Blogs

How to Choose the Right Beryllium Copper Sheet Suppliers: A Step-by-Step Guide

Introduction

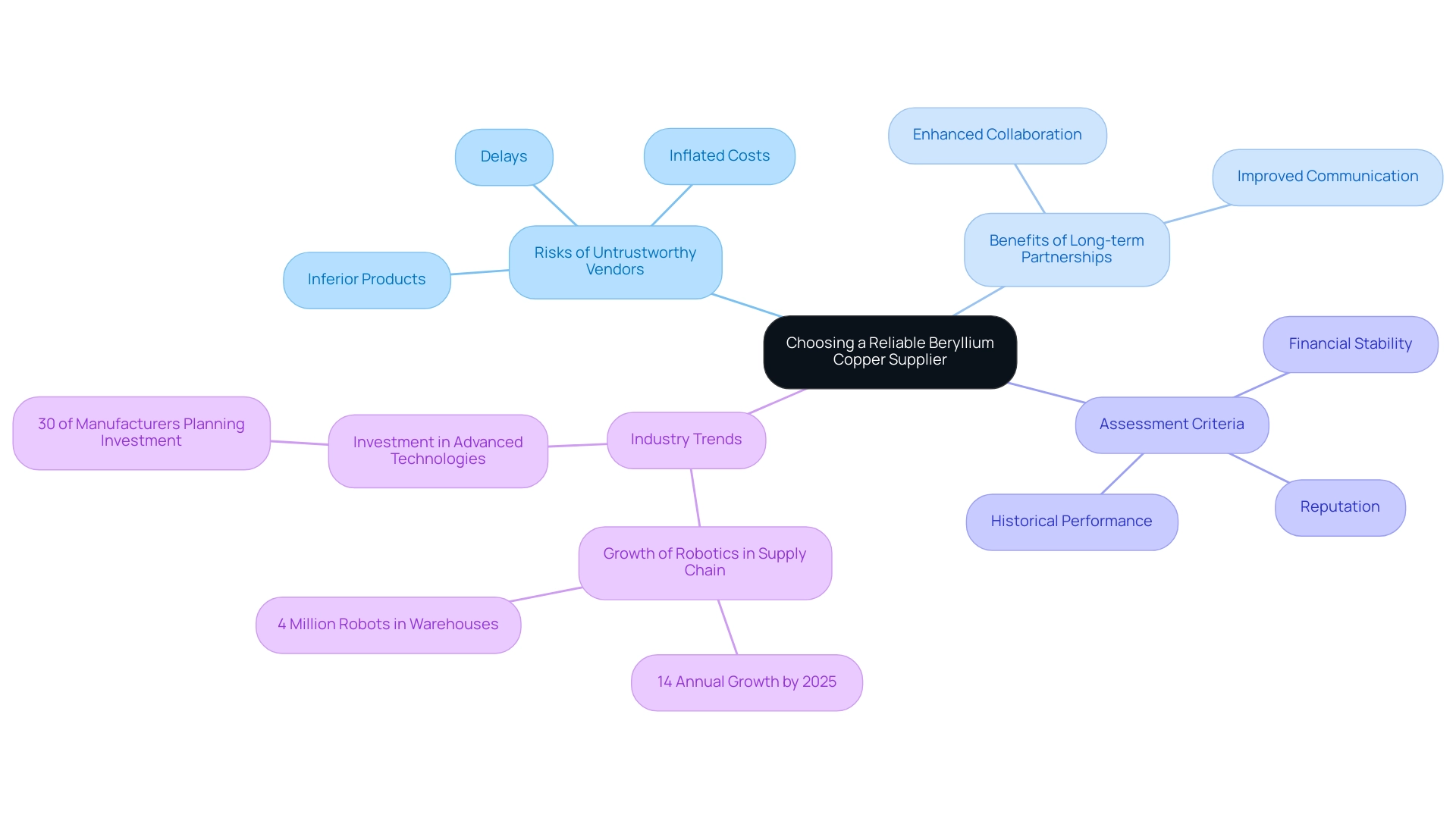

In the realm of industrial procurement, the selection of a reliable Beryllium Copper supplier stands as a pivotal decision that can significantly influence project outcomes. As industries increasingly rely on high-quality materials to meet demanding performance standards, the risks associated with choosing an unreliable supplier become all too evident—delays, subpar products, and inflated costs can derail even the most meticulously planned projects.

This article delves into the critical factors that procurement managers must consider when evaluating potential suppliers, including:

– Product quality

– Certifications

– Customer service

– Delivery reliability

Furthermore, it explores the distinct types of Beryllium Copper alloys and their applications across various sectors, emphasizing the importance of safety and compliance in supplier selection. By understanding these elements, procurement professionals can forge strategic partnerships that not only enhance operational efficiency but also drive competitive advantage in an ever-evolving marketplace.

The Importance of Choosing a Reliable Beryllium Copper Supplier

Choosing a trustworthy beryllium copper sheet suppliers is crucial for securing high-quality materials that meet your specific needs. An untrustworthy vendor can introduce significant risks, leading to delays, inferior products, and ultimately inflated costs. At Domadia, we are committed to providing high-quality customized Beryllium Copper Plates, tailored to your project needs, and backed by our expert support.

Our clients have consistently praised our products, with one stating, ‘Domadia’s Beryllium Copper Plates exceeded our expectations in quality and service.’ Establishing a long-term partnership with beryllium copper sheet suppliers not only mitigates these risks but also fosters enhanced collaboration and communication throughout the procurement process. To gauge vendor reliability, it is essential to assess their reputation, financial stability, and historical performance.

Christine Evans, Sr. Director of Marketing at Fictiv, emphasizes that ‘these important supply chain statistics will provide insight into the future of supply chain management and give you a competitive advantage.’ This perspective is critical as nearly 30% of industrial product manufacturers are poised to invest in advanced technologies, underscoring the need for dependable partners capable of adapting to evolving demands. Furthermore, with the anticipated growth of robotics in the supply chain projected at 14% annually by 2025, the efficiency and reliability of providers become even more crucial.

Comprehending the effect of provider quality on production costs is essential, as it directly affects overall operational efficiency and competitive positioning in the market. Domadia exemplifies this commitment by addressing supply chain challenges through our high-quality Beryllium Copper Plates sourced from beryllium copper sheet suppliers, as well as our range of related products, including Kovar and Nickel materials. Contact us today to learn more about how we can support your project needs and ensure your success.

Key Criteria for Evaluating Beryllium Copper Sheet Suppliers

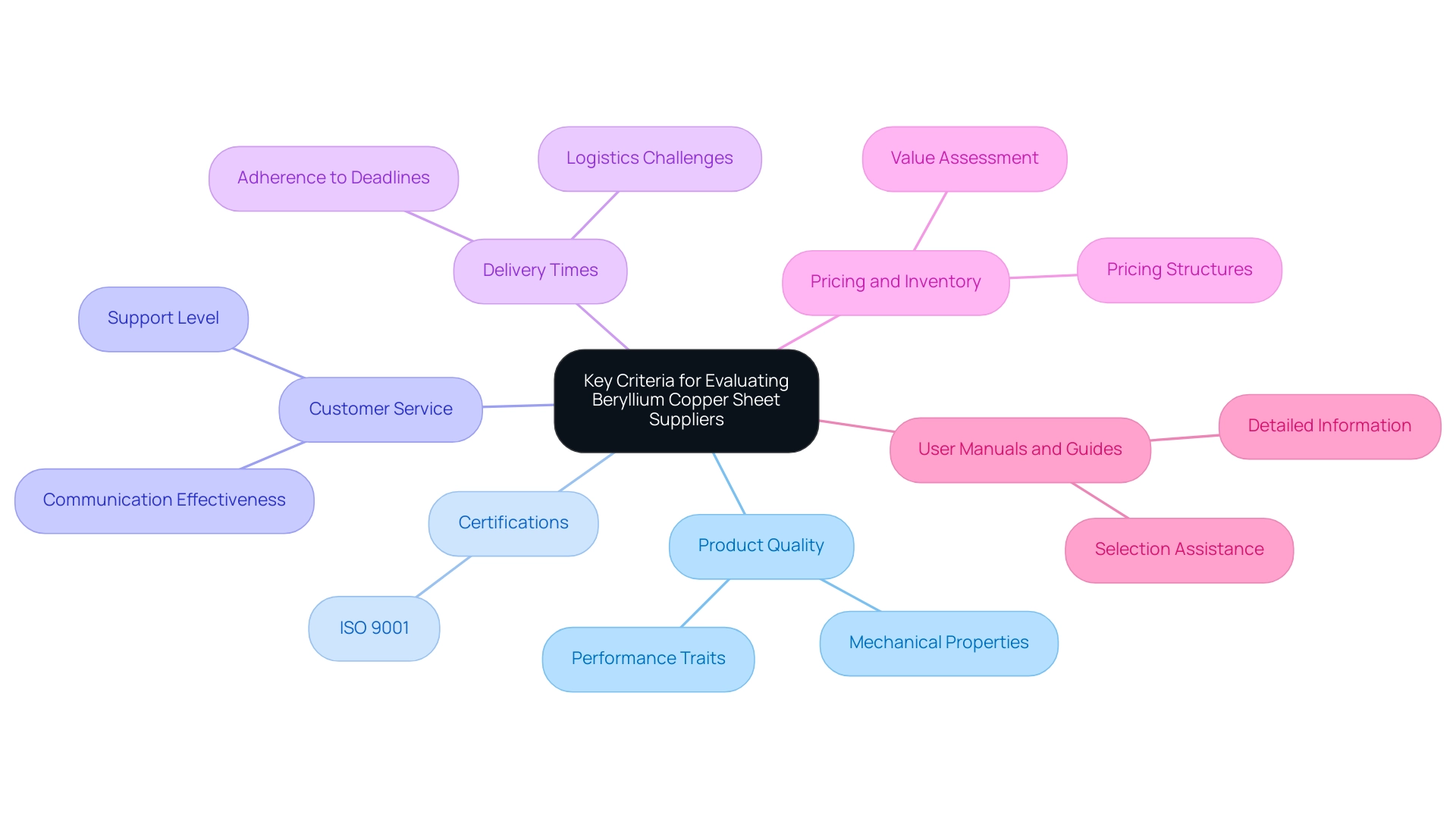

When evaluating alloy sheet providers, it is crucial to take into account various important standards to guarantee the best procurement results:

- Product Quality: Assess the caliber of materials offered, concentrating on mechanical properties and performance traits. High-quality metal is crucial for applications requiring exceptional conductivity and strength. At Domadia, we provide a wide variety of beryllium copper solutions, including foils, sheets, rods, and wires, customized to meet the specific needs of beryllium copper sheet suppliers.

- Certifications: Ensure that vendors possess relevant industry certifications, notably ISO 9001. This certification serves as a testament to their commitment to quality management practices, ensuring that the materials provided meet stringent quality standards.

- Customer Service: Analyze the level of support and responsiveness offered by the vendor. Effective communication and support are essential for a seamless purchasing experience, as they can significantly influence resolution times for any issues that arise. Domadia takes pride in being your reliable ally in success, delivering outstanding customer service during the purchasing process.

- Delivery Times: Examine the vendor’s capacity to adhere to delivery deadlines. Timely delivery is critical for maintaining production schedules and avoiding costly downtimes in operations. Notably, the global demand for air cargo fell by 14.9% in January 2023 compared to the previous year, which may present challenges in logistics that affect delivery reliability. At Domadia, we ensure prompt delivery to support your operational needs.

- Pricing and Inventory: Compare pricing structures among potential beryllium copper sheet suppliers, focusing on specific pricing for Beryllium Copper strips and considering the overall value provided, including product quality and service levels, rather than solely focusing on the lowest price. With competitive pricing and a commitment to high-quality products, Domadia aligns its offerings with your long-term organizational goals. Additionally, our inventory details are readily available to assist you in making informed decisions.

- User Manuals and Guides: Utilize our user manuals and guides for detailed information on the use and benefits of Beryllium Copper products. These resources can improve your comprehension and selection process, making sure you select the best choices for your requirements.

By utilizing these standards and taking advantage of advancements in technology, such as AI in the supply chain, sourcing managers can refine their supplier assessment process, resulting in more informed choices and better results in the acquisition of metal sheets.

Understanding Different Types of Beryllium Copper Alloys

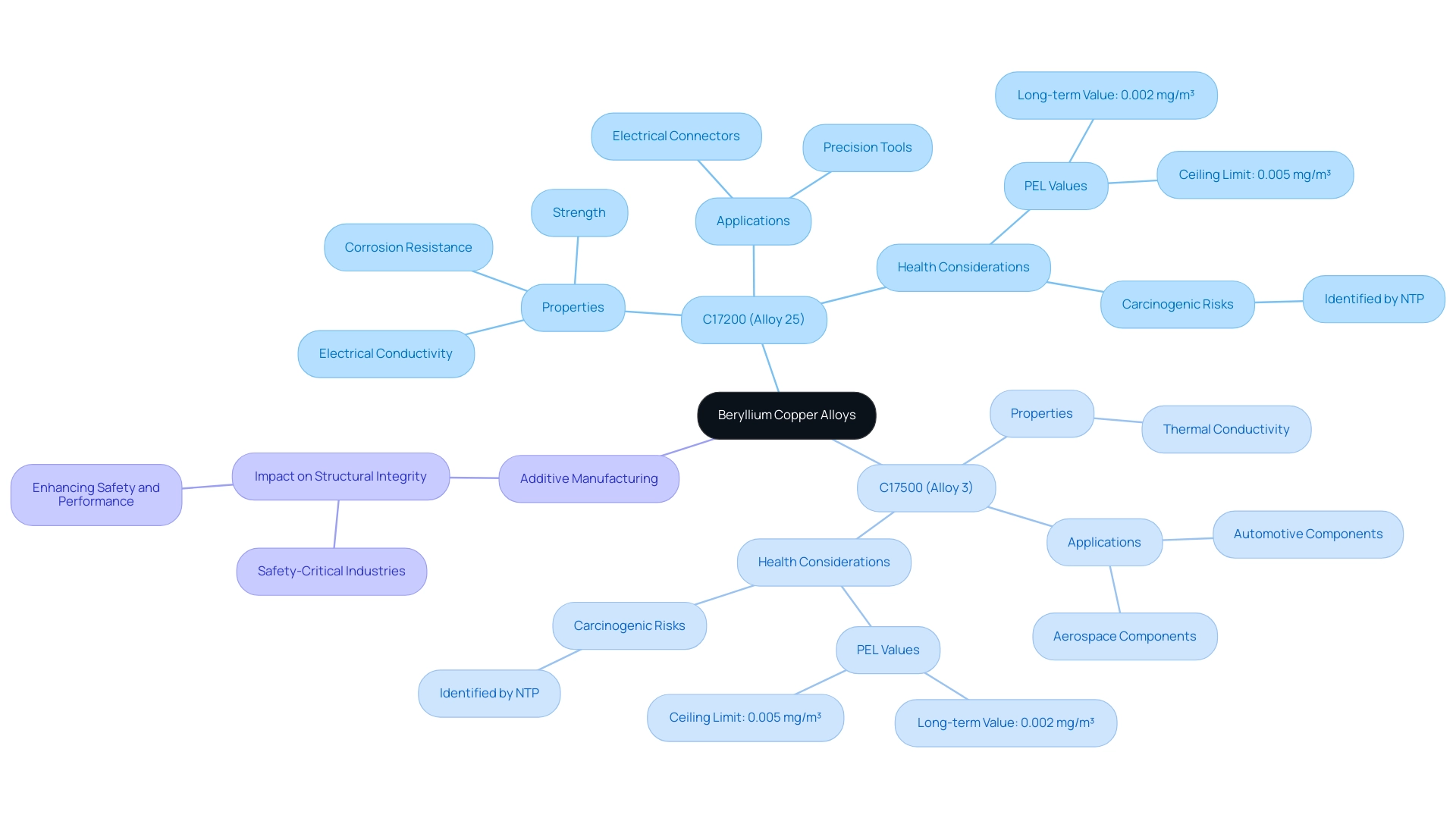

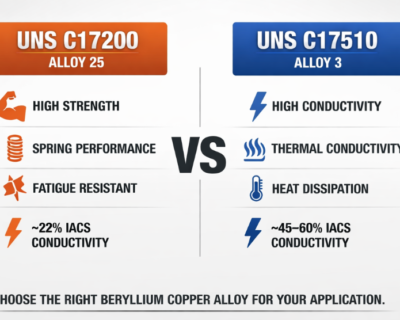

Beryllium copper alloys are primarily classified into two distinct types, each possessing unique properties that cater to different applications:

- C17200 (Alloy 25): Renowned for its remarkable strength, exceptional electrical conductivity, and corrosion resistance, C17200 is frequently utilized in the manufacturing of electrical connectors and precision tools. This alloy is particularly valued in industries where reliability and performance are paramount, showcasing Domadia’s leadership as one of the top beryllium copper sheet suppliers in providing high-quality Beryllium Copper solutions through innovative manufacturing processes and rigorous quality control.

- C17500 (Alloy 3): Distinguished by its superior thermal conductivity, C17500 is ideally suited for applications that demand efficient heat dissipation, making it a preferred choice in aerospace and automotive components.

It is crucial for sourcing managers to be aware of the health risks associated with this element. The PEL (USA) long-term value for this element is 0.002 mg/m³, with a ceiling limit value of 0.005 mg/m³, underscoring the importance of safety when handling these alloys. Additionally, the National Toxicology Program (NTP) identifies this element as a carcinogen, which should be a significant consideration in decision-making processes.

Understanding these distinctions and health considerations is essential for procurement managers seeking to select the appropriate alloy from beryllium copper sheet suppliers that aligns with specific project performance requirements. Moreover, the importance of Non-Sparking Tools in explosive environments cannot be overstated, as they provide a safe alternative for applications prone to ignition risks. The case study titled ‘Additive Manufacturing and Structural Integrity‘ by Prof. Bo Chen illustrates the impact of additive manufacturing on structural integrity in safety-critical industries, showcasing how these alloys can enhance safety and performance in various applications.

By leveraging the properties of each alloy and Domadia’s commitment to innovative manufacturing, professionals can enhance the operational efficiency and safety of their applications.

The Role of Certifications and Standards in Supplier Selection

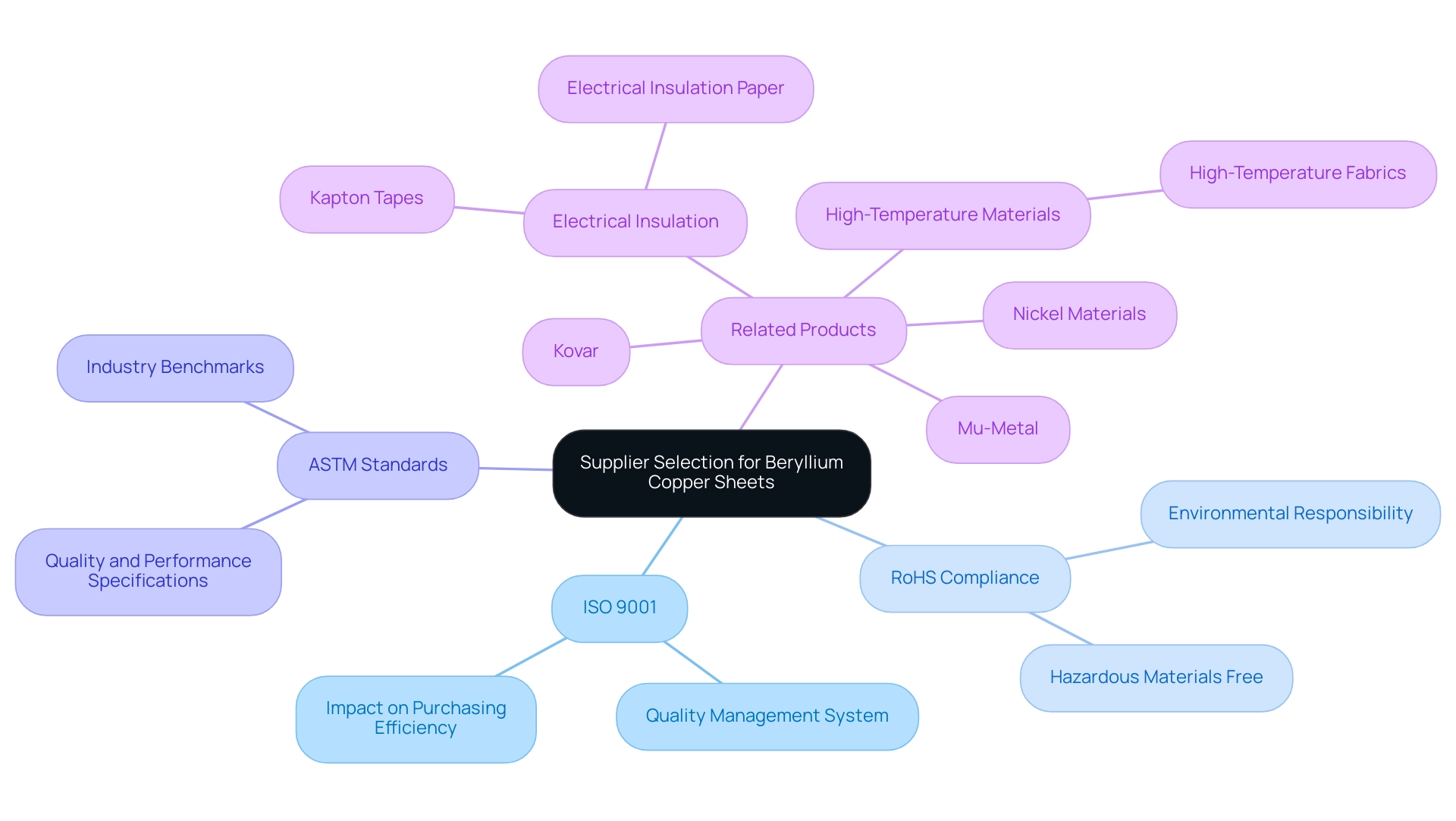

When selecting beryllium copper sheet suppliers, it is essential to prioritize those with key certifications that reflect their commitment to quality and compliance. Among the most critical certifications are:

- ISO 9001: This certification signifies that an organization adheres to a robust quality management system, ensuring consistent quality in their products and services. Significantly, a case study on the importance of ISO 9001 in vendor selection illustrates how certified vendors can greatly improve purchasing efficiency and product reliability.

- RoHS Compliance: Suppliers meeting RoHS (Restriction of Hazardous Substances) standards demonstrate their commitment to environmental responsibility by ensuring that their products are free from hazardous materials, a critical requirement in today’s regulatory landscape.

Compliance with ASTM standards is crucial for beryllium copper sheet suppliers, as these specifications govern the quality and performance of metals and alloys, ensuring that their beryllium copper materials meet industry benchmarks. Alongside these certifications, procurement managers should consider providers of related products such as Kovar, Mu-Metal, and nickel materials, which are also essential in various applications. Furthermore, it is important to assess providers of electrical insulation and high-temperature materials, including electrical insulation paper, Kapton tapes, and high-temperature fabrics. These providers not only enhance the reliability of the products delivered but also reflect a dedication to maintaining high industry standards.

In a setting where 83% of Chief Procurement Officers highlight the significance of digitizing purchasing, utilizing certified vendors can enhance processes and boost overall supply chain integrity. As the landscape of supplier selection evolves, the impact of certifications and related product offerings on decision-making in 2024 will become increasingly significant, reinforcing the need for procurement managers to prioritize these factors.

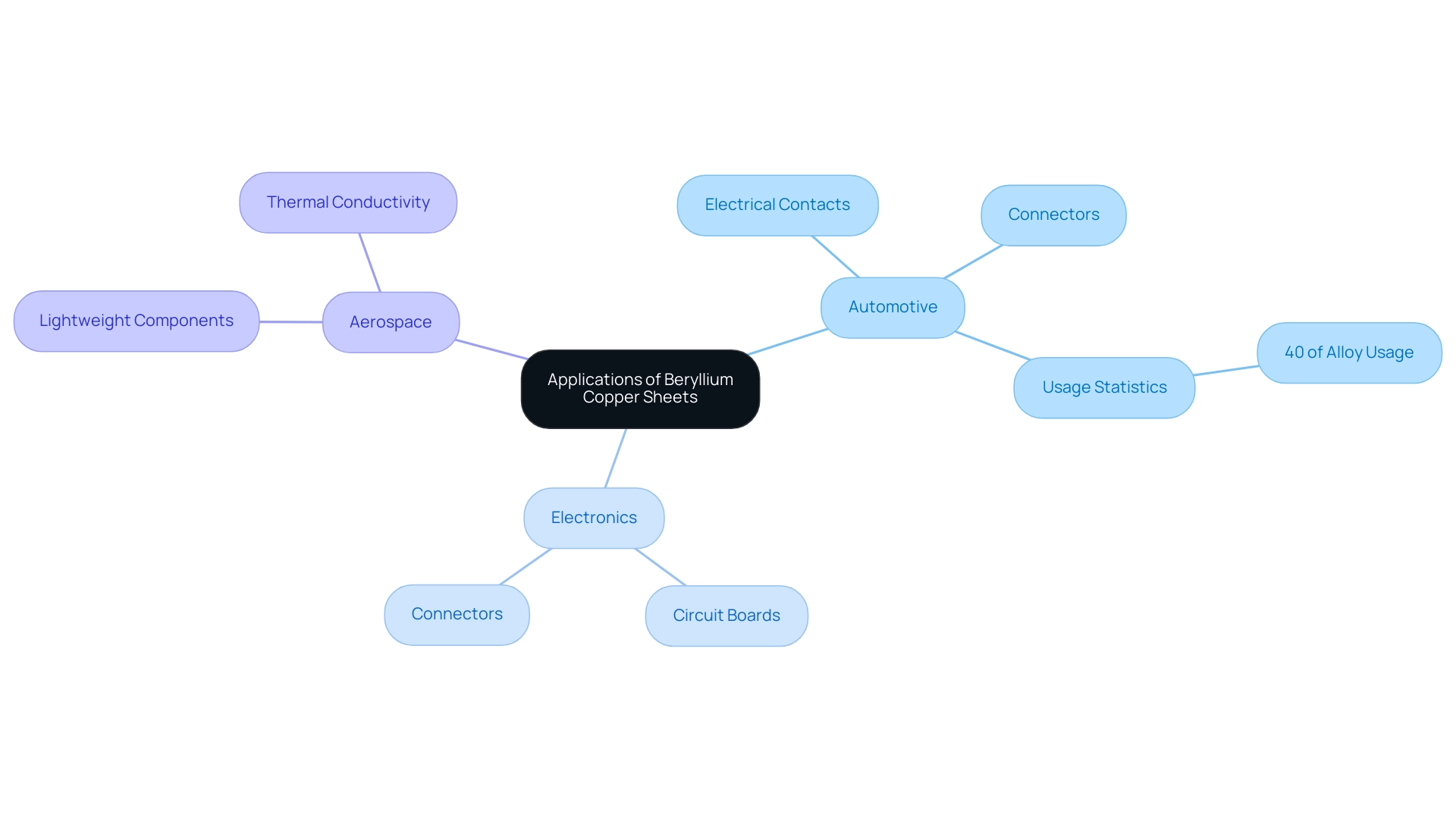

Applications of Beryllium Copper Sheets in Various Industries

Beryllium metal sheets are integral to several industries, each benefiting from their unique properties. In the automotive industry, these sheets are essential for electrical contacts and connectors, where high conductivity and mechanical strength are paramount. Industry statistics indicate that roughly 40% of the alloy’s usage is linked to automotive applications, highlighting its essential role in contemporary manufacturing.

According to industry leader John Doe, CEO of Copper Innovations, ‘Beryllium’s unique properties make it an indispensable material for automotive applications, especially as we push for more efficient and reliable systems.’ In electronics, the outstanding electrical conductivity of this alloy makes it a preferred material for circuit boards and connectors, ensuring reliable performance in high-speed applications. Furthermore, the aerospace sector utilizes a specific alloy for critical components that require lightweight yet strong materials with superior thermal conductivity, which is essential for operational efficiency in flight.

A recent case study from AeroTech Solutions demonstrated how alloy components improved the performance of their aircraft systems by reducing weight while enhancing durability. At Domadia, we are committed to providing high-quality, customized Beryllium Copper Plates sourced from trusted beryllium copper sheet suppliers and tailored to your specifications, along with expert support to ensure your project’s success. Our clients have commended our products, with one mentioning, ‘Domadia’s alloy plates greatly enhanced our production efficiency.’

Additionally, we offer a range of beryllium copper non-sparking wrenches, known for their safety features and reliability in hazardous environments. With our comprehensive inventory and competitive pricing, procurement managers can strategically select us from the beryllium copper sheet suppliers as a reliable option, ensuring optimal performance and safety in their operations.

Conclusion

Selecting the right Beryllium Copper supplier is a critical decision that can profoundly impact project success. As highlighted throughout the article, evaluating key factors such as:

- Product quality

- Certifications

- Customer service

- Delivery reliability

- Pricing

is essential for procurement managers. A reliable supplier not only mitigates risks associated with delays and inferior products but also enhances operational efficiency, ultimately leading to a competitive advantage in the marketplace.

Understanding the distinct types of Beryllium Copper alloys and their applications further empowers procurement professionals to make informed choices that align with specific project requirements. Safety considerations, particularly regarding the health risks associated with handling beryllium, must also be at the forefront of decision-making processes. By prioritizing suppliers who adhere to recognized certifications and standards, procurement managers can ensure compliance and quality, reinforcing the integrity of their supply chains.

In conclusion, the strategic selection of a Beryllium Copper supplier is not merely a logistical task; it is a vital component of successful procurement strategy. By fostering partnerships with reputable suppliers like Domadia, procurement managers can secure high-quality materials that meet demanding industry standards while promoting safety and efficiency in their operations. The importance of these relationships cannot be overstated, as they lay the foundation for sustainable growth and innovation in an increasingly complex industrial landscape.