Blogs

How to Find the Best Monel K500 Price: A Step-by-Step Guide

Introduction

In the competitive landscape of procurement, understanding the intricacies of sourcing materials like Monel K500 is paramount for achieving strategic advantages. This nickel-copper alloy, celebrated for its remarkable strength and resistance to corrosion, presents a unique set of challenges and opportunities for procurement managers.

From navigating fluctuating market conditions to evaluating supplier reliability, every decision impacts not only the bottom line but also the overall success of projects across various industries.

This article delves into the critical factors influencing Monel K500 pricing, offers a comprehensive guide to effective sourcing, and highlights best practices for negotiating favorable terms, ensuring that procurement professionals are equipped with the insights necessary to make informed decisions in a dynamic market environment.

Understanding Factors Influencing Monel K500 Pricing

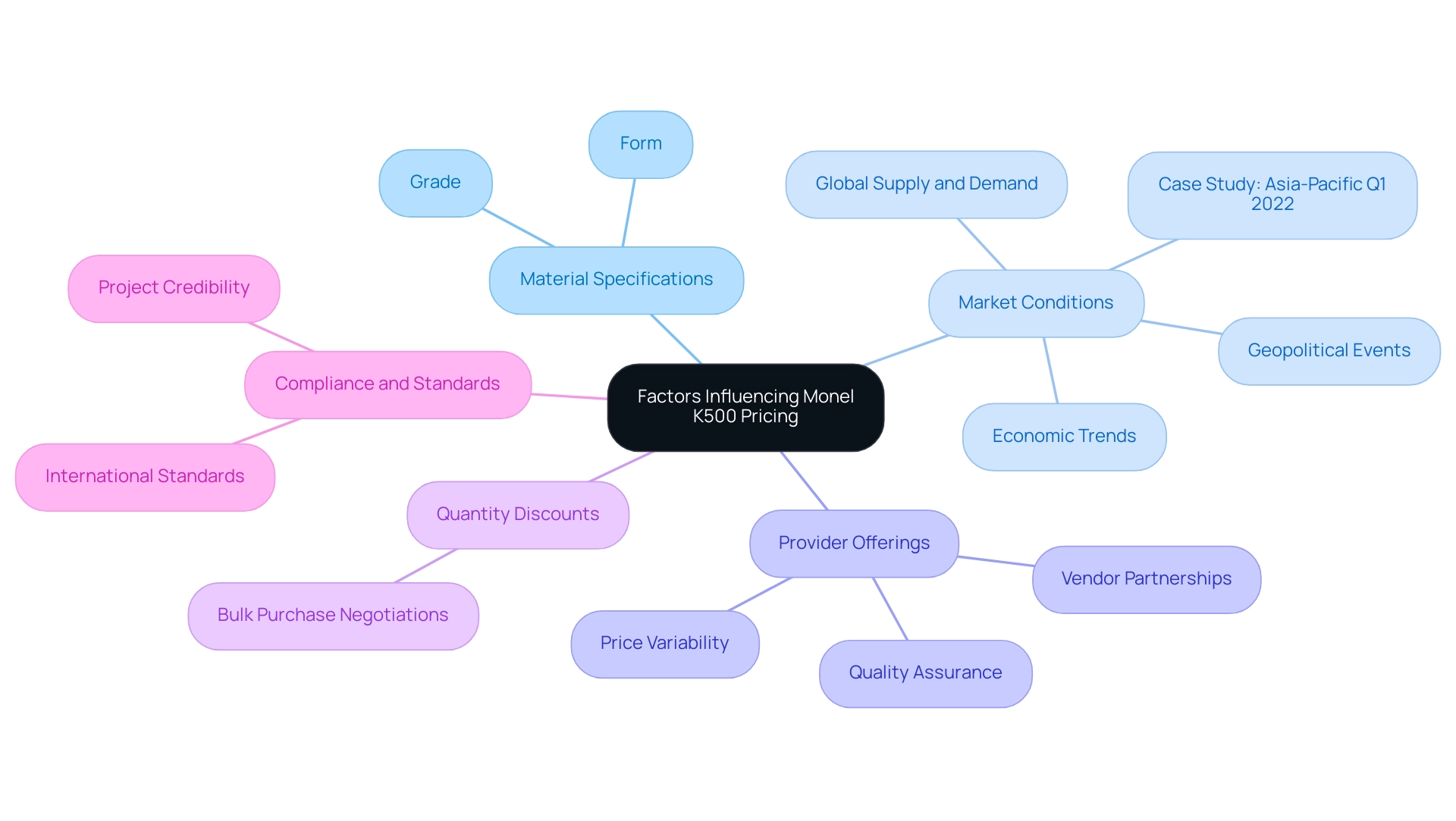

When evaluating the cost of this alloy, several essential factors must be considered:

- Material Specifications: Monel K500, a nickel-copper alloy, is renowned for its exceptional strength and corrosion resistance. At Domadia, we offer a diverse range of copper nickel alloys tailored for various applications, including marine engineering, electronics, and chemical processing.

Variations in material specifications can lead to significant price disparities; therefore, it’s imperative to have a precise understanding of the grade and form required for your specific application.

- Market Conditions: The cost landscape is heavily influenced by global supply and demand dynamics, geopolitical events, and broader economic trends. For instance, in the Asia-Pacific market, Alloy 400 prices surged in Q1 2022 due to escalating crude oil and raw material costs amid geopolitical tensions, showcasing how external factors can impact pricing.

This case illustrates the importance of staying informed about market dynamics, as prices can fluctuate dramatically based on current events. Regularly consult metal market reports and indices to remain informed about potential fluctuations.

- Provider Offerings: The prices for Monel K500 can vary substantially among different providers.

At Domadia, we pride ourselves on our commitment to quality, ensuring that each product undergoes rigorous testing and inspection processes to meet the highest industry standards. Price differences among vendors may stem from sourcing strategies, inventory levels, and customer service practices. It’s essential to assess various vendors to discover competitive cost alternatives that match your requirements.

As noted by Renine Metalloys, ‘Becoming on top of High Nickel Provider in this only one place, Renine Metalloys hits on expectation of any Steel related Products. It is better to contact us today than tomorrow!’ This underscores the significance of developing robust partnerships with vendors to guarantee favorable pricing, such as the Monel K500 price, and availability.

Quantity and Volume Discounts: Larger orders often qualify for volume discounts, which can significantly reduce overall costs. Engage in discussions with suppliers about potential discounts for bulk purchases to optimize your procurement strategy.

Compliance and Standards: Ensure that the alloy you intend to source adheres to relevant international standards and certifications.

Compliance not only influences costs but also impacts the availability of the material in the market. For example, sourcing compliant materials can enhance project credibility and reduce risks associated with non-compliance.

In a market where firms examine over 25,000 high-impact and niche markets, understanding these factors becomes crucial for procurement managers. By thoroughly grasping these factors, procurement managers can effectively navigate the pricing environment of this alloy, enabling more strategic purchasing decisions that align with market conditions and business objectives.

At Domadia, we are dedicated to offering high-quality alloy, supported by thorough testing and customer satisfaction, guaranteeing that you obtain the best value for your investment.

Step-by-Step Guide to Sourcing Monel K500

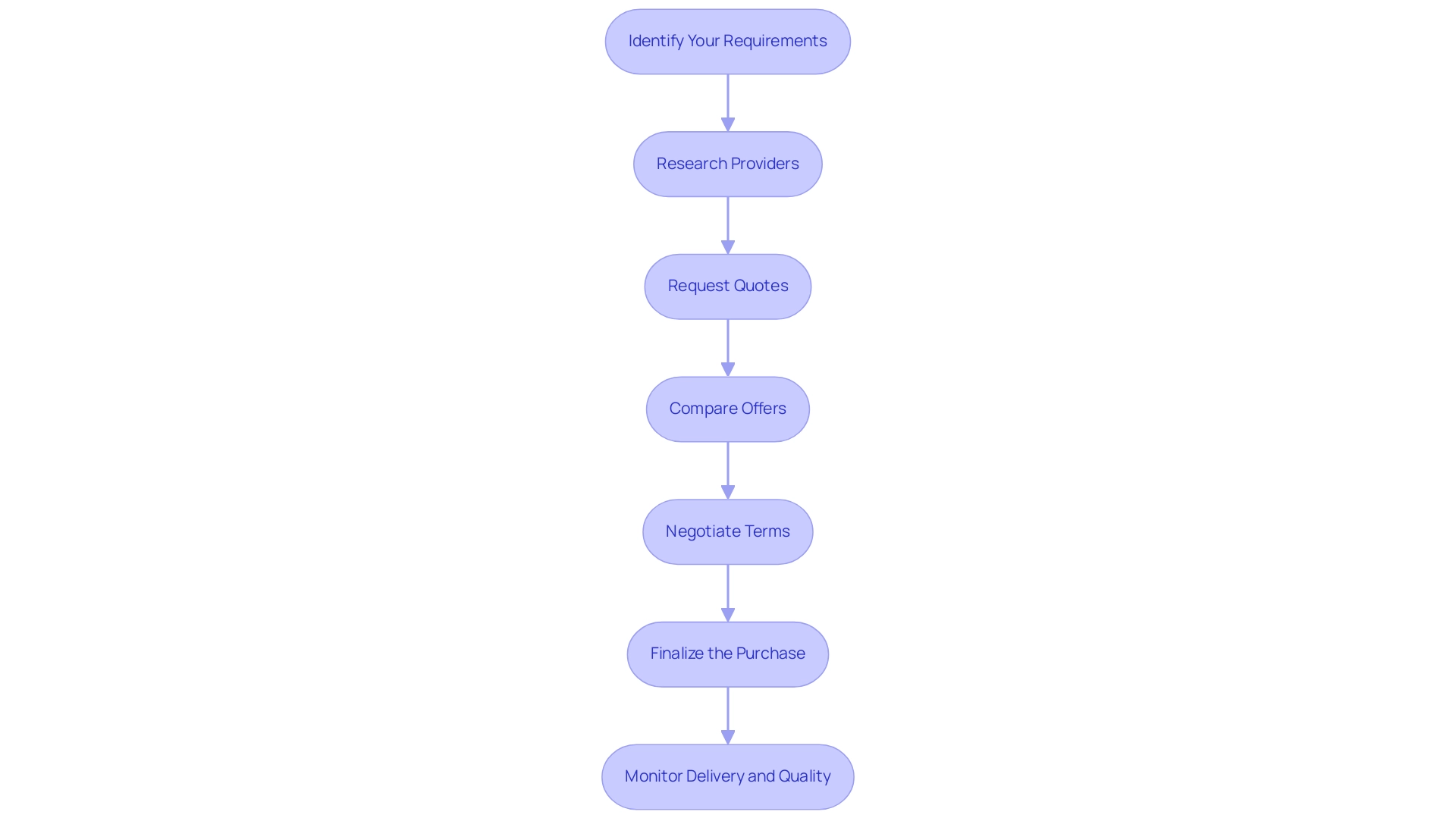

To effectively source the alloy while ensuring safety in explosive environments, procurement managers should adhere to the following structured approach:

Identify Your Requirements: Clearly define the specifications and quantities of K500 alloy needed. Understanding the application and any relevant industry standards—such as those established by ASTM and ASME—is crucial for precise procurement.

Research Providers: Utilize industry databases, trade shows, and online platforms to identify potential providers. Resources like ThomasNet and Alibaba are invaluable for discovering reputable options within the Model alloy market. Additionally, consider vendors that specialize in electrical insulation and high-temperature materials, as they may offer complementary products that enhance safety in explosive environments.

Evaluate Vendor Credentials: Assess vendors based on their reputation, years of experience, and compliance with industry standards. Seek out reviews or testimonials from prior clients to gauge reliability. As noted by specialists at Midwest Alloys & Technology Inc.,

> Midalloy specializes in high-performance nickel alloy welding consumables, offering a comprehensive range of products that meet various industry standards.

Midwest Alloys & Technology Inc. has an estimated revenue of $10 – 24.9 million, which reflects its significant market position and credibility. This underscores the significance of vendor specialization.Request Quotes: Engage multiple suppliers for quotes on K500 alloy. Be sure to provide detailed specifications to obtain an accurate monel k500 price. This step is especially crucial as the market for these products, particularly the monel k500 price, can vary significantly in pricing.

Compare Offers: Analyze quotes not only on price but also on delivery terms, payment options, and additional services like certification or testing, which are essential for ensuring compliance and quality assurance. Furthermore, consider vendors that provide Non-Sparking Tools as alternatives for applications in explosive environments, ensuring safety and compliance in procurement. For instance, using Non-Sparking Tools in conjunction with Monel K500 can significantly reduce the risk of ignition during maintenance or assembly tasks in hazardous settings.

Negotiate Terms: Enter negotiations with an understanding of current market conditions and vendor offerings, which can empower you to secure the best possible pricing and terms. This strategic approach can yield significant savings.

Finalize the Purchase: Upon choosing a vendor, finalize the purchase agreement. Ensure that all terms—including delivery timelines and payment conditions—are clearly documented to avoid misunderstandings.

Monitor Delivery and Quality: Maintain communication with the provider throughout the delivery process. Upon receipt, verify that the alloy meets the specified quality standards and application requirements. This monitoring is vital for maintaining operational integrity.

Additionally, keep in mind the physical constants of MONEL Alloy K-500: it has a density of 8.44 g/cm³, a melting range of 2400-2460 °F (1315-1350 °C), a modulus of elasticity in tension of 26.0 ksi, and a Poisson’s ratio of 0.32 for aged material at room temperature. Comprehending these specifications can assist in assessing the material’s appropriateness for particular uses.

By methodically adhering to these steps and taking into account the technical specifications and vendor assessments, procurement managers can enhance the sourcing process for this alloy, ensuring they attain the optimal combination of cost and quality. The adaptability of this product is showcased through its uses in different sectors like glass production, chemical processing, and aerospace, emphasizing the significance of choosing the appropriate provider according to sector-specific requirements.

Evaluating Supplier Quality and Reliability

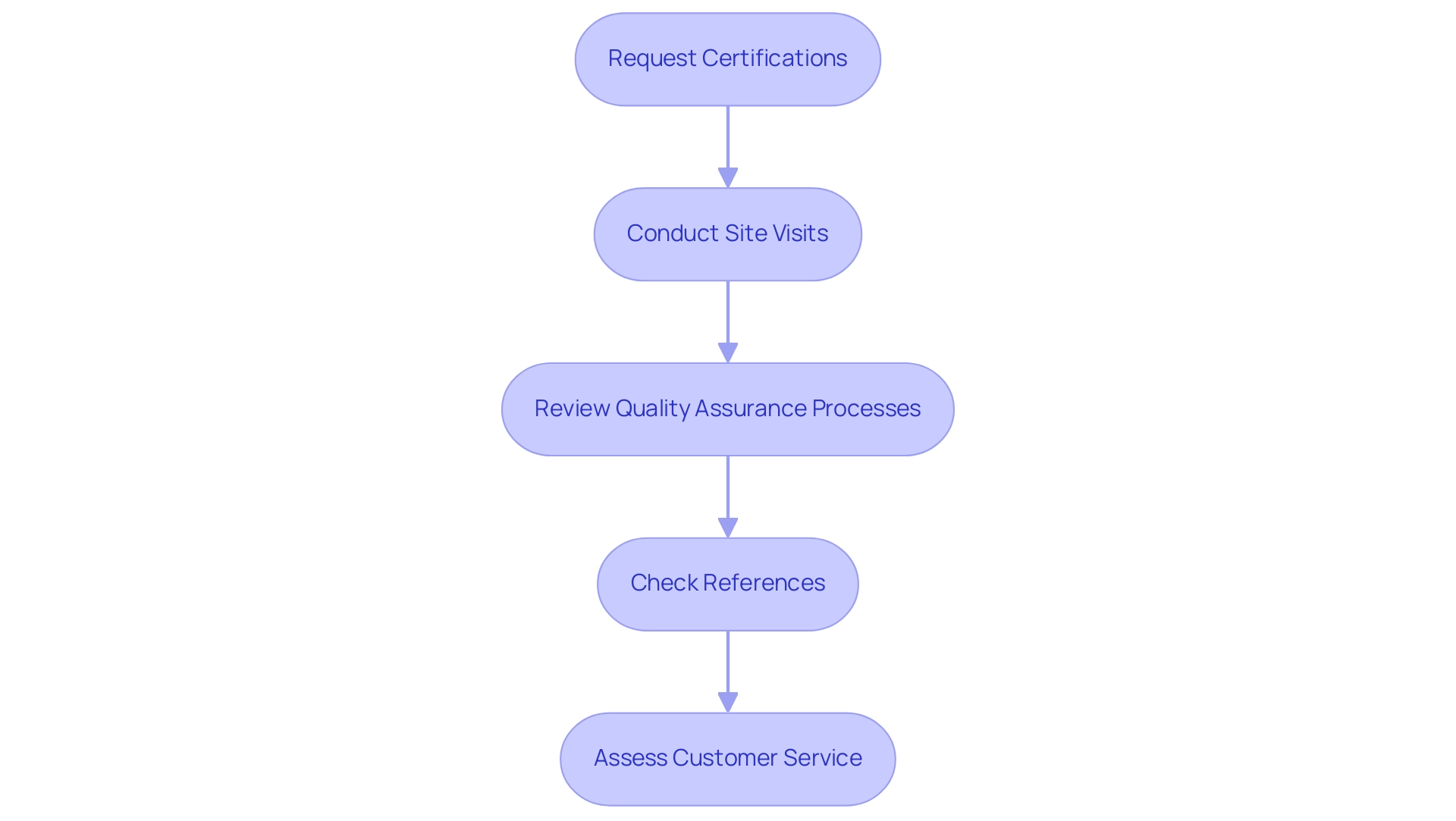

Assessing the quality and reliability of vendors is crucial for ensuring that the Monel K500 price reflects consistent performance in demanding applications, particularly in fields such as oil and gas production and aerospace. With an estimated revenue of $10 – 24.9 million for manufacturers in San Diego, CA, the financial stakes in sourcing high-quality materials highlight the significance of vendor reliability. Here are key steps to guide procurement managers in this process:

- Request Certifications: Begin by asking vendors for relevant certifications such as ISO 9001, which signifies a commitment to quality management. It is essential to verify compliance with industry standards specifically applicable to the Monel K500 price.

- Conduct Site Visits: If feasible, arrange visits to the manufacturer’s production facility. This direct observation allows you to assess their production processes and quality control measures in real-time.

- Review Quality Assurance Processes: Inquire about the provider’s quality assurance protocols. Understanding how they test and validate the materials they produce—particularly through third-party testing—can provide assurance of compliance and reliability.

- Check References: Request references from other clients who have sourced Monel K500 and inquire about the Monel K500 price from the vendor. This step can yield valuable insights into their reliability and quality performance over time.

- Assess Customer Service: Evaluate the provider’s responsiveness and their willingness to address any concerns. Strong customer service often correlates with a provider’s reliability and commitment to quality.

A real-world example is AEM & Forge, LLC, a distributor of Monel® and Monel® alloys, which offers various fabrication capabilities, including shielding, etching, and milling. By utilizing these assessment methods, procurement managers can strategically collaborate with partners such as AEM & Forge that consistently provide high-quality alloy, thereby improving their supply chain resilience and operational efficiency. Moreover, considering recent insights into the uses of this alloy in essential sectors, guaranteeing supplier quality is more crucial than ever.

Negotiating the Best Price for Monel K500

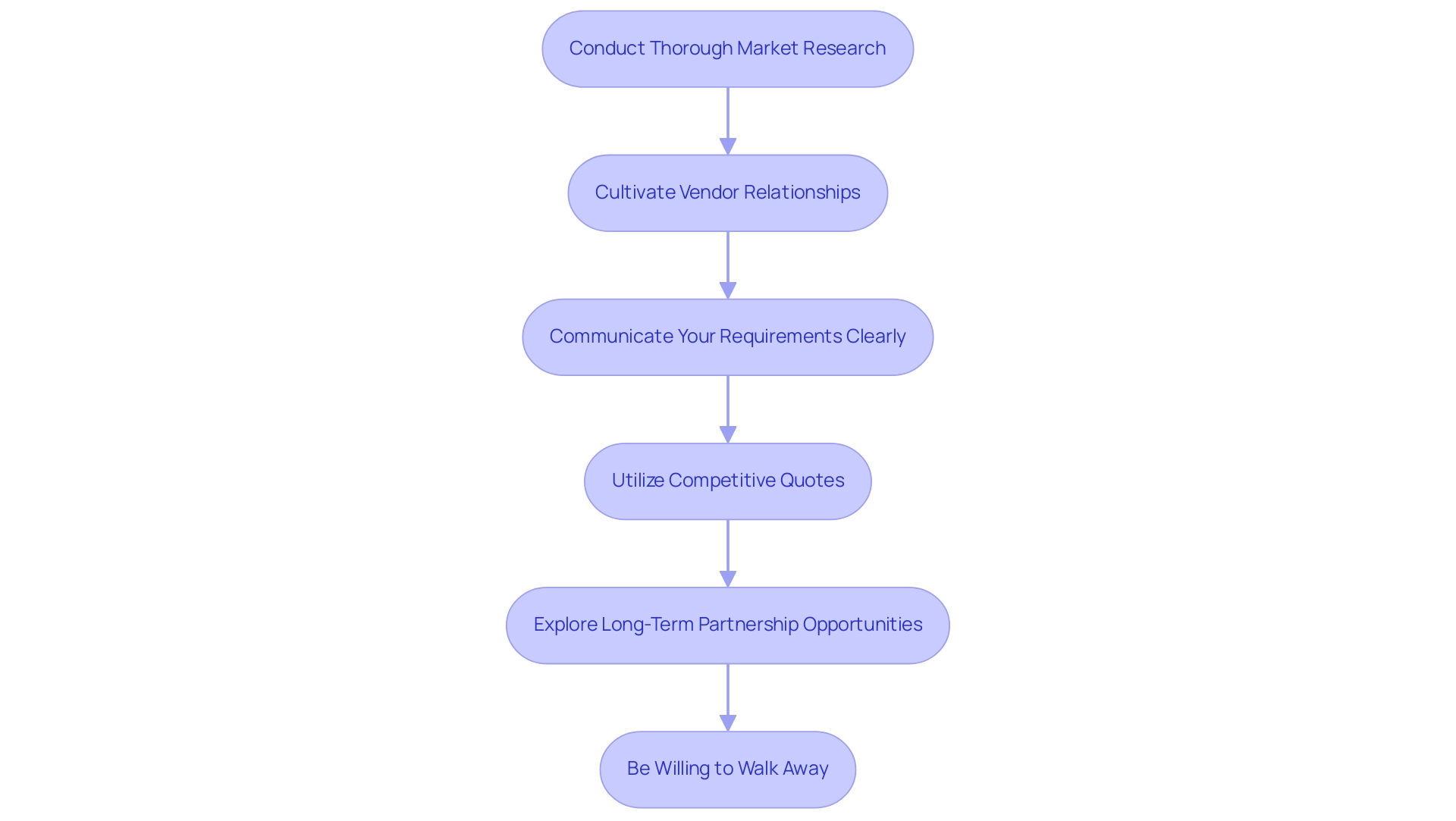

To negotiate the best price for the alloy, consider implementing the following strategies:

Conduct Thorough Market Research: Understand the current market prices and trends for Monel K500 price, which, as of late December 2022, was approximately USD 42,825/MT for Alloy 400 in Europe. This knowledge not only empowers you to negotiate effectively but also helps you understand how fluctuations in prices, driven by raw material costs, may affect your negotiations.

Cultivate Vendor Relationships: Building strong connections with vendors can result in improved rates and conditions. As noted by a leading global consulting firm,

Our company has been working with for some years now and we are very happy with the quality of the reports provided by the company.

This highlights that trust and positive engagement can significantly impact negotiations, especially as the market sees continuous development of new Monel alloys tailored for specific applications, which can influence the Monel K500 price and its availability.Communicate Your Requirements Clearly: Be explicit about your needs and expectations. Transparency fosters trust and minimizes misunderstandings, which is crucial for maintaining strong partnerships.

Utilize Competitive Quotes: Gather and present quotes from various vendors to bolster your negotiating position. Indicating that you are exploring diverse options encourages vendors to provide more competitive pricing to secure your business.

Explore Long-Term Partnership Opportunities: If applicable, discuss the potential for long-term contracts or ongoing business relationships. Suppliers may be more inclined to provide discounts for the assurance of repeat orders, thus enhancing your negotiating leverage.

Be Willing to Walk Away: If the proposed price exceeds your budget or does not align with your expectations, be prepared to consider alternatives. This attitude not only strengthens you during negotiations but also conveys to suppliers your dedication to obtaining the best agreement.

By applying these strategic negotiation methods, procurement managers can effectively lower expenses while guaranteeing the procurement of high-quality alloy. This is particularly important in a fluctuating market landscape characterized by rising prices due to raw material costs, as illustrated by the recent case study showing how these pressures have influenced metal prices.

Finalizing the Procurement Process

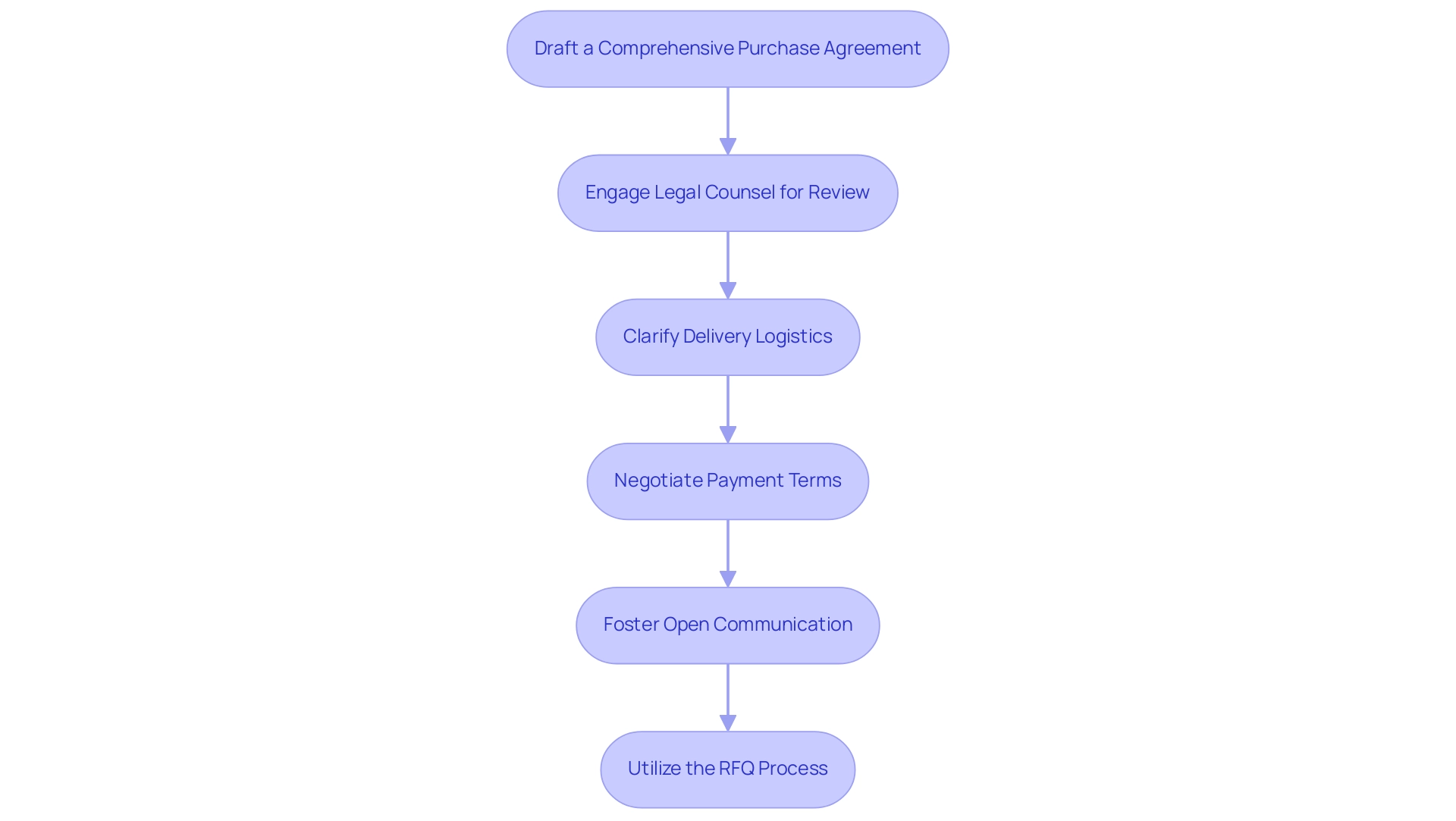

To effectively finalize the procurement process for Monel K500, procurement managers should adhere to the following strategic steps:

Draft a Comprehensive Purchase Agreement: Begin by formulating a thorough purchase agreement that meticulously details all pertinent terms. This should include cost structures, delivery timelines, payment conditions, and quality specifications to mitigate any potential ambiguities.

Engage Legal Counsel for Review: Collaborate with your legal team to evaluate the agreement. Their insights will ensure compliance with applicable regulations and safeguard your interests against potential disputes.

Clarify Delivery Logistics: Establish clear logistics for delivery, identifying the shipping methods, expected timelines, and responsibilities regarding import duties or customs clearance.

This step is crucial to maintaining a seamless supply chain.Negotiate Payment Terms: Set payment terms that are advantageous for both parties. Options may include partial payments upon order confirmation, with the remainder due upon successful delivery, facilitating trust and financial clarity.

Foster Open Communication: Maintain consistent communication with your provider throughout the procurement process. Regular interaction is vital for preemptively addressing issues and ensuring that the transaction proceeds smoothly.

Utilize the RFQ Process: Implement a request for quote (RFQ) to manage the bidding process effectively and obtain competitive pricing.

This structured method enables tracking and comparing vendor responses, ensuring the best value for your procurement.

By adhering to these structured steps, procurement managers can secure Monel K500 effectively while ensuring alignment among all stakeholders concerning the Monel K500 price. As emphasized by industry experts, the involvement of all key stakeholders at an early stage—encompassing procurement, legal, finance, security, IT, and business leadership—significantly contributes to the success of the procurement process. Additionally, leveraging the expertise of professionals like Rahul Asthana, who has 25 years of experience in supply chain management, can provide valuable insights into best practices.

Furthermore, establishing clear key performance indicators (KPIs), as highlighted in the case study on tracking performance, allows for monitoring supplier performance and internal progress, which is essential for ongoing business growth and informed decision-making.

Conclusion

Understanding the complexities surrounding the procurement of Monel K500 is essential for making informed decisions that align with both market dynamics and organizational goals. Key factors influencing pricing, such as material specifications, market conditions, and supplier reliability, play a crucial role in shaping procurement strategies. By staying informed about these elements, procurement managers can navigate the market effectively, ensuring they secure the best possible value for their investments.

The step-by-step guide to sourcing Monel K500 emphasizes the importance of thorough research and supplier evaluation. Identifying specific requirements, comparing quotes, and maintaining strong supplier relationships are vital processes that can lead to significant cost savings and enhanced quality assurance. Furthermore, negotiating favorable terms not only helps in managing expenses but also fosters long-term partnerships that can benefit both parties.

As the landscape of procurement continues to evolve, prioritizing quality and compliance remains paramount. The emphasis on rigorous supplier evaluations and adherence to standards can significantly mitigate risks associated with sourcing materials. By implementing a structured procurement process and leveraging industry knowledge, procurement managers can enhance their operational efficiency and ensure the successful execution of projects across various sectors.

Ultimately, a strategic approach to procuring Monel K500 not only addresses immediate needs but also positions organizations for long-term success in a competitive market. By embracing these best practices and remaining adaptable to changing conditions, procurement professionals can secure the materials necessary for their projects while maximizing value and minimizing risk.