Blogs

Understanding the High Electrical and Thermal Conductivity of Beryllium Copper: A Tutorial for Low Wear & Tear Bearing Applications

Overview:

The article focuses on the high electrical and thermal conductivity of beryllium copper and its suitability for low wear and tear bearing applications. It supports this by detailing the alloy’s impressive conductivity levels, mechanical strength, and resistance to wear and corrosion, making it an ideal choice for performance-critical environments such as aerospace and automotive industries.

Introduction

The significance of beryllium copper in modern engineering cannot be overstated, as its remarkable electrical and thermal conductivity positions it as a vital material across various high-performance applications. With conductivity levels that rival pure copper and exceptional resistance to wear, this alloy is increasingly favored in sectors ranging from aerospace to industrial machinery.

As procurement managers navigate the complexities of material selection, understanding the unique properties and advantages of beryllium copper becomes essential. This article delves into the multifaceted applications of beryllium copper, comparing it with alternative materials, exploring manufacturing processes, and outlining best practices for sourcing.

By equipping decision-makers with comprehensive insights, it facilitates informed choices that enhance operational efficiency and ensure quality in performance-critical environments.

Exploring the Electrical and Thermal Conductivity of Beryllium Copper

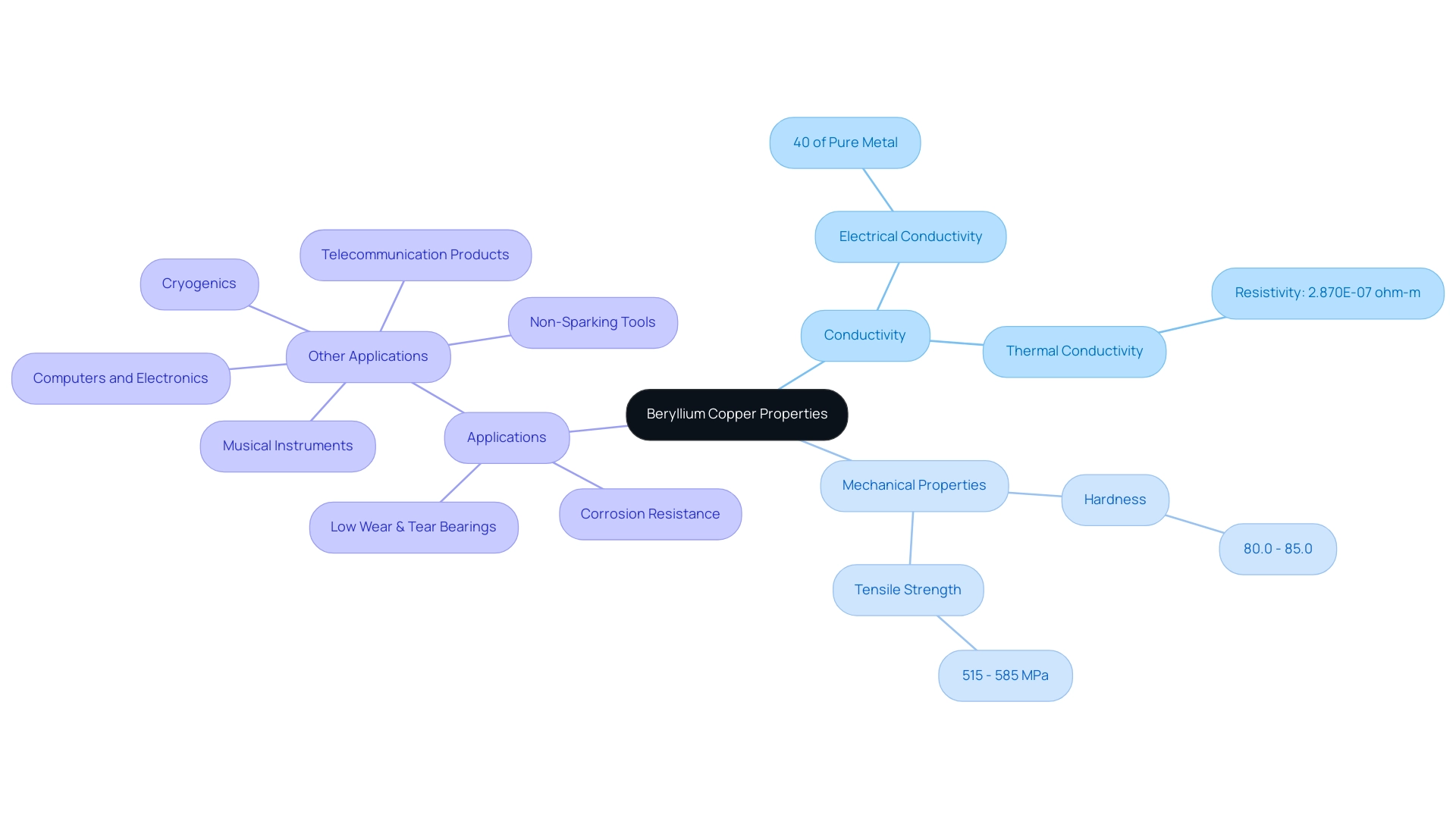

Beryllium alloy is renowned for its outstanding electrical and thermal conductivity, establishing itself as a critical material in various engineering applications. With conductivity levels reaching approximately 40% of that of pure metal, this alloy excels in efficiently transmitting electricity and heat. Notably, the C75200 copper alloy boasts a resistivity of 2.870-07 ohm-m, providing a quantitative basis for its conductivity discussion.

Such capabilities are particularly beneficial in low wear and tear bearing uses, thanks to the high electrical and thermal conductivity of beryllium copper for bearings in low wear & tear applications, where effective thermal management and electrical performance are paramount. The mechanical characteristics of UNS C17200 further demonstrate the strength and resilience of this alloy, with a Rockwell hardness of 80.0 – 85.0 and ultimate tensile strength of 515 – 585 MPa, making it appropriate for performance-critical applications. Furthermore, this alloy is acknowledged for its outstanding resistance to corrosion, which is essential for durability in challenging conditions.

Domadia’s commitment to producing Copper Plates that meet international standards such as UNS and ASTM ensures that our clients receive only the highest quality solutions. The high electrical and thermal conductivity of beryllium copper for bearings in low wear & tear applications is crucial in dissipating heat generated during mechanical operations, thereby enhancing both the longevity and reliability of components. As procurement managers, understanding these characteristics is essential for optimizing material selection in performance-critical contexts and ensuring adherence to modern engineering demands.

Domadia stands at the forefront of this industry by continually providing innovative, tailored solutions designed to meet the rigorous requirements of our clients.

Applications of Beryllium Copper in Low Wear & Tear Bearings

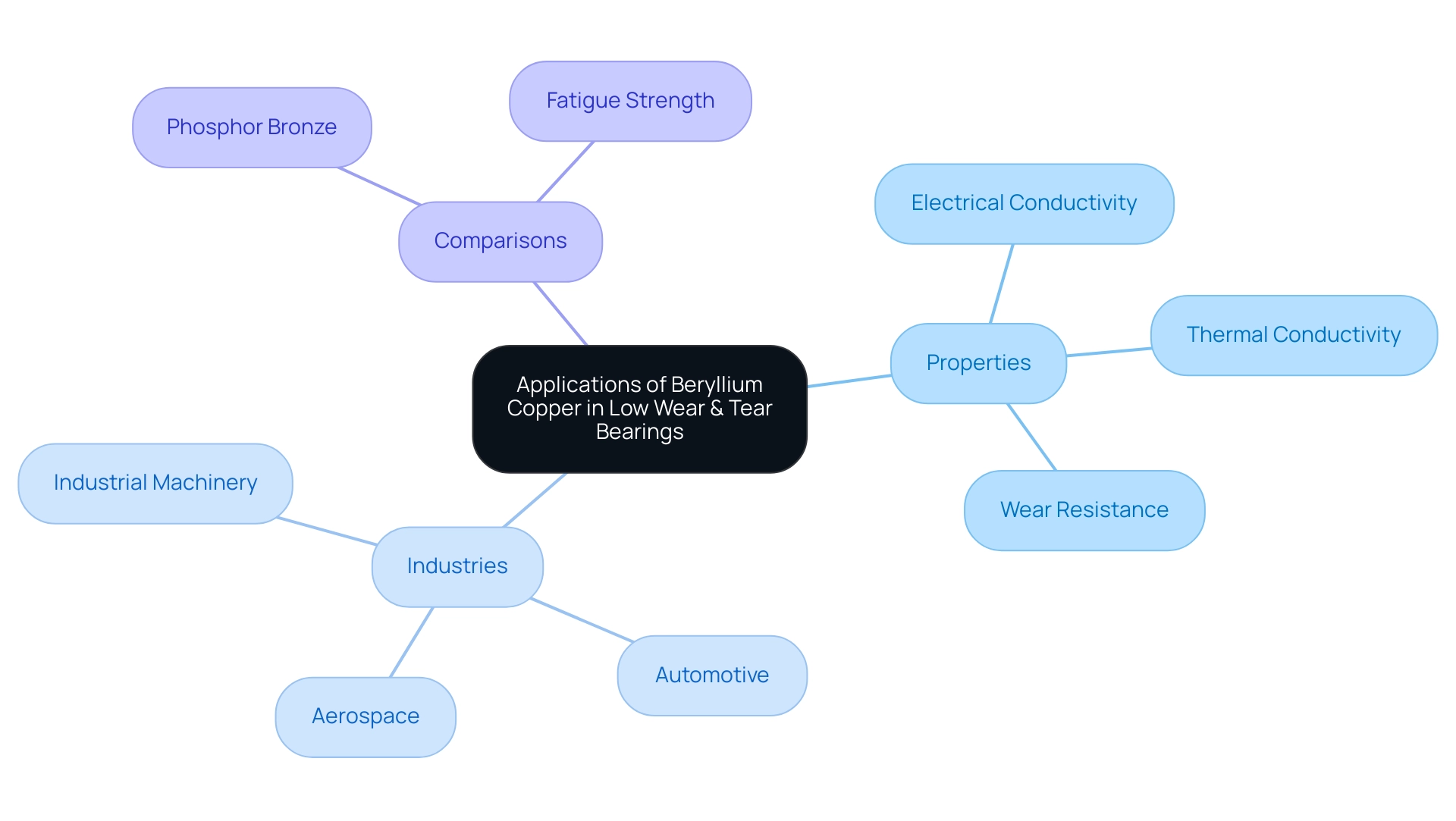

This alloy, known for the high electrical and thermal conductivity of beryllium copper for bearings in low wear & tear applications, has become a favored option in low wear and tear bearing uses, especially in high-performance fields like aerospace, automotive, and industrial machinery. Its remarkable resistance to wear and ability to retain strength under elevated temperatures render it ideal for components subjected to continuous friction. Domadia’s commitment to providing high-quality, customized Beryllium Copper Plates ensures that your projects benefit from materials tailored to your specific needs.

Our competitive pricing starts at $XX per unit, and we maintain a robust inventory to meet your demands efficiently. A recent case study titled ‘Growth and Investment Prospects in Copper-Beryllium Alloys’ highlights the increasing demand for high-performance materials in these industries, indicating favorable prospects for investment in copper-beryllium alloys. When contrasted with phosphor bronze, beryllium metal exhibits superior mechanical characteristics, including improved fatigue resistance and minimized thermal expansion—essential factors in precision-engineered uses.

Statistics indicate that beryllium alloy displays fatigue strength roughly 50% superior to that of phosphor bronze, rendering it a more dependable option for demanding applications. The high electrical and thermal conductivity of beryllium copper for bearings in low wear & tear applications aids in efficient heat dissipation in electric motor bearings, significantly lowering the risk of overheating and thereby prolonging motor life. As aerospace engineer Dr. Jane Smith states, ‘The unique properties of beryllium copper make it indispensable in our designs, especially where reliability and performance are paramount.’

Moreover, the Non-Sparking Wrench, created with safety as a priority, guarantees that tasks in dangerous environments can be carried out without the threat of sparks. This alloy’s adaptability allows for its use in a variety of components, such as bushings, thrust washers, and rotor parts, effectively meeting the stringent requirements of contemporary engineering applications. A pleased client stated, ‘Domadia’s alloy products have greatly enhanced our project results, due to their quality and dependability.’

As the market for high-performance materials continues to expand, the strategic benefits of beryllium alloy in aerospace and automotive contexts are increasingly acknowledged, paving the way for further investment and innovation. Reach out to Domadia today to discover our inventory and pricing information for Copper products, and experience the difference quality and expertise can bring to your next project.

Comparing Beryllium Copper to Other Materials

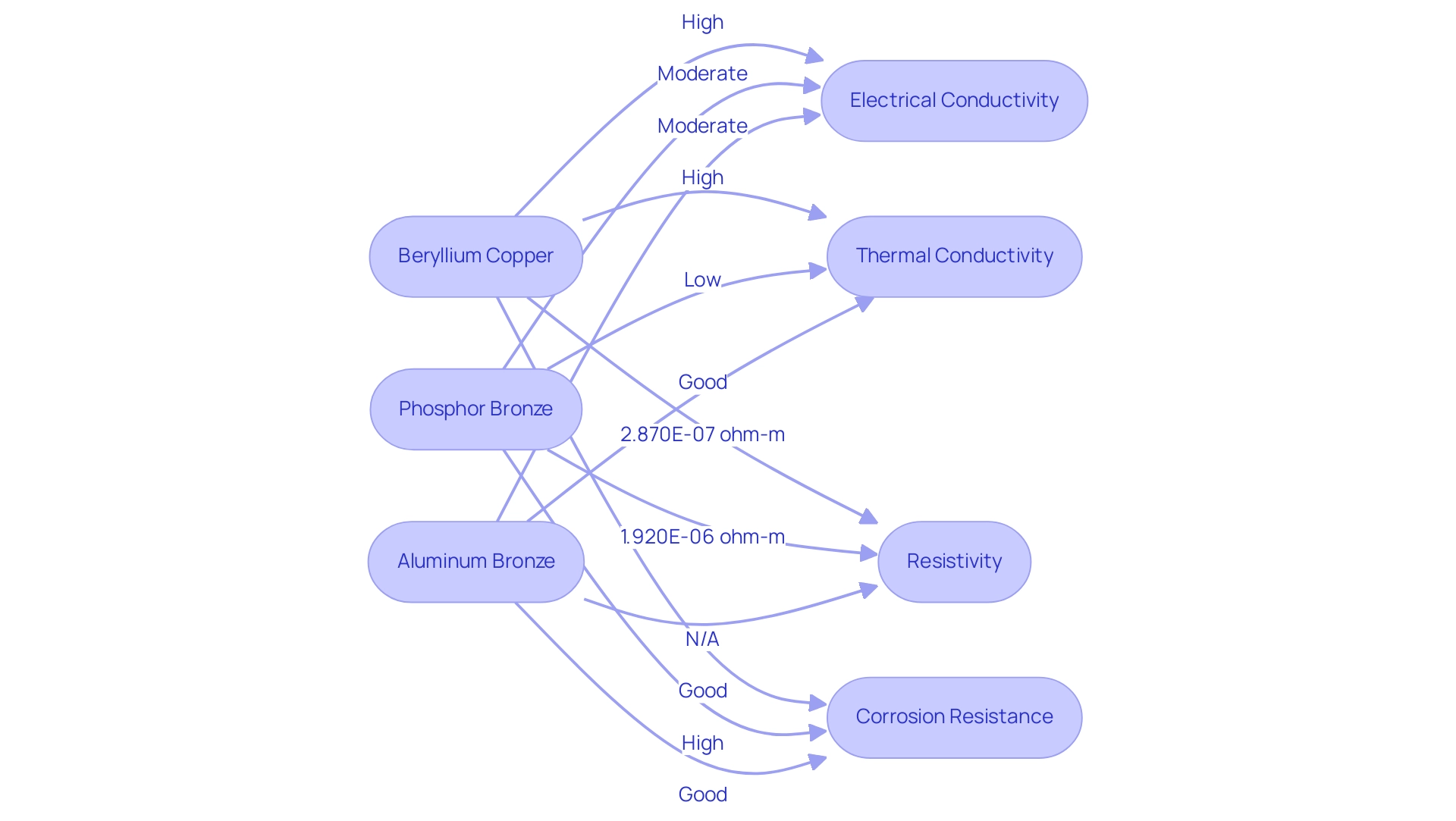

In the realm of bearing materials, the comparison between beryllium alloy, phosphor bronze, and aluminum bronze is vital for informed procurement decisions. Beryllium alloy is distinguished by its high electrical and thermal conductivity of beryllium copper for bearings in low wear & tear applications, boasting a resistivity of approximately 2.870-07 ohm-m, significantly outperforming phosphor bronze, which has a resistivity of 1.920E-06 ohm-m. While phosphor bronze is recognized for its durability and corrosion resistance, its lower thermal conductivity makes it less effective in applications where efficient heat dissipation is crucial.

Conversely, aluminum bronze offers good corrosion resistance but lacks the exceptional strength and conductivity qualities of beryllium. The manufacturing process of beryllium alloy involves casting and extrusion, where the mixture is melted and poured into molds, contributing to its desirable properties. This combination of attributes positions beryllium copper as the preferred option in high-performance applications, particularly in explosive environments where the high electrical and thermal conductivity of beryllium copper for bearings in low wear & tear applications, as well as non-sparking and non-magnetic characteristics, are critical for safety.

The pricing for beryllium metal strips typically ranges from $X to $Y per unit, depending on the supplier and quantity ordered, making it a significant investment for procurement managers. Case studies have shown the effectiveness of beryllium tools, such as non-sparking wrenches, which are designed with safety features to prevent sparks during use, thus minimizing the risk of ignition in explosive atmospheres. Although beryllium alloy may present a higher initial expense compared to phosphor bronze, the overall cost evaluation indicates that its benefits in performance, safety, and durability can result in considerable savings over time, justifying the investment for procurement managers in aerospace and electrical fields.

Manufacturing Processes for Beryllium Copper Components

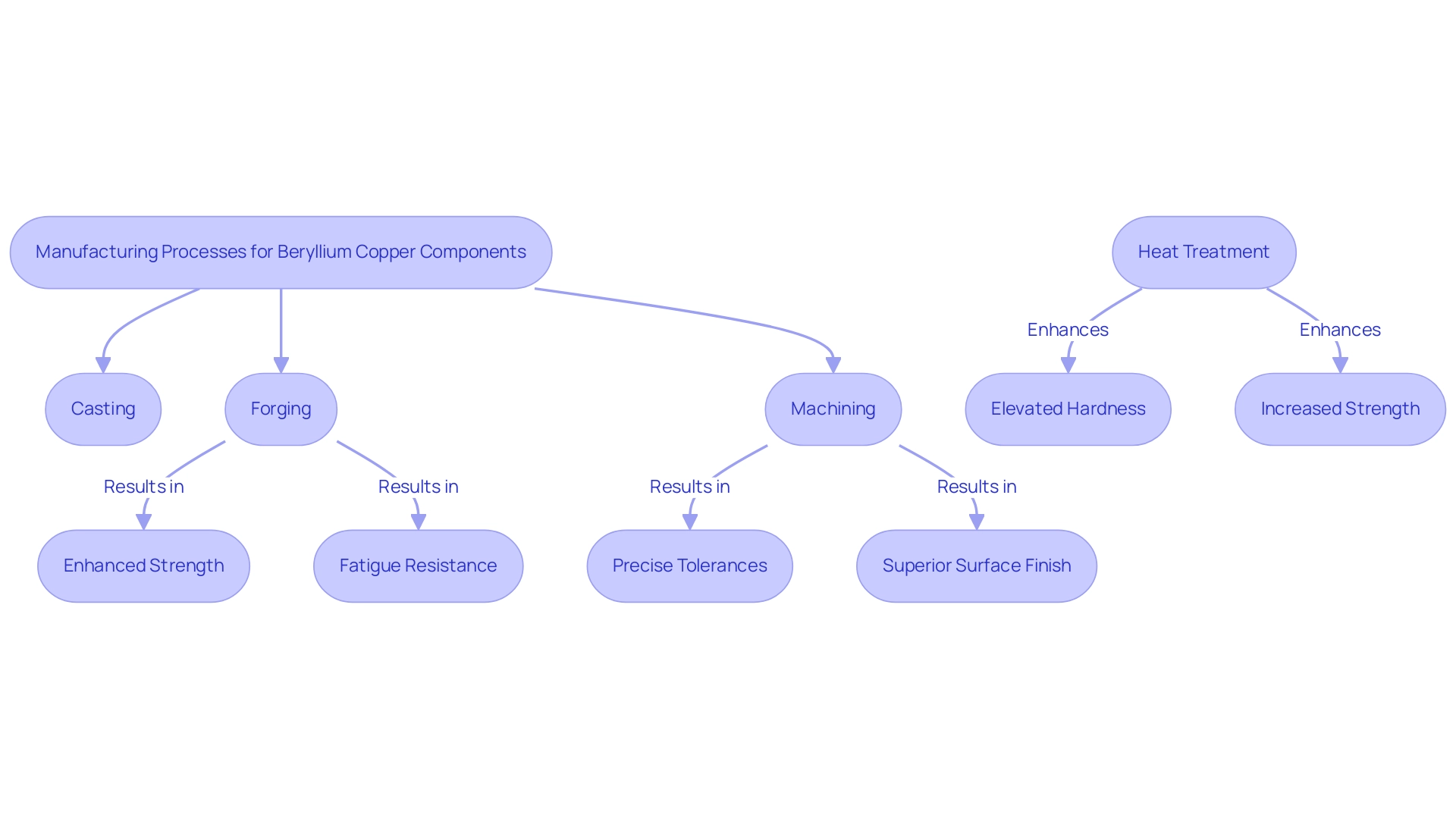

Beryllium alloy components are produced through several manufacturing processes, notably casting, forging, and machining. Each method uniquely influences the mechanical properties of the resulting product. Forging, for instance, significantly enhances strength and fatigue resistance, making it particularly suitable for high-performance bearings that leverage the high electrical and thermal conductivity of beryllium copper for bearings in low wear & tear applications.

In contrast, machining is essential for achieving precise tolerances and superior surface finishes, critical for components requiring exact fits in assemblies. Furthermore, the use of heat treatment processes can elevate the hardness and strength of beryllium copper, which contributes to the high electrical and thermal conductivity of beryllium copper for bearings in low wear & tear applications, optimizing its performance under demanding operational conditions. Understanding these manufacturing processes is crucial for procurement managers as it ensures that sourced components not only meet stringent specifications but also align with expected performance standards in aerospace and electrical applications.

Domadia stands as your reliable partner in this regard, offering an extensive range of beryllium products, including foils, sheets, rods, and wires, along with non-sparking tools that are corrosion-resistant and durable, ensuring safety in explosive environments. We provide custom fabrication options tailored to your specific needs, ensuring you have access to the best solutions. Recent industry developments highlight a growing demand for beryllium copper alloys, prompting companies to enhance their production capabilities.

For instance, the case study titled ‘Beryllium Alloy Industry Developments’ illustrates how mergers and acquisitions among key players are shaping a dynamic environment, indicating robust demand for these alloys. Furthermore, safety aspects are paramount; as noted by Sterner and Eisenbud (1951), potential health concerns associated with beryllium are critical considerations for procurement managers when sourcing materials. This comprehensive method not only improves the overall reliability and availability of these essential components but also strengthens Domadia’s dedication to delivering high-quality alloy wire and outstanding customer service for project success.

Pricing and inventory information for beryllium alloys strips are readily accessible to help you in making informed purchasing choices.

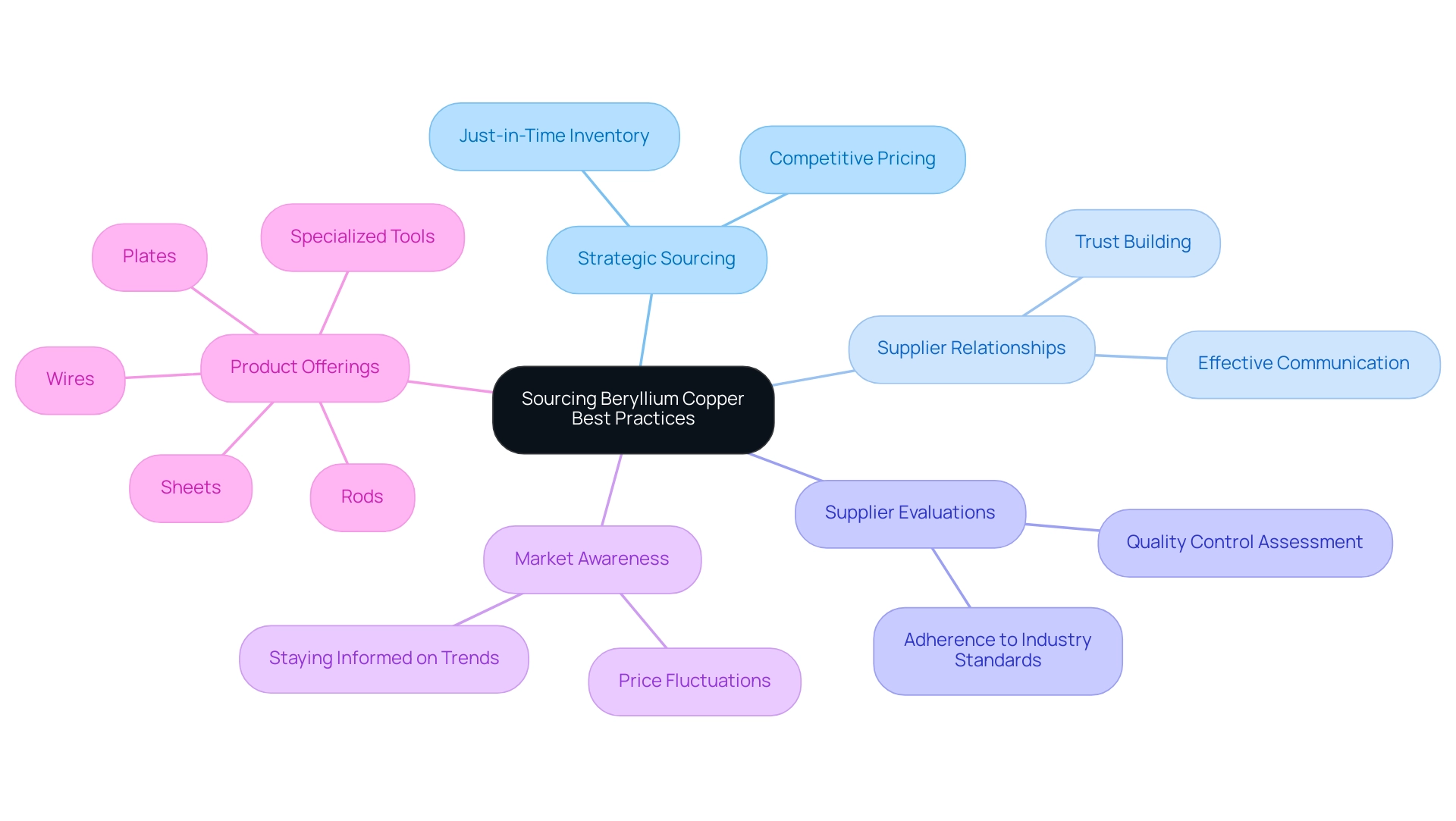

Sourcing Beryllium Copper: Best Practices

Sourcing beryllium alloy necessitates procurement managers to embrace a strategic method that includes various best practices, guaranteeing the acquisition of high-quality materials at competitive prices. Considering that electrical applications of the reddish metal represent approximately three quarters of overall usage, the importance of a specific alloy in the sector is emphasized. At Domadia, we provide an extensive variety of alloy solutions, including:

- Plates

- Rods

- Sheets

- Wires

- Specialized tools

These are customized for aerospace, automotive, electrical, oil and gas, and defense uses.

Our pricing structure is competitive, with tiered options available based on order volume, ensuring flexibility for various project budgets. Establishing robust relationships with suppliers is paramount; such relationships foster trust and create a platform for more favorable negotiation outcomes. As one procurement expert noted, ‘Effective communication and collaboration with suppliers can lead to better pricing and service.’

It is also critical to conduct thorough supplier evaluations, which should include a comprehensive assessment of their quality control processes and adherence to industry standards. Implementing just-in-time inventory practices can significantly minimize holding costs while ensuring materials are readily available when required. Furthermore, our inventory consists of associated items like electrical insulation papers and high-temperature fabrics, which can enhance your solutions involving specific metal alloys.

Furthermore, referencing the case study on overcoming resistance to budget analysis illustrates the importance of effective communication and training in supplier evaluations. Staying informed about market trends and price fluctuations is essential for making educated purchasing decisions, thereby optimizing both cost and quality within the procurement process. By adhering to these practices and leveraging the extensive inventory of Beryllium Copper products and related materials, procurement managers can enhance their operational efficiency and contribute to the overall success of their projects in aerospace and electrical applications, especially given the high electrical and thermal conductivity of beryllium copper for bearings in low wear & tear applications.

Conclusion

Beryllium copper emerges as a cornerstone material in modern engineering, perfectly balancing exceptional electrical and thermal conductivity with remarkable mechanical properties. Its unique characteristics not only make it ideal for high-performance applications in sectors like aerospace, automotive, and industrial machinery, but also position it as a superior alternative to traditional materials such as phosphor bronze and aluminum bronze. The comprehensive analysis of its applications, manufacturing processes, and strategic sourcing best practices underscores the necessity for procurement managers to prioritize beryllium copper in their material selection.

The advantages of beryllium copper are manifold. Its superior fatigue resistance, enhanced thermal management, and corrosion resistance contribute to the longevity and reliability of components subjected to demanding operational conditions. As industries increasingly recognize the value of high-performance materials, the investment in beryllium copper becomes not only justifiable but essential for maintaining competitive advantages in innovation and safety.

Ultimately, informed procurement decisions regarding beryllium copper can significantly enhance operational efficiency, reduce long-term costs, and ensure quality in performance-critical environments. By adopting best practices in sourcing and staying attuned to market trends, procurement managers can leverage the full potential of beryllium copper, driving success in their projects and contributing to the advancement of engineering excellence.