Blogs

Understanding Beryllium Density (g/cm3): An In-Depth Tutorial

Introduction

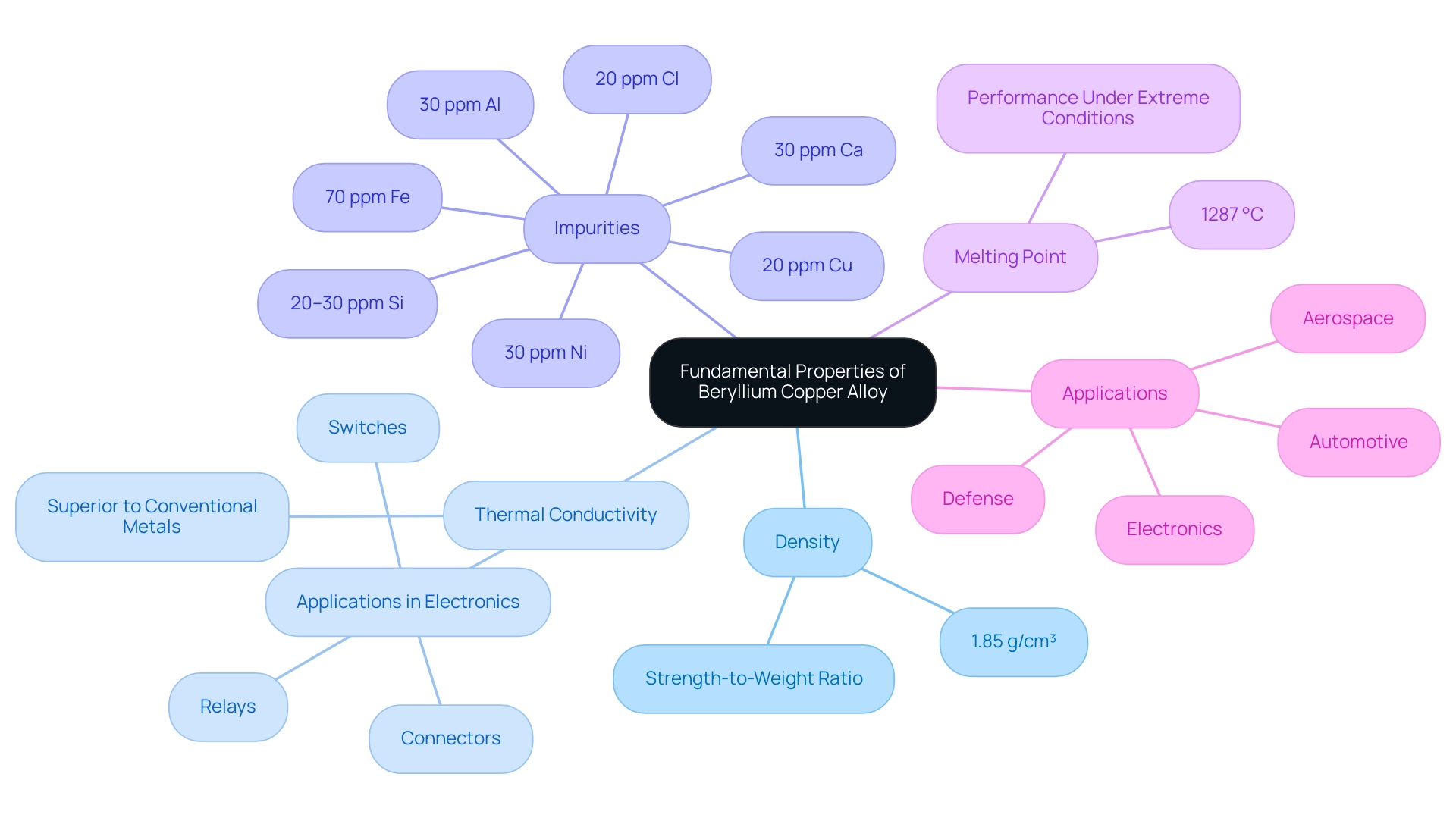

The properties of beryllium and its alloys, particularly Beryllium Copper, have garnered significant attention in various industries due to their unique characteristics and applications. With a density of approximately 1.85 g/cm³, Beryllium Copper stands out as one of the lightest structural metals, offering an impressive strength-to-weight ratio that is invaluable in sectors like aerospace, automotive, and electronics.

This article delves into the fundamental properties of beryllium, exploring its remarkable thermal conductivity and high melting point, which enhance its utility in demanding environments. Additionally, it highlights the critical role of density in the performance of beryllium components, the importance of regulatory compliance for safe handling, and best practices for sourcing quality materials.

By understanding these aspects, procurement managers can make informed decisions that not only meet performance requirements but also ensure safety and compliance in their operations.

Fundamental Properties of Beryllium: Density and Beyond

Copper alloy, especially the DOMADIA type, is characterized by its remarkable weight of around 1.85 g/cm³, placing it among the lightest structural metals accessible. This light mass contributes to a remarkable strength-to-weight ratio, making this copper alloy an appealing option for specialized uses in various sectors, including aerospace, automotive, and electronics. In addition to its density, Copper alloyed with beryllium showcases impressive thermal conductivity, with values that surpass many conventional metals, enhancing its utility in electronic applications such as connectors, switches, and relays.

DOMADIA ensures that its Copper products comply with international standards such as UNS and ASTM, reflecting our commitment to quality and customer satisfaction. Typical impurity contents of electrolytic metal after vacuum remelting include:

- 30 ppm Al

- 30 ppm Ca

- 20 ppm Cl

- 20 ppm Cu

- 70 ppm Fe

- 30 ppm Ni

- 20–30 ppm Si

These impurities are crucial for assessing quality during procurement. With a high melting point of 1287 °C and outstanding stiffness, Copper Alloy maintains its integrity and performance under extreme conditions—qualities essential in sectors such as aerospace, defense, and electronics.

Furthermore, DOMADIA’s commitment to customization and expert assistance guarantees our clients obtain tailored solutions that fulfill their specific requirements, fostering global trust in our Copper supply. Grasping these essential characteristics, along with the various uses and distinct attributes of Copper Plates, is vital for procurement managers assessing Copper for their applications, enabling informed choices that correspond with both performance requirements and safety factors.

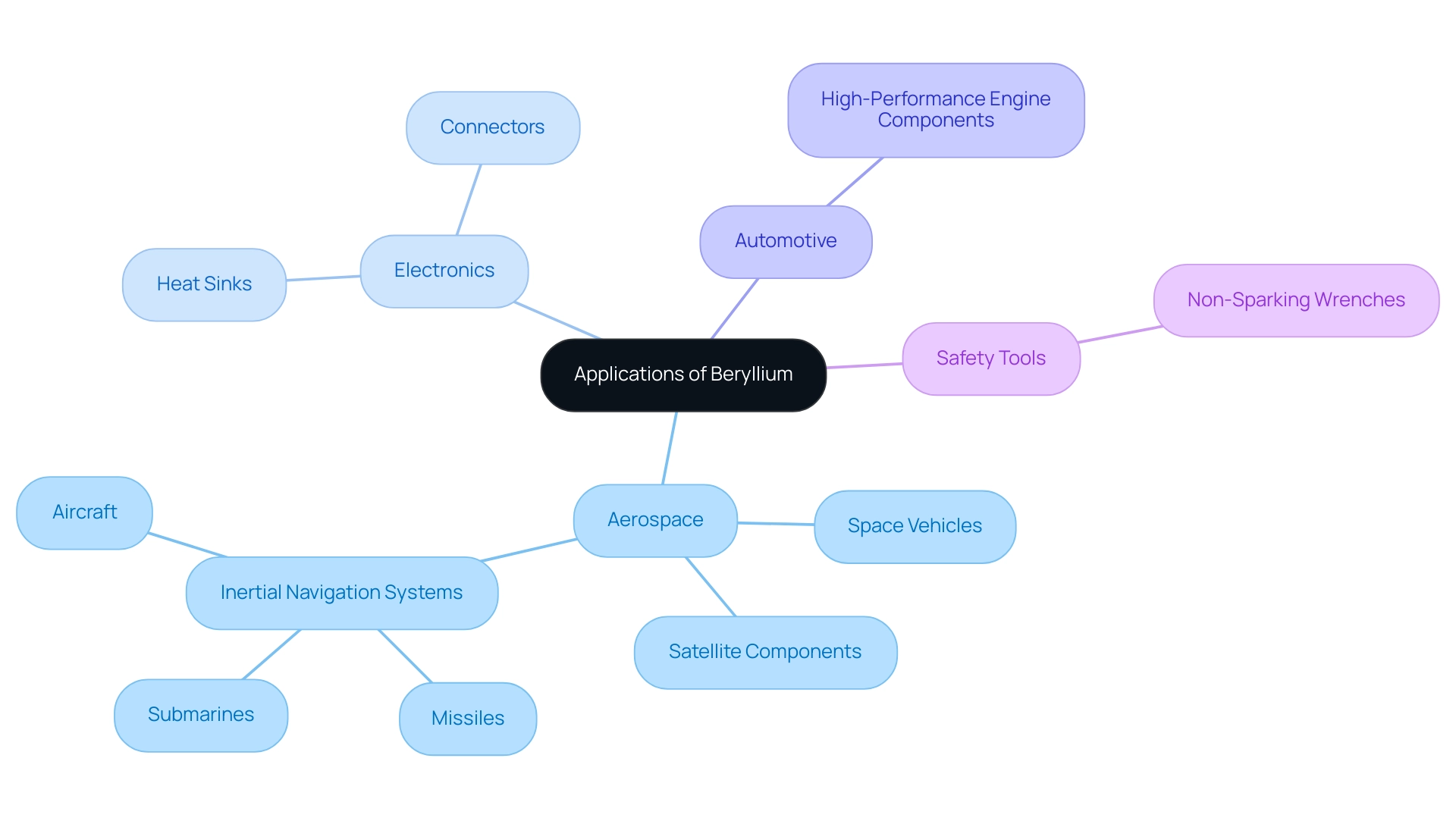

Applications of Beryllium: The Importance of Density in Industry

Beryllium’s unique low beryllium density g/cm3 offers significant advantages in sectors where weight reduction is paramount. In aerospace applications, for instance, this material is integral to the construction of satellite components and space vehicles, where every gram saved can enhance performance and efficiency. Its remarkable strength allows manufacturers to produce thinner yet robust components, preserving structural integrity without excess weight.

Additionally, this element is essential for inertial navigation systems used in missiles, submarines, and aircraft, further underscoring its critical role in advanced technologies. In the realm of electronics, this element’s exceptional thermal conductivity is crucial for applications such as heat sinks and connectors, where efficient heat dissipation is vital for optimal performance. The automotive sector also gains advantages from this element, particularly in high-performance engine components, where its lightweight properties contribute to enhanced fuel efficiency.

Since the United States is one of just three nations that handle specific ores and produce related products, procurement experts must acknowledge the significance of the beryllium density g/cm3 and its applications across these sectors. Furthermore, the use of Beryllium Copper Non-Sparking Wrenches, which feature a unique alloy that prevents sparking during use, presents a critical safety advantage in explosive environments. These tools are designed with enhanced grip and durability, making them indispensable in settings where flammable materials are present.

Strict adherence to safety protocols during handling and disposal is essential, as highlighted in the case study titled ‘Safety and Performance Considerations,’ which emphasizes the importance of using non-sparking tools to protect workforce health and ensure material integrity. As Jim Sims, Director of Investor Relations at IBC Advanced Alloys, aptly states, this material is not just a component; it is a strategic asset in modern engineering, especially when safety is a primary concern.

Density Measurement Techniques for Beryllium

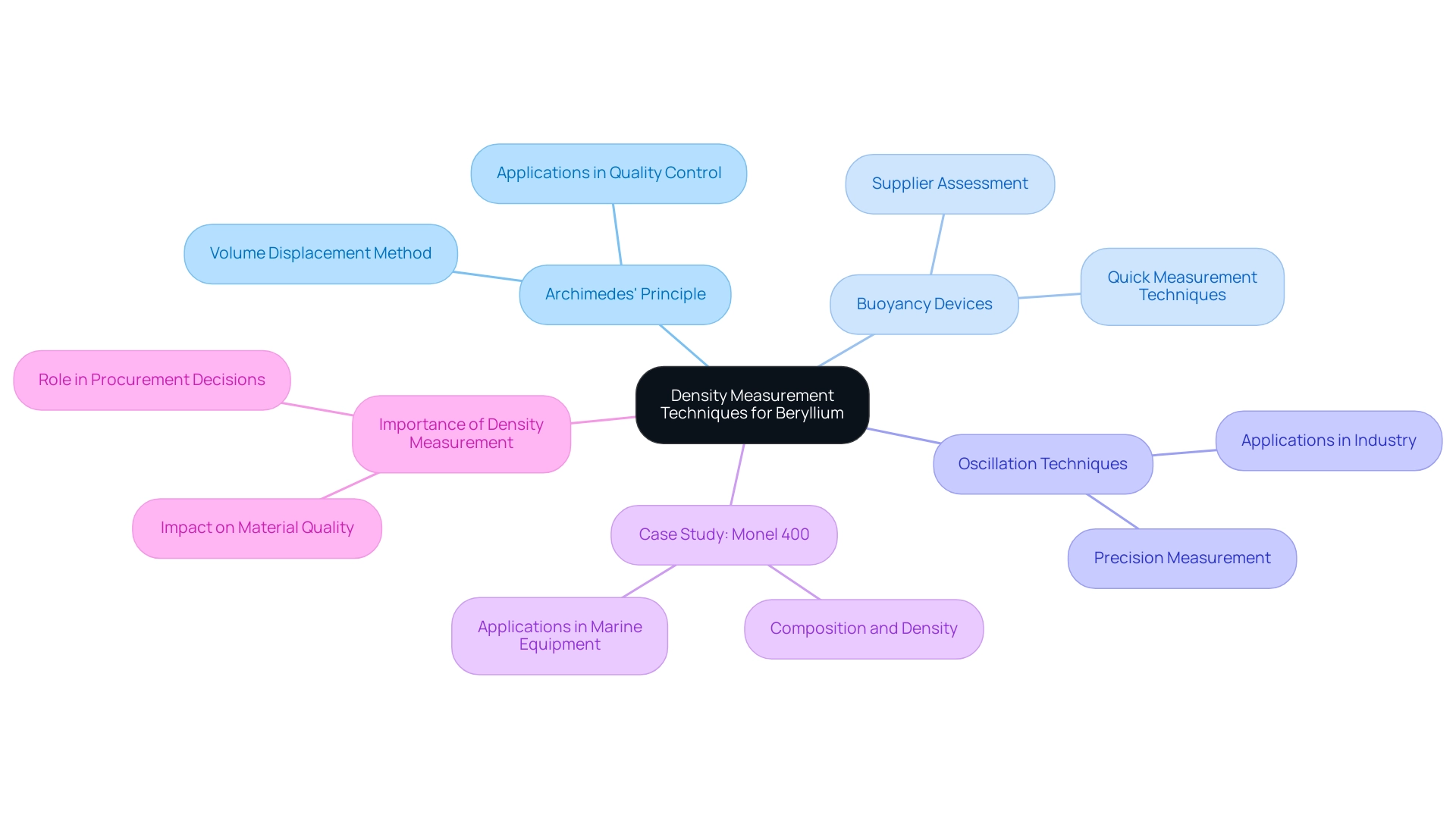

The assessment of this element’s mass can be precisely performed using various recognized methods. One widely recognized method is Archimedes’ principle, which involves submerging the beryllium sample in water to measure the volume of liquid displaced, thereby determining the mass per unit volume. This technique not only illustrates fundamental physics but also acts as a dependable method to determine the mass per unit volume of materials.

For comparative context, Model 400, with a mass per unit volume ranging from 8.2 to 8.9 g/cm³, illustrates the importance of understanding variations among metals. Additionally, measurement devices are increasingly utilized, employing principles of buoyancy or oscillation to quickly and precisely ascertain value measurements. These methods are indispensable in quality control processes, ensuring that the beryllium sourced from trusted partners like Domadia meets the stringent specifications for beryllium density g/cm³ required for various applications.

Domadia provides a wide variety of Copper products, including foils, sheets, rods, and wires, with options for custom fabrication tailored to specific project requirements. This commitment to high-quality Beryllium Copper wire and exceptional customer service enhances project success by ensuring that products not only meet but exceed industry standards. The importance of precise measurement of mass per volume is further highlighted by considering Lithium, which has a value of only 0.534 g/cm³ and plays crucial roles in rechargeable batteries.

By mastering these measurement techniques, purchasing professionals can more effectively assess supplier capabilities, such as those provided by Domadia, and make informed choices that align with their operational standards. Furthermore, the case study of Monel 400 demonstrates how these techniques are applied in real-world scenarios, showcasing their practical relevance in the industry. By understanding how density impacts the quality and performance of materials, procurement managers can ensure they select the best products for their applications.

Regulatory Standards and Compliance for Beryllium Use

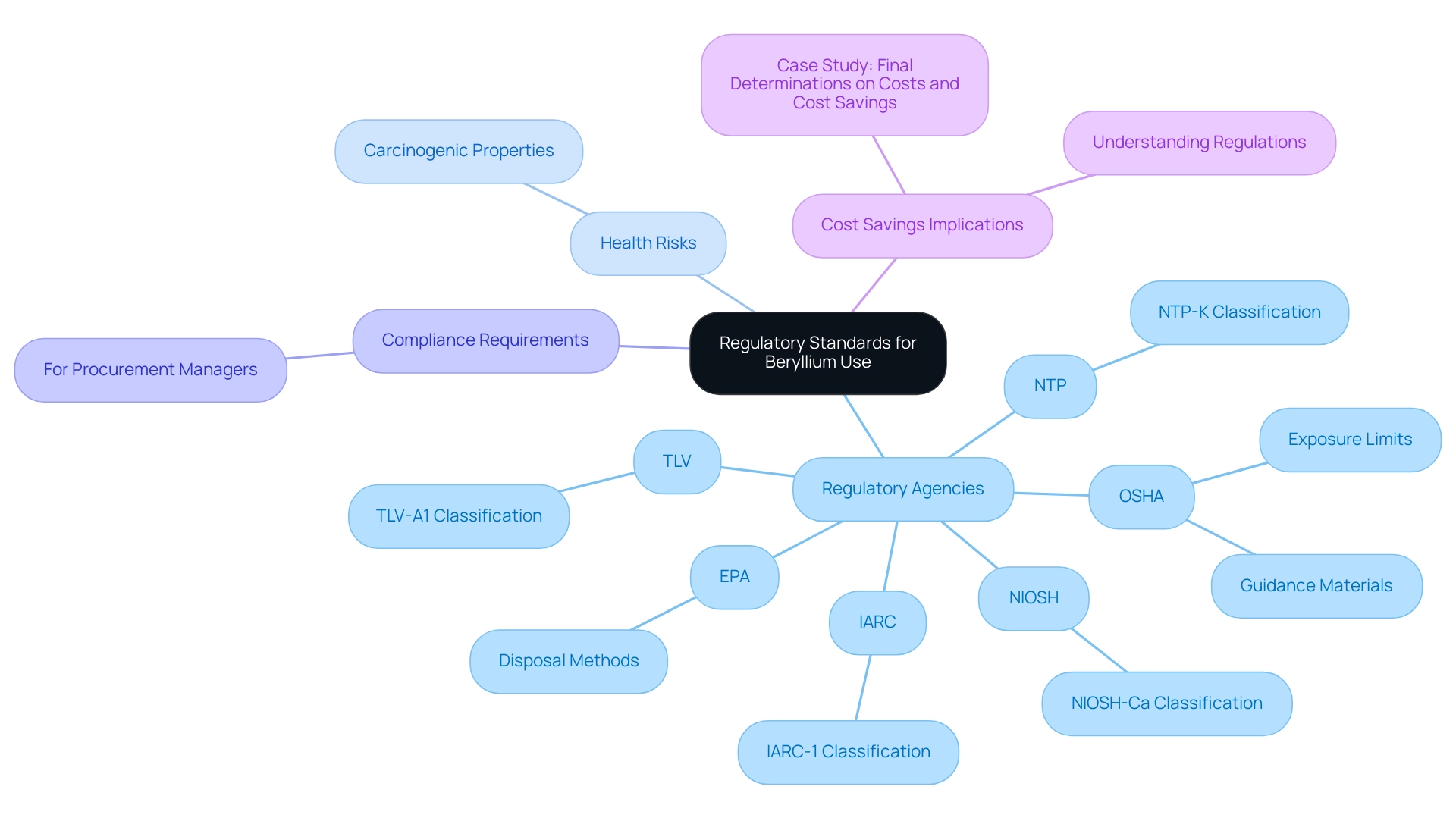

Beryllium’s potential health risks necessitate stringent regulatory oversight, particularly from agencies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA). These organizations have established comprehensive regulations governing exposure limits and disposal methods for the substance to safeguard workers and the environment. Notably, this element is classified as a carcinogen by several agencies, including:

- IARC (IARC-1)

- NIOSH (NIOSH-Ca)

- NTP (NTP-K)

- TLV (TLV-A1)

- EPA (EPA-B1)

This classification highlights the serious health risks associated with exposure.

In a recent announcement, James S. Frederick, Deputy Assistant Secretary of Labor for Occupational Safety and Health, emphasized the importance of evolving these standards, stating that guidance materials will replace outdated appendices from the previous rule, thereby enhancing clarity for compliance. For procurement managers, it is imperative to stay informed about these regulations to align sourcing practices with current legal requirements and industry best practices. Adhering to these regulations not only protects employees but also reinforces the reputation of the supplying company.

The recent analysis by OSHA regarding proposed changes to the standard suggests that an improved understanding of these rules will lead to significant cost savings, as outlined in the case study titled ‘Final Determinations on Costs and Cost Savings.’ This analysis categorizes proposed changes into clarifications and revisions, indicating that understanding and applying the rule effectively can offset minimal familiarization costs for employers. Furthermore, copper non-sparking wrenches are essential tools in environments where spark generation poses risks, particularly in hazardous material handling.

Their non-sparking properties make them suitable for use in volatile settings, ensuring safety during operations. Grasping the latest OSHA and EPA rules regarding exposure and disposal of that substance is essential for upholding a sustainable sourcing strategy, ensuring not only compliance but also the safety of personnel in the workplace.

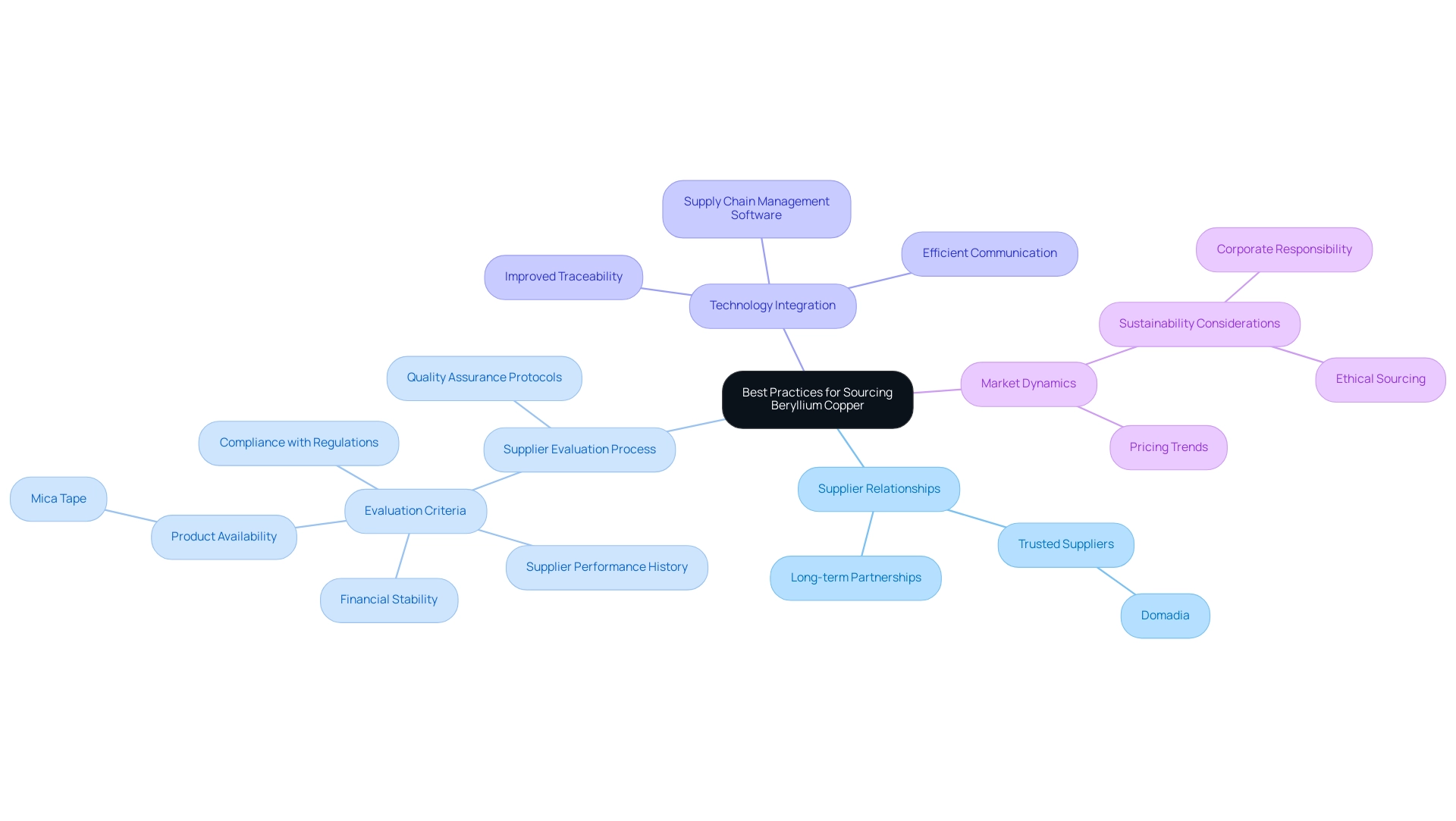

Best Practices for Sourcing Beryllium

In the search for quality beryllium copper, purchasing managers should focus on cultivating long-term partnerships with trusted suppliers like Domadia, recognized not only for their adherence to quality standards and regulatory compliance but also for their commitment to fostering business growth through reliable and sincere service. A comprehensive supplier evaluation process is crucial, encompassing an assessment of certifications, quality assurance protocols, and overall operational integrity. For instance, recent statistics indicate that 23 contributions were made within 24 minutes to keep a project on track when a key team member departs, underscoring the importance of maintaining strong supplier relationships and effective communication in the supply chain.

Embracing technology, such as advanced supply chain management software, can significantly enhance purchasing workflows by improving traceability and facilitating efficient communication. Furthermore, staying vigilant about market dynamics and pricing trends equips purchasing professionals to negotiate more favorable contracts. As Domadia aptly states, ‘By embracing responsible practices, organizations can ensure a reliable supply of beryllium copper while positioning themselves as leaders in sustainable industrial practices.’

Applying these best practices not only strengthens the quality of sourced materials but also encourages cost savings and develops stronger supplier collaboration, ultimately improving the purchasing process. Additionally, drawing insights from case studies like ‘Integrating Renewable Energy in Geology Exploration‘ can provide valuable lessons on sustainability and responsible sourcing practices. Specific evaluation criteria such as:

- Supplier performance history

- Financial stability

- Compliance with environmental regulations

- The ability to provide essential products like Mica Tape

should be integral to the supplier evaluation process.

This ensures a thorough and effective procurement strategy while considering the safe application of Non-Sparking Tools, which are vital in explosive environments due to their ability to prevent sparks and minimize risks associated with flammable materials.

Conclusion

The exploration of beryllium and its alloys, particularly Beryllium Copper, reveals a material that is not only lightweight but also incredibly strong and thermally conductive. These properties make it an essential choice across various industries, including aerospace, automotive, and electronics. The unique density of approximately 1.85 g/cm³ enables manufacturers to innovate and create components that are both efficient and effective, while the high melting point ensures performance under extreme conditions.

Understanding the regulatory landscape is equally critical, as the health risks associated with beryllium necessitate compliance with stringent safety standards. Procurement managers must remain vigilant about these regulations to ensure safe handling and effective risk management. By prioritizing regulatory compliance, organizations not only protect their workforce but also enhance their operational integrity.

Best practices in sourcing beryllium underscore the importance of establishing long-term relationships with reputable suppliers. By focusing on quality assurance, effective communication, and technological integration, procurement professionals can optimize their supply chains and drive efficiencies. Embracing these strategies not only facilitates the acquisition of high-quality materials but also positions organizations as leaders in responsible and sustainable procurement practices.

In summary, beryllium’s unique characteristics, coupled with a thorough understanding of compliance and sourcing strategies, empower procurement managers to make informed decisions that align with both performance and safety standards. As industries continue to evolve, leveraging the strengths of beryllium and its alloys will be paramount for driving innovation and maintaining competitive advantage.