Blogs

Understanding the Density of Beryllium Copper: An In-Depth Tutorial

Introduction

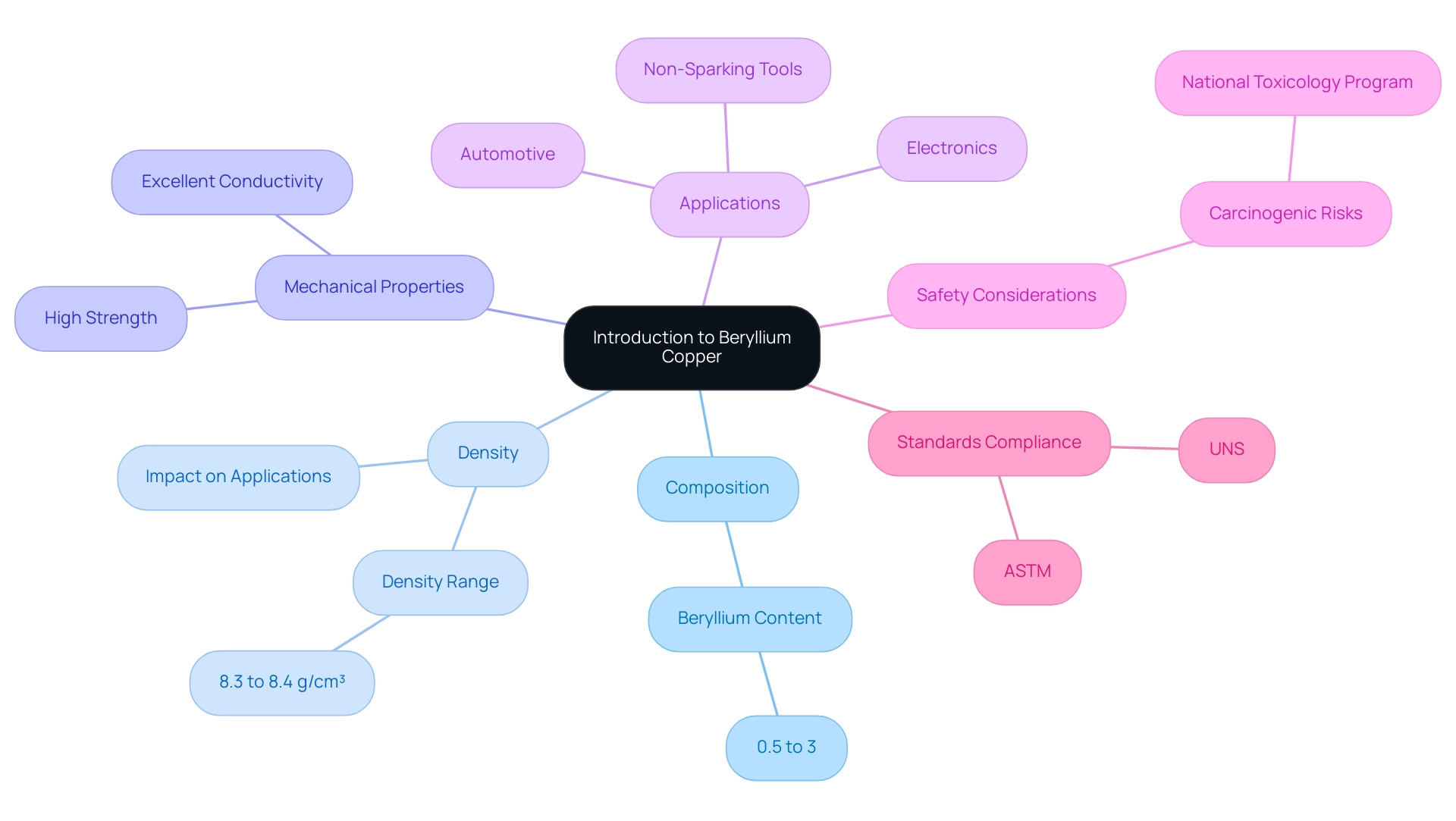

In the realm of advanced materials, beryllium copper stands out as a remarkable alloy, merging the strengths of copper with the unique properties of beryllium. This specialized alloy, characterized by its exceptional mechanical properties, density, and conductivity, has become integral to a multitude of industries, including automotive and electronics.

With a density that ranges from 8.3 to 8.4 g/cm³, beryllium copper not only enhances performance but also influences the design and functionality of components. As procurement managers navigate the complexities of material selection, understanding the nuances of beryllium copper’s composition and its implications for safety and application is paramount.

This article delves into the critical aspects of beryllium copper, including:

- Mechanical properties

- Applications

- Health considerations

These factors must be addressed in its usage, providing valuable insights for informed decision-making in procurement strategies.

Introduction to Beryllium Copper: Composition and Density Overview

Beryllium bronze is a specialized mixture mainly comprising Cu with a beryllium (Be) content varying from 0.5% to 3%. This specific composition endows the alloy with remarkable mechanical properties, being an age-hardening alloy that attains the highest strength of any base alloy. Additionally, it exhibits excellent electrical and thermal conductivity, making it suitable for various applications.

The density of beryllium copper falls within the range of 8.3 to 8.4 g/cm³, a critical factor that significantly impacts its applicability in sectors such as automotive and electronics. The density of beryllium copper influences not only the performance of the material under varying conditions but also the overall design and functionality of components produced from this substance. Furthermore, DOMADIA Beryllium Copper adheres to international standards, including UNS and ASTM, ensuring quality and safety in procurement decisions.

It is crucial to note that the National Toxicology Program (NTP) identifies this element as a carcinogen, emphasizing the need for careful handling and safety considerations in procurement processes. As industries increasingly seek materials that offer both strength and conductivity, understanding these properties becomes essential for optimizing product development and enhancing operational efficiency. Real-world uses of age-hardened beryllium copper alloys, such as C17200 and C17300, demonstrate their suitability for high-strength and conductivity requirements, particularly in springs and intricate forms.

Additionally, DOMADIA Beryllium Copper is specifically utilized in the production of non-sparking tools, which are essential in environments where flammable gases or vapors may be present. For the latest insights into Beryllium Copper and its uses in non-sparking tools, please refer to our blog updates from February and May 2022. The product specifications for DOMADIA Beryllium Copper include sizes ranging from small components to larger parts, with weights varying according to the specific application needs.

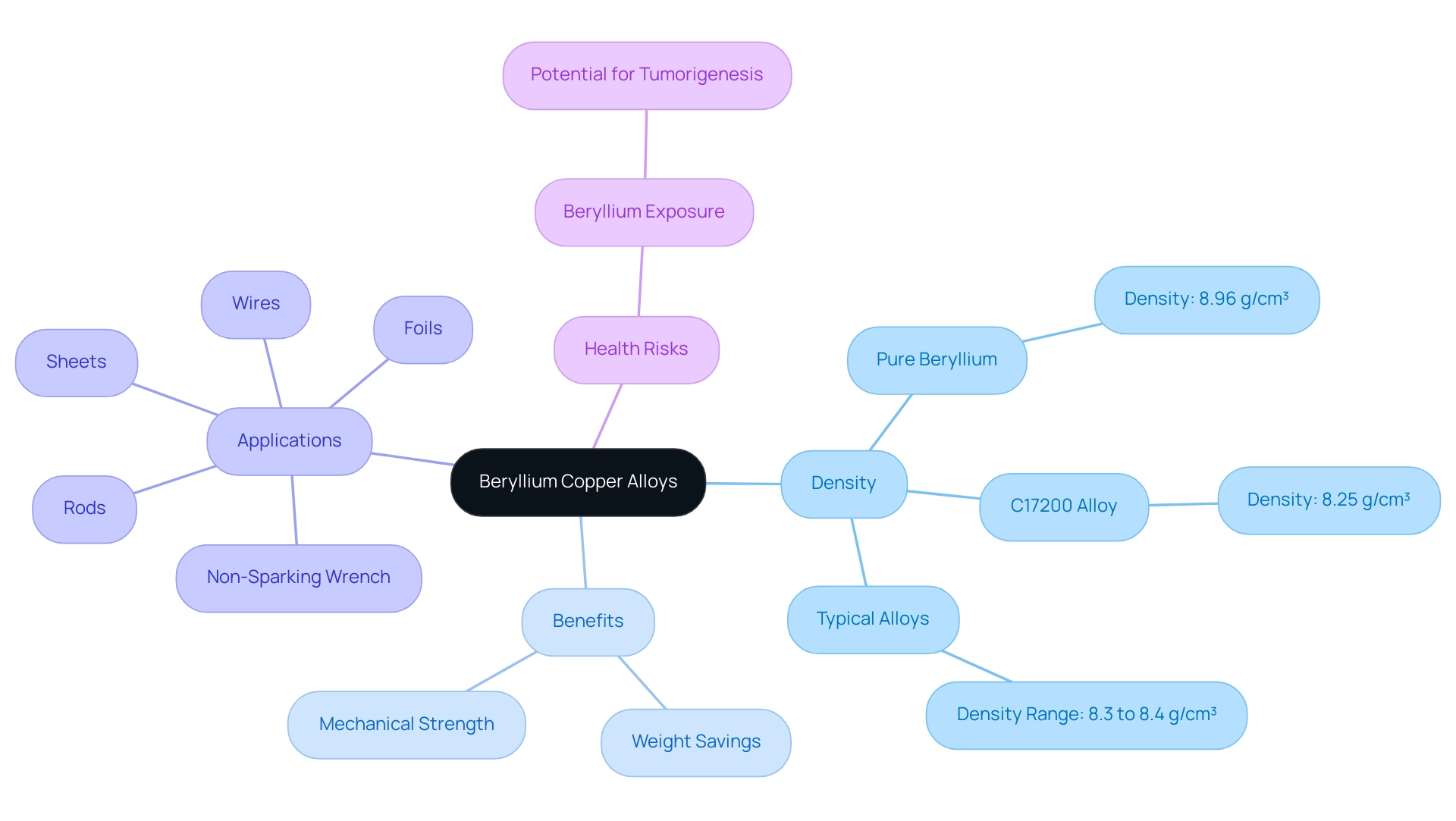

Understanding the Density of Beryllium Copper Alloys

Beryllium metal mixtures are distinguished by a density that surpasses that of typical metal combinations, mainly because of the high density of beryllium copper. Specifically, while pure metal boasts a density of approximately 8.96 g/cm³, typical alloys containing elements such as those with between 1.8% and 2.0% of a certain element by weight exhibit a density in the range of 8.3 to 8.4 g/cm³. Notably, the C17200 beryllium copper alloy exhibits a density of beryllium copper of approximately 8.25 g/cm³, demonstrating its high strength and excellent fatigue resistance.

This marginal reduction in density can provide significant benefits in scenarios where weight savings are paramount, all while maintaining mechanical strength. Furthermore, understanding the relationship between density and properties such as thermal conductivity and electrical performance is crucial when selecting materials for specific applications. The European Commission identifies copper mixtures containing beryllium as one of the 34 essential materials for the European Union, highlighting the significance of these materials in selection.

Domadia stands out as your trusted partner in Beryllium Copper solutions, offering an extensive product range, including:

– Foils

– Sheets

– Rods

– Wires

with ready stock and custom fabrication options. Among our offerings is the Beryllium Copper Non-Sparking Wrench, specifically designed for use in explosive environments, ensuring safety and durability. Additionally, we provide detailed pricing and inventory information to assist procurement managers in making informed decisions.

However, it is vital to consider the potential health risks associated with beryllium exposure, as the overexpression of proto-oncogenes in response to beryllium can lead to cell transformation and tumorigenesis. As procurement managers evaluate material choices, they must thoroughly consider the density of beryllium copper, the benefits of this material, and the significance of selecting the right products to enhance performance results and ensure the appropriateness of these materials in their respective uses.

Mechanical Properties and Their Relation to Density

Beryllium copper is distinguished by its remarkable mechanical properties, which include impressive tensile strength, hardness, and fatigue resistance—attributes that are critical in explosive environments where non-sparking tools are essential. This metal is recognized for its distinctive blend of strength, conductivity, and corrosion resistance, rendering it essential in numerous industrial uses. These characteristics are inherently linked to the density of beryllium copper; generally, a higher density of beryllium copper is associated with enhanced strength and durability.

Significantly, the yield strength of beryllium copper can reach levels up to 1,400 MPa, making it appropriate for challenging uses such as bearings and electrical connectors that require durability and resilience under considerable stress. Furthermore, the density of beryllium copper has a positive influence on its resistance to wear and deformation, making it an ideal choice for high-performance components, including tools and various precision machined parts. Domadia stands at the forefront of supplying and manufacturing Beryllium Copper Plates, ensuring clients have access to a material that is indispensable for numerous industrial applications.

The National Toxicology Program highlights the significance of understanding the properties of this element, noting its classification as a carcinogen, which underscores the need for careful handling in industrial settings. Along with its strength, this alloy shows a Rockwell hardness of 80.0 – 85.0 and an elongation at break of 15.0 – 30.0%, further establishing it as a leading candidate in high-stress environments. For procurement managers, it is vital to take into account the pricing and inventory specifics of beryllium alloys, along with the safety features and uses of the beryllium non-sparking wrench, which increase its significance in explosive settings.

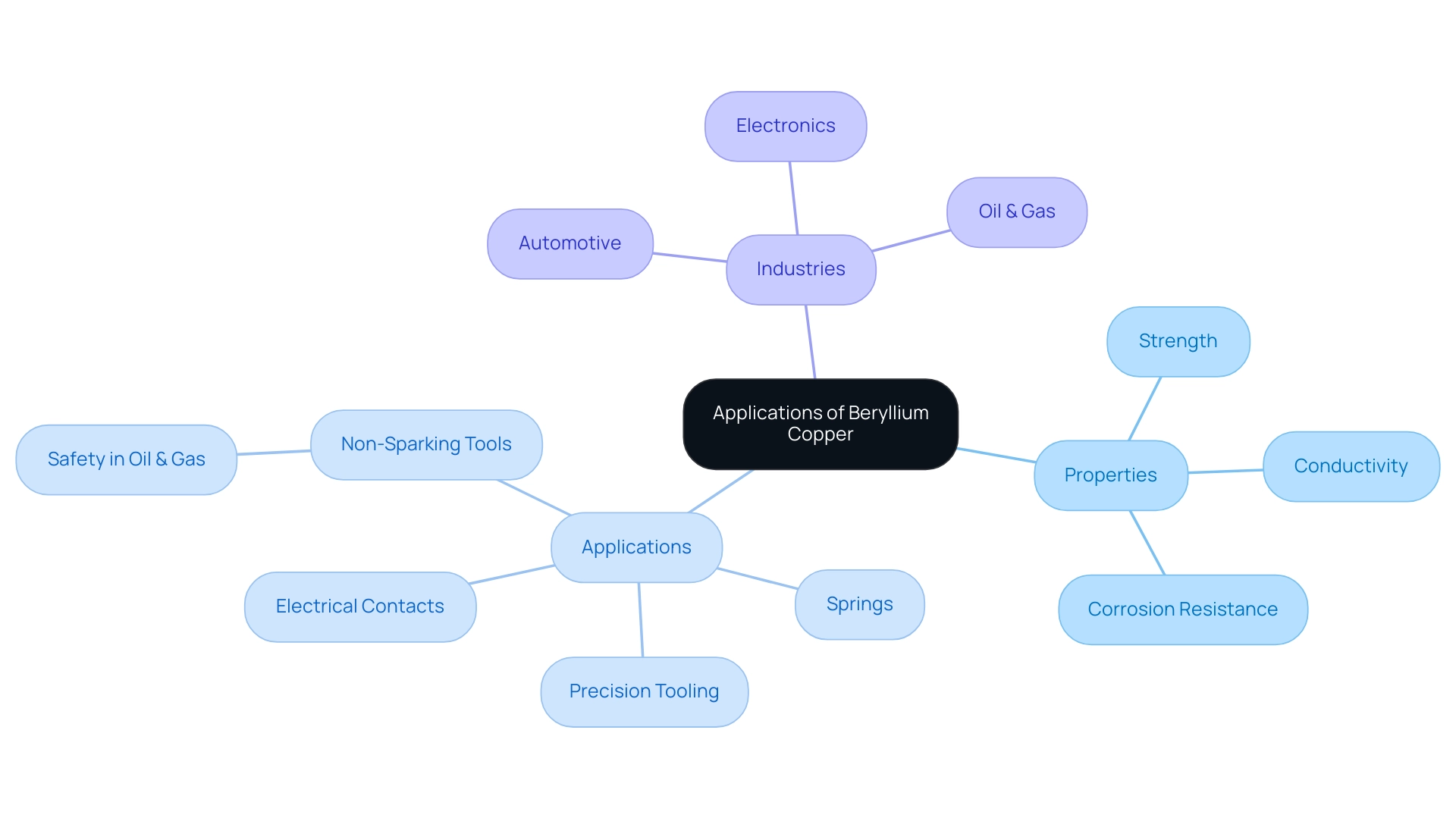

Applications of Beryllium Copper: Leveraging Density for Performance

Beryllium metal is recognized for its superior combination of strength, conductivity, and corrosion resistance, making it a pivotal material in numerous industries, particularly automotive and electronics. Its uses encompass a variety of components, including:

- Electrical contacts

- Springs

- Precision tooling

where reliability is paramount. The density of beryllium copper is crucial for its performance, allowing for the design of lightweight yet sturdy components that can withstand high stress.

This characteristic is especially vital in contexts demanding both performance and safety. Furthermore, the material’s excellent thermal conductivity renders it ideal for heat sinks and electrical connectors, facilitating efficient heat dissipation while preserving structural integrity. The non-sparking wrench made from a specific alloy, designed for safety in dangerous settings, exemplifies the material’s use in tools that demand non-sparking characteristics.

This wrench is essential in industries such as oil and gas, where avoiding sparks is critical. Furthermore, comprehending the pricing and inventory specifics of alloy strips and the non-sparking tool is essential for procurement strategies, ensuring that organizations can acquire these materials efficiently. As the Plastic Molds & Tooling segment is expected to grow at a significant CAGR during the forecast period, understanding the advantages related to the density of beryllium copper becomes increasingly vital for procurement strategies.

Industry specialists observe that innovations employing a specific alloy for lightweight components are increasing, further reinforcing its role as a crucial contributor in contemporary manufacturing. According to a Senior Analyst at Cognitive Market Research,

‘Our research team provides intelligence on industry stats, market structure, company profiles, and competition analysis, which are critical for informed decision-making.’

Additionally, ongoing research into copper-based alloys is expected to enhance predictive adaptability, paving the way for more informed decision-making in applications where precision and efficiency are critical.

For example, the case study named ‘Prioritizing Features Based on User Research’ emphasizes approaches for aligning features with market needs, which can be utilized in the acquisition of specific alloy components.

Health and Safety Considerations in Beryllium Copper Usage

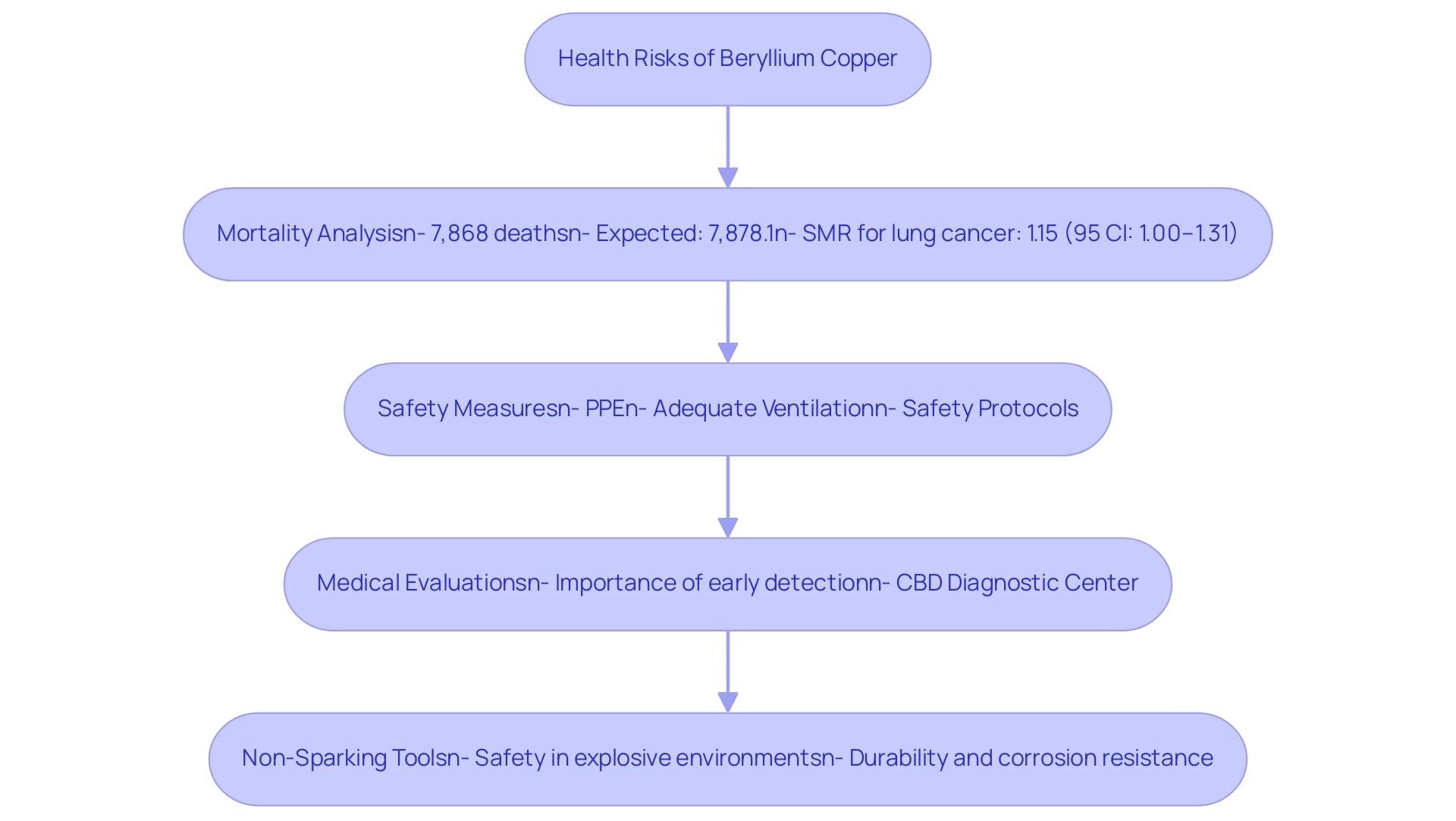

Beryllium copper is renowned for its exceptional performance attributes, making it a preferred choice in high-risk environments. However, it is crucial to acknowledge the health risks associated with exposure to this element. Inhalation of dust from a certain metal can lead to chronic disease (CBD), a debilitating lung condition with serious health threats.

A mortality analysis revealed that the cohort experienced 7,868 deaths compared to an expected 7,878.1 deaths, with a standardized mortality ratio (SMR) for lung cancer among workers employed before 1965 in Reading standing at 1.15 (95% CI: 1.00–1.31), underscoring the elevated risk associated with exposure to the substance. To protect against these dangers, rigorous safety measures must be implemented during the handling and machining of copper. Effective strategies include:

- Utilizing appropriate personal protective equipment (PPE)

- Ensuring adequate ventilation in workspaces

- Adhering to established safety protocols, such as those outlined by OSHA and other regulatory bodies

Additionally, specialized medical diagnostic centers focused on chronic illness have emerged, providing evaluations and testing for affected workers, which is crucial for early detection and management. Given these health considerations, it is vital to re-evaluate hazard classifications for beryllium, as the density of beryllium copper can influence cancer risks that vary by chemical form. In this context, Domadia’s non-sparking tools, including our Beryllium Copper Non-Sparking Wrench, not only provide exceptional durability and corrosion resistance but also ensure safety in explosive environments, reflecting our unwavering commitment to quality and excellence.

Conclusion

Beryllium copper represents a sophisticated amalgamation of strength, conductivity, and durability, making it an invaluable asset across various industries. Its unique composition, featuring a beryllium content of 0.5% to 3%, not only enhances mechanical properties but also influences the density, which ranges from 8.3 to 8.4 g/cm³. This density plays a critical role in optimizing performance, particularly in applications demanding high strength and electrical conductivity, such as automotive components and electronic connectors.

The applications of beryllium copper are diverse, extending to essential tools like non-sparking wrenches that ensure safety in hazardous environments. The alloy’s impressive mechanical properties, including high tensile strength and fatigue resistance, further solidify its position as a material of choice for high-stress applications, reinforcing its relevance in sectors where reliability is non-negotiable. However, the potential health risks associated with beryllium exposure must not be overlooked. Effective safety measures and adherence to regulatory standards are paramount to safeguard workers while harnessing the benefits of this remarkable alloy.

In summary, understanding the multifaceted advantages of beryllium copper—coupled with a keen awareness of health and safety considerations—empowers procurement managers to make informed decisions. By leveraging the unique properties of this alloy, organizations can enhance operational efficiency and product performance, ensuring they remain competitive in an evolving marketplace. As industries continue to innovate and seek advanced materials, beryllium copper stands out as a pivotal component in the pursuit of excellence.