Blogs

Understanding Elgiloy Spring Material: A Complete Tutorial on Properties and Applications

Introduction

In the realm of high-performance materials, Elgiloy alloy emerges as a pivotal player, captivating industries with its exceptional properties and versatility. Renowned for its remarkable strength, corrosion resistance, and fatigue performance, Elgiloy’s unique composition positions it as a preferred choice across critical sectors, including:

- Aerospace

- Medical devices

- Automotive applications

As procurement managers navigate the complexities of material selection, understanding Elgiloy’s advantages over traditional alloys becomes essential for making informed decisions that enhance operational efficiency and product reliability. This article delves into the properties, applications, and future trends of Elgiloy, offering insights that empower professionals to leverage this advanced material effectively in their strategic sourcing endeavors.

Introduction to Elgiloy Alloy: Properties and Significance

This high-performance cobalt-based alloy is acclaimed for its exceptional durability, corrosion resistance, and fatigue characteristics. Its nominal composition primarily includes cobalt, nickel, chromium, and molybdenum, with a maximum of 0.015% sulfur, which contributes to its unique balance of tensile resilience and ductility. This combination makes this alloy especially appropriate for uses that require complex shapes and high performance, such as those found in aerospace and medical sectors.

Notably, this alloy’s mechanical properties showcase:

- Tensile strength: 970 MPa

- Yield strength: 480 MPa

- Elastic modulus: 189.6 GPA

These characteristics not only demonstrate the durability of elgiloy spring material but also its capability to withstand extreme conditions, which is essential in critical applications such as springs, fasteners, and connectors. Furthermore, this material is non-magnetic and retains its physical properties even at elevated temperatures, making it an invaluable asset in industries where reliability is paramount.

As Stephane Guignard points out,

The aerospace industry is currently very energy-intensive,

which underscores the increasing need for materials that can meet these rigorous demands. Its applications extend beyond aerospace to include elgiloy spring material used in springs, seals, semiconductor components, orthodontics, medical devices, surgical implants, and satellite communications equipment, highlighting its significance across multiple industries.

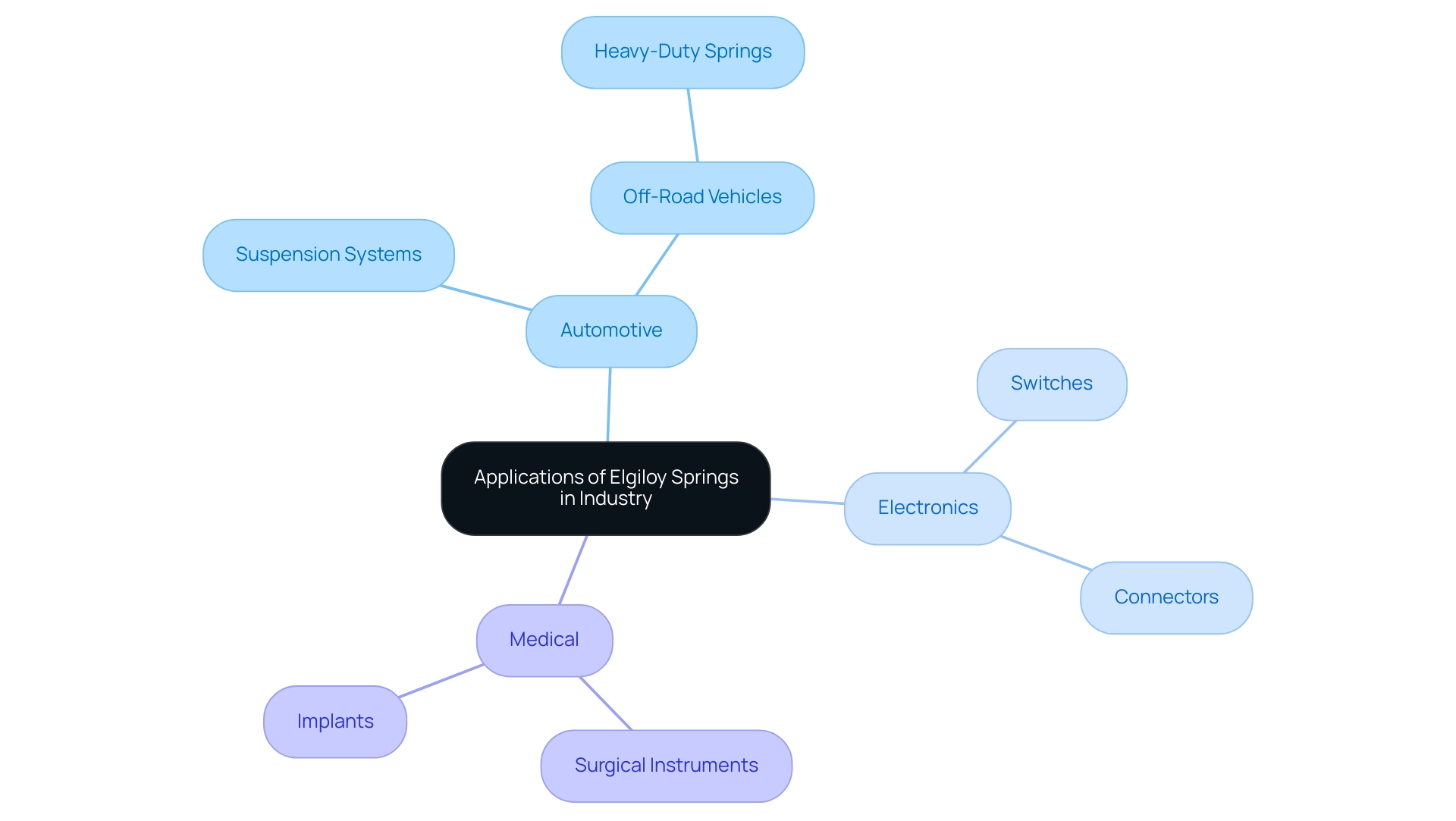

Applications of Elgiloy Springs in Industry

These springs, known as elgiloy spring material, are integral components within the automotive, electronics, and medical industries, valued for their remarkable resilience and high-performance capabilities under stress. In the automotive sector, they are primarily employed in suspension systems, where their distinctive blend of durability and flexibility enables effective shock and vibration absorption. Significantly, the elgiloy spring material provides enhanced strength in a compact form when compared to Inconel X-750 and MP35N, making it an ideal option for rigorous uses.

This performance is particularly crucial in the context of the rising demand for off-road vehicles, which accounted for a significant portion of the automotive spring market revenue in 2023, representing approximately 35%. Manufacturers are developing specialized automotive springs with higher load-bearing capacity to cater to off-road vehicle drivers. Furthermore, in electronics, elgiloy spring material is favored for precision applications, such as switches and connectors, where reliability and durability are non-negotiable.

The medical sector also utilizes elgiloy spring material in critical devices, including surgical instruments and implants, where biocompatibility and corrosion resistance are paramount. Additionally, the springs made from this alloy adhere to rigorous industry standards, meeting specifications such as AMS 5833 and ASTM F1058. The versatility of these springs across these sectors underscores their significance in the development of high-performance components, making them a preferred choice for manufacturers aiming to deliver quality and reliability.

Comparative Analysis: Elgiloy vs. Other Alloys

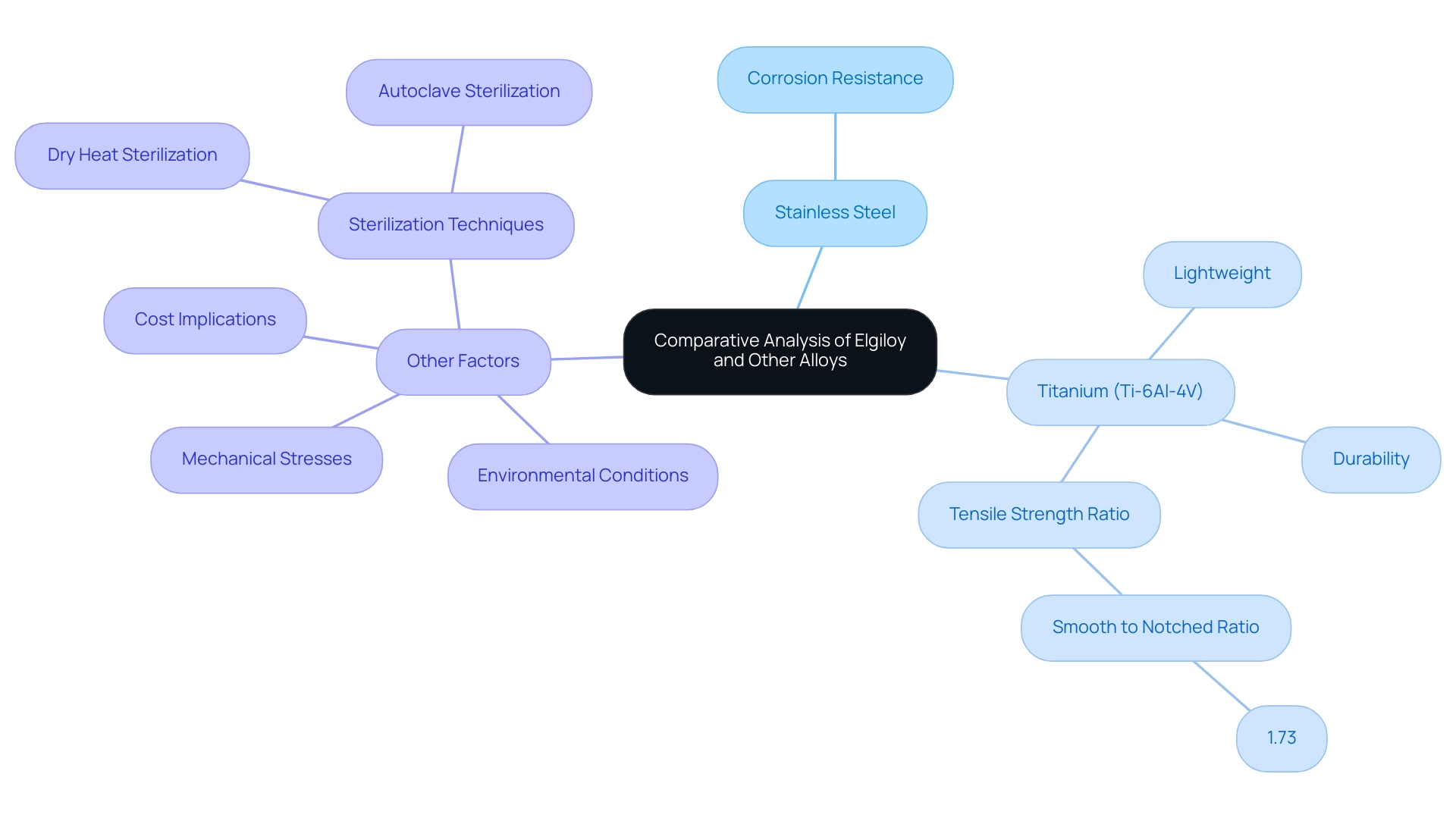

This elgiloy spring material stands out among high-performance materials when compared to substances like stainless steel and titanium, providing a compelling combination of properties essential for various applications. While stainless steel is acknowledged for its excellent corrosion resistance, this alloy significantly excels in fatigue durability and shows effective performance over a wider temperature range. On the other hand, titanium, particularly Ti-6Al-4V, which possesses a smooth tensile to notched tensile ratio of 1.73, is appreciated for its lightweight and remarkable durability; however, it may not equal the corrosion resistance of elgiloy spring material under certain conditions.

Additionally, the mechanical strengths of implantable metals, such as those enhanced by manufacturing processes and heat treatment, further illustrate how these factors influence the performance of both the elgiloy spring material and its competitors. As procurement managers navigate component selection, it is crucial to consider application-specific requirements, encompassing:

- Environmental conditions

- Mechanical stresses

- Associated cost implications

Additionally, as highlighted by Shiva Alavi in the Dental Research Journal, the influence of sterilization techniques on mechanical properties introduces another layer of complexity, emphasizing the necessity for thorough assessment to guarantee optimal performance in clinical environments.

A case study evaluating the mechanical properties of beta-titanium wires demonstrated significant differences in force during activation and deactivation, indicating varying mechanical properties that could influence clinical applications. This nuanced understanding of substance characteristics empowers procurement professionals to make informed decisions tailored to their operational needs.

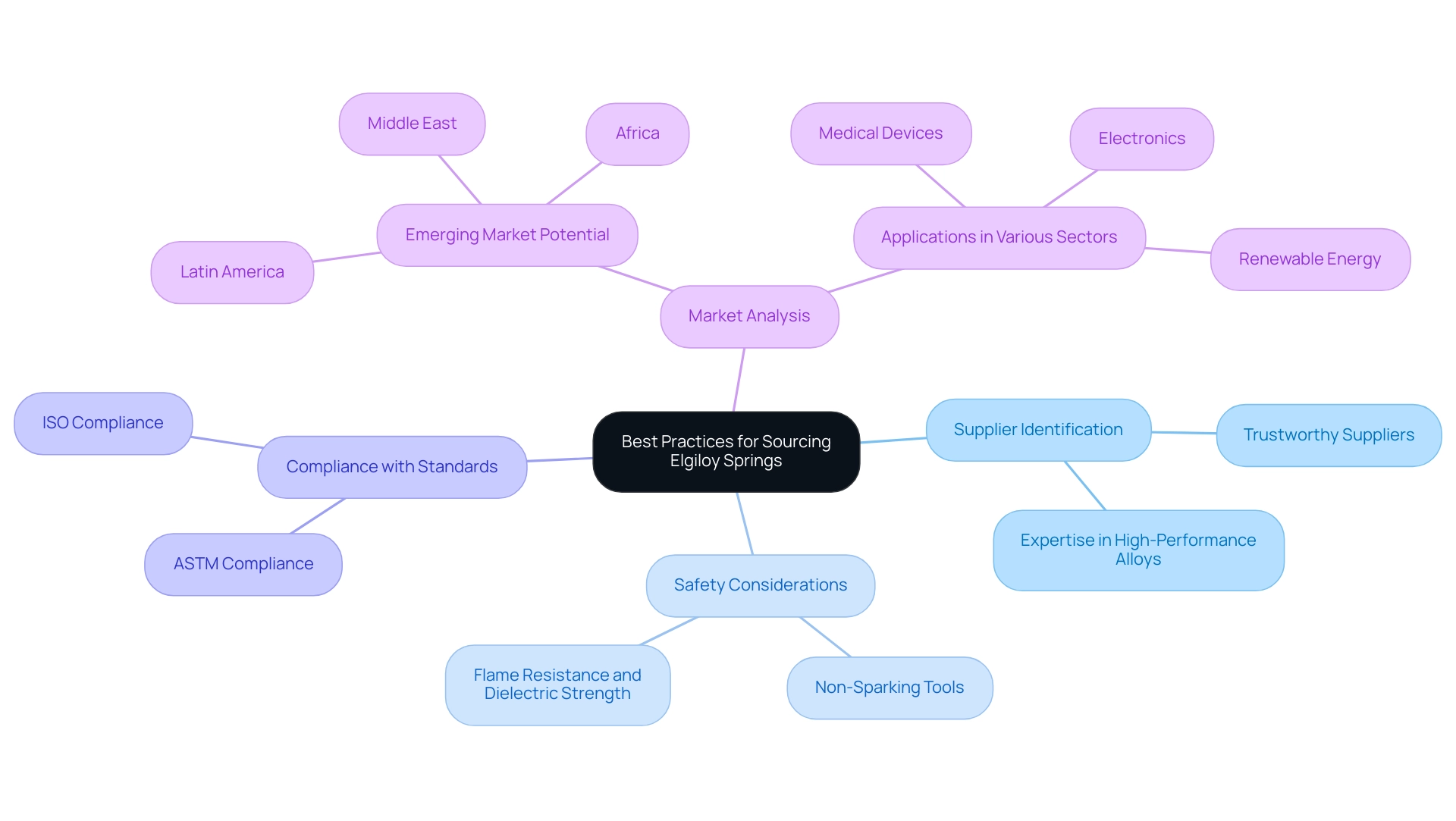

Best Practices for Sourcing Elgiloy Springs

To effectively source springs made from a specific alloy, procurement managers must prioritize identifying trustworthy suppliers with expertise in high-performance alloys and electrical insulation substances, such as Mica Tape products, which provide excellent flame resistance and dielectric strength. Creating enduring collaborations with these suppliers is crucial for guaranteeing consistent quality and dependability in the resources obtained, particularly in uses demanding high-temperature resistance. A critical aspect of supplier evaluation involves assessing compliance with international standards, including ASTM and ISO, particularly for Mica Tape products and Non-Sparking Tools, which mitigates procurement risks and enhances product integrity.

Additionally, the growing emphasis on safety in explosive environments makes non-sparking tools a key consideration for procurement managers. As Boeing’s 2020 Commercial Market Outlook forecasts a need for 43,110 new airplanes over the next twenty years, there is a considerable demand for innovative substances to improve performance, underscoring the significance of obtaining superior alloys. Negotiating favorable terms that align with organizational budgets is vital; however, this should not come at the expense of quality.

Regular performance reviews and fostering open communication with suppliers can significantly improve procurement outcomes, leading to cost savings and enhanced operational efficiency. Moreover, the regional analysis of the high-performance alloys market reveals substantial growth potential in emerging economies in Latin America, Africa, and the Middle East, necessitating customized strategies to meet diverse market needs. As high-performance alloys like elgiloy spring material discover new uses in medical devices, electronics, and renewable energy sectors, staying informed on current trends in procurement will further empower professionals to make strategic sourcing decisions.

Future Trends in Elgiloy Applications

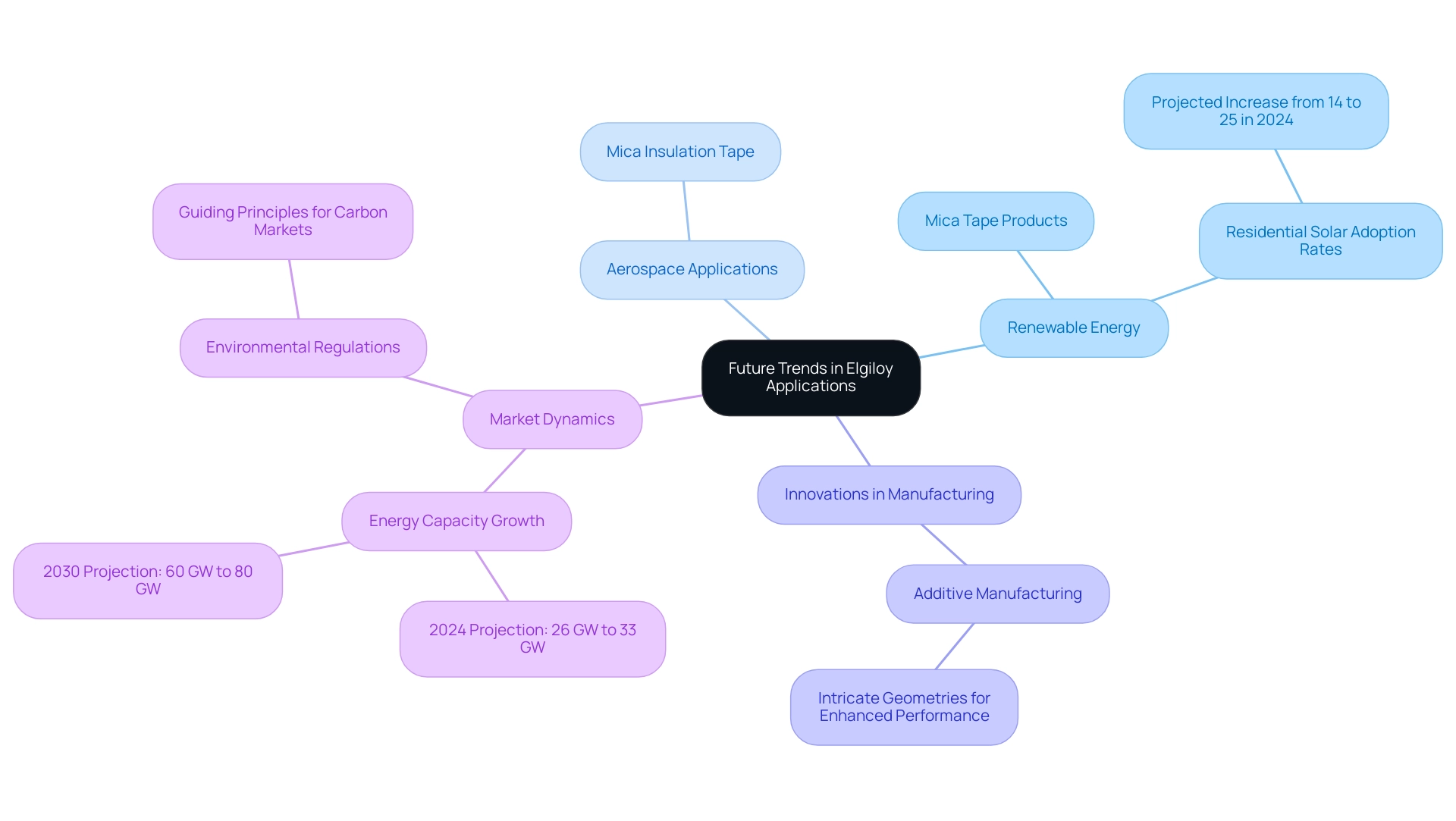

As industries keep progressing, the need for high-performance substances like Mica Tape products is expected to considerably rise, especially in the renewable energy and aerospace sectors. Mica Insulation Tape, recognized for its high-temperature resistance, flame resistance, and dielectric strength, is essential for uses ranging from household appliances to industrial machinery, ensuring reliability and durability. According to Deloitte’s analysis, energy capacity is anticipated to increase from 26 GW to 33 GW in 2024, reaching 60 GW to 80 GW by 2030, highlighting a strong market for resources such as Mica Tape that can fulfill these requirements.

Innovations in manufacturing technologies, particularly additive manufacturing, are likely to unlock new uses for elgiloy spring material, enabling the production of intricate geometries that enhance performance capabilities. Furthermore, with tightening environmental regulations and the recent guiding principles for high-integrity voluntary carbon markets, the necessity for materials that not only endure extreme conditions but are also environmentally sustainable will become increasingly pressing. The projected rise in residential solar attachment rates from 14% in 2023 to 25% in 2024 reflects a growing trend towards decentralized energy solutions, where Mica Tape products, including Mica Sheet Tape and Insulating Mica Tapes, could play critical roles in aerospace and automotive applications.

Procurement managers must remain vigilant about these evolving trends to effectively anticipate market shifts and refine their sourcing strategies, ensuring alignment with industry standards and sustainability goals.

Conclusion

Elgiloy alloy’s exceptional properties make it a critical material across diverse industries, from aerospace to medical devices. Its impressive strength, corrosion resistance, and fatigue performance position it as a superior choice compared to traditional alloys like stainless steel and titanium. The versatility of Elgiloy springs in applications such as automotive suspension systems and surgical instruments underscores the necessity for procurement managers to prioritize this high-performance material in their sourcing strategies.

As industries evolve, the demand for Elgiloy is expected to rise, particularly in the context of renewable energy and advanced manufacturing techniques. Understanding the unique benefits of Elgiloy, alongside best practices for sourcing and supplier evaluation, empowers procurement professionals to make informed decisions that enhance operational efficiency and product reliability. By embracing innovations and staying attuned to market trends, organizations can leverage Elgiloy’s advantages to meet the challenges of an increasingly demanding landscape.

In conclusion, the strategic integration of Elgiloy into material selection processes not only supports immediate operational needs but also positions companies for future growth and sustainability. As the market for high-performance materials expands, prioritizing Elgiloy will be essential for maintaining a competitive edge and ensuring the integrity of critical applications across various sectors.