Blogs

How to Use Beryllium Copper for Controlling Fission Reactions: A Practical Guide

Introduction

The significance of beryllium copper in the realm of nuclear technology cannot be overstated. This remarkable alloy, characterized by its exceptional strength, thermal and electrical conductivity, and corrosion resistance, plays a pivotal role in various applications critical to the nuclear industry. From control rods to heat exchangers, its unique properties ensure stability and reliability under the extreme conditions present in nuclear reactors.

As procurement managers navigate the complexities of sourcing high-performance materials, understanding the nuances of beryllium copper—its compliance with international standards, its role in enhancing reactor safety, and best practices for procurement—becomes essential.

This article delves into the multifaceted applications of beryllium copper, exploring its properties, the importance of quality assurance, and future trends that will shape its use in nuclear technology, equipping professionals with the insights necessary for strategic decision-making in this vital sector.

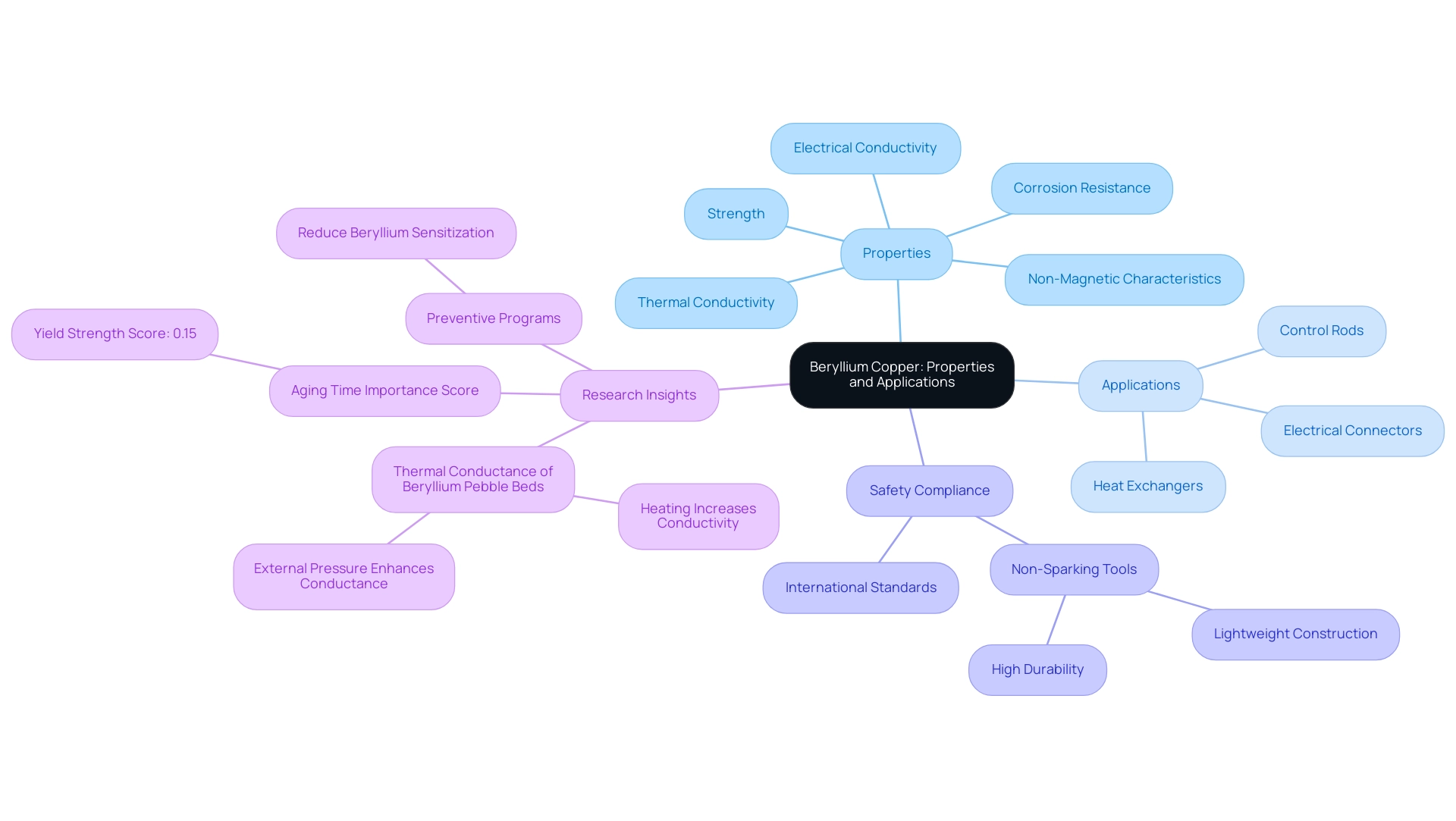

Understanding Beryllium Copper: Properties and Applications in Nuclear Physics

Beryllium copper, an alloy predominantly made of copper and beryllium, is distinguished by its remarkable properties, including exceptional strength, superior thermal and electrical conductivity, and notable corrosion resistance. These attributes render it highly suitable for diverse applications within atomic physics, particularly in components such as:

- Control rods

- Heat exchangers

- Electrical connectors

Where beryllium copper for controlling fission reactions is crucial for ensuring stability and reliability. The alloy’s ability to withstand high temperatures and resist deformation under stress is crucial for elements used in reactors.

Furthermore, its non-magnetic characteristics provide significant advantages in scenarios where magnetic interference must be minimized, such as in sensitive measurement devices. Notably, DOMADIA Beryllium Copper complies with international standards, including UNS and ASTM, ensuring that procurement managers can confidently choose resources that meet stringent safety protocols. Additionally, the importance of non-sparking tools in explosive potential environments cannot be overstated; they serve as the best alternative for applications where safety is paramount.

These tools are designed with features such as:

- Lightweight construction

- High durability

Minimizing the risk of sparks during use. According to Lisa A Maier, ‘The distinctive characteristics of beryllium copper for controlling fission reactions render it an essential substance in the nuclear sector, especially in areas where performance and safety are vital.’ A quantitative perspective on the substance’s performance is highlighted by the aging time’s importance score of 0.15 for yield strength, indicating its significant influence on the alloy’s durability.

Research at UCLA on the thermal conductance of pebble beds further demonstrates that heating increases effective thermal conductivity, and external pressure significantly enhances thermal conductance, aligning with theoretical predictions. A comprehensive grasp of these attributes is crucial for procurement managers seeking to choose the best resources for particular applications, thus guaranteeing compliance with global standards and safety protocols. Improved preventive programs have been effectively demonstrated to reduce beryllium sensitization among new employees, highlighting the significance of responsible handling of substances in atomic settings.

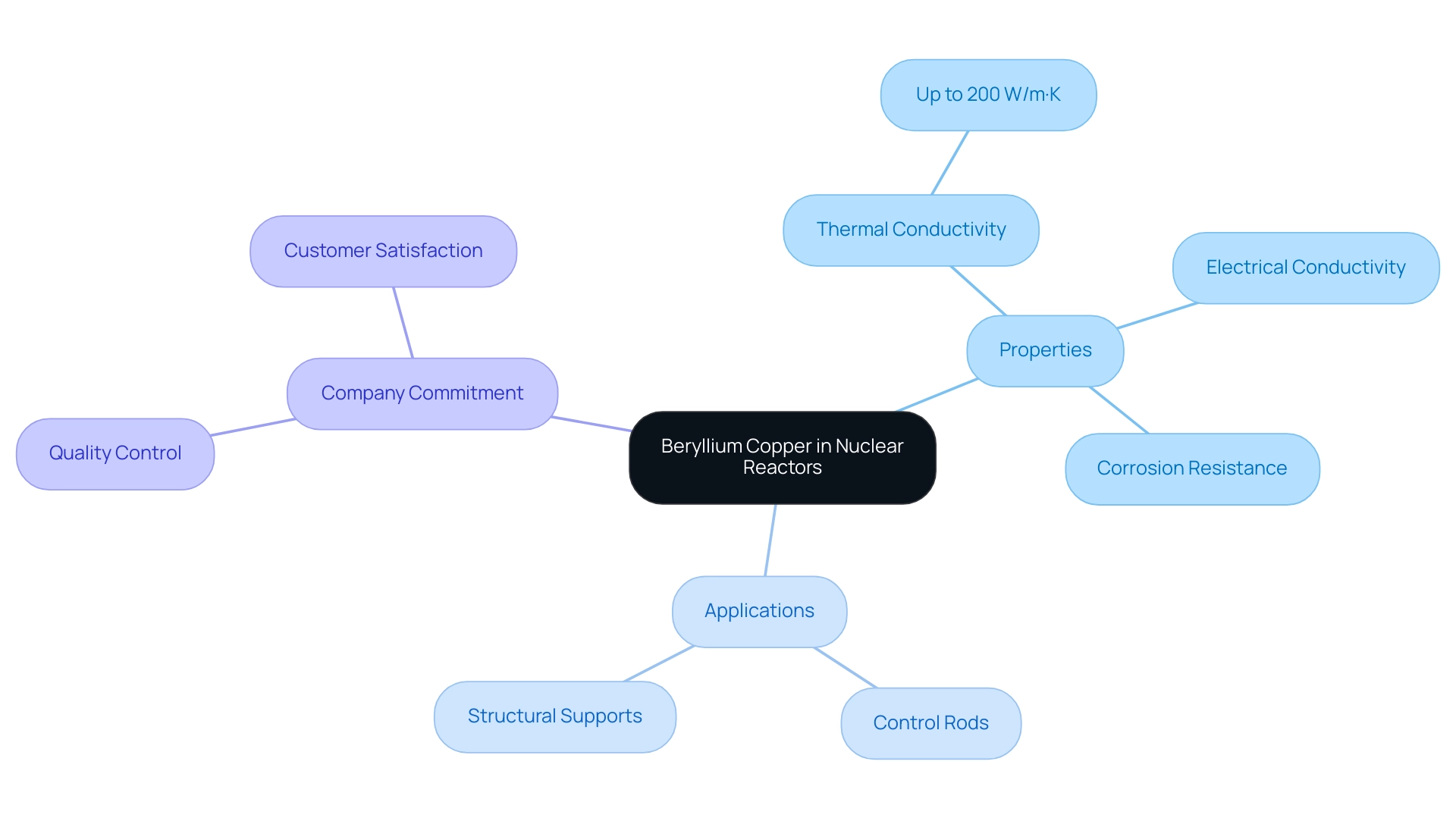

The Role of Beryllium Copper in Controlling Fission Reactions

Beryllium copper for controlling fission reactions within atomic reactors is crucial, primarily due to its outstanding thermal conductivity, which can reach up to 200 W/m·K. This property enables effective heat dissipation, crucial for regulating the heat produced during fission processes. Domadia, a leader in supplying and manufacturing high-performance Beryllium Copper Plates, ensures these products meet the rigorous demands of the nuclear industry.

Our commitment to high-quality solutions, innovative manufacturing practices, and strict quality control translates into products that excel in critical applications such as control rods and structural supports, which must endure the extreme conditions within a reactor environment. Furthermore, tempered alloys such as C17510 and C17500 are specifically engineered for uses demanding excellent electrical conductivity and wear resistance. These alloys improve performance when utilized with other substances, ensuring adherence to rigorous safety and efficiency standards.

The compatibility of a specific alloy with various neutron-absorbing substances, particularly beryllium copper for controlling fission reactions, further enhances precise control over the fission process, solidifying its significance in modern reactor designs. Furthermore, the corrosion resistance of this alloy improves its durability and dependability in severe conditions. Recent advancements in materials science highlight the importance of a specific alloy in improving nuclear reactor safety, making it a vital factor for procurement managers responsible for acquiring high-performance materials for nuclear operations.

Our satisfied customers have praised the quality and performance of our Beryllium Copper Plates, highlighting their effectiveness in critical applications. By choosing Domadia, you partner with an expert committed to supporting your project’s success through customized Beryllium Copper Plates tailored to your specifications. Contact us today to learn more about how we can meet your Beryllium Copper needs.

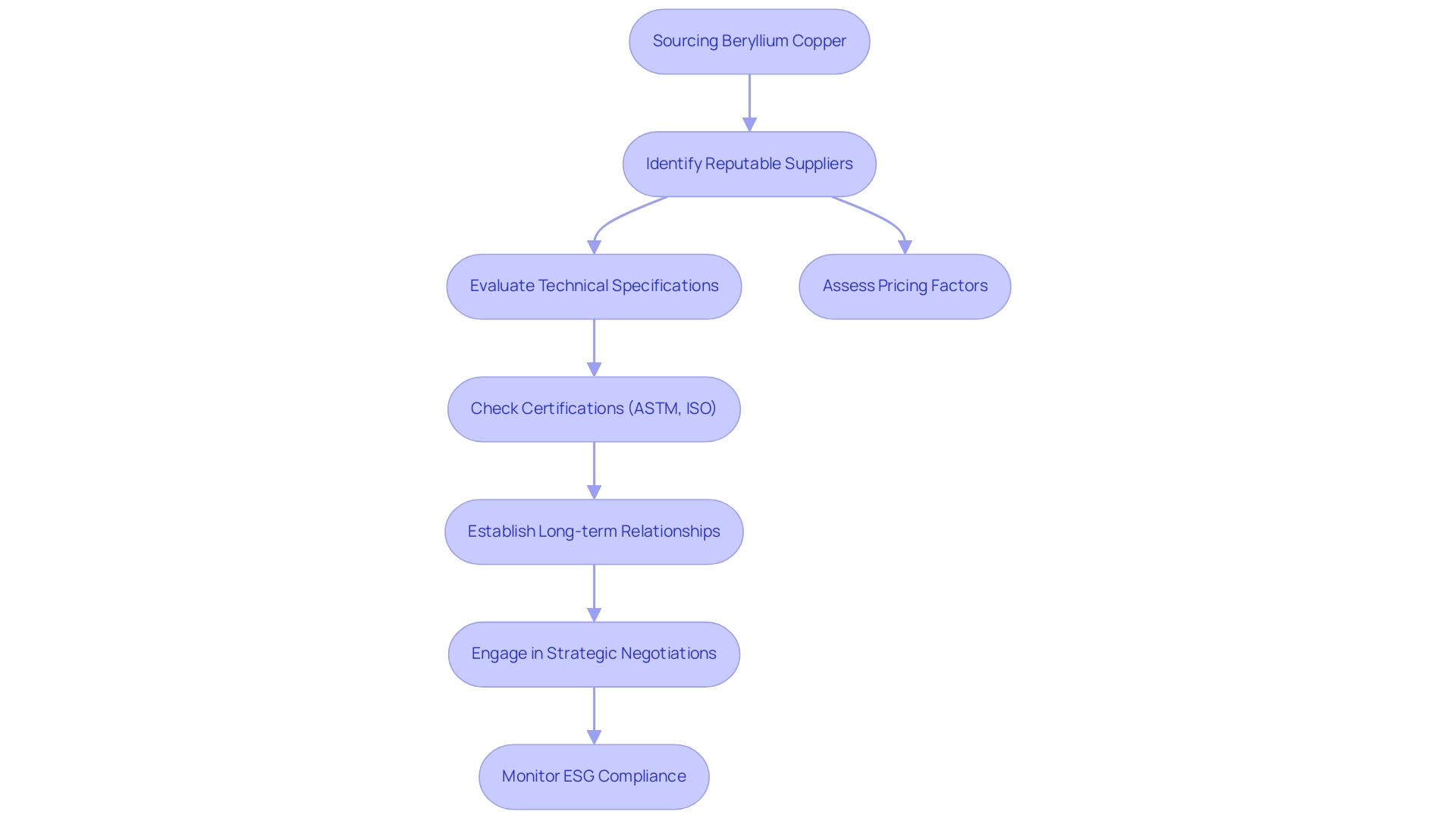

Sourcing Beryllium Copper: Best Practices for Procurement Managers

To effectively source a specific alloy, procurement managers should focus on identifying suppliers with a robust reputation in high-performance metals. The conductivity of a certain alloy wire varies from 20% to 95% of the International Annealed Copper Standard (IACS), highlighting its technical credibility. Factors affecting alloy scrap pricing, such as market demand, purity, and current metal prices, are crucial for procurement decisions.

At Domadia, we are committed to providing fair and transparent pricing for all beryllium copper transactions, ensuring that our pricing remains competitive and attractive. It is essential to evaluate supplier adherence to international standards, such as ASTM and ISO certifications, to ensure quality and safety. Establishing long-term relationships with these suppliers can yield benefits in pricing and supply chain reliability.

Furthermore, evaluating various suppliers, including those providing related products like Kovar, Mu-Metal, and Nickel, is advised to guarantee optimal results, using their business profiles and RFQ forms for inquiries. Technical support and comprehensive documentation from suppliers are essential, especially for ensuring the effective use of beryllium copper for controlling fission reactions and meeting stringent regulatory requirements within the nuclear sector. Regular performance reviews and audits are critical practices to confirm that materials consistently adhere to the necessary specifications.

Furthermore, engaging in strategic negotiations can help achieve favorable terms while maintaining high-quality standards, ultimately aligning with the industry’s growing emphasis on environmental, social, and governance (ESG) principles. As Maya Garcia-Hector aptly points out,

Procurement’s role in ESG and carbon reduction is crucial for the future,

highlighting the significance of responsible sourcing in today’s market landscape. The future prospects for the beryllium copper target market are optimistic, driven by technological advancements and increasing demand from end-user industries.

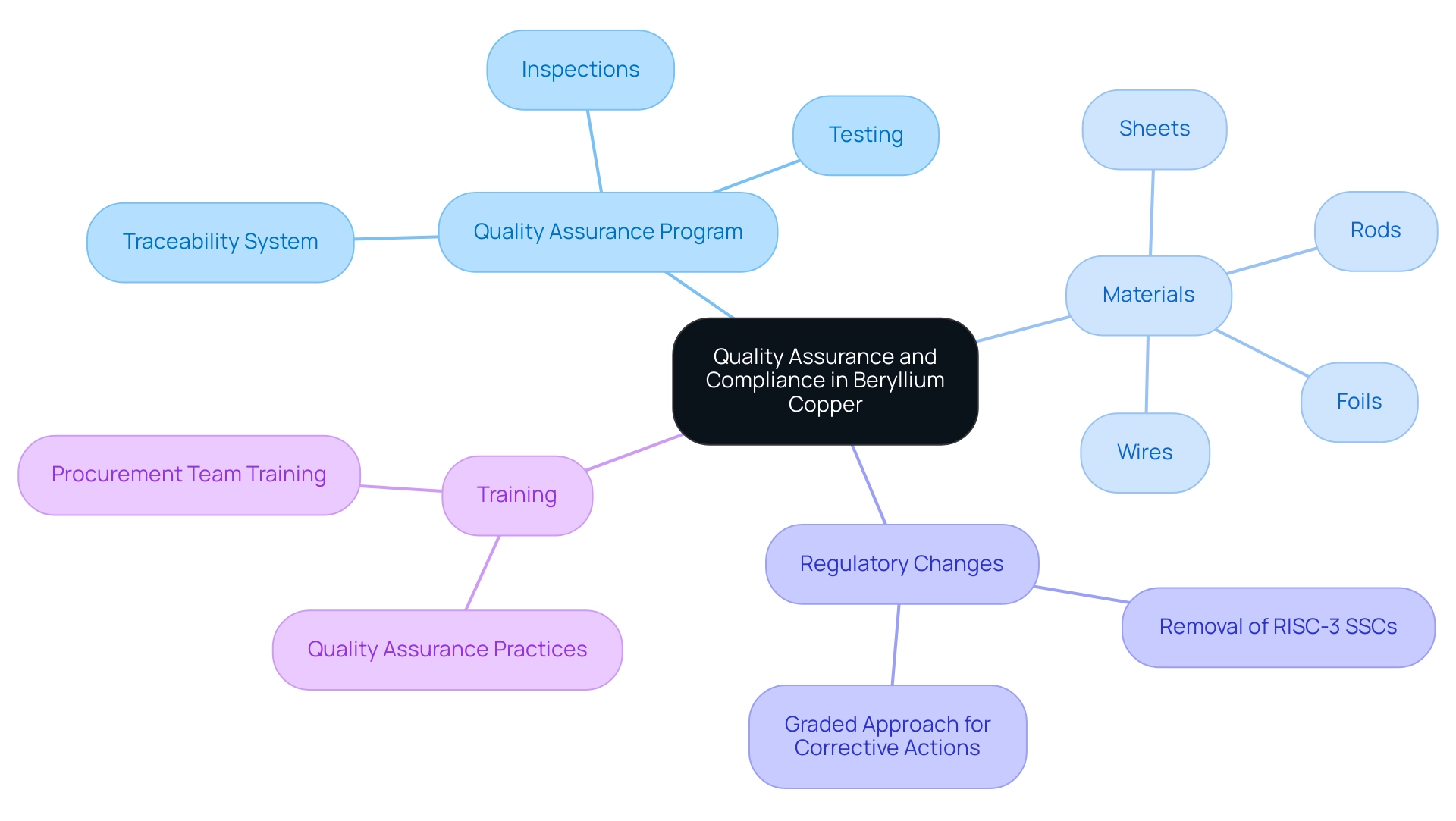

Quality Assurance and Compliance in Using Beryllium Copper

To ensure the safe and efficient application of Beryllium Copper in atomic technology, implementing a comprehensive quality assurance program is crucial. This program should include meticulous inspections and testing of substances upon receipt to confirm adherence to specifications, reflecting Domadia’s commitment to providing high-quality beryllium copper for controlling fission reactions, tailored to project needs, including:

- Foils

- Sheets

- Rods

- Wires

A well-established traceability system for all materials used within atomic reactors not only fosters accountability but also enhances safety protocols.

As regulatory landscapes evolve, particularly with updates like the removal of RISC-3 SSCs from quality assurance mandates in Appendix B to 10 CFR Part 50, it is important to note that the corrective action process for RISC-3 SSCs allows for a graded approach with less stringent timeliness requirements compared to previous regulations. Remaining vigilant about compliance requirements becomes essential. Furthermore, regular training sessions for procurement teams on quality assurance practices, supported by Domadia’s exceptional customer service, can significantly improve the procurement process’s effectiveness.

Non-Sparking Tools, as part of Domadia’s offerings, are critical for applications in explosive environments, ensuring safety and compliance. As noted by Hossen, M.M., in the Journal of Nuclear Engineering, ‘Reliability Assessment of NPP Safety Class Equipment Considering the Manufacturing Quality Assurance Process,’ emphasizes the importance of quality assurance in ensuring safety. By referencing the case study on the removal of RISC-3 SSCs from existing quality assurance requirements, organizations can see a real-world example of how simplifying the regulatory framework can impact operations.

By emphasizing quality assurance and compliance, organizations can effectively mitigate risks associated with energy operations while ensuring the integrity and safety of their facilities.

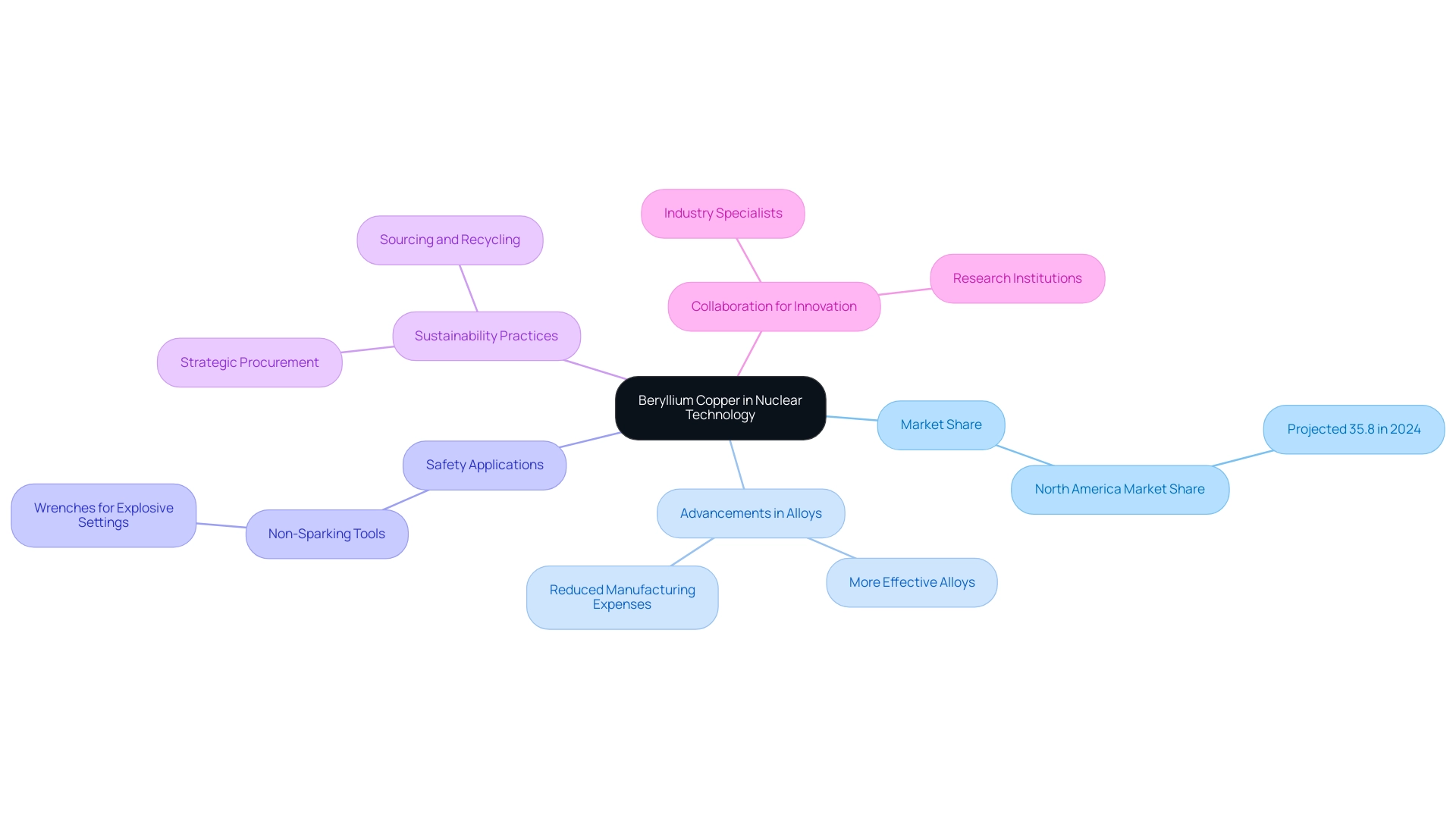

Future Trends in Beryllium Copper Applications within Nuclear Technology

As the nuclear technology landscape continues to change, the role of a specific metal is anticipated to grow considerably, propelled by advancements in reactor design and improved safety protocols. North America is projected to possess 35.8% of the worldwide market share for the element in 2024, highlighting its significance in the sector. Upcoming advancements may concentrate on producing more effective alloys that enhance performance while reducing manufacturing expenses.

Furthermore, there is a growing focus on sustainability and ecological factors, promoting advancements in the sourcing and recycling of materials. The use of non-sparking tools made from a specific alloy, including wrenches, is especially crucial in explosive settings, where safety is essential. These tools are designed to prevent sparks that could ignite flammable substances, making them essential in sectors such as atomic technology.

For instance, the pricing of beryllium copper strips currently ranges from $X to $Y per unit, and inventory levels are monitored closely to meet demand. According to industry consultant Vidyesh Swar, “Properties like high strength and light weight also reduce device size, making minimally invasive surgeries less complex,” illustrating how these characteristics facilitate advancements in device design. Procurement managers must remain vigilant and informed about these emerging trends to adapt their strategies effectively, ensuring they meet the shifting demands of the nuclear sector.

Collaborating with research institutions and industry specialists is essential for acquiring knowledge about upcoming innovations, enabling organizations to remain competitive in the procurement of high-performance resources. Furthermore, as the European Commission recognizes this metal as one of the 34 critical materials for the EU, understanding advancements and sustainability practices in sourcing beryllium copper will be crucial for strategic procurement. The case study titled ‘Beryllium in Nuclear Applications‘ highlights how beryllium copper for controlling fission reactions is utilized in nuclear weapon designs and as a neutron source when mixed with alpha emitters, demonstrating its effectiveness as a neutron reflector and implosion pusher in nuclear reactors.

Conclusion

Beryllium copper stands as a cornerstone in the nuclear technology sector, offering unparalleled properties that ensure safety, efficiency, and reliability in critical applications. Its exceptional strength, thermal and electrical conductivity, and corrosion resistance make it indispensable in components such as control rods, heat exchangers, and non-sparking tools. As procurement managers navigate the complexities of sourcing this vital material, understanding its compliance with international standards and best practices for quality assurance becomes essential.

The role of beryllium copper in managing fission reactions cannot be overlooked. Its ability to dissipate heat effectively allows for the safe regulation of the fission process, enhancing reactor performance. By partnering with reputable suppliers and focusing on long-term relationships, procurement managers can secure high-quality materials that meet stringent safety protocols while also embracing the industry’s shift toward sustainability and responsible sourcing practices.

Looking ahead, the future of beryllium copper applications in nuclear technology is promising, with ongoing innovations poised to enhance its performance and efficiency. Staying informed about emerging trends and engaging with industry experts will empower procurement professionals to adapt their strategies effectively, ensuring they remain competitive in this dynamic market. Ultimately, by prioritizing quality assurance and compliance, organizations can mitigate risks and promote the integrity of their nuclear operations, reinforcing the critical role that beryllium copper plays in shaping a safer and more efficient nuclear landscape.