Blogs

Best Practices for Using HyMu80 Magnetic Permeability in Shielding Sensitive Electronic Equipment

Overview:

The best practices for using HyMu80 magnetic permeability in shielding sensitive electronic equipment include proper processing to maintain its magnetic properties, careful design of shield geometry, and ensuring a tight fit to prevent gaps that could allow interference. The article supports this by discussing the critical role of these practices in enhancing shielding effectiveness, alongside the integration of complementary materials like Mica Tapes to further improve protection against electromagnetic interference.

Introduction

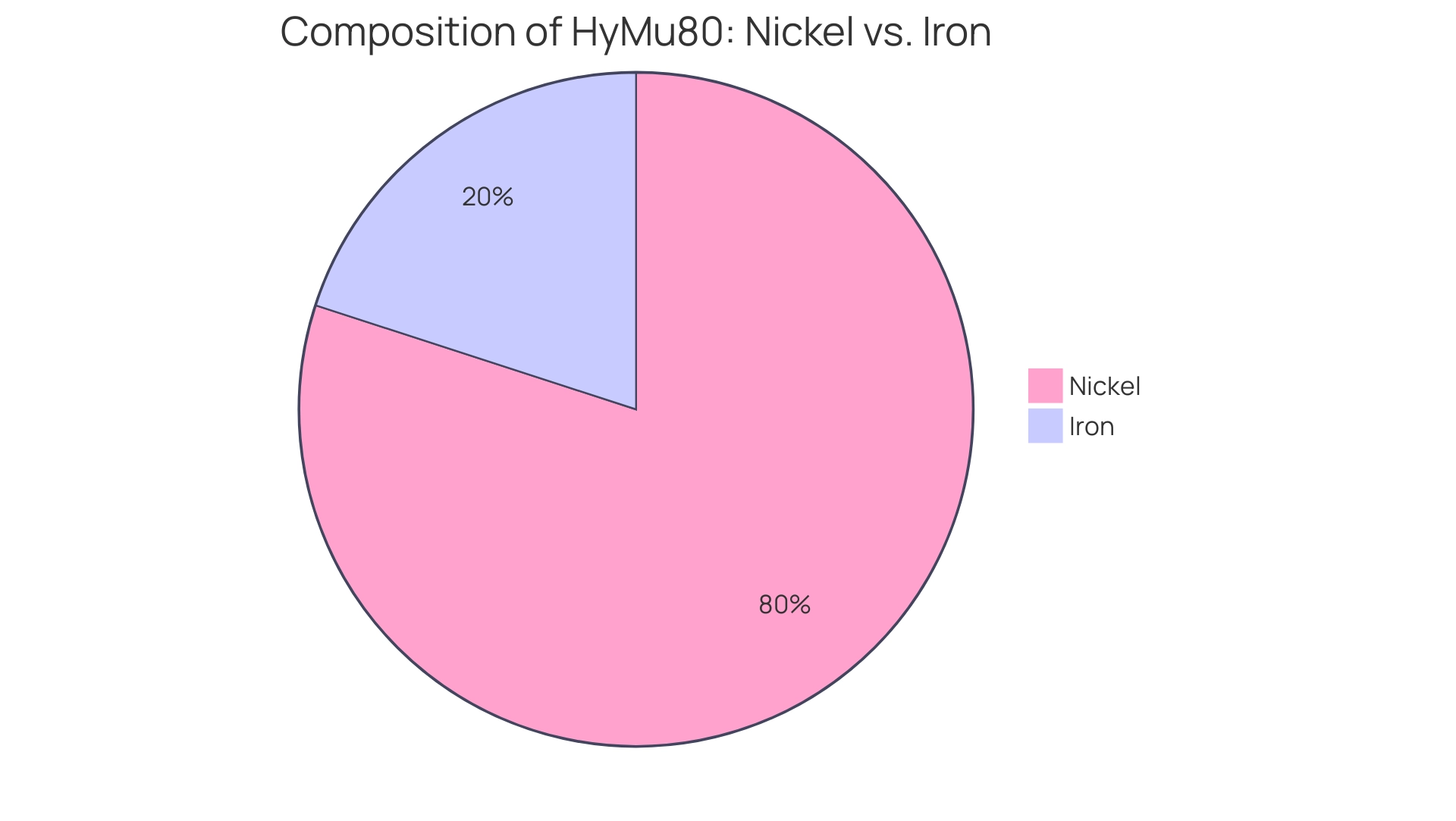

In the realm of electronic shielding, the choice of materials can significantly influence performance and reliability. HyMu80, a nickel-iron alloy renowned for its impressive magnetic permeability, has emerged as a leading solution for protecting sensitive electronic components from electromagnetic interference. With a composition that boasts 80% nickel and 20% iron, this alloy not only minimizes energy loss during magnetic cycles but also enhances the efficiency of vital applications like transformers and inductors.

As procurement managers navigate the complexities of material selection, understanding the unique properties and applications of HyMu80 becomes essential. This article delves into the composition, applications, best practices, challenges, and future trends associated with HyMu80, providing valuable insights for decision-makers seeking to optimize their electronic shielding strategies.

Understanding HyMu80: Composition and Key Properties

A nickel-iron mixture consisting of around 80% nickel and 20% iron is highly valued for its hymu80 magnetic permeability for shielding sensitive electronic equipment, which is an essential characteristic for efficiently protecting these devices. According to recent studies, the hymu80 magnetic permeability for shielding sensitive electronic equipment significantly surpasses that of many competing materials, making it a preferred choice in the industry. The metal’s low hysteresis loss, which refers to the energy dissipated during magnetic cycles, is particularly advantageous in high-efficiency applications such as transformers and inductors.

Kevin D. Costa, a specialist in the field, observes, ‘The HyMu80 magnetic permeability for shielding sensitive electronic equipment is essential for its unique composition, which enables outstanding performance in electromagnetic protection and ensures the safety of sensitive electronics.’ This efficiency is crucial for procurement specialists who must assess the alloy’s performance in various shielding scenarios. Furthermore, case studies, including the traction force microscopy analysis, illustrate the effectiveness of this material in real-world scenarios, showing its strong relationship with the stiffness and performance of electronic components.

By comprehending these traits, decision-makers can effectively assess its suitability for particular uses, ensuring optimal safeguarding of electronic components against electromagnetic interference.

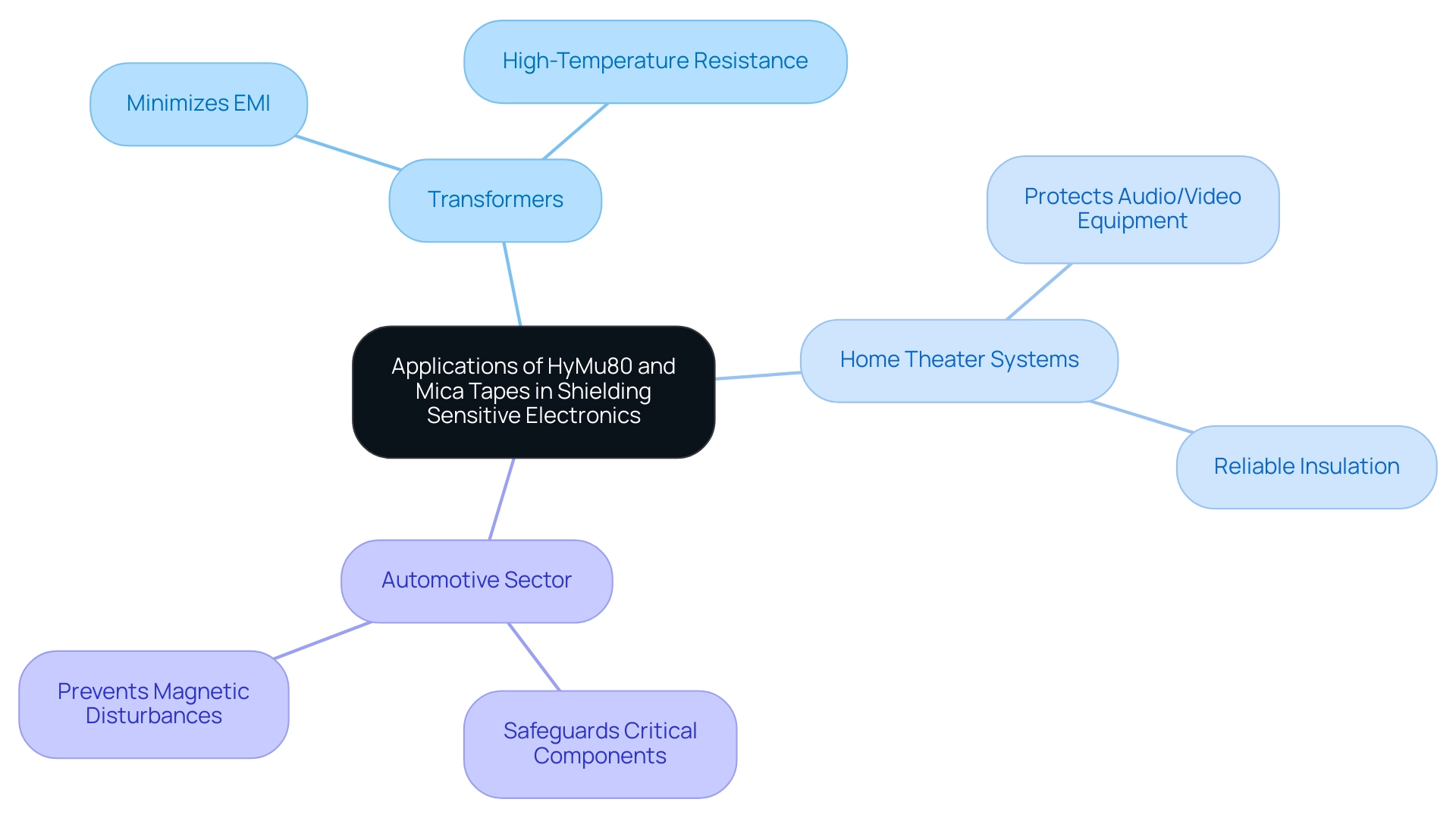

Applications of HyMu80 in Shielding Sensitive Electronics

HyMu 80 is recognized as a premier solution due to its hymu80 magnetic permeability for shielding sensitive electronic equipment. This alloy is commonly used in various uses such as transformers, where it plays a crucial role in minimizing electromagnetic interference (EMI). Complementing this, Domadia’s Mica Tape products, including Mica Sheet Tape and Insulating Mica Tapes, offer high-temperature resistance and excellent electrical insulation, making them ideal for use in systems that require both thermal stability and safety.

These tapes offer exceptional flame resistance and dielectric strength, crucial for electrical uses needing extra safety precautions against fire hazards. In home theater systems, the device effectively protects audio and video equipment from disruptive external magnetic fields, while Mica Tapes provide reliable insulation for critical components, ensuring superior performance. Furthermore, its use extends into the automotive sector, where it safeguards critical components—including sensors and control units—against magnetic disturbances that could compromise functionality.

These practical uses not only showcase the substantial impact of this product in improving electronic performance but also emphasize how Mica Tapes guarantee adherence to stringent industry standards for electromagnetic compatibility (EMC). Specialists in the area have acknowledged the use of this material as crucial in attaining optimal protection solutions, and when combined with Mica Tapes, they enhance the overall efficiency of electrical insulation in high-temperature applications.

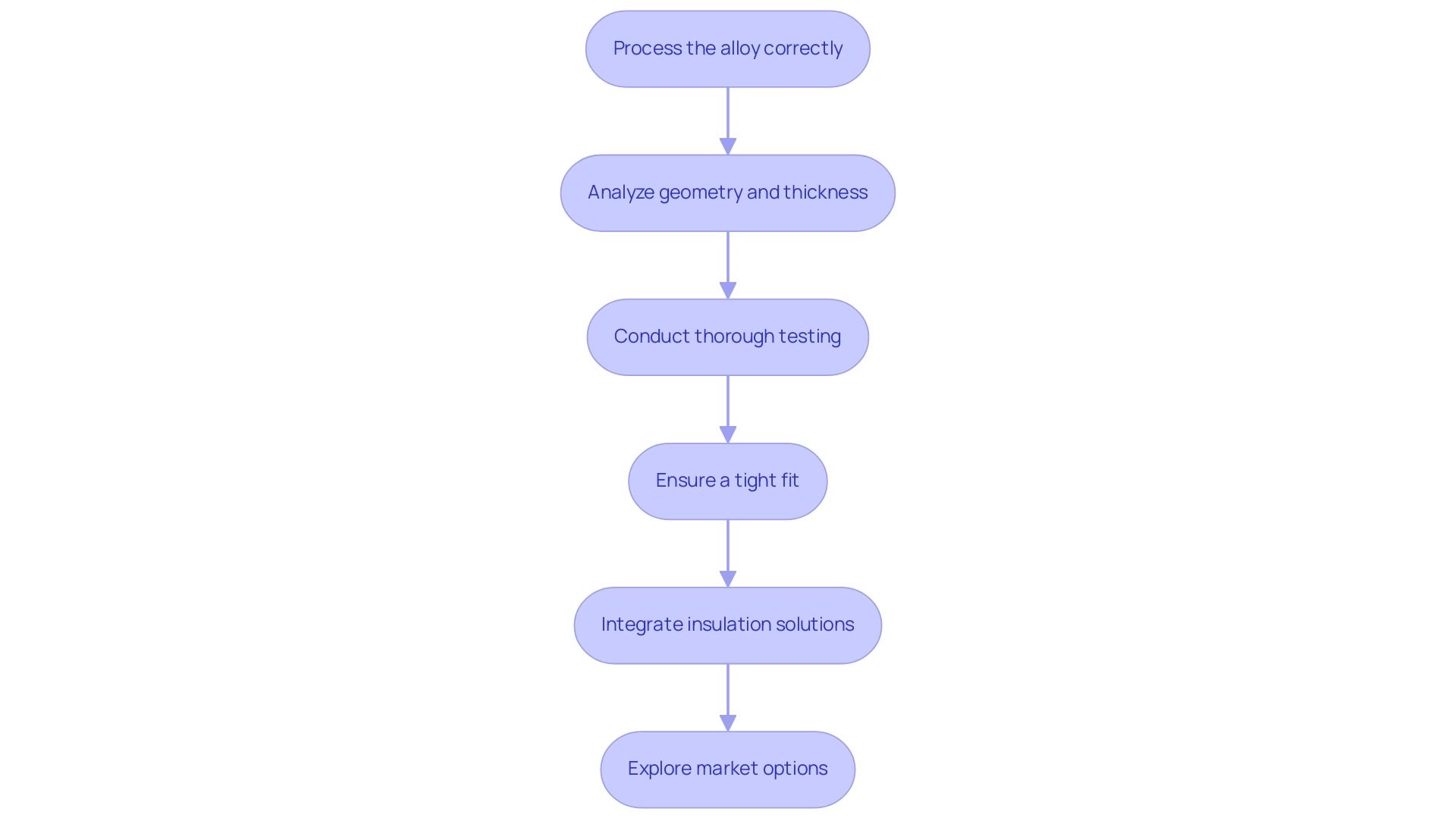

Best Practices for Implementing HyMu80 in Shielding Solutions

Implementing HyMu 80 in protective solutions requires adherence to several best practices to ensure maximum effectiveness. Firstly, it is essential to process the alloy correctly to preserve its magnetic properties, avoiding excessive heat during fabrication that could compromise performance. As noted by Allan Moulton, materials that summon ‘buckets full of colorful timbre detail and contrast’ can significantly enhance the overall performance of sensitive electronics.

Secondly, the geometry of the shield plays a critical role; the shape and thickness significantly impact shielding effectiveness. It is advisable to conduct thorough testing to identify the optimal configuration tailored to particular uses. Furthermore, achieving a tight fit between the HyMu 80 shield and the protected equipment is crucial, as any gaps may permit magnetic interference, diminishing the shield’s effectiveness.

For example, the Shunyata Research Omega USB is considered one of the best products in its category, successfully eliminating common issues found in USB interfaces and delivering stunning dynamics and deep bass extension. Furthermore, integrating high-temperature electrical insulation solutions like Domadia’s Mica Tapes can further improve the efficiency and dependability of protective uses. Market options such as the Synergistic Research HFT, priced at $299 for a 5-pack, also provide viable solutions for those seeking to invest in effective protective materials.

By adhering to these best practices and considering the advantages of Mica Tapes, practitioners can significantly enhance the shielding performance of HyMu 80 magnetic permeability for shielding sensitive electronic equipment, ensuring robust protection across various electronic uses. To explore our range of Mica Tapes and learn more about how they can benefit your business, visit our website or contact our expert team today. Furthermore, copper nickel mixtures are extensively utilized in marine engineering and automotive systems because of their outstanding corrosion resistance and adaptability in numerous uses, rendering them a significant factor for procurement managers.

Challenges and Considerations in Using HyMu80

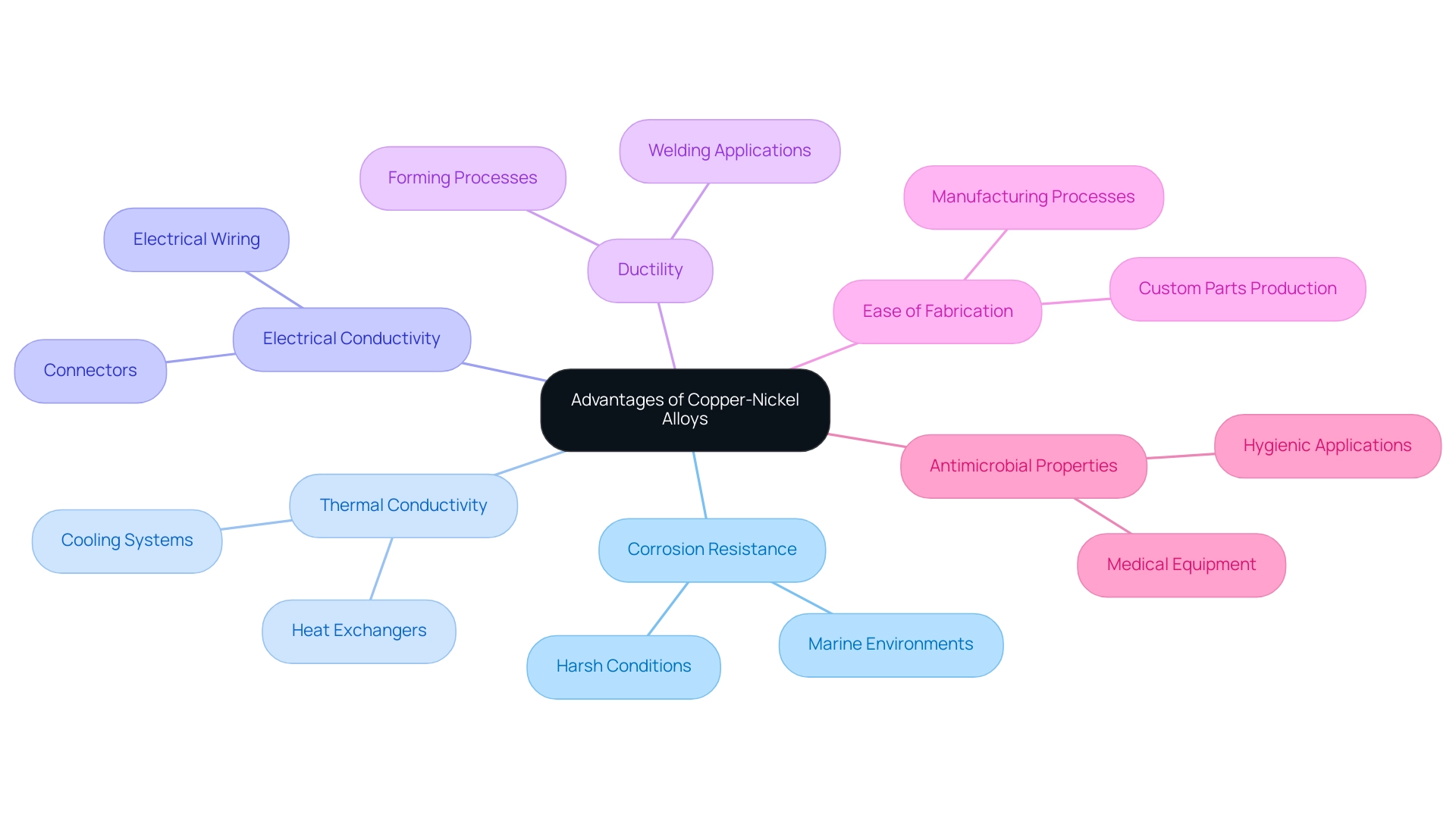

Q: What are the main advantages of using copper nickel mixtures?

A: Copper nickel alloys provide numerous important benefits, especially in marine environments and electrical uses. They exhibit high resistance to corrosion, making them superior to stainless steel in harsh conditions.

Additionally, their excellent thermal and electrical conductivity, good ductility, and ease of fabrication enhance their suitability for various applications. Notably, their antimicrobial properties are crucial for environments where hygiene is paramount.

Future Trends in Magnetic Shielding Materials

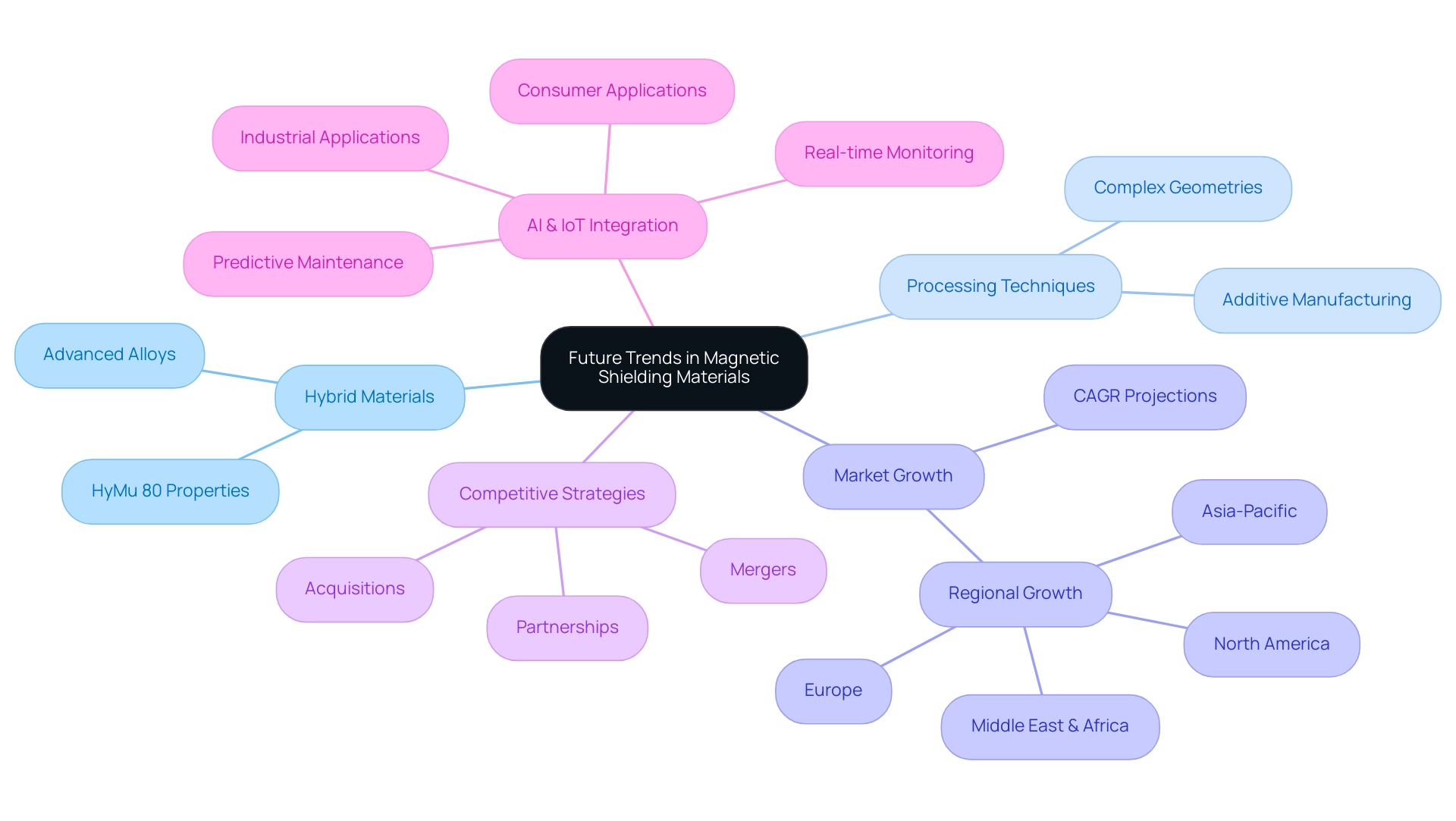

The landscape of magnetic protection materials is rapidly advancing, driven by the need for enhanced performance and usability in increasingly sophisticated electronic devices. A significant trend on the horizon is the emergence of hybrid materials that synergize the properties of HyMu 80 with advanced alloys. This combination aims to improve protection effectiveness while achieving weight reduction, which is critical in compact electronic designs.

Furthermore, innovations in processing techniques—particularly additive manufacturing—are poised to revolutionize the field, facilitating the creation of complex geometries that optimize magnetic shielding to cater to the evolving demands of the industry. The global Amorphous Magnetic Shielding Sheet market is expected to see significant growth across North America, Europe, Asia-Pacific, and the Middle East & Africa, indicating a steady growth trajectory in this sector. According to industry reports, the competitive strategies of major players include:

- Mergers

- Acquisitions

- Partnerships

alongside product innovations that help stakeholders anticipate shifts in the market and remain competitive.

The integration of AI and IoT technologies is also gaining traction, as illustrated by a case study on the integration of these technologies in Soft Magnetic Shielding Materials Solutions, which demonstrates real-time monitoring and predictive maintenance. These smart solutions not only improve operational efficiency but also enhance results. As we look toward 2024 and beyond, continual advancements in materials technology will ensure that the HyMu80 magnetic permeability for shielding sensitive electronic equipment and similar alloys remain essential in safeguarding sensitive electronics against electromagnetic interference, meeting the high standards expected in today’s electronic applications.

Conclusion

The exploration of HyMu80 as a premier nickel-iron alloy reveals its pivotal role in enhancing electronic shielding solutions. With its remarkable composition of 80% nickel and 20% iron, HyMu80 exhibits exceptional magnetic permeability and low hysteresis loss, making it a superior choice for protecting sensitive electronic components from electromagnetic interference. The alloy’s applications span various sectors, including:

- Transformers

- Automotive systems

- Home theater setups

where it effectively minimizes disruptive magnetic fields and ensures optimal performance.

Implementing HyMu80 requires adherence to best practices, including careful processing and precise geometry to maximize shielding effectiveness. The integration of complementary materials, such as Mica Tapes, further enhances the reliability and safety of shielding solutions, demonstrating the importance of a strategic approach in material selection. While challenges exist, such as maintaining the alloy’s properties during fabrication, the ongoing advancements in magnetic shielding materials and processing techniques promise to address these issues and expand the potential of HyMu80.

As the industry evolves, the future of magnetic shielding is characterized by the emergence of hybrid materials and innovative processing methods, which will enhance performance while accommodating the compact designs of modern electronics. The anticipated growth in the magnetic shielding materials market underscores the importance of staying informed about these trends, ensuring that procurement managers can make strategic decisions that align with the demands of contemporary electronic applications. In conclusion, leveraging the advantages of HyMu80 and remaining adaptable to emerging technologies will be crucial for optimizing electronic shielding strategies in an increasingly complex landscape.