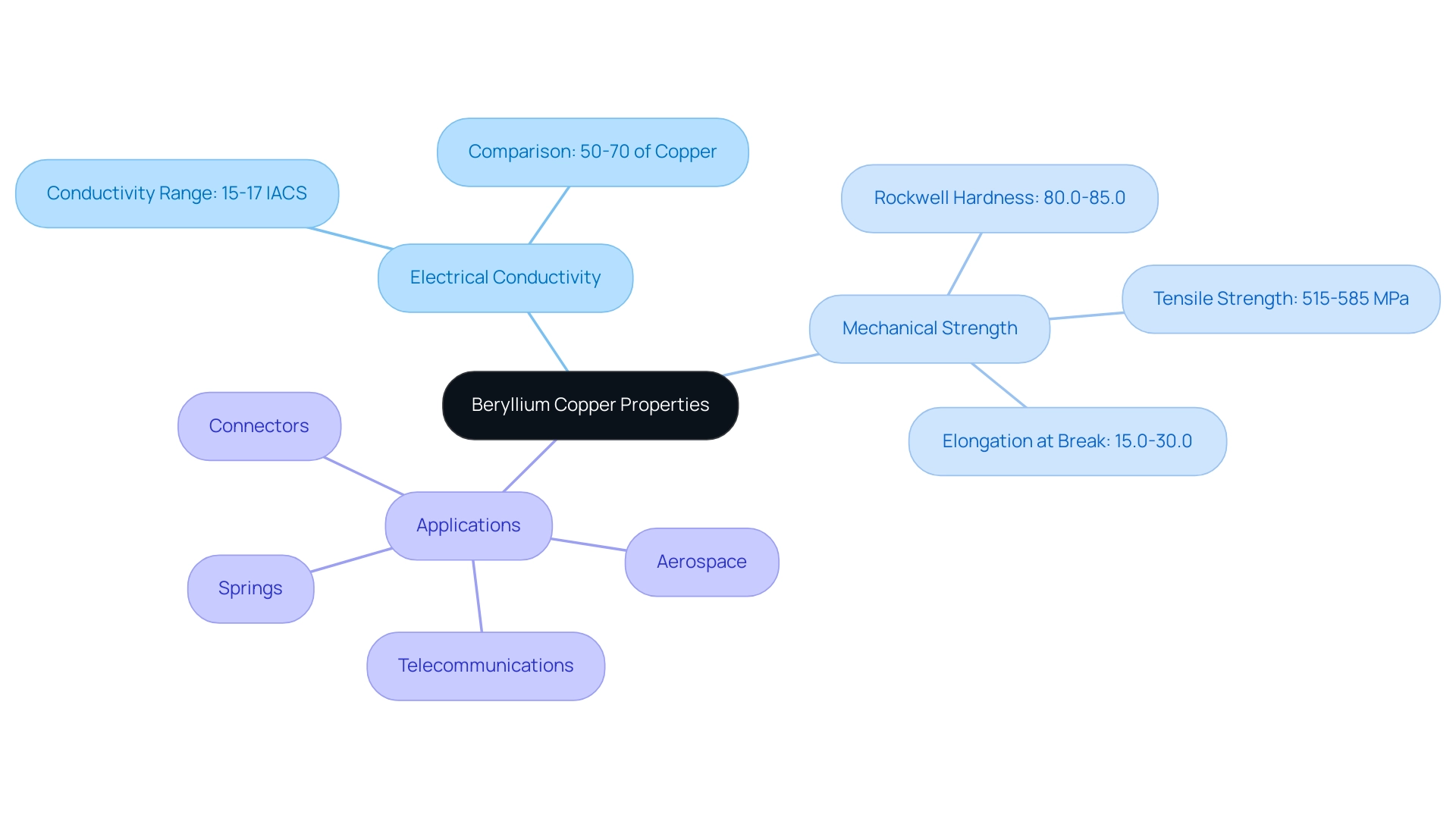

Beryllium alloy is distinguished by its exceptional electrical conductivity, typically ranging from 15-17% IACS, positioning it at approximately 50-70% of the conductivity of this metal. This unique characteristic, combined with its remarkable strength and corrosion resistance, makes it particularly advantageous for a variety of electrical applications, including connectors, switches, and relay contacts. At Domadia, we take pride in supplying and manufacturing Beryllium Copper Plates that exemplify the highest standards of quality and performance in accordance with international standards such as UNS and ASTM.

The nominal makeup of alloys containing beryllium and metal, which includes specific percentages of cobalt, nickel, and other elements, contributes to its superior characteristics. Beyond its conductivity, this alloy showcases beryllium copper’s electrical conductivity for telecommunication cables, along with remarkable fatigue resistance and high strength—with a tensile strength ranging from 515 to 585 Mpa—making it an ideal choice for demanding environments, particularly in aerospace and telecommunications. The alloy’s capacity to retain its mechanical properties at high temperatures further improves its appropriateness for contexts where components face varying environmental conditions.

Moreover, tempered alloys provide outstanding electrical conductivity and wear resistance, rendering them perfect for uses such as springs and wire. As mentioned by Tim Bradow of Rigaku, advancements in CT instruments highlight the increasing significance of a specific alloy in cutting-edge technologies. With superior mechanical characteristics, including a Rockwell hardness between 80.0 and 85.0 and an elongation at break between 15.0 and 30.0%, beryllium alloy not only meets but often surpasses the performance expectations of contemporary electrical components, ensuring reliability and durability in crucial uses.

Domadia’s commitment to high-quality Beryllium Copper solutions through innovative manufacturing and rigorous quality control positions us as a leading supplier in the market. Our Beryllium Copper Plates come in different sizes and weights, customized to fulfill the unique requirements of our clients, guaranteeing satisfaction and optimal performance in every context.

Applications of Beryllium Copper in Telecommunications: Enhancing Connectivity

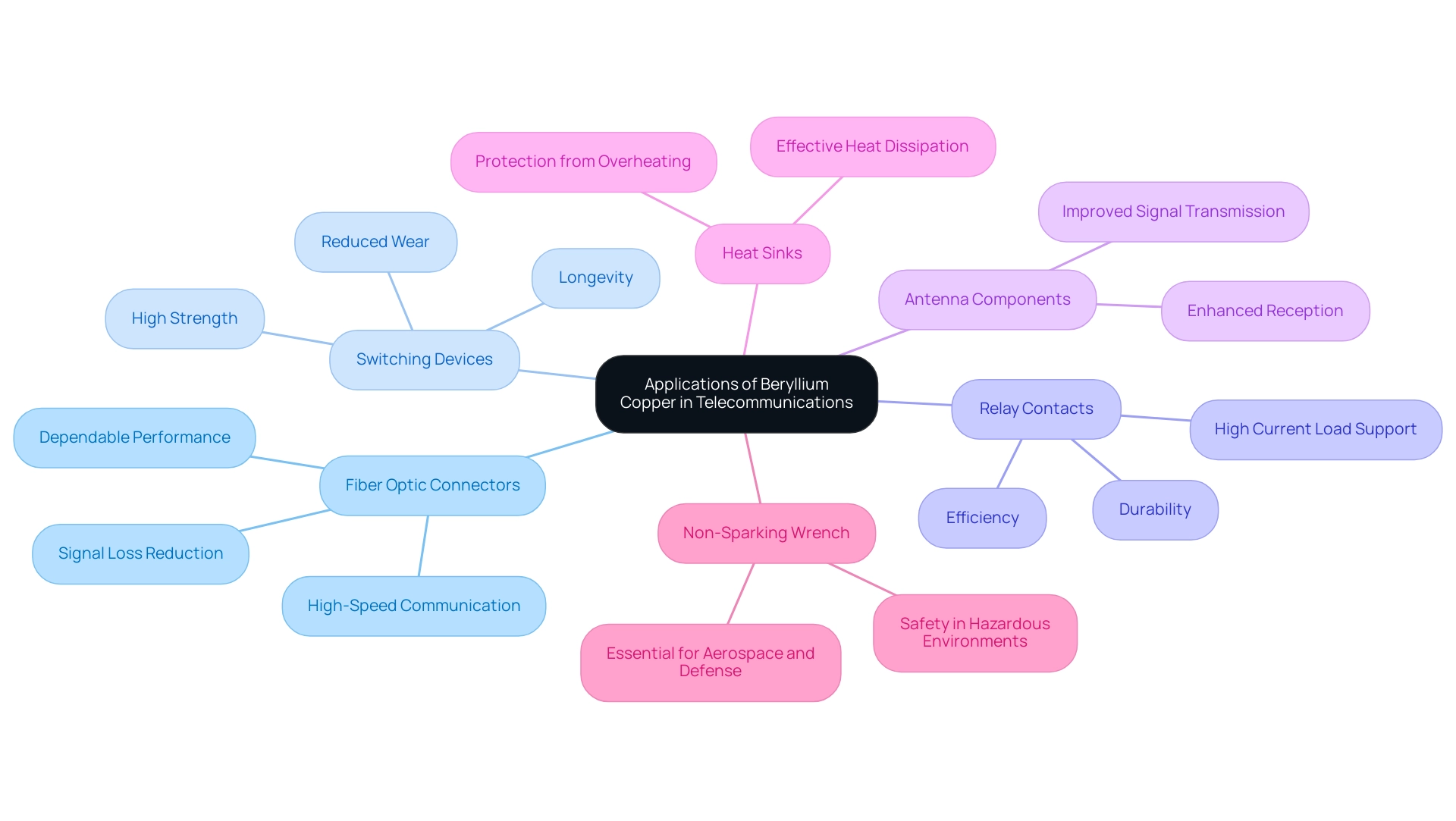

Beryllium copper’s electrical conductivity for telecommunication cables makes it a premier choice in telecommunications, thanks to its exceptional electrical properties and mechanical strength. Its applications are diverse and critical, particularly in the following areas:

- Fiber Optic Connectors: The application of a certain alloy in producing fiber optic connectors is crucial for reducing signal loss and guaranteeing dependable performance, which is essential in high-speed communication networks.

Recent innovations have allowed for improved connector designs that leverage the material’s unique properties.

- Switching Devices: Renowned for its high strength, this alloy, with beryllium copper’s electrical conductivity for telecommunication cables, is ideal for contact points in switches.

This software guarantees longevity and decreases wear, thus enhancing device reliability over time.

- Relay Contacts: The capability of a certain metal, particularly beryllium copper’s electrical conductivity for telecommunication cables, to support high current loads while preserving conductivity is essential for relay applications.

In environments where reliability is paramount, this material provides the necessary durability and efficiency.

Antenna Components: The durability and beryllium copper’s electrical conductivity for telecommunication cables significantly enhance the components in antenna systems, leading to improved signal transmission and reception, which is increasingly important in modern telecommunications.

Heat Sinks: With its outstanding thermal conductivity, a specific alloy is also employed in heat sinks for electronic devices, enabling effective heat dissipation and safeguarding delicate components from overheating. Moreover, high-performance engines often include parts made from a specific metal alloy for enhanced efficiency and reliability, underscoring its significance across various sectors, including telecommunications.

In the automotive sector, for example, the use of beryllium copper’s electrical conductivity for telecommunication cables is crucial for components requiring high reliability and precision, such as sensors, connectors, and switches, ensuring accurate readings and durability. This real-world example illustrates the material’s versatility and effectiveness. Alongside these uses, the Beryllium Copper Non-Sparking Wrench is an essential tool intended for operation in dangerous settings where sparks might lead to explosions.

Its non-sparking properties make it an essential choice for professionals in the aerospace and defense industries. By comprehending these essential uses and the distinctive characteristics of the Non-Sparking Wrench, sourcing managers can make informed purchasing choices that guarantee optimal performance and reliability in telecommunication systems. For detailed pricing and inventory information regarding our Beryllium Copper products, including the Non-Sparking Wrench, please contact us.

As highlighted by E-Fab, a leader in manufacturing with over four decades of experience and a commitment to customer service throughout the project lifecycle, ‘With more than four decades of manufacturing experience and four L-3 Supplier of the Year Awards, E-Fab makes an excellent partner for almost any project,’ reinforcing the industry’s needs for quality and innovation.

Manufacturing Processes for Beryllium Copper Components

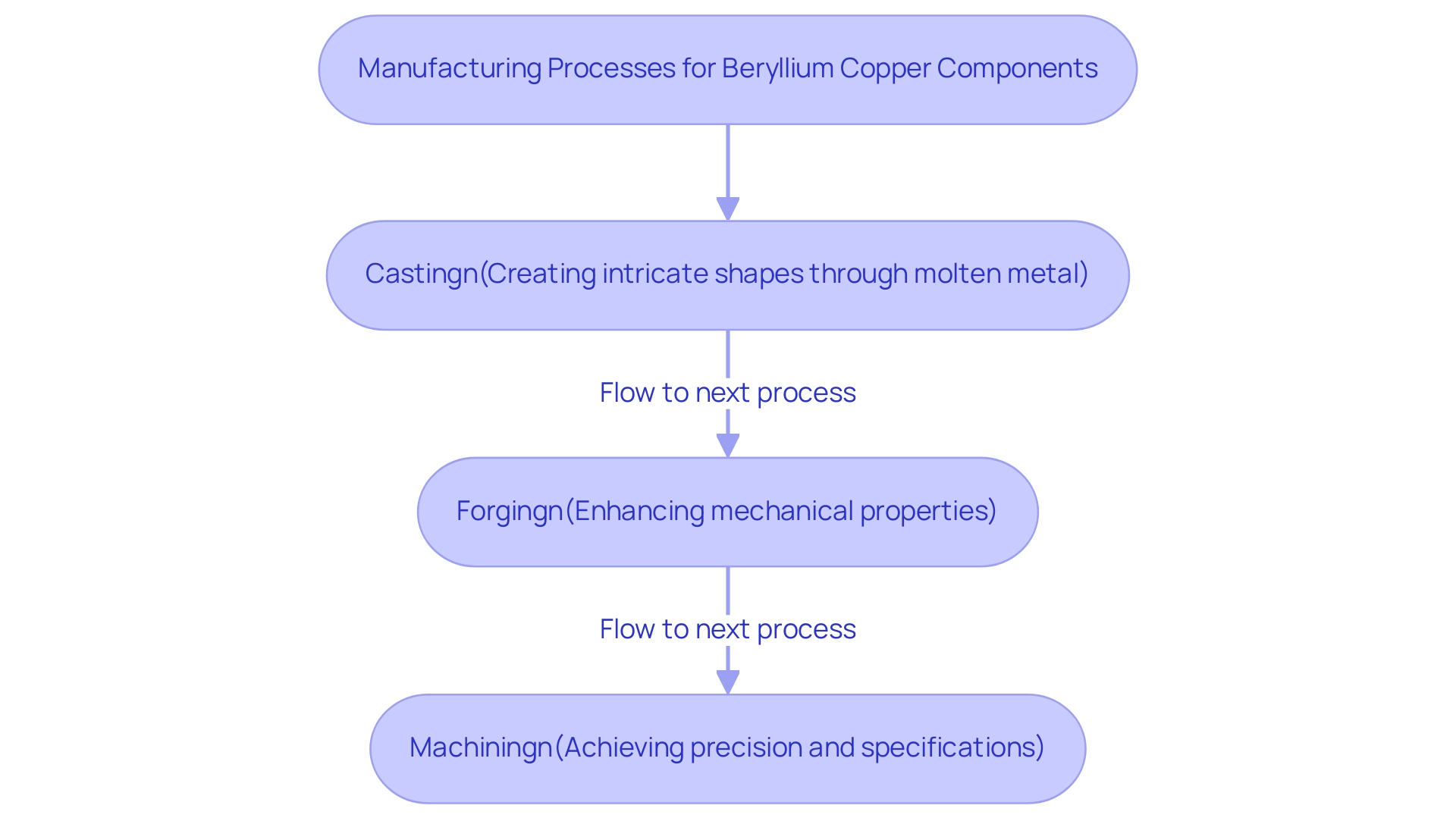

The manufacturing of Beryllium Copper components involves several key processes: casting, forging, and machining, each contributing uniquely to the final product’s quality and performance. As your trusted partner for Beryllium Copper solutions, Domadia not only offers an extensive product range, including high-performance foils, sheets, rods, and wires tailored to meet the diverse needs of the aerospace, defense, and telecommunications sectors, but also ensures ready stock and custom fabrication options to suit your specific requirements.

Casting: This method entails pouring molten Beryllium Copper into molds, allowing for the creation of intricate shapes. While casting is ideal for complex geometries, it necessitates precise control of cooling rates to prevent defects that could compromise structural integrity.

Forging: By applying compressive forces, forging significantly enhances the mechanical properties of Beryllium Copper. This process not only enhances strength and durability but also ensures that the material demonstrates superior heat dissipation and corrosion resistance—qualities that are particularly advantageous in aerospace and telecommunications fields, especially when considering beryllium copper’s electrical conductivity for telecommunication cables. The demand for Beryllium Copper alloys is driven by these superior physical characteristics, which are expected to significantly boost product adoption in the market.

Machining: Following the initial forming processes, components typically undergo precision machining. This step is vital for achieving exact specifications and tolerances, ensuring the functionality and reliability of parts in demanding environments.

As the global market for Beryllium Copper alloys is projected to grow from USD 1.51 billion in 2023 to USD 2.53 billion by 2032, purchasing managers must prioritize suppliers like Domadia with demonstrated expertise in these manufacturing techniques. Such diligence not only guarantees the production of high-quality Beryllium Copper components but also aligns with industry standards and enhances overall product performance.

Furthermore, it is crucial to consider safety and environmental aspects in the manufacturing processes. Non-sparking tools, crafted from Beryllium Copper, are essential for explosive environments, ensuring safety without compromising performance.

Understanding these factors is vital for compliance and minimizing risks associated with Beryllium exposure. Additionally, the body-centered cubic crystal structure and paramagnetic properties of Beryllium Copper contribute to its applications, offering procurement managers a reliable choice for high-performance solutions. At Domadia, we are committed to being your partner in success, providing not just products but tailored solutions that meet your unique needs.

Cost Considerations and Procurement Strategies for Beryllium Copper

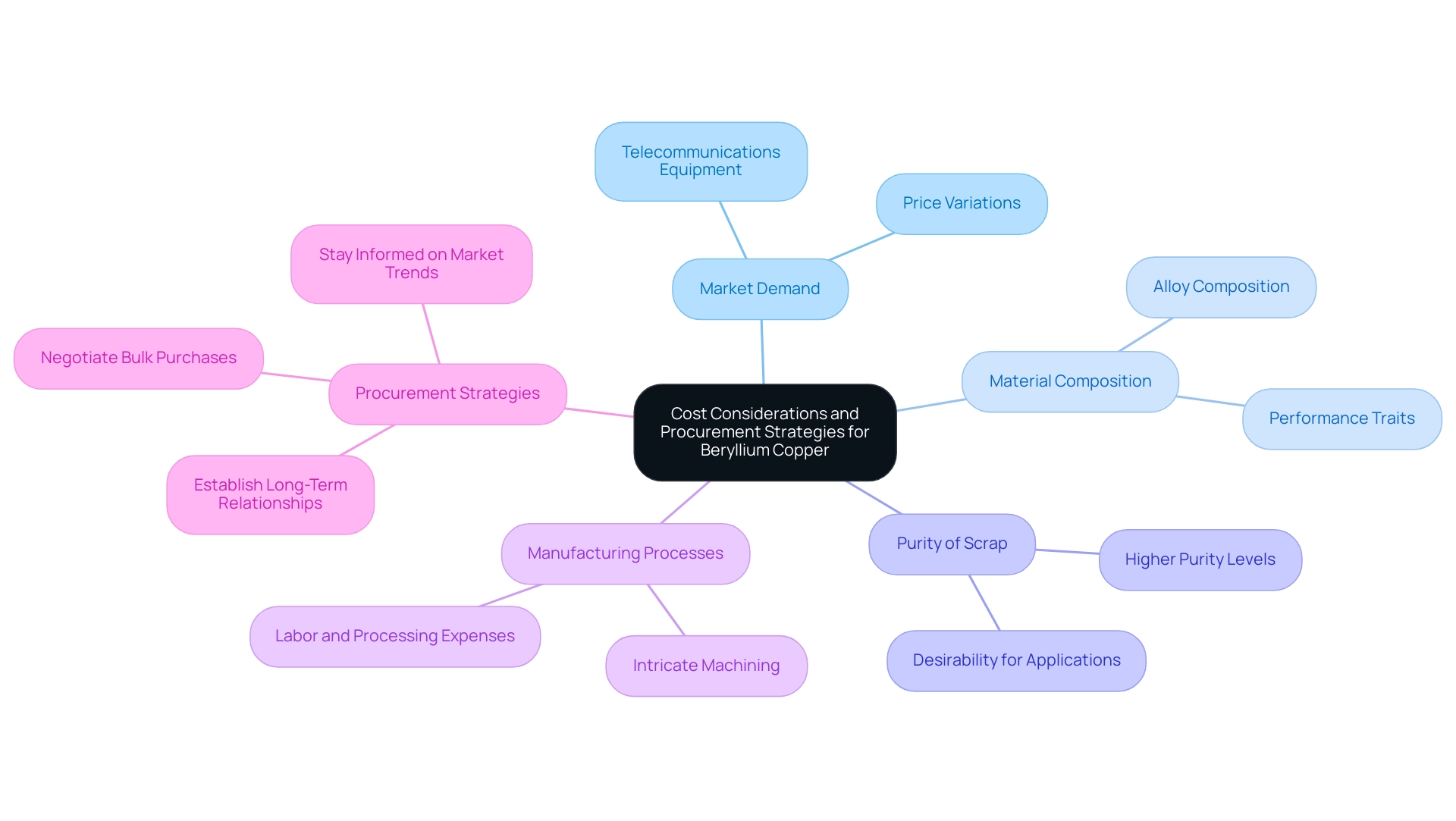

When procuring the alloy, several essential elements greatly affect expenses, including market demand, material composition, purity, and production methods. The worldwide demand for beryllium copper’s electrical conductivity for telecommunication cables significantly influences price variations, particularly in advanced technology fields. Notably, the telecommunications equipment segment is projected to lead the global market share through 2028, highlighting the significance of beryllium copper’s electrical conductivity for telecommunication cables in advancing technology.

As demand surges, procurement managers must be prepared for potential price increases driven by this trend. Domadia remains dedicated to providing equitable and clear pricing for all metal scrap transactions, ensuring competitiveness in a fluctuating market. Alloy Composition: The particular mixture of a certain metal directly affects pricing.

Alloys with a greater content of certain elements frequently incur higher costs due to their improved performance traits, making it crucial for procurement managers to assess the advantages against the extra expenses involved. Purity of the Scrap: The purity level of beryllium copper scrap is a crucial determinant of its price. Higher purity levels typically result in increased costs, as they are more desirable for applications requiring superior conductivity and strength, including beryllium copper’s electrical conductivity for telecommunication cables.

Manufacturing Processes: The fabrication method selected can also affect overall costs. For instance, intricate machining processes may incur higher labor and processing expenses, which should be considered during purchasing planning.

To optimize purchasing strategies, consider the following approaches:

- Establish Long-Term Relationships: Cultivating strong partnerships with suppliers can yield better pricing arrangements and ensure priority access during periods of high demand. This relationship-building is essential, especially as production and supply operations across key industries have been affected by issues such as COVID-19, which has resulted in supply chain shortages and a growing demand-supply gap.

- Negotiate Bulk Purchases: Engaging in discussions for bulk orders can secure significant discounts, providing a cost-effective solution for your purchasing needs.

- Stay Informed on Market Trends: Keeping updated on fluctuations in the market for beryllium is vital for making timely and informed buying decisions. This proactive method will enable procurement managers to manage market dynamics efficiently and take advantage of potential opportunities.

Additionally, the pricing and inventory information for metal alloys is essential in evaluating the overall procurement strategy. At present, alloy strips are valued at around $1,050.00 each, indicating the most recent market conditions. The Asia-Pacific area, for instance, is anticipated to witness significant expansion in the alloy market owing to escalating industrialization and the growing need for advanced materials.

This trend highlights the importance of being well-informed about regional developments and market conditions to leverage growth opportunities.

Compliance and Standards in Beryllium Copper Procurement

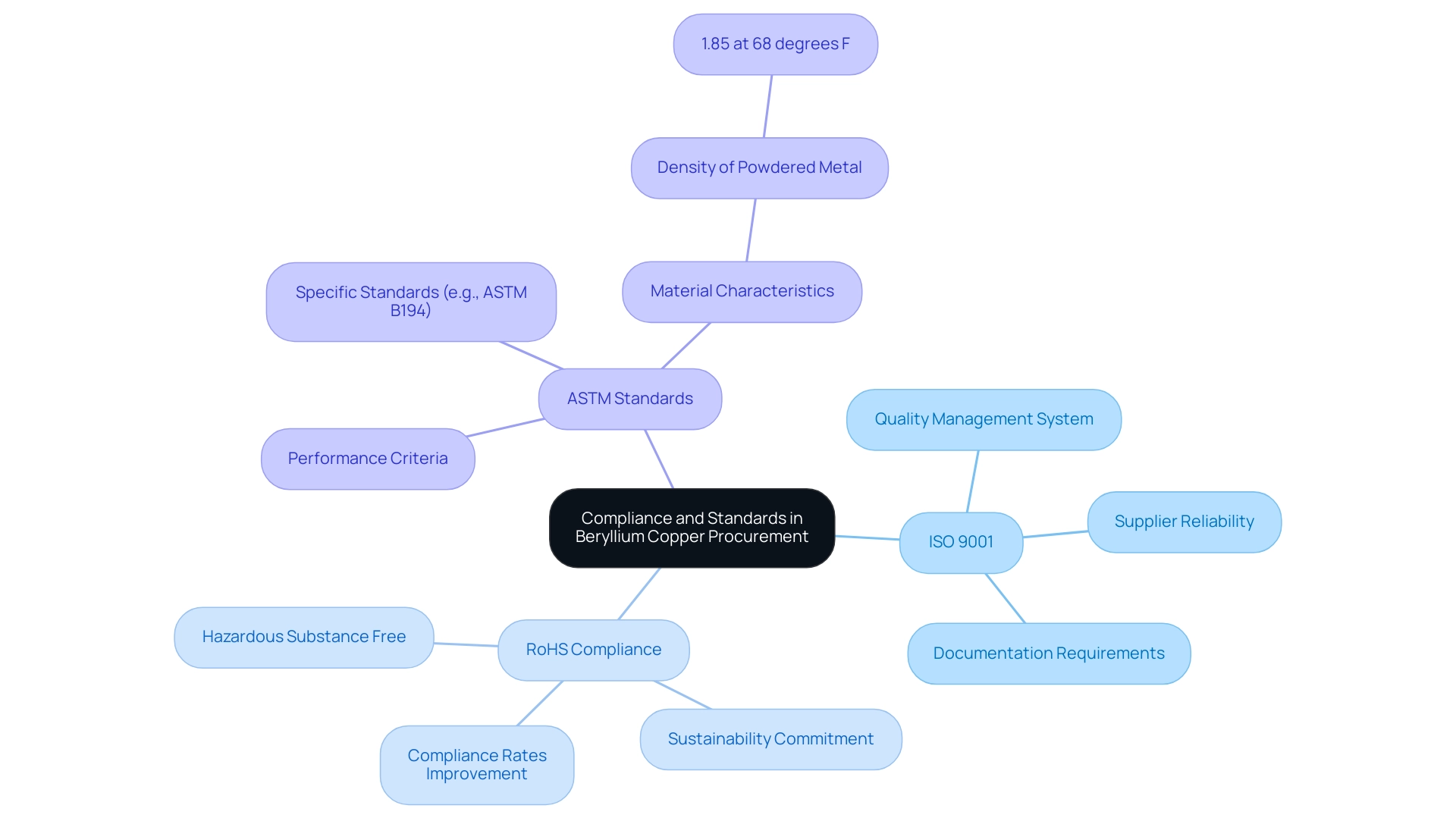

Ensuring adherence to international standards is crucial in the procurement of a specific alloy, as it assures product quality and safety across diverse uses, particularly in aerospace, defense, and telecommunications, where beryllium copper’s electrical conductivity for telecommunication cables is essential. Key standards to consider include:

ISO 9001: This standard sets the criteria for a robust quality management system, ensuring that suppliers, like Domadia, consistently deliver superior quality Beryllium Copper Plates.

Procurement managers should prioritize suppliers with documented adherence to this standard, as it significantly enhances supplier reliability.RoHS Compliance: This directive is vital for ensuring that electronic components, particularly in telecommunications, are free from hazardous substances.

Recent improvements in RoHS compliance rates reflect a broader industry commitment to sustainability and safety, which suppliers like Domadia uphold through their extensive range of ultra-thin metal foils.ASTM Standards: Numerous ASTM standards, such as ASTM B194, provide detailed specifications for copper alloys, ensuring they meet stringent performance criteria necessary for aerospace and defense sectors.

Furthermore, it is significant to mention that powdered metal has a density of 1.85 at 68 degrees F, which is essential for evaluating material characteristics for these uses.

Procurement managers are advised to conduct thorough due diligence to confirm that their suppliers comply with these standards and maintain comprehensive documentation for compliance audits. This proactive approach not only mitigates risks associated with non-compliance but also fortifies the integrity of the supply chain, aligning with industry best practices.

Moreover, Domadia’s commitment to unmatched quality and unparalleled expertise in ultra-thin metal foil manufacturing is essential for meeting the rigorous demands of the industry. The application of Non-Sparking Tools in explosive environments underscores the necessity for high-quality materials that meet rigorous standards. The case study of the San Diego Beryllium Manufacturer illustrates how adherence to these standards can facilitate successful partnerships in sectors like shipbuilding and defense, showcasing their compliance with multiple industry standards including MIL-P Spec, ASTM, ASME, and AMS.

As stated by Busby Metals, ‘We are pleased to announce our participation at the Farnborough Airshow,’ which underscores the industry’s ongoing commitment to quality and compliance in high-stakes environments.

Future Trends in Beryllium Copper Usage for Telecommunications

The telecommunications environment is experiencing considerable change, affecting the use of a specific metal in various ways:

Growing Demand for High-Speed Connectivity: The emergence of 5G technology is set to significantly boost the need for high-performance substances like advanced alloys. According to recent industry reports, the demand for beryllium copper is expected to rise by 30% over the next five years, driven by beryllium copper’s electrical conductivity for telecommunication cables and its thermal stability, which make it an ideal candidate for the advanced applications required in next-generation telecom infrastructure.

Commitment to Sustainability: As the industry shifts towards more sustainable practices, there is a clear trend towards using recyclable materials and implementing eco-friendly manufacturing processes. A recent survey found that 75% of purchasing managers are prioritizing sustainable sourcing strategies in response to consumer demand for environmentally friendly products. This evolution necessitates purchasing managers to adapt their sourcing strategies to align with sustainability goals while still meeting performance requirements.

Advancements in Materials Science: Continuous innovations in materials science are likely to yield new alloys or alternatives to beryllium copper. Staying informed about these developments will be crucial for sourcing professionals to effectively adjust sourcing strategies and leverage advancements that may enhance operational efficiency. For instance, a recent case study on a telecommunications firm highlighted how they successfully integrated a new alloy, resulting in a 20% improvement in energy efficiency, showcasing the importance of remaining agile in sourcing decisions.

Managing Stakeholder Expectations: As purchasing managers navigate these trends, they must also manage stakeholder expectations, particularly when data insights are inconclusive. Clear communication and transparency regarding sourcing decisions and sustainability initiatives can assist in aligning stakeholder interests with purchasing strategies.

Utilizing Supplier Insights: To further enhance their purchasing strategies, managers should consider integrating insights from suppliers of electrical insulation materials and high-temperature products. Engaging with suppliers of beryllium copper strips can provide valuable information on pricing and inventory levels, especially in relation to beryllium copper’s electrical conductivity for telecommunication cables, enabling procurement managers to make informed decisions that align with market trends and demands. To remain competitive, procurement managers must actively monitor these industry trends and ensure their sourcing strategies are agile and responsive to the dynamic telecommunications sector.

Conclusion

Understanding the multifaceted advantages of beryllium copper is crucial for procurement managers aiming to enhance operational efficiency and product reliability. The exceptional electrical conductivity, strength, and corrosion resistance of this alloy position it as an indispensable material in telecommunications and aerospace applications. From fiber optic connectors to non-sparking tools, the diverse applications underscore its significance in ensuring seamless communication and safety in hazardous environments.

Manufacturing processes such as casting, forging, and machining are integral to producing high-quality beryllium copper components. Each method contributes uniquely to the alloy’s performance, making it essential for procurement managers to partner with suppliers who demonstrate expertise in these processes. Additionally, understanding cost considerations—such as market demand, alloy composition, and purity—will empower managers to make informed sourcing decisions that align with their operational needs.

Compliance with international standards, including ISO 9001 and ASTM specifications, is paramount to maintaining product quality and safety. As the industry evolves, staying informed about future trends, such as the growing demand for sustainable practices and advancements in materials science, will be critical for adapting procurement strategies. By leveraging supplier insights and fostering strong partnerships, procurement managers can navigate the complexities of the beryllium copper market effectively.

In conclusion, the strategic sourcing of beryllium copper not only enhances product performance but also positions organizations to meet the challenges of an ever-changing market landscape. Embracing these insights ensures that procurement managers are well-equipped to make decisions that support both operational excellence and compliance with industry standards.