Blogs

Understanding Invar 36 Price: A Comprehensive Tutorial on Market Dynamics

Overview:

The article focuses on understanding the price dynamics of Invar 36, influenced by factors such as supply and demand, raw material costs, and global economic conditions. It elaborates on how these elements affect pricing strategies and negotiations, emphasizing the importance of informed decision-making for procurement managers in various industries that utilize this alloy.

Introduction

Invar 36, a nickel-iron alloy, stands out in the materials landscape for its unique properties, particularly its remarkably low coefficient of thermal expansion. This characteristic makes it indispensable in industries where precision and stability are paramount, such as:

- Aerospace

- Electronics

- Medical devices

As procurement managers navigate the complexities of sourcing this versatile alloy, understanding its key properties, market dynamics, and applications becomes essential. With demand driven by technological advancements and the need for high-performance components, strategic decision-making in procurement is crucial.

This article delves into the intricacies of Invar 36, offering insights into its characteristics, pricing trends, supply chain factors, and effective negotiation strategies that can empower procurement professionals to optimize their purchasing processes and secure advantageous contracts.

Key Properties and Characteristics of Invar 36

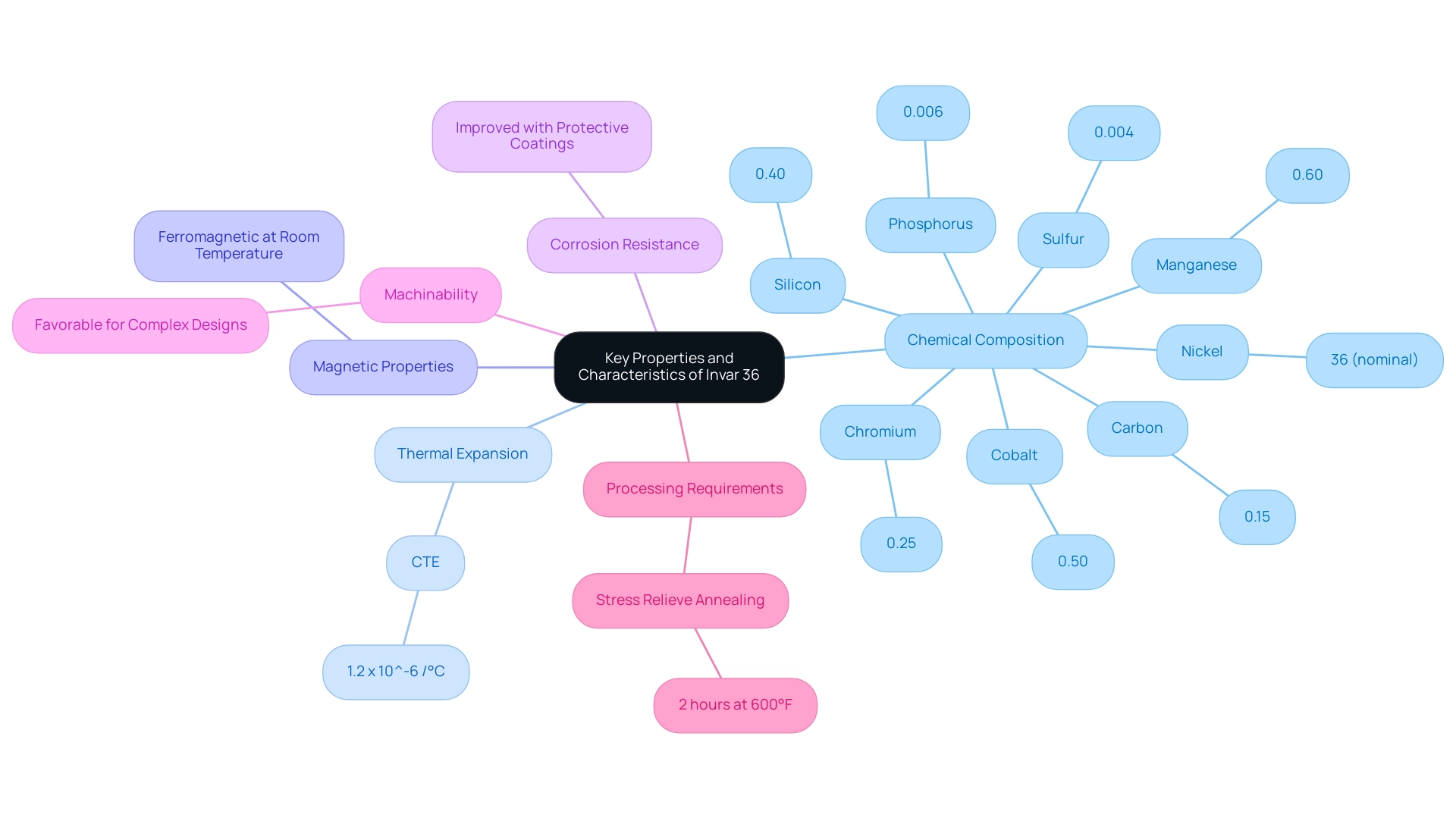

The nickel-iron alloy 36 is renowned for its exceptional properties, particularly its low coefficient of thermal expansion (CTE), which is critical for applications demanding dimensional stability across varying temperatures. Comprising approximately 36% nickel, along with key elements such as 0.15% carbon, 0.006% phosphorus, 0.40% silicon, 0.60% manganese, 0.004% sulfur, 0.25% chromium, and 0.50% cobalt, this alloy exhibits remarkable mechanical characteristics that enhance its utility in various sectors. The key characteristics of Alloy 36 include:

- Thermal Expansion: With a CTE of approximately 1.2 x 10^-6 /°C, Alloy 36 demonstrates minimal thermal expansion when subjected to heat, making it an ideal choice for precision instruments and aerospace components where dimensional accuracy is paramount.

- Magnetic Properties: Retaining its ferromagnetic properties at room temperature, Alloy 36 is particularly valuable in the production of specific electronic components, where magnetic stability is essential.

- Corrosion Resistance: Although Alloy 36’s resistance to corrosion is not as pronounced as some other alloys, its performance can be significantly improved with the application of protective coatings, thereby extending its operational lifespan in challenging environments.

- Machinability: The alloy’s favorable machinability facilitates the production of intricate parts across diverse industries, enabling manufacturers to meet complex design specifications efficiently.

- Processing Requirements: Stress relieve annealing of Alloy 36, if required, typically necessitates a duration of 2 hours at 600°F, which should be considered during planning and production.

A relevant case study titled ‘Validation of WAAM Technology for Alloy 36‘ demonstrates the application of Wire-Arc Additive Manufacturing (WAAM) technology in producing aerospace tooling from Alloy 36. This study highlights that GMAW technology is superior for manufacturing alloy parts, exhibiting similar thermal expansion behavior to reference materials while showing fewer precipitates and no significant macrostructural failures. Grasping these attributes provides purchasing leaders with the knowledge required to evaluate the suitability of a specific alloy for particular projects and to negotiate beneficial agreements that represent its worth in precision applications.

Market Dynamics and Pricing Trends of Invar 36

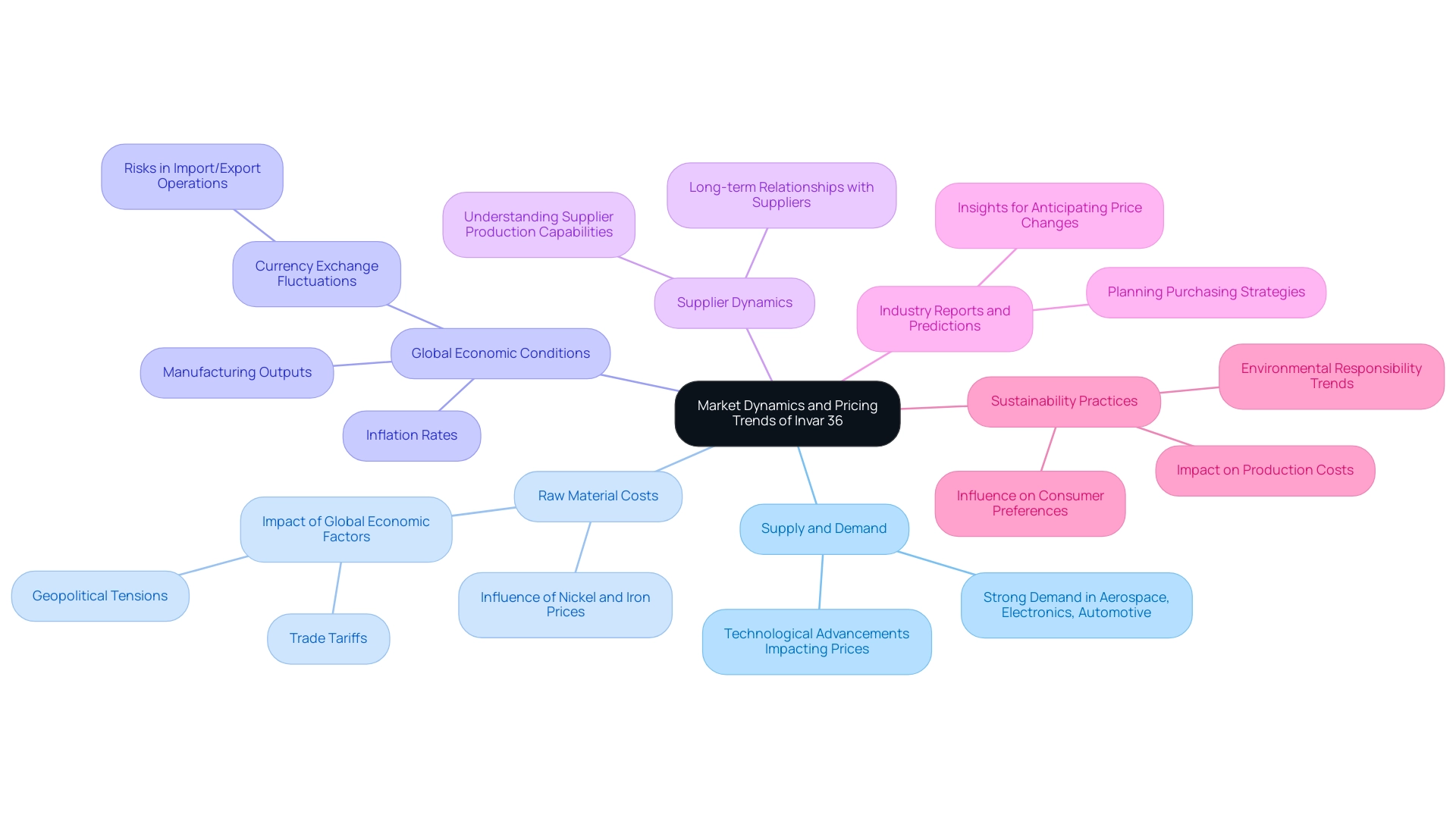

The pricing of this alloy is influenced by various dynamic factors that purchasing supervisors must navigate:

Supply and Demand: The demand for this material is particularly strong in sectors like aerospace, electronics, and automotive. As technological advancements arise, heightened demand can lead to increased prices, reflecting economic responsiveness.

Raw Material Costs: The invar 36 price is heavily influenced by the fluctuating costs of its primary components, nickel and iron. These expenses can be influenced by global economic factors, trade tariffs, and geopolitical tensions, making it essential for purchasing supervisors to carefully observe the invar 36 price to anticipate changes.

Global Economic Conditions: Broader economic elements, including inflation rates, currency exchange fluctuations, and manufacturing outputs, significantly influence the invar 36 price and play a critical role in shaping pricing strategies and negotiations with suppliers. Understanding these elements allows for more informed decision-making concerning invar 36 price. For example, currency exchange risks can significantly impact import/export operations, as highlighted in recent case studies that outline strategies to safeguard transactions against these risks.

Supplier Dynamics: Establishing and nurturing long-term relationships with reliable suppliers can yield more favorable pricing arrangements. A thorough understanding of the supplier environment, including their production capabilities, is essential for efficient purchasing.

Industry Reports and Predictions: Keeping informed about industry reports and predictions allows purchasing supervisors to obtain valuable insights into anticipated changes in invar 36 price. This knowledge is essential for planning purchasing strategies and enhancing acquisition processes.

Sustainability Practices: Recent trends in sustainability practices within production are gaining traction, making the industry more environmentally responsible. This shift not only affects production costs but also influences consumer preferences and regulatory requirements, which procurement managers must consider in their strategies.

By remaining informed about these market dynamics, including the integration of sustainability practices and understanding the risks associated with currency fluctuations, procurement managers can enhance their purchasing strategies, negotiate more effectively, and achieve greater cost efficiency.

Applications of Invar 36 in Various Industries

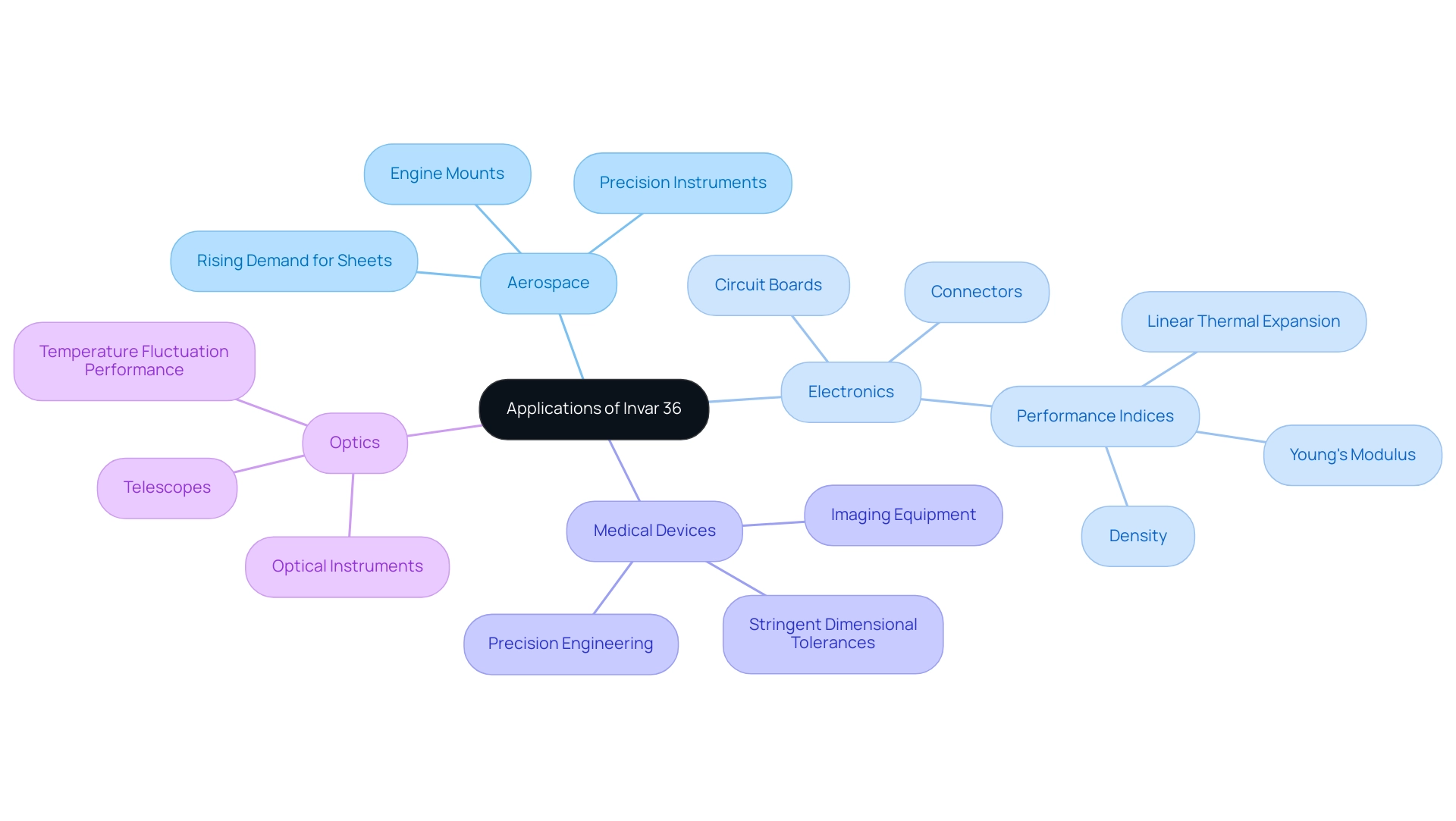

Alloy 36 is a critical material across multiple industries, prized for its exceptional thermal stability and precision. Its key applications span the following sectors:

Aerospace: This material is integral to components such as engine mounts and precision instruments, where maintaining dimensional stability under temperature variations is non-negotiable. Aerospace engineers frequently rely on this alloy for its performance in environments that demand the highest levels of accuracy. According to industry analyses, the demand for this alloy in aerospace is expected to rise significantly, particularly for sheets, which are favored for their precision and stability.

Electronics: In the electronics sector, this material is utilized in devices requiring minimal thermal expansion and high precision, such as connectors and circuit boards. Recent market analyses indicate that alloy 36 holds a significant share in this domain, driven by the need for reliable performance in increasingly sophisticated electronic systems. The usage of alloy 36 in electronics is projected to grow as manufacturers seek materials that meet strict performance indices, including linear thermal expansion, Young’s modulus, and density.

Medical Devices: The stability of alloy 36 is vital in medical devices and imaging equipment, where dimensional accuracy is essential for effective diagnosis and treatment. Ongoing trends reflect a growing demand for this alloy in advanced medical technologies, highlighting its role in enhancing patient care through precision engineering. Expert opinions suggest that this alloy’s properties are particularly beneficial in applications requiring stringent dimensional tolerances.

Optics: This alloy is also employed in optical instruments and telescopes, ensuring precise alignment and performance, even in fluctuating temperature conditions. This reliability is essential for applications demanding precise standards of clarity and focus.

Comprehending these applications allows procurement managers to better evaluate market trends and identify potential growth areas for the material 36. As the demand for high-precision components continues to rise, particularly in the aerospace and medical sectors, strategic sourcing of this alloy can enhance competitive advantage. As mentioned by a representative from a Global Consulting Firm, ‘Our company has been collaborating with 36 for some years now and we are very satisfied with the quality of the reports provided.’

I, on behalf of my organization, would like to thank you for offering professional reports. This testimonial highlights the reliability and quality associated with 36, reinforcing its position as a preferred material in high-precision applications.

Factors Impacting Invar 36 Supply Chain

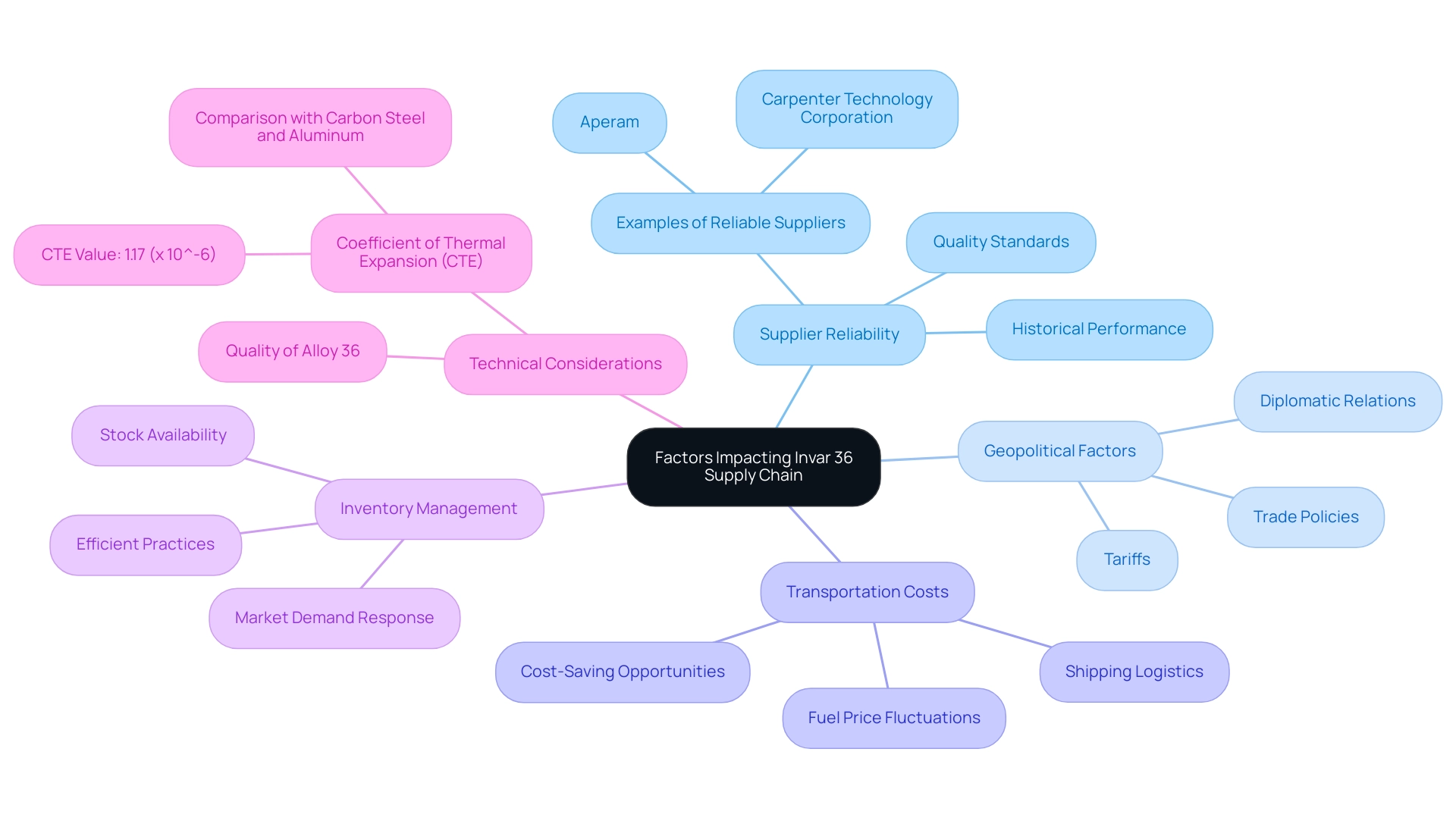

The supply chain of Invar 36 is influenced by several critical factors, which procurement managers must navigate strategically:

Supplier Reliability: The consistency and dependability of suppliers are paramount. Procurement professionals should assess suppliers not only on their historical performance but also on their capacity to meet rigorous quality standards consistently. Companies like Aperam and Carpenter Technology Corporation exemplify reliability in this sector, leveraging advanced manufacturing processes and robust customer relationships to maintain their market leadership.

Geopolitical Factors: The landscape of international commerce can substantially affect the sourcing of Alloy 36. Factors such as trade policies, tariffs, and diplomatic relations can influence the availability and cost of raw materials and finished products. Staying informed about these dynamics is essential for effective risk management and sourcing strategies.

Transportation Costs: Fluctuations in fuel prices and shipping logistics can significantly affect the total expenses related to this material’s acquisition. A thorough understanding of the transportation networks can reveal potential cost-saving opportunities and help mitigate unexpected financial burdens.

Inventory Management: Implementing efficient inventory management practices is crucial for mitigating supply disruptions. By ensuring consistent availability of a specific alloy, procurement managers can better respond to market demands and reduce the risk of stockouts.

Technical Considerations: It is important to note that this material has a coefficient of thermal expansion (CTE) of 1.17 (x 10 to the minus 6), which is significantly lower than that of carbon steel or aluminum. This property emphasizes the significance of obtaining high-quality alloy 36, considering the Invar 36 price for applications requiring precise thermal stability.

As Michael, the host of Michael Talks Metal, highlights, “Grasping the subtleties of obtaining resources is essential for sustaining a competitive edge in the current landscape.” Proactively addressing these supply chain factors empowers procurement managers to refine their negotiation strategies, ultimately leading to a more stable and reliable supply of a specific alloy. Furthermore, companies like Robemetall highlight the importance of fast handling of orders through generous stockholding and optimized logistics, showcasing practical applications of effective supply chain management.

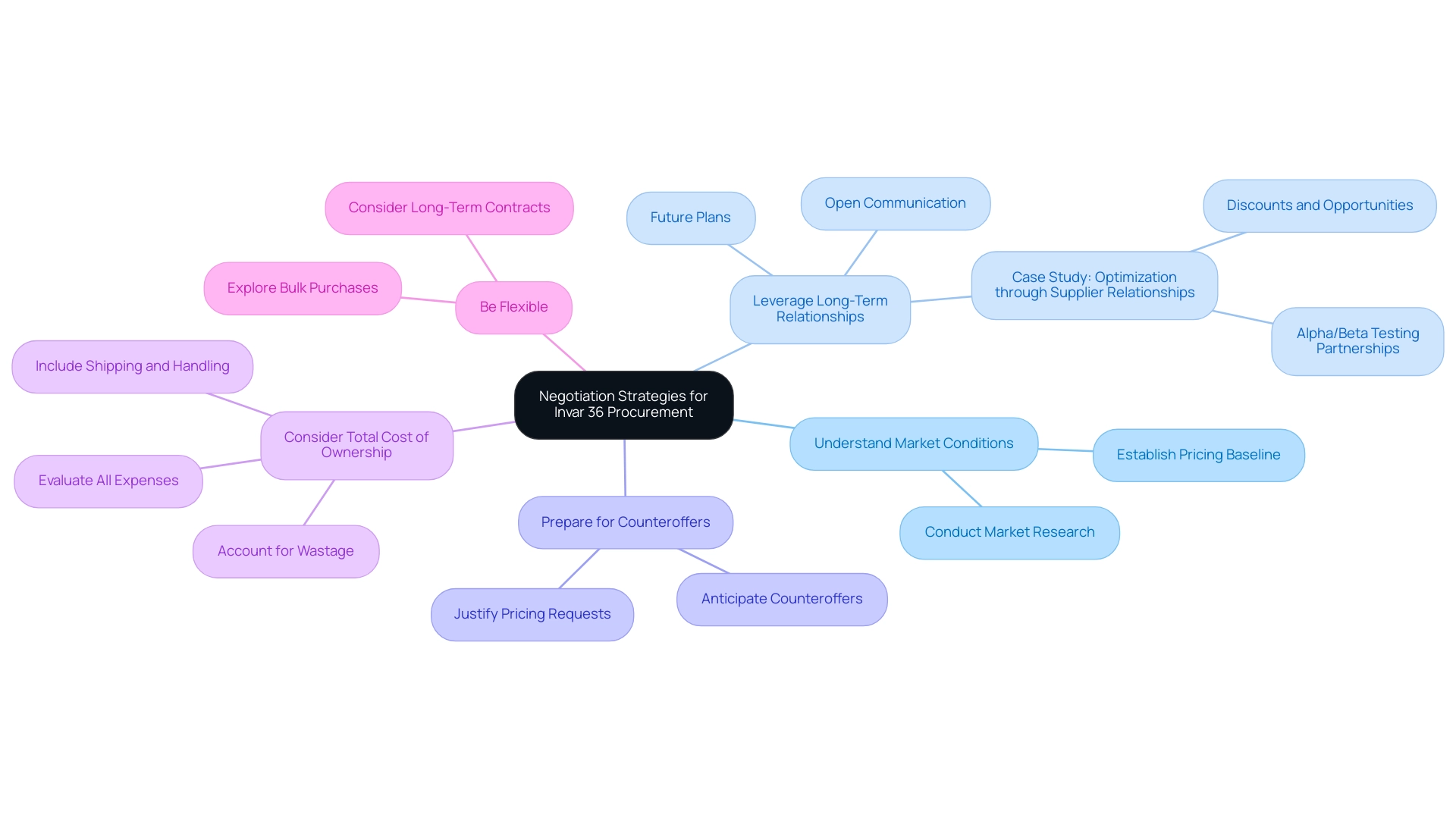

Negotiation Strategies for Invar 36 Procurement

Effective negotiation for Invar 36 requires a strategic approach that encompasses the following key strategies:

- Understand Market Conditions: Conduct thorough research on current market trends and pricing to establish a robust baseline for negotiations. A firm grasp of economic dynamics not only empowers you with leverage but also positions you better in discussions with suppliers.

- Leverage Long-Term Relationships: Cultivating strong relationships with suppliers can significantly enhance your negotiation outcomes. Open communication regarding your purchasing needs fosters collaboration and can lead to improved pricing and terms. As highlighted in the case study titled “Optimization through Supplier Relationships,” building strong ties with suppliers can facilitate discussions about future plans and innovations, yielding significant discounts and opportunities.

- Prepare for Counteroffers: Anticipate potential counteroffers from suppliers and define your limits beforehand. Being prepared to justify your pricing requests with relevant market data can strengthen your negotiating position.

- Consider Total Cost of Ownership: Evaluate the total expense related to the material acquisition, including shipping, handling, and any potential wastage. Adopting this comprehensive view can profoundly influence negotiation results, ensuring you account for all financial implications.

- Be Flexible: While it is essential to pursue the best price, remain open to alternative solutions such as bulk purchases or long-term contracts. These options may provide more favorable terms and enhance overall cost-effectiveness.

Interestingly, many companies utilize an 80/20 rule in their purchasing policies, awarding contracts to two different suppliers. This strategy can inform your negotiation tactics and supplier selection process.

By implementing these strategies, purchasing managers can significantly enhance their negotiating power, ensuring they secure the most advantageous agreements regarding Invar 36 price. As Meghan Rexer from KPMG notes, low touch planning in purchasing can yield substantial financial benefits, improving Return on Equity (ROE) by 2 to 4 percentage points and adding 1 to 3 percent to gross margins. Such insights highlight the importance of effective negotiation strategies in achieving optimal purchasing outcomes.

Additionally, procurement managers are encouraged to explore Sievo’s resources, including eBooks and webinars related to procurement analytics, to further enhance their sourcing strategies for the Invar 36 price.

Conclusion

Invar 36 is a unique nickel-iron alloy that plays a critical role across various high-precision industries, thanks to its exceptional properties such as:

- A low coefficient of thermal expansion

- Ferromagnetic characteristics

- Reliable machinability

Understanding these key properties equips procurement managers with the necessary insights to effectively assess its applicability in projects, negotiate favorable contracts, and ultimately secure a competitive edge within their sectors.

Navigating the market dynamics and pricing trends surrounding Invar 36 is equally essential. Factors such as:

- Supply and demand fluctuations

- Raw material costs

- Global economic conditions

all play pivotal roles in shaping pricing strategies. By remaining informed about these elements, procurement professionals can enhance their purchasing strategies, anticipate price adjustments, and build strong relationships with suppliers to facilitate more advantageous negotiations.

Moreover, the applications of Invar 36 in:

- Aerospace

- Electronics

- Medical devices

- Optics

highlight its versatility and the growing demand for high-performance components. As industries continue to evolve, so too will the requirements for precision materials like Invar 36, reinforcing the need for strategic sourcing and effective supply chain management.

Finally, implementing robust negotiation strategies is crucial for optimizing procurement outcomes. By understanding market conditions, leveraging supplier relationships, and considering the total cost of ownership, procurement managers can significantly enhance their negotiating power. Invariably, the combination of informed decision-making and strategic negotiation will empower procurement professionals to navigate the complexities of sourcing Invar 36 successfully, ensuring that they are well-equipped to meet the demands of their industries.