Blogs

Understanding CTE Invar: An In-Depth Tutorial on Properties and Applications

Introduction

In the realm of advanced materials, CTE Invar emerges as a cornerstone for industries demanding unparalleled precision and stability. This unique alloy, characterized by its exceptionally low coefficient of thermal expansion, plays a pivotal role in applications ranging from aerospace to electronics, where even the slightest dimensional changes can lead to significant operational failures.

As procurement managers navigate the complexities of sourcing this critical material, understanding its properties, applications, and the associated cost and compliance considerations is essential. By exploring the multifaceted advantages of CTE Invar and the importance of complementary materials like Mica Tape, organizations can strategically enhance their procurement processes, ensuring both safety and reliability in their operations.

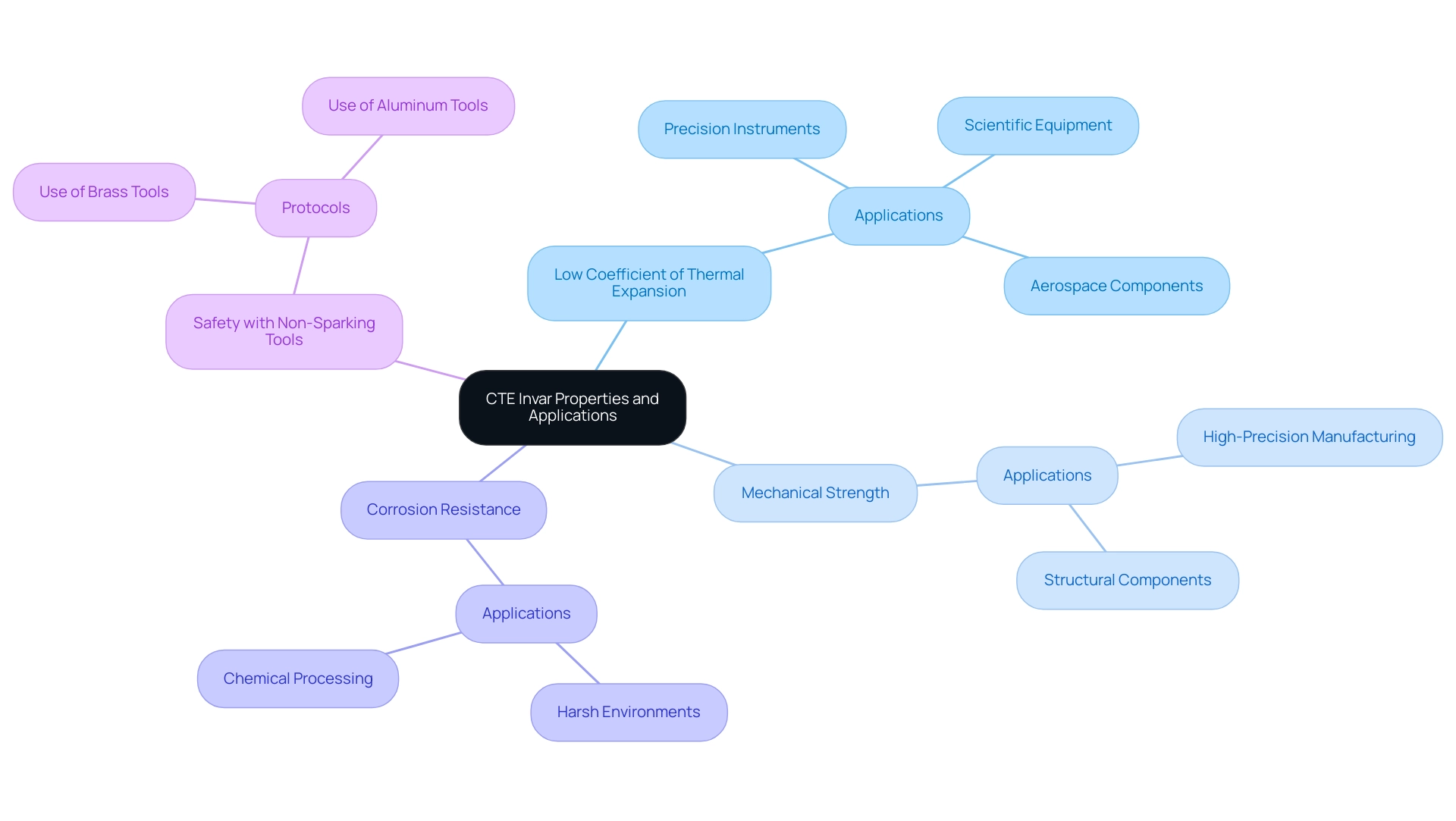

Exploring the Unique Properties of CTE Invar

CTE invar, an alloy primarily composed of iron and nickel, is distinguished by its remarkably low coefficient of thermal expansion, measured at approximately 7 × 10^-3 at room temperature. This value is notably 10 to 100 times lower than leading thermoelectric substances, reinforcing its critical role in applications demanding exceptional precision. The alloy’s thermal expansion characteristics, which include cte invar, facilitate outstanding dimensional stability across a wide temperature range, making it indispensable in the manufacturing of precision instruments, scientific equipment, and aerospace components.

Furthermore, CTE exhibits excellent mechanical strength and notable corrosion resistance, enabling it to thrive in harsh environments. As Stephane Guignard aptly observes,

The aerospace sector is presently very energy-intensive,

highlighting the urgent requirement for substances such as cte invar that can endure demanding conditions while ensuring reliability and efficiency. In environments with explosive potential, the use of Non-Sparking Tools becomes crucial.

These tools are created to stop sparks that could set off combustible substances, ensuring safety during the handling and processing of high-precision items such as CTE. For example, using Non-Sparking Tools made from materials such as brass or aluminum can significantly reduce the risk of ignition, thus enhancing safety protocols in sensitive environments. Insights from the case study titled ‘Combining Particle Size, Zeta Potential and Shelf-life for Cutting Edge Research’ illustrate how the properties of cte invar can enhance research methodologies and results, demonstrating its adaptability in various uses.

By understanding these properties and the importance of Non-Sparking Tools, procurement managers can make informed decisions when selecting CTE invar materials for applications that require unparalleled precision and durability, while also prioritizing safety in their operational environments.

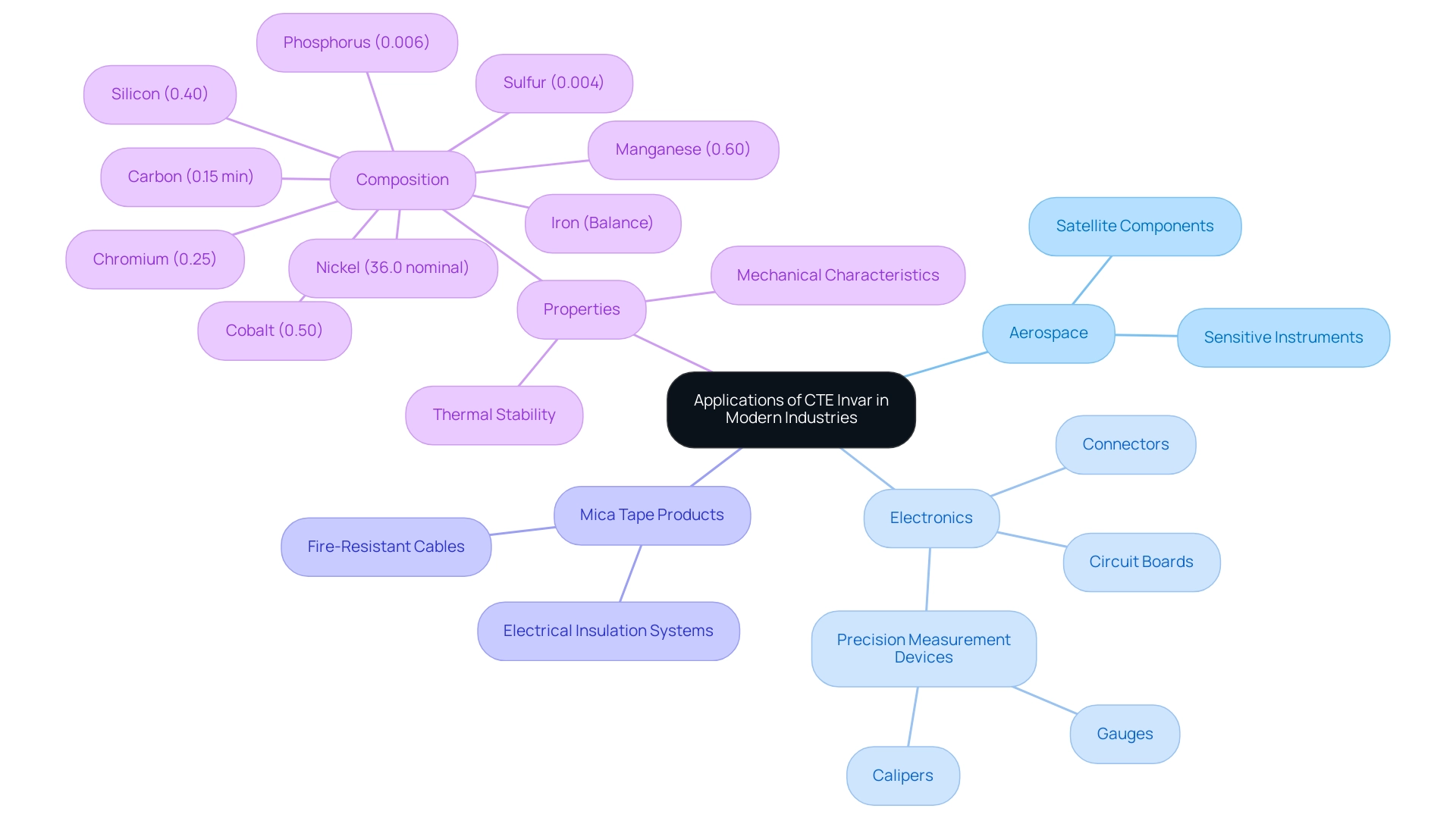

Applications of CTE Invar in Modern Industries

CTE alloy stands out in several contemporary industries, primarily due to its exceptional thermal stability and mechanical characteristics. In the aerospace sector, it plays a crucial role in the manufacturing of satellite components and sensitive instruments that demand precise dimensional stability across varying environmental conditions. Notably, aerospace engineers emphasize the significance of CTE alloys, stating,

Finally, these alloys are selected by the use of relevant performance indices taking into account requirements for linear thermal expansion, Young’s modulus, and density.

This highlights the alloy’s importance in ensuring operational reliability. The composition of CTE typically includes:

- Carbon (0.15 min)

- Nickel (36.0 nominal)

- Phosphorus (0.006)

- Iron (Balance)

- Silicon (0.40)

- Manganese (0.60)

- Sulfur (0.004)

- Chromium (0.25)

- Cobalt (0.50)

These elements contribute to its unique properties. The reported experimental Poisson’s ratio of metamaterials, previously within the range of [-4, 1], underscores the advancements in material science that enhance CTE performance.

In the electronics field, the use of CTE Invar is essential for producing circuit boards and connectors where controlled thermal expansion is vital to prevent operational failures. Furthermore, its use extends to the fabrication of precision measurement devices, such as gauges and calipers in metrology, where even minor thermal distortions can lead to significant inaccuracies.

Transitioning to Mica Tape products, recognized for their high-temperature resistance and electrical insulation characteristics, these materials are essential in various uses, particularly in the production of fire-resistant cables and critical electrical insulation systems.

Mica Tapes provide unique characteristics like outstanding flame resistance and high dielectric strength, making them essential for ensuring safety and performance in electrical uses. By comprehensively understanding these applications, procurement managers can strategically align their sourcing decisions to meet industry demands, thereby enhancing product performance and reliability.

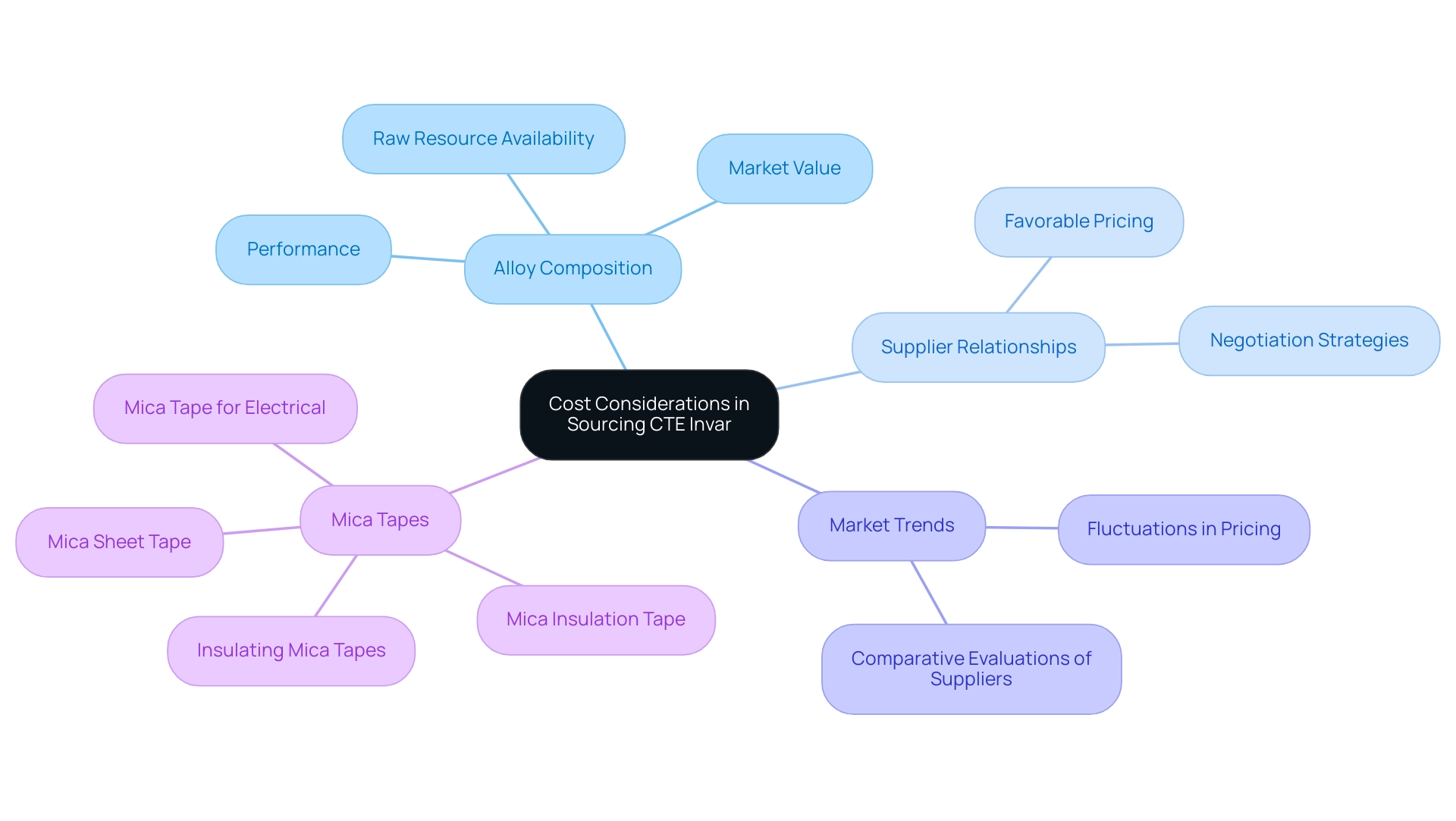

Cost Considerations in Sourcing CTE Invar

When it comes to sourcing CTE materials, procurement managers must navigate a complex landscape of cost factors that significantly influence pricing. Key considerations include:

- The alloy composition, which can directly impact performance and market value.

- The dynamics of supplier relationships.

Prices for CTE alloys are subject to fluctuations driven by the availability of raw resources and geopolitical factors that can disrupt supply chains.

For instance, recent analyses suggest that enhanced supplier relationships often yield more favorable pricing and terms, enabling organizations to optimize their procurement strategies. Moreover, as the case study titled ‘Understanding the Anomalous Properties of the alloy’ emphasizes its distinctive features, such as low thermal expansion and high dimensional stability, it is vital to also consider additional substances like Mica Tapes in sourcing decisions.

Domadia offers a variety of Mica Tapes, including:

- Mica Insulation Tape

- Mica Tape for Electrical

- Mica Sheet Tape

- Insulating Mica Tapes

All designed for high-temperature resistance and electrical insulation. These tapes are indispensable in the manufacture of fire-resistant cables and for use in high-voltage machinery.

Regularly monitoring market trends and conducting comparative evaluations of suppliers is crucial to ensure competitiveness in pricing. Additionally, as Jingying Zuo, an expert in the field, notes, ‘These findings demonstrate the essential role of Mica Tape products in designing more efficient systems,’ emphasizing their significance in enhancing safety and efficiency in demanding environments.

By understanding these financial considerations and the value of high-quality insulation solutions, procurement professionals can effectively budget, negotiate advantageous contracts, and uphold stringent quality standards, thus maximizing the overall value of their sourcing decisions.

Compliance and Quality Standards for CTE Invar

Adhering to international standards like ASTM and ISO certifications is crucial for CTE, as these standards outline the material’s quality, performance, and safety criteria. For procurement managers, verifying supplier documentation that demonstrates adherence to these standards is crucial; failure to do so can expose organizations to significant legal and operational risks. Regular audits and quality checks should be an integral part of procurement practices to ensure that the supplied cte invar consistently meets the necessary specifications.

Furthermore, evaluate the dependability of mica insulation tape products, which are engineered for high-temperature resistance and electrical insulation, rendering them suitable for essential uses across various industries. Our Mica Insulation Tape, for instance, offers superior insulation properties and durability, suitable for both household appliances and industrial machinery. Mica Tape for Electrical offers excellent flame resistance and dielectric strength, essential for uses such as fire-resistant cables.

As Markus Merkel emphasizes,

Minimum and Stable Coefficient of Thermal Expansion by Three-Step Heat Treatment of Alloys 36,

stability in thermal expansion is essential for preserving product integrity. Furthermore, the low coercivity values (20 OE to 25 OE) of these alloys increase their sensitivity in aerospace uses, making adherence to these standards even more essential. The electrical resistivity of the alloy 36® is approximately 78 µΩ·cm at 20°C, which is an important consideration for its application in various industries.

The Kovar Alloy case study exemplifies how consistent cte invar characteristics prevent the fracturing of brittle glass and ceramic components, reinforcing the significance of quality assurance in sourcing materials. Additionally, the pricing for Kovar Sheet is currently ₹3,000.00, down from the original ₹5,000.00, which is a critical factor for procurement decisions. By prioritizing compliance and implementing robust quality assurance practices, procurement professionals can effectively mitigate risks, ensuring the integrity and reliability of their supply chains.

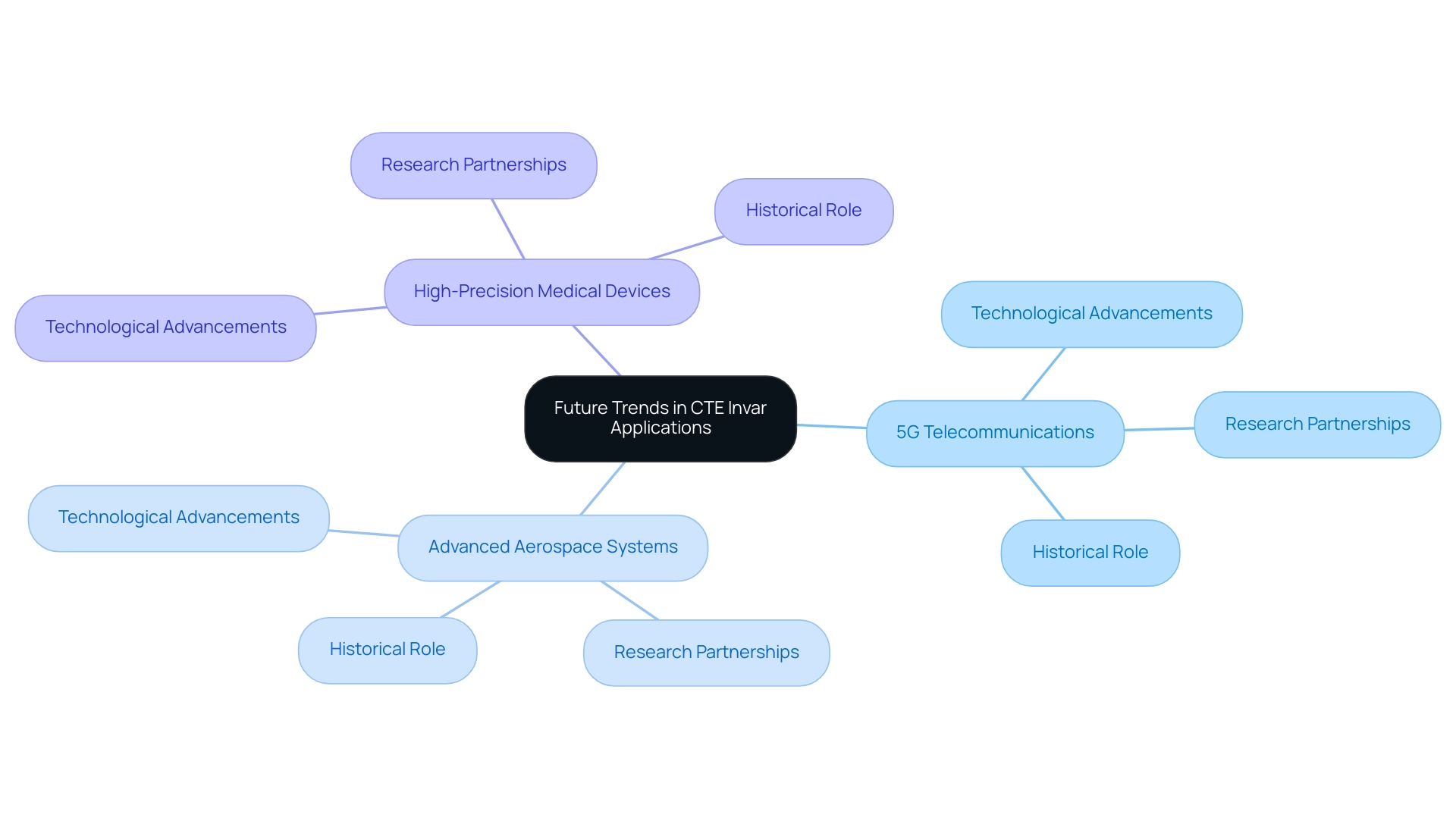

Future Trends in CTE Invar Applications

The evolution of industries is driving a significant increase in the demand for CTE invar materials, particularly within high-tech sectors such as:

- 5G telecommunications

- Advanced aerospace systems

- High-precision medical devices

The expected growth in these areas can be attributed to ongoing technological advancements that enhance the performance of these programs. For instance, advancements in production methods and substance science are anticipated to produce new formulations of CTE invar alloy, further enhancing its characteristics and suitability for specialized tasks.

As emphasized by Markus Merkel in the publication on the ‘Minimum and Stable Coefficient of Thermal Expansion by Three-Step Heat Treatment of Invar 36’, these advancements are vital for fulfilling the increasing demands for precision in various fields. Additionally, recent magnetic properties analysis showed that all samples exhibited soft magnetic properties, with saturation magnetization improving from 126 emu/g to 130 emu/g after warm rolling and heat treatment, underscoring the material’s evolving capabilities. For procurement managers, staying abreast of these trends is essential for aligning sourcing strategies with the evolving market landscape.

Participating in research and development partnerships can also provide a strategic benefit, as such collaborations not only foster innovation but may also reveal new uses for this remarkable alloy. Furthermore, the historical significance of Invar, as discussed in the case study on ‘Invar and Invar-Effect Alloys‘, demonstrates its critical role over the past century, which is expected to continue as demand grows, particularly due to its unique properties that provide different expansivities over a broad temperature range.

In this context, suppliers like Domadia offer a range of Mica Tape products specifically designed for high-temperature electrical insulation, featuring exceptional flame resistance, dielectric strength, and durability in diverse applications.

Understanding these dynamics, along with the innovative solutions provided by manufacturers of high-temperature materials, will be vital for informed decision-making in procurement. To explore our range of Mica Tapes and learn more about how they can benefit your business, contact our expert team today.

Conclusion

The significance of CTE Invar in modern industries cannot be overstated. With its unparalleled low coefficient of thermal expansion, this alloy is indispensable in sectors where precision is paramount, including aerospace and electronics. Its remarkable mechanical strength and corrosion resistance further enhance its applicability in harsh environments, ensuring that critical components maintain their integrity under varying conditions. The integration of complementary materials like Mica Tape not only bolsters the performance of CTE Invar but also reinforces safety protocols, particularly in high-risk applications.

As procurement managers navigate the complexities of sourcing this vital material, understanding the cost dynamics and compliance requirements is crucial. Fluctuating market conditions and supplier relationships can significantly impact pricing, making informed decision-making essential. Adhering to international quality standards ensures that organizations mitigate legal and operational risks, safeguarding their investments in high-performance materials.

Looking ahead, the future of CTE Invar is promising, with increasing demand driven by advancements in technology and emerging applications in fields like 5G telecommunications and precision medical devices. By staying attuned to these trends and fostering collaborative partnerships, procurement professionals can leverage the unique properties of CTE Invar to enhance product reliability and operational efficiency. Prioritizing strategic sourcing not only strengthens supply chains but also positions organizations to capitalize on the evolving landscape of advanced materials.