Blogs

Understanding the Thermal Expansion Coefficient of Aluminum: A Complete Tutorial

Introduction

In the realm of engineering and materials science, understanding the coefficient of thermal expansion (CTE) is paramount for ensuring the performance and integrity of components across various applications. This critical metric not only influences how materials like aluminum and specialized Mica Tapes respond to temperature changes, but also shapes the strategic decisions procurement managers must make when sourcing materials.

As industries increasingly demand lightweight and high-performance solutions, the implications of thermal expansion become more pronounced, necessitating a thorough grasp of material properties and their behaviors under thermal stress. From automotive to aerospace, the ability to select the right materials can significantly impact operational efficiency and product reliability.

This article delves into the intricate dynamics of thermal expansion, offering insights into best practices for sourcing aluminum and the vital role of Mica products in enhancing safety and performance in high-temperature environments.

Understanding the Coefficient of Thermal Expansion (CTE)

The coefficient of heat increase (CTE) acts as an essential measure for comprehending how substances, including Domadia’s Mica Tapes, react to temperature fluctuations. Expressed as a fractional change in length per unit temperature change (°C or K), the CTE is pivotal in engineering applications. For instance, the thermal expansion coefficient of aluminum ranges from approximately 22 to 24 x 10^-6 /°C, which signifies considerable growth when subjected to heat.

Alternatively, zirconium possesses a heat growth coefficient of 3.2 x 10^-6 in/(in F), demonstrating the variability of heat increase among different substances. This property is particularly crucial in scenarios where temperature fluctuations are prevalent, as it directly influences fit, clearance, and the overall structural integrity of components. Domadia’s Mica Insulation Tapes, created for high-temperature resistance and electrical insulation, guarantee reliability in various applications—from home appliances to industrial machinery—by reducing the risks linked with heat growth.

These tapes offer excellent flame resistance and dielectric strength, thereby enhancing safety and performance in critical electrical insulation systems. Additionally, our Mica Sheet Tape and Insulating Mica Tapes provide robust solutions for insulating large flat surfaces and constructing coils, capacitors, and other components requiring high-grade insulation. As noted by Colin Ophus from the National Center for Electron Microscopy, robust uncertainty analysis in computational methods can yield precise localized lattice parameters, underscoring the importance of accurate CTE measurements.

Moreover, the research named ‘Mechanically Sensing and Tailoring Electronic Properties in Two-Dimensional Atomic Membranes‘ showcases practical uses of heat expansion in cutting-edge substances and systems, emphasizing how mechanical disturbances can be utilized to detect and adjust electronic attributes. Procurement and engineering experts must consider the CTE when choosing components, ensuring that their heat properties align with project specifications. Grasping these dynamics not only helps in enhancing performance but also reduces potential risks linked to material failure caused by heat stresses.

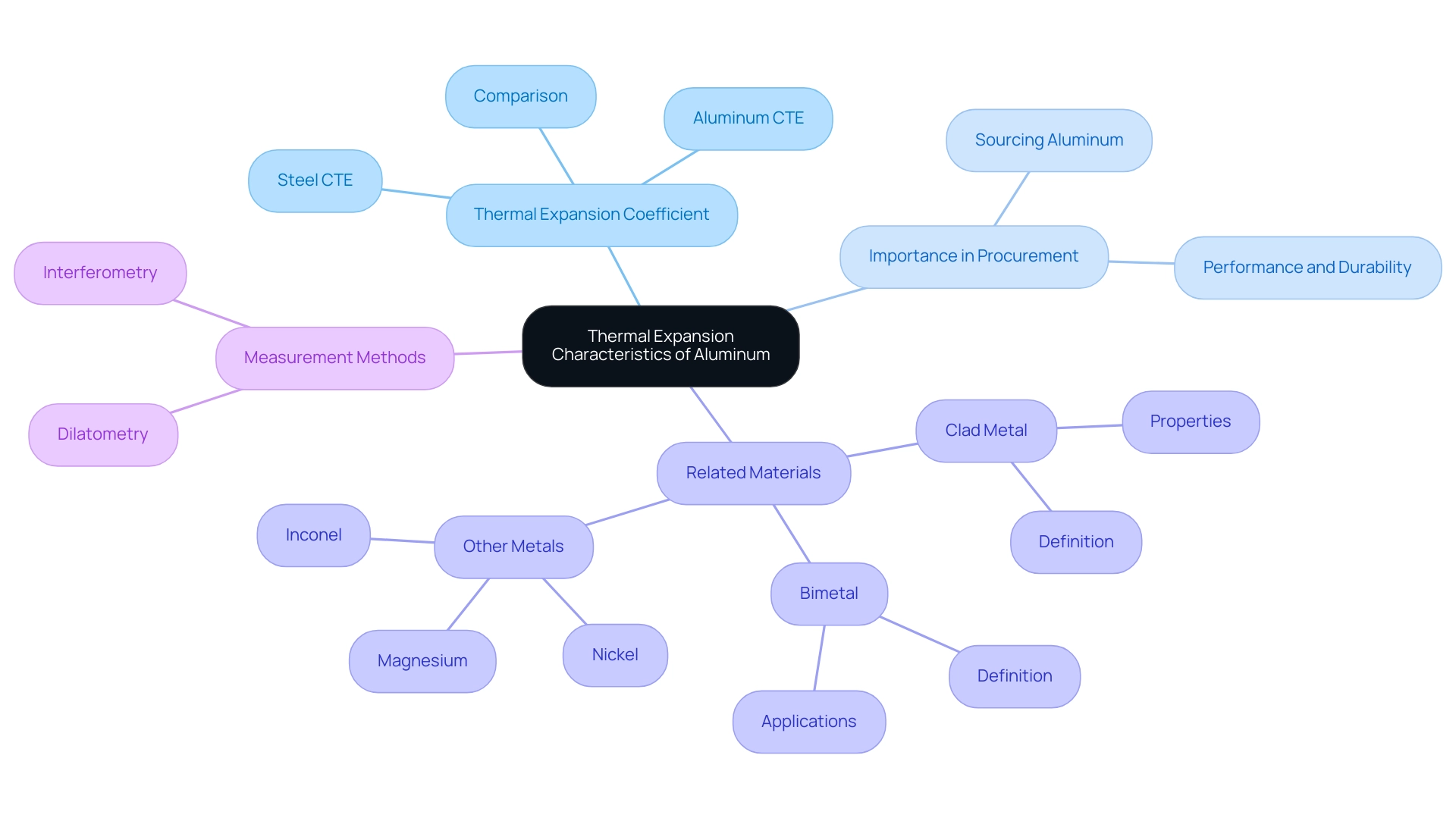

Thermal Expansion Characteristics of Aluminum

Aluminum is characterized by a significantly greater thermal expansion coefficient compared to steel, which generally possesses a CTE of about 11 x 10^-6 /°C. This increased CTE suggests that metal components require careful attention for temperature variation in settings exposed to changing temperatures, like engine parts and electronic housings. Furthermore, the consistent growth of this metal in every direction reduces the chances of warping or distortion, rendering it especially beneficial in uses demanding strict tolerances and accurate fits.

For procurement managers, it is essential to source aluminum that has a clearly defined thermal expansion coefficient. This practice not only ensures compatibility with other substances but also enhances overall performance and durability in engineering applications. Recent studies indicate that various metals, including magnesium, nickel, and Inconel, exhibit coefficients ranging from 12.3 to 29.3 (°C) and 6.8 to 16.3 (°F), further underscoring the importance of understanding these characteristics in selection.

Furthermore, Mica Tape products offer outstanding insulation characteristics for heat and electricity, including flame resistance and dielectric strength, rendering them essential for high-temperature uses in electrical engineering, such as in the production of fire-resistant cables and insulation systems. Grasping the distinctions between substances such as Clad Metal, which merges characteristics of various metals, and Bimetal, which employs differential temperature change, improves your strategic method for sourcing resources.

- Clad Metal refers to a composite substance created by bonding two or more distinct metals to combine their properties.

- Bimetal consists of two metals joined together that expand at different rates when heated, commonly used in temperature-sensitive applications like switches or thermostats.

The methods used to measure thermal expansion coefficients, such as dilatometry and interferometry, are critical for ensuring precision in these assessments, as highlighted in case studies. As the field advances, remaining updated on recent studies and innovations in metals and high-temperature substances, including Mica Tape, will be essential for enhancing procurement strategies.

Applications of Aluminum in Engineering

Aluminum’s lightweight nature and impressive strength-to-weight ratio make it a preferred material in numerous engineering applications, particularly in automotive and aerospace engineering. A detailed segmentation analysis by application, product, and vehicle type from 2019 to 2031 reveals the increasing significance of this metal in these sectors. In the automotive sector, components such as engine blocks and heat exchangers utilize the thermal expansion coefficient aluminum, allowing them to withstand significant temperature variations without sacrificing performance.

This adaptability is crucial, especially as the industry increasingly prioritizes lightweight designs to enhance fuel efficiency. Cognitive Market Research emphasizes this point by stating,

Aluminum’s lightweight properties make it ideal for enhancing fuel efficiency and performance in powertrain systems.

Furthermore, statistics indicate that Asia-Pacific is the fastest-growing area in the automotive metal market, driven by rising disposable incomes and increasing demand for lightweight vehicles.

In the realm of electronics, metal casings are favored for their ability to dissipate heat effectively. Comprehending the thermal expansion coefficient aluminum is essential for ensuring that these components fit together seamlessly during both assembly and operation. Additionally, the competitive landscape is illustrated by Wacker Chemie Ag’s recent opening of a training center in Japan, focusing on automotive and other sectors, highlighting industry engagement and innovation.

As procurement managers assess metal suppliers, it is crucial to take these applications into account to obtain materials capable of enduring the specific temperature requirements of their projects. This strategic approach not only ensures quality but also aligns with the latest trends in metal usage across industries.

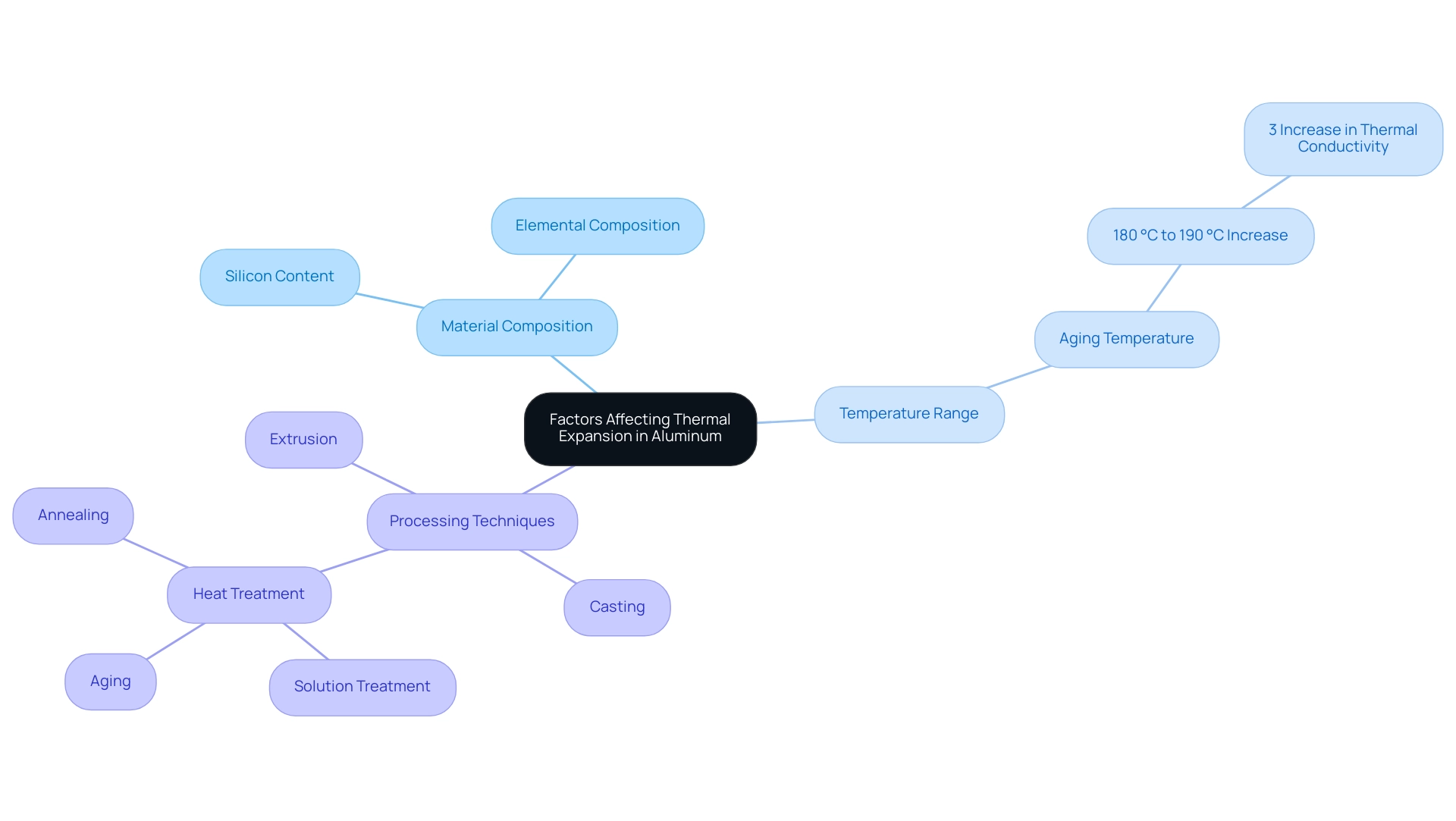

Factors Affecting Thermal Expansion in Aluminum

The heat increase of a specific metal is affected by various elements, such as material composition, temperature range, and processing techniques. Each metal alloy exhibits unique thermal expansion coefficient aluminum values that are closely associated with their elemental composition. For example, a rise in silicon content within an alloy can result in changes in expansion behavior compared to that of pure aluminum.

Moreover, the manufacturing processes—such as extrusion or casting—play a pivotal role in determining the characteristics of the substance. These processes can introduce residual stresses, which further influence the alloy’s response to temperature fluctuations.

Grasping these dynamics is essential for procurement managers responsible for sourcing materials that meet specific performance standards related to heat. For instance, recent research emphasizes that the aging temperature can significantly influence the heat conductivity of alloy materials; raising the aging temperature from 180 °C to 190 °C has been demonstrated to enhance heat conductivity by roughly 3%. This corresponds with results from the case study titled ‘Effects of Heat Treatment on Conductivity,’ which shows that appropriate heat treatment can enhance both conductivity and mechanical characteristics of alloys.

Moreover, the heat conductivity of Al-Ni is roughly 35 W/m, offering a tangible illustration of conductivity values in alloy metals.

These insights illustrate the importance of not only selecting the right alloy but also considering processing methods to optimize performance. The latest research highlights that alloy composition, especially in aluminum alloys, can significantly change the thermal expansion coefficient aluminum values, making it crucial for professionals to stay informed about ongoing advancements in material science to ensure that sourced aluminum meets the strict temperature requirements necessary for their applications. As noted by Y.L., effective supervision and project administration are critical in steering such research initiatives, ensuring that procurement managers have access to the most relevant and authoritative information.

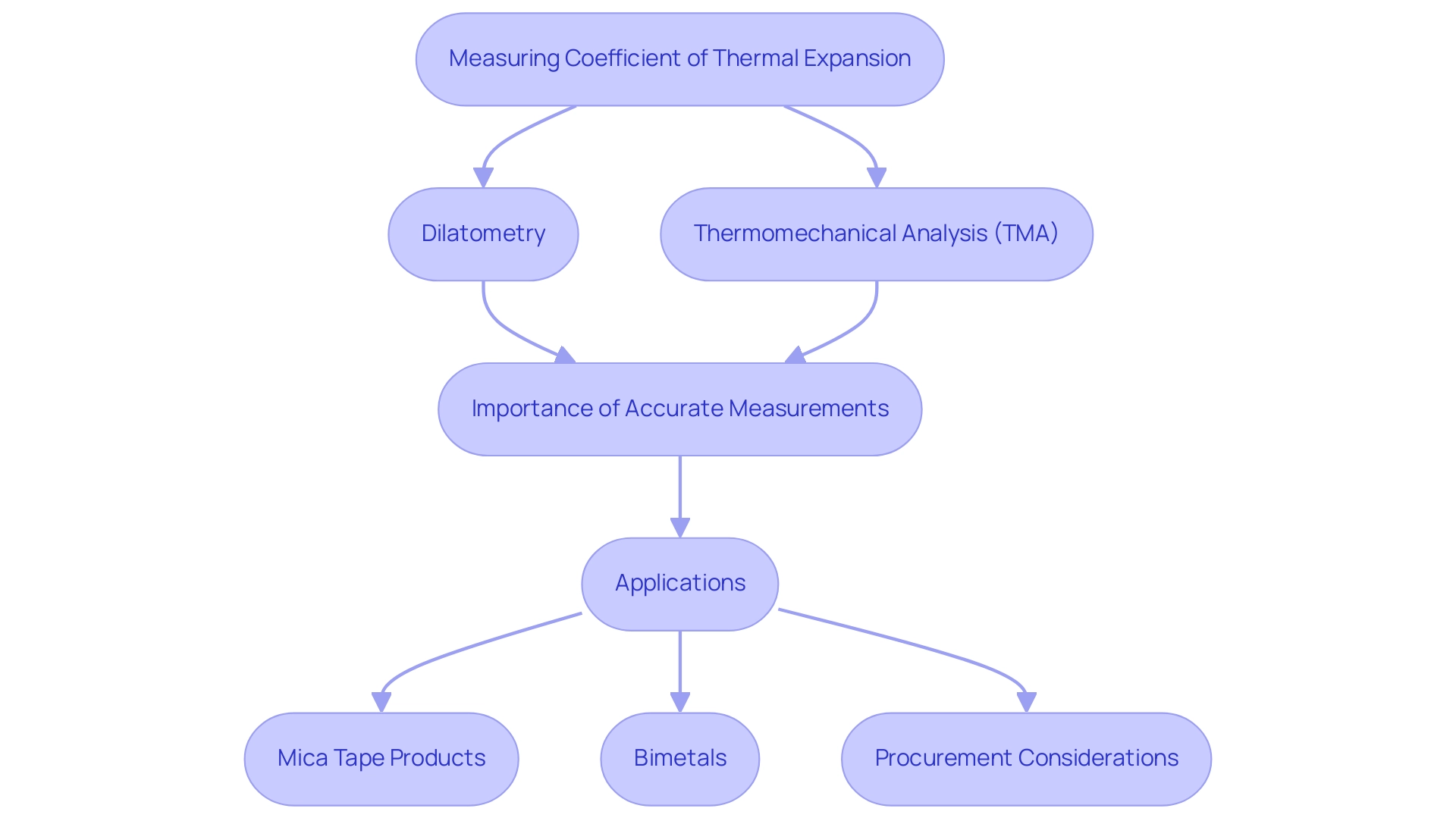

Measuring the Coefficient of Thermal Expansion

The thermal expansion coefficient aluminum is a critical parameter that requires precise measurement, typically achieved through techniques such as dilatometry and thermomechanical analysis (TMA). In dilatometry, a specimen is subjected to controlled temperature variations, and the resulting dimensional changes are meticulously recorded, focusing on capturing length changes crucial for understanding thermal behavior. Conversely, TMA functions by applying a constant load to the substance as it is heated, facilitating the measurement of dimensional alterations under stress.

Both methods adhere to standardized protocols that ensure accuracy and repeatability in results. As highlighted in a recent review, ‘after the growth process, the WSe sample was naturally cooled to room temperature,’ emphasizing the importance of accurate measurements during temperature fluctuations. For procurement managers, a thorough understanding of these measurement techniques is essential when evaluating specifications and certifications.

This knowledge is essential to ensure that sourced metal products meet necessary performance characteristics, guaranteeing reliability in applications exposed to temperature variations. Furthermore, exploring Domadia’s Mica Tape products reveals their high-temperature resistance and superior electrical insulation properties, making them ideal for critical applications in electrical engineering. These tapes excel not only in flame resistance and dielectric strength but also in their application across various sectors.

For instance, Mica Insulation Tape is widely used in household appliances, ensuring safety and efficiency, while Mica Sheet Tape provides robust solutions for insulating large flat surfaces in challenging environments, such as aerospace and automotive industries. Additionally, understanding the mechanisms of bimetals, which consist of two metals joined together that expand at different rates when heated, is crucial for applications in temperature-sensitive devices that rely on the thermal expansion coefficient aluminum. This knowledge complements the differentiation between clad metal as a composite substance and bimetal, providing procurement managers with comprehensive insights into performance and safety requirements.

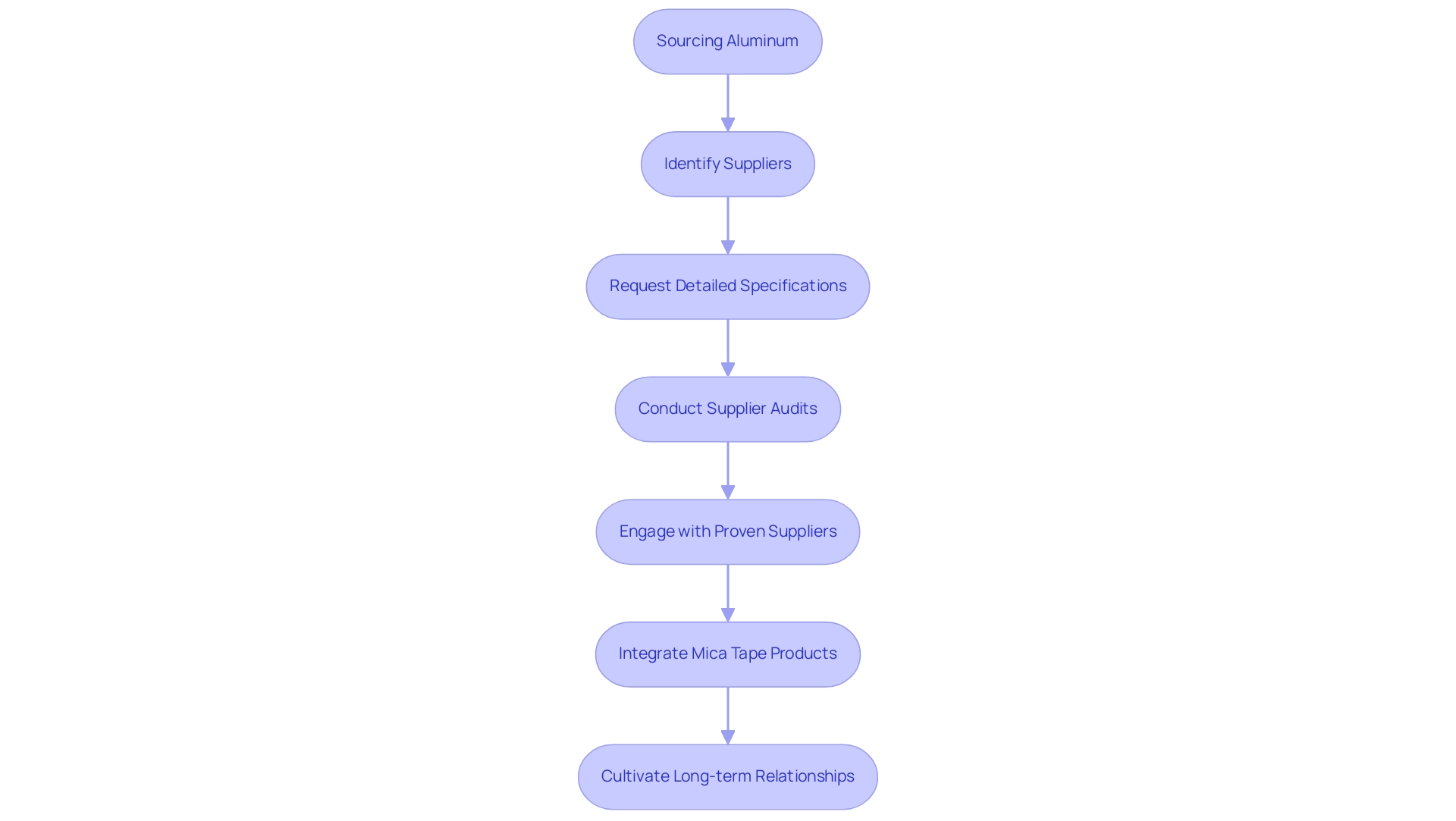

Best Practices for Sourcing Aluminum

For procurement managers, it is essential to prioritize suppliers who provide detailed specifications, including the thermal expansion coefficient aluminum, when sourcing aluminum. Engaging with suppliers that have demonstrated a robust track record in quality assurance and adherence to international standards is crucial. Notably, integrating high-quality insulation substances like Mica Tape—designed for high-temperature resistance and electrical insulation—can significantly enhance product reliability in diverse applications.

Mica Tape products, such as Mica Insulation Tape, Mica Tape for Electrical, and Mica Sheet Tape, each offer unique advantages, including flame resistance and high mechanical strength, which are vital for applications in fire-resistant cables and electrical insulation systems. Conducting regular supplier audits and requesting sample products can act as effective methods for verifying performance claims, ensuring the substances meet required thermal specifications. Furthermore, cultivating long-term relationships with suppliers can enhance negotiation leverage and facilitate access to specialized alloys tailored to specific project needs.

As highlighted in the recent Sheet and Plate Shipments report updated on December 23, 2024, staying informed about market trends can significantly impact sourcing decisions. Additionally, as illustrated in the case study titled ‘Demonstrating Empathy to Unhappy Clients,’ building trust through empathy can enhance supplier relationships, ensuring smoother negotiations and collaboration. By consistently reviewing and refining sourcing strategies in response to evolving project requirements and market dynamics, procurement managers can secure materials characterized by superior quality and performance.

Moreover, ensuring that a team with diverse economic knowledge is aligned can further strengthen procurement strategies. As one procurement specialist aptly stated,

Keep your data accurate even when under tight deadlines with these practical strategies. Automate tasks, verify sources, and take short breaks.

This highlights the necessity of maintaining rigorous standards in supplier evaluations and quality assurance within aluminum procurement, especially with respect to the thermal expansion coefficient aluminum.

Conclusion

Understanding the coefficient of thermal expansion (CTE) is essential for procurement managers navigating the complexities of material selection, particularly in industries where temperature fluctuations are a given. The article emphasizes the significant role that CTE plays in ensuring the performance and integrity of materials such as aluminum and Mica Tapes. By recognizing how different materials respond to thermal stresses, professionals can make informed decisions that enhance the reliability and efficiency of their applications.

The insights provided highlight the importance of sourcing aluminum with clearly defined thermal properties, as well as the advantages of integrating high-quality insulation materials like Mica Tape. These products not only offer exceptional thermal and electrical insulation but also contribute to safety and performance in high-temperature environments. The strategic approach to procurement discussed throughout the article underscores the necessity of understanding both material characteristics and supplier capabilities to optimize project outcomes.

Ultimately, staying informed about the latest research and best practices in thermal expansion and material science is crucial for procurement managers. By prioritizing comprehensive supplier specifications and fostering strong relationships with reliable vendors, professionals can secure materials that meet rigorous thermal performance standards. This proactive approach not only mitigates risks associated with material failure but also drives operational efficiency and innovation in engineering applications across various sectors.