Blogs

How to Purchase Invar Bar Stock: A Step-by-Step Guide

Overview:

To purchase Invar bar stock effectively, one should begin by clearly defining specifications and researching reputable vendors, then proceed through a structured process of requesting quotes, evaluating suppliers, and ensuring compliance with industry standards. The article outlines a comprehensive step-by-step guide that emphasizes the importance of quality control and building long-term relationships with suppliers, which are crucial for successful procurement and operational efficiency.

Introduction

In the realm of precision engineering and advanced manufacturing, the selection of materials can significantly influence the success of projects. Invar bar stock, a nickel-iron alloy renowned for its minimal thermal expansion, stands out as a critical choice for applications where dimensional stability is paramount. Industries such as aerospace and automotive rely on this alloy not only for its mechanical properties but also for its compliance with stringent industry standards.

As procurement managers navigate the complexities of sourcing Invar, understanding its properties, evaluating supplier capabilities, and ensuring compliance with regulatory requirements become essential components of the decision-making process. This article delves into the intricacies of Invar bar stock, providing a comprehensive guide for procurement professionals seeking to optimize their material acquisition strategies while maintaining the highest standards of quality and performance.

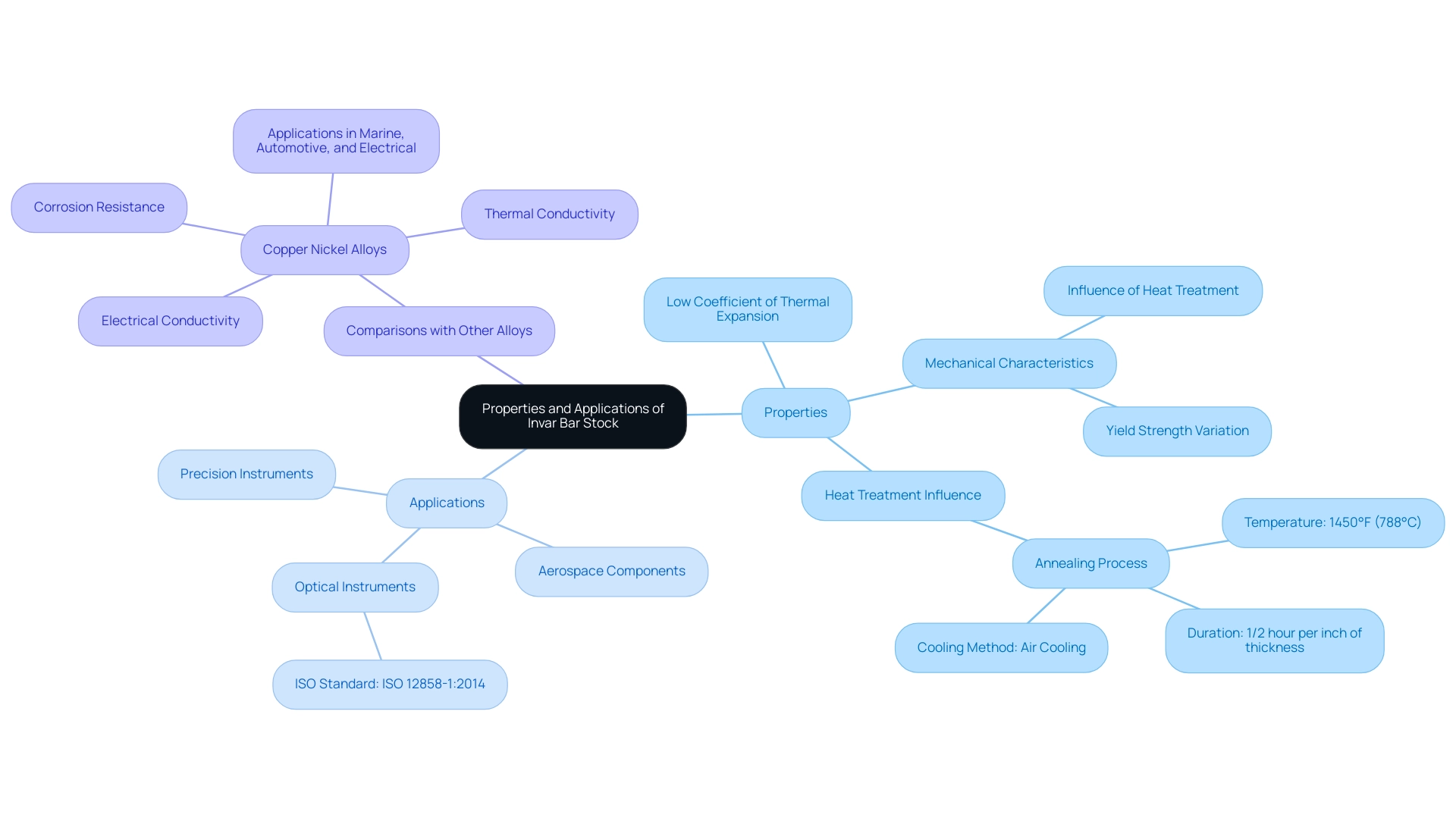

Understanding Invar Bar Stock: Properties and Applications

The nickel-iron alloy is distinguished by its remarkably low coefficient of thermal expansion, making it an exceptional choice for applications demanding stringent dimensional stability. This property is particularly crucial in precision instruments, measuring devices, and aerospace components, where even minute changes in size can significantly affect performance and accuracy. The ISO standard ‘ISO 12858-1:2014’ underscores the importance of such precision in optics and optical instruments, further validating the use of this alloy in these applications.

This material’s capability to retain its form and dimensions under different temperatures guarantees dependability in delicate applications. Additionally, the alloy’s mechanical characteristics can be significantly influenced by heat treatment, with yield strength varying based on the treatment temperature, which is essential for understanding its performance in demanding environments. Furthermore, while this alloy boasts robust mechanical characteristics and ease of machining, it is essential to consider other alloys, such as copper nickel, known for their exceptional corrosion resistance, high thermal and electrical conductivity, and performance in marine, automotive, and electrical applications.

These properties render copper nickel alloys viable options where reliability is paramount. As noted by Sergej Baričević in his work on calibration methods, the integration of advanced technologies is vital for achieving precision in instrument applications. As you evaluate the suitability of invar bar stock for your specific requirements, understanding these key properties and the comparative advantages of related alloys, including their applications in demanding environments, is essential for informed decision-making in procurement.

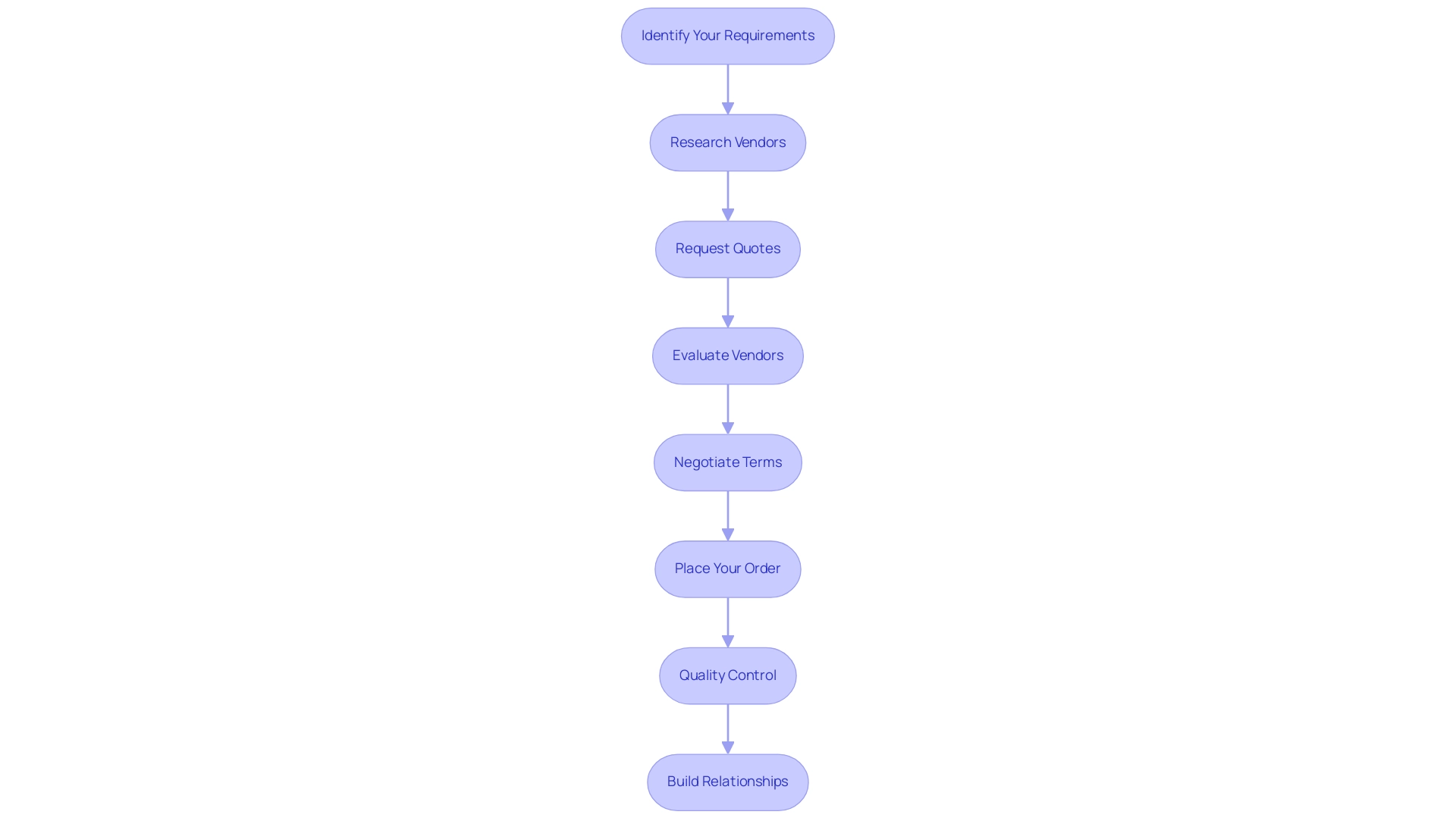

Step-by-Step Guide to Purchasing Invar Bar Stock

Identify Your Requirements: Begin by clearly defining the specifications needed for the invar bar stock, including precise dimensions, tolerances, and adherence to relevant industry standards. This foundational step is critical for effective communication with potential suppliers.

Research Vendors: Seek out reputable vendors, such as Domadia, that specialize in high-performance metals and Mica Tape, as well as electrical insulation and high-temperature materials. Domadia stands out for its exceptional product quality and commitment to customer service, ensuring that procurement managers receive tailored solutions. Utilize industry directories, attend trade shows, and explore online platforms to compile a robust list of potential vendors. Notably, companies like City Special Metals are recognized for their extensive offerings, including Aluminum alloys, showcasing their breadth in the market.

Request Quotes: Reach out to your selected vendors to request detailed quotes. Include comprehensive specifications and inquire about lead times, minimum order quantities, and pricing. It’s important to note that delivery times for orders typically range from 30 to 60 days, so factor this into your planning.

- Evaluate Vendors: Carefully assess the received quotes, taking into account not only the pricing but also the vendor’s reputation, delivery capabilities, and compliance with international standards. Assess their experience in providing the specific material, particularly concerning your unique needs and requirements. For instance, a case study on the production and delivery of Super Invar 32-5 demonstrates the importance of timely delivery and quality assurance in vendor evaluation.

Negotiate Terms: After selecting a preferred vendor, engage in negotiations to finalize pricing, payment terms, and delivery schedules. Leverage your negotiation skills to secure a favorable agreement, ensuring that all terms are clear and mutually beneficial.

Place Your Order: Upon finalizing terms, proceed to place your order with the supplier. Ensure that all specifications are meticulously outlined in the purchase order to prevent any misunderstandings that could impact your production timeline.

Quality Control: Upon receiving the invar bar stock, conduct thorough inspections to ensure it meets the agreed-upon specifications. As emphasized by Merck KGaA’s recent quote regarding product safety and traceability, this critical step is essential to avoid complications in production and to uphold quality standards.

Build Relationships: Finally, foster ongoing communication with your supplier, such as Domadia, to build a long-term relationship. By choosing Domadia, you benefit from their dedication to supporting your business’s growth through reliable service and innovative solutions. This strategy can lead to improved pricing, priority service, and enhanced collaboration on future projects, ultimately contributing to your operational efficiency and supporting your business’s growth.

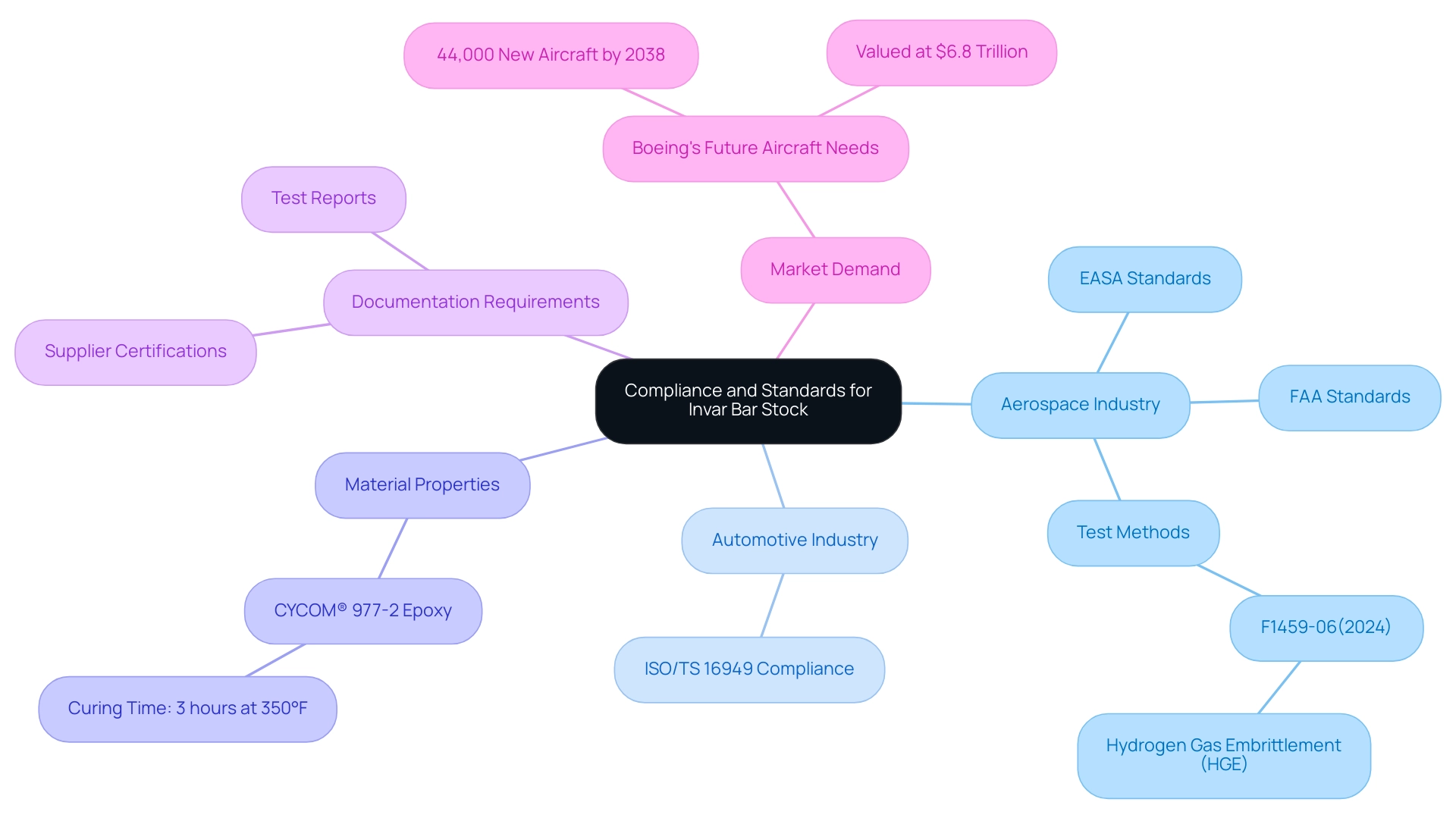

Understanding Compliance and Standards

Understanding the compliance standards associated with invar bar stock is critical for procurement managers, especially in the aerospace and automotive industries. Aerospace substances must adhere to rigorous standards set forth by organizations like the FAA and the European Union Aviation Safety Agency (EASA). Specifically, the F1459-06(2024) Standard Test Method for Determination of the Susceptibility of Metallic Materials to Hydrogen Gas Embrittlement (HGE) is essential for ensuring material integrity in these sectors.

In the automotive sector, ISO/TS 16949 compliance is crucial for ensuring excellence across supply chains. As Tajammul Pangarkar, CMO at Prudour Pvt Ltd, notes,

Compliance is not just a regulatory requirement; it’s a commitment to quality and safety across industries.

Additionally, understanding substance properties such as the curing time of CYCOM® 977-2 epoxy, which requires three hours at 350°F, can provide insights into performance criteria that are crucial for compliance.

To mitigate potential liabilities and to ensure the integrity of your supply chain, it is essential to request comprehensive documentation from suppliers. This should include certifications and test reports that confirm compliance with all relevant standards. Moreover, Boeing’s projection of needing over 44,000 new commercial aircraft by 2038 highlights the increasing demand for modern materials and the necessity of adhering to compliance standards in procurement.

By prioritizing these checks, procurement managers can safeguard their organizations against the risks associated with non-compliance while also ensuring that the invar bar stock meets the necessary performance criteria.

Evaluating Supplier Capabilities

Assessing a vendor’s abilities is essential for guaranteeing that your acquisition meets both excellence and operational standards. Consider the following key factors in your assessment:

Production Capacity: It is imperative to determine if the provider can accommodate your order size and adhere to delivery timelines. Engage in discussions regarding their production schedules and lead times to ensure alignment with your project requirements.

Control Processes: Delve into the supplier’s assurance protocols, as a robust control system is essential to guarantee that the invar bar stock aligns with your specifications. Domadia’s pure nickel products undergo stringent control measures, utilizing advanced manufacturing processes and cutting-edge technologies to deliver unmatched standards and purity. A structured quality control approach mitigates risks associated with material defects and enhances supply chain reliability.

Customer References: Collect references from previous clients to assess the provider’s reliability and performance. Insights from other procurement managers can provide a clearer picture of the provider’s operational capabilities and customer service record.

Certifications: Verify any relevant certifications that demonstrate the provider’s dedication to quality and compliance, such as ISO 9001. Domadia holds various certifications that serve as a testament to their commitment to maintaining high standards in their operations.

Technical Expertise: Evaluate the provider’s technical capabilities and their ability to offer support tailored to your specific requirements. A knowledgeable provider like Domadia, with years of experience in producing and supplying pure nickel, can offer valuable insights and innovative solutions, enhancing the overall value of your procurement process.

Competitive Pricing: Understand the importance of cost-effectiveness in today’s competitive market. Domadia offers competitive pricing on all pure nickel products, ensuring you receive the best value without compromising on quality.

In the current market landscape, understanding the broader implications of vendor capabilities is vital. For instance, the United States currently consumes about one-seventh of the world’s zinc output, highlighting the demand for materials and the importance of dependable sources. Additionally, as Madhumitha Jaganmohan emphasizes, “Get in touch with us now,” to ensure that procurement strategies align with environmental sustainability goals.

Furthermore, the recent case study on the economic impact on tool steel demand illustrates how fluctuations in market conditions can affect procurement decisions and supplier evaluation processes.

By systematically evaluating these aspects, procurement managers can make informed decisions that significantly impact the quality and reliability of their supply, ultimately contributing to operational efficiency and project success.

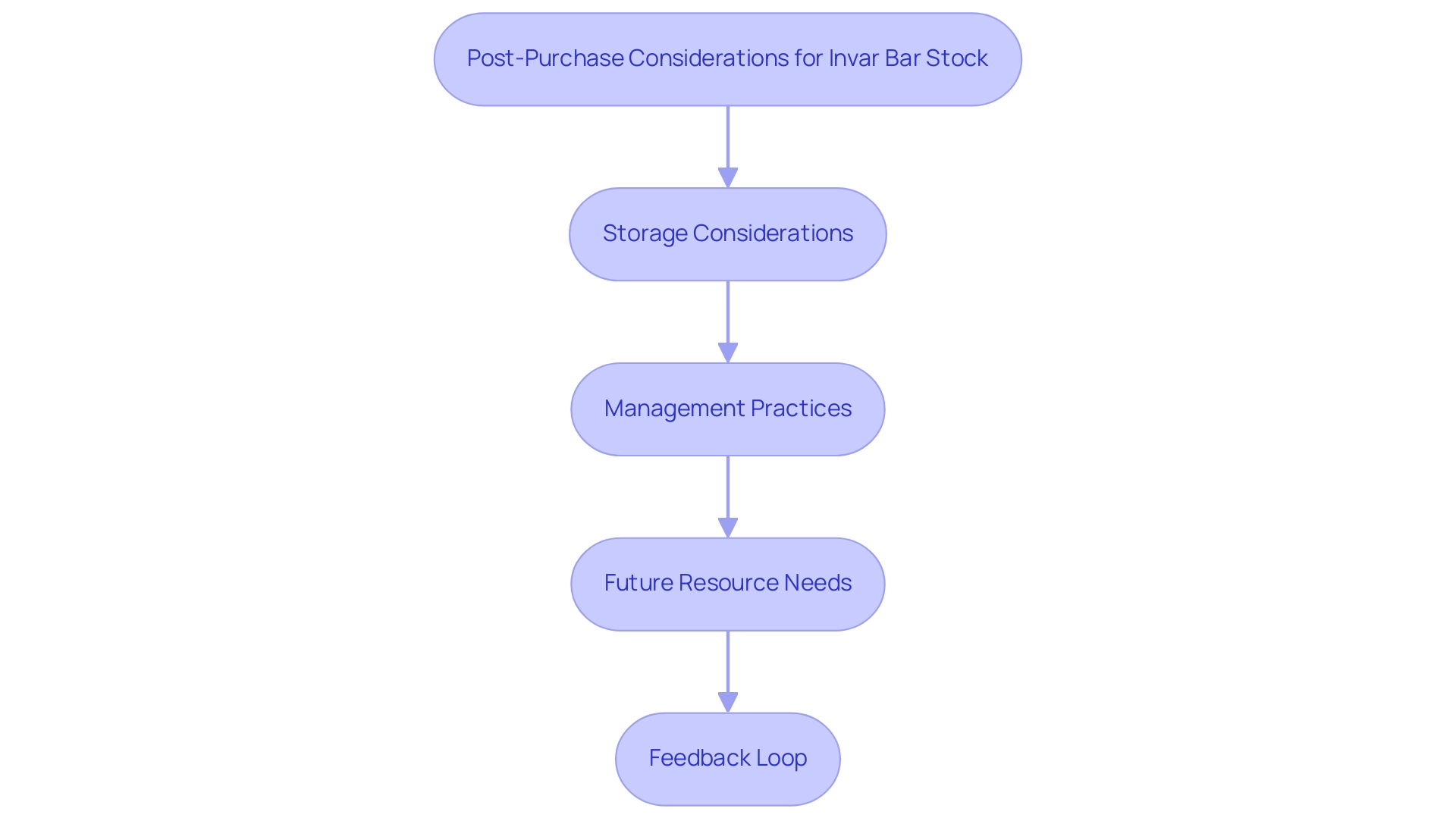

Post-Purchase Considerations

- Ensuring the proper storage of invar bar stock is crucial for preserving its integrity and performance. It is recommended to store the items in a clean, dry environment, shielding them from moisture and contaminants that could lead to corrosion. For instance, using PVC pipes with an 8-inch diameter for storage can help maintain proper air circulation and reduce the risk of moisture accumulation. Furthermore, adequate support is essential to prevent bending or warping of invar bar stock; these bars should be placed on racks that distribute weight evenly, thus maintaining their shape and quality over time.

Management: Effective management of bar stock requires the use of appropriate lifting equipment to minimize the risk of injury and prevent damage to the substance. Adopting best practices for handling heavy items is paramount in maintaining a safe workplace environment. This includes training personnel in proper lifting techniques and ensuring all safety equipment is readily available. Richard emphasizes the importance of vigilance in handling specialty items, stating,

Gary, looks like you have a ‘ultra-rare’ ‘D’ shaped piece of tubing in your rack. You might want to separate that one from the rest so it’s not grabbed accidentally and used on a project.

This underscores the necessity for careful management of unique substances, particularly considering the findings from the case study on the thermal expansion behaviors of Super Invar alloy, which indicate that special storage and handling practices can significantly influence performance.

Future Needs: As you evaluate your procurement strategy, it is essential to consider your future resource requirements based on ongoing and upcoming projects. Nurturing a solid connection with your vendors can result in advantageous conditions for upcoming orders and guarantee that you receive prompt shipments when extra resources are needed. This proactive approach can prevent disruptions in your supply chain and maintain project momentum.

- Feedback Loop: Establishing a feedback loop with your suppliers is essential for optimizing procurement processes. Regular discussions about the performance of the supplies received can help identify any issues early, enabling both parties to address concerns and enhance future orders. This collaborative approach fosters a culture of continuous improvement, ensuring that your sourcing strategy evolves in line with project requirements and material performance.

Conclusion

Invar bar stock serves as a pivotal material in precision engineering, particularly due to its unique properties that ensure minimal thermal expansion. This characteristic is especially valuable in industries such as aerospace and automotive, where dimensional stability is critical. Understanding the properties of Invar, alongside its mechanical performance and heat treatment influences, allows procurement managers to make informed decisions regarding material selection.

The procurement process for Invar involves several strategic steps:

- Identifying specific requirements

- Evaluating supplier capabilities

- Researching suppliers with a strong reputation, such as Domadia

- Negotiating favorable terms

Furthermore, compliance with industry standards is vital to ensure the integrity and safety of materials, especially in highly regulated sectors. By prioritizing thorough documentation and quality assurance, procurement managers can mitigate risks and uphold high standards in their supply chains.

Post-purchase considerations, including proper storage and handling practices, are essential for maintaining the integrity of Invar bar stock. Establishing strong supplier relationships and a feedback loop can enhance future procurement efforts, ensuring alignment with project demands and fostering continuous improvement.

In summary, the strategic procurement of Invar bar stock not only contributes to operational efficiency but also reinforces the commitment to quality and compliance in critical applications. By leveraging expert insights and adhering to best practices, procurement professionals can optimize their material acquisition strategies, ultimately supporting the success of their projects.