Blogs

Understanding C17200 Beryllium Copper Sheets: An In-Depth Tutorial on Properties and Applications

Introduction

In the realm of industrial materials, C17200 Beryllium Copper sheets stand out as a premier choice, renowned for their unique blend of strength, conductivity, and resistance to corrosion. This alloy is not just a material; it is a strategic asset for procurement managers seeking to enhance their operational efficiency and product reliability.

With applications spanning from aerospace components to electrical connectors, understanding the key properties and fabrication techniques of C17200 Beryllium Copper is essential for making informed sourcing decisions.

As industries evolve and the demand for high-performance materials increases, this guide delves into the critical aspects of C17200 Beryllium Copper, providing insights that empower procurement professionals to leverage its advantages effectively and navigate the complexities of compliance and cost considerations.

Key Properties of C17200 Beryllium Copper Sheets

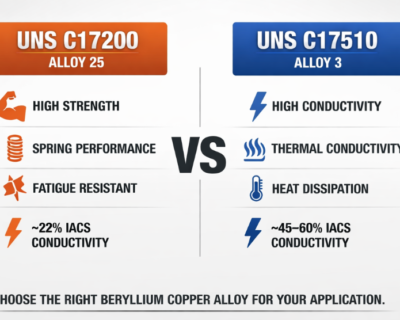

C17200 Beryllium Copper is distinguished by a range of exceptional properties that make it highly sought after in industrial applications:

- High Strength: This alloy is recognized for its remarkable strength, making it an optimal choice for demanding environments where durability is paramount. Its compliance with international standards, including UNS and ASTM, ensures that it meets the rigorous requirements of various industries.

- Excellent Electrical Conductivity: With a minimum electrical conductivity of 22% IACS, this material is particularly advantageous for electrical contacts and components, ensuring efficient performance in electrical applications. This statistic underscores its significance in applications requiring reliable electrical performance.

- Corrosion Resistance: The alloy exhibits robust corrosion resistance, especially in atmospheric and moist conditions, thereby extending the lifespan of components made from this material, making it ideal for diverse industrial applications.

- Thermal Conductivity: This alloy showcases high thermal conductivity, which is crucial for effective heat dissipation in various devices and systems, enhancing their operational efficiency.

- Workability: Its machinability and formability allow for precise fabrication, accommodating complex designs and specifications with ease. This versatility establishes Domadia as a leader in providing high-performance metal plates customized to client requirements.

- Tensile Strength: The tensile strength of this alloy can reach up to 1,400 MPa (200,000 psi), placing it among the strongest metal alloys available and suitable for aerospace and precision applications.

Specific applications of the alloy include its use in electrical connectors, aerospace components, and precision instruments where strength and conductivity are essential. Domadia’s innovative manufacturing techniques and strict quality control measures further guarantee that our alloys meet the highest standards of excellence.

Tim Bradow from Rigaku mentions, “CT instruments can alter battery analysis workflows,” emphasizing the importance of materials such as a specific alloy in contemporary technological applications.

These characteristics collectively make the C17200 Beryllium Copper sheet a favored choice across various applications, balancing durability with exceptional performance. As recent research continues to explore further advancements in its properties, procurement professionals can confidently consider this alloy for both current and future projects, leveraging its superior qualities for enhanced operational efficiency.

Applications of C17200 Beryllium Copper in Industry

Alloy sheets of c17200 beryllium copper sheet are essential to various sectors, appreciated for their outstanding characteristics that provide benefits in functionality and dependability. Key applications include:

- Electrical Connectors: This alloy is extensively utilized in electrical connectors, where its outstanding electrical conductivity and mechanical strength ensure optimal performance and longevity.

- Aerospace Components: In the aerospace sector, the c17200 beryllium copper sheet is preferred for its lightweight yet robust characteristics, making it ideal for components where weight reduction without compromising strength is critical.

- Automotive Parts: The automotive industry also benefits from this alloy, particularly in high-performance components such as springs and valve guides, which require substances that can withstand stress and provide durability.

- Tooling and Molds: The C17200 beryllium copper sheet excels in manufacturing tooling and molds, particularly for injection molding processes, thanks to its superior thermal conductivity that facilitates efficient heat transfer during production.

- Defense Equipment: In defense applications, the alloy’s reliability and durability are paramount, making it suitable for a variety of critical equipment and components.

The telecommunications sector leverages the excellent electrical properties of c17200 beryllium copper sheet, which enhances signal integrity and overall performance in various devices.

In explosive environments, the use of Non-Sparking Tools made from this alloy is vital for ensuring safety while performing critical tasks. These tools are specifically designed to prevent sparks that could ignite flammable substances, providing peace of mind for workers in hazardous conditions. Domadia is dedicated to providing high-quality, tailored alloy plates, and our expert assistance guarantees that you possess the appropriate materials for your projects.

We encourage procurement managers to reach out to us today to find out more about our alloys and explore how we can assist with your project requirements. Comprehending major rivals in the alloy sector, like NGK BERYLCO and Materion, can offer important perspectives on market dynamics and assist you in making knowledgeable procurement choices. These insights, along with our commitment to quality, position Domadia as a reliable partner in your sourcing strategy.

Fabrication Techniques for C17200 Beryllium Copper Sheets

The effective fabrication of Beryllium Copper sheets necessitates a thorough understanding of several critical techniques, underscoring Domadia as your trusted partner for Beryllium Copper solutions:

- Machining: Utilizing standard metalworking tools, this alloy can be machined efficiently. It is crucial to employ sharp tools along with carefully optimized feeds and speeds to minimize tool wear and achieve a superior surface finish. Recent advancements in machining techniques have further refined the processes, making it easier to attain precise dimensions and high-quality results. Significantly, changes in electro discharge machining parameters can result in electrode shape distortions, which should be observed to guarantee optimal outcomes.

- Bending: Cold bending is typically the favored technique for forming this alloy, as it maintains the substance’s inherent strength and ductility. Alternatively, heated bending can be employed but requires meticulous temperature control to avoid compromising the material’s properties. This balance is crucial for preserving the structural integrity of the final product.

- Welding: Welding this alloy poses unique challenges due to its beryllium content; however, specialized techniques can yield effective results. The use of TIG welding has proven to be successful when proper safety precautions and methods are employed. This is particularly important, as Carlos Cruz Wilson, a metals specialist, notes,

The person exposed also needs to be allergic to beryllium to get the disease, and statistics show that only about three to four percent of the population is susceptible to the effects of beryllium.

Thus, understanding the risks associated with welding is crucial for ensuring worker safety, especially given the low susceptibility rate among the general population. - Heat Treatment: Implementing heat treatment processes can significantly enhance the mechanical properties of this alloy, particularly its strength and hardness. It is vital to conduct these treatments in controlled environments to prevent oxidation and ensure consistent quality.

Additionally, a case study on optimizing process parameters of electrochemical machining (ECM) using the Taguchi method illustrates the importance of precise control in machining techniques. This study emphasizes how elements such as voltage and electrolyte concentration can greatly influence material removal rates and surface roughness.

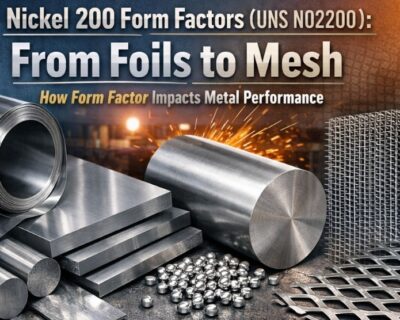

Domadia provides a wide variety of products, including foils, sheets, rods, and wires, ensuring that you have access to the finest solutions customized to your specific needs. Custom fabrication options are also available, allowing us to meet diverse application needs effectively. Mastering these fabrication techniques is essential for processing c17200 beryllium copper sheets to meet specific application requirements, ultimately contributing to the efficiency and effectiveness of industrial operations.

Moreover, the inclusion of Non-Sparking Tools in explosive settings not only improves safety but also supports the overall strategy for utilizing Beryllium-based solutions effectively.

Standards and Compliance for C17200 Beryllium Copper

When acquiring c17200 beryllium copper sheets, it is essential for procurement managers to become acquainted with the relevant standards and compliance requirements that regulate this substance. Key among these are:

- ASTM B194: This standard delineates the specifications for beryllium copper alloys, including C17200, providing detailed insights into the necessary mechanical and chemical properties that ensure superior performance and durability.

- ISO 9001: Adherence to ISO 9001 standards is essential for manufacturers, as it ensures the implementation of effective quality management systems that maintain product consistency and reliability.

- RoHS Compliance: Given that beryllium is regulated under the RoHS (Restriction of Hazardous Substances) directive, it is imperative for procurement managers to verify that the resources sourced comply with these environmental regulations, which aim to minimize harmful substances in electrical and electronic equipment.

- Material Safety Data Sheets (MSDS): Always obtain MSDS documents to access vital safety information regarding the handling and potential hazards associated with the c17200 beryllium copper sheet, ensuring that workplace safety protocols are followed.

Furthermore, it is essential to examine the case study of the c17200 beryllium copper sheet, which exhibits a high tensile strength of over 1380 MPa (200 ksi) and is suitable for various applications due to its malleability and heat treatability. This real-world example emphasizes the importance of adhering to the discussed standards to ensure the performance in practical applications.

Furthermore, procurement managers should be aware that shipping fees for orders exceeding $5000.00 amount to $225.00, which can impact budgeting and logistics planning. Additionally, our company, a leading supplier of Beryllium Copper plates, offers competitive pricing and maintains a robust inventory to meet diverse customer needs. We also offer assistance for inquiries concerning our extensive range of related items, including Kovar, Mu-Metal, and Nickel.

As Tim Bradow from Rigaku observes, “Adherence to industry standards is not merely a regulatory obligation; it greatly improves the reliability and efficiency of sourcing and application processes.” This expert opinion reinforces the critical nature of understanding and implementing the relevant standards.

By thoroughly understanding these standards and incorporating practical insights, procurement managers can confidently source resources that not only meet industry compliance but also mitigate risks linked to non-compliance, thus enhancing operational efficiency.

Cost Considerations for Sourcing C17200 Beryllium Copper Sheets

When sourcing C17200 alloy sheets, several critical cost factors must be considered:

- Raw Costs: The prices of this alloy can vary significantly due to market demand, purity levels, availability, and the specific grade of the substance. Understanding these dynamics is essential for accurate budgeting.

- Processing Costs: Additional expenses related to machining, bending, and fabrication processes can significantly impact overall costs. Being aware of these factors will facilitate more effective financial planning.

- Supplier Relationships: Establishing long-term relationships with suppliers is crucial in the metal industry, where strong partnerships can lead to improved pricing and terms. Domadia emphasizes maintaining strong supplier ties to ensure competitive and fair pricing for beryllium copper scrap transactions, as well as a reliable supply of high-quality materials. A satisfied buyer noted,

Just as advertised. Packaged well for shipping. I am very happy with this product. Thank you!

highlighting the importance of reliable suppliers. - Volume Pricing: Purchasing larger quantities often results in discounts, making it beneficial to assess projected needs and explore bulk buying options. For instance, high-quality alloy 25 wire is currently available at US $36-38 per kg, with a minimum order requirement of 10 kg, emphasizing the need for strategic sourcing. Additionally, leveraging one-stop purchasing services can streamline procurement processes and enhance efficiency. By considering these cost factors and Domadia’s commitment to fair and transparent pricing, procurement managers can strategically optimize their sourcing approaches, ultimately enhancing profitability and ensuring a reliable supply of C17200 beryllium copper sheet. Moreover, related products such as Electrical Insulation Paper, Kapton Tapes, and High-Temperature Fabrics can also be sourced through Domadia, providing comprehensive solutions for various industrial needs.

Conclusion

C17200 Beryllium Copper sheets exemplify a superior choice for procurement managers aiming to enhance operational efficiency across diverse industries. The alloy’s remarkable properties—high strength, excellent electrical and thermal conductivity, corrosion resistance, and impressive workability—position it as a critical asset in applications ranging from aerospace components to electrical connectors. Understanding these attributes is essential for making informed sourcing decisions that align with industry demands.

Moreover, the strategic fabrication techniques, compliance with industry standards, and cost considerations associated with C17200 underscore the importance of meticulous planning in procurement processes. Familiarity with standards such as ASTM B194 and RoHS not only ensures compliance but also reinforces the reliability and performance of sourced materials.

By integrating these insights into sourcing strategies, procurement professionals can navigate the complexities of the market with confidence. Leveraging the advantages of C17200 Beryllium Copper will not only enhance product reliability but also contribute to overall operational success. As industries continue to evolve, the informed selection of high-performance materials like C17200 will remain pivotal in maintaining competitive advantage and driving innovation.