Blogs

Top 7 Applications of Invar Blend You Should Know

Overview:

The article focuses on the top applications of Invar Blend, highlighting its significance in various industries due to its low thermal expansion properties. It discusses specific uses in aerospace components, optical devices, measurement tools, and cryogenic applications, demonstrating that the unique characteristics of Invar Blend enhance precision and reliability in environments where dimensional stability is critical.

Introduction

Invar Blend stands at the forefront of advanced materials, prized for its exceptional low thermal expansion properties that are critical in precision applications across various industries. With its unique composition of iron and nickel, this alloy ensures dimensional stability even under fluctuating temperatures, making it indispensable in sectors such as aerospace, optics, and cryogenics.

As procurement managers navigate the complexities of material selection, understanding the nuances of Invar Blend and its variants, such as Super Invar, becomes paramount. This article delves into the properties, applications, and comparative advantages of Invar Blend, while also addressing key cost considerations and future trends that will shape its role in modern manufacturing.

As industries evolve, the strategic use of Invar Blend not only enhances operational efficiency but also positions organizations for long-term success in an increasingly competitive landscape.

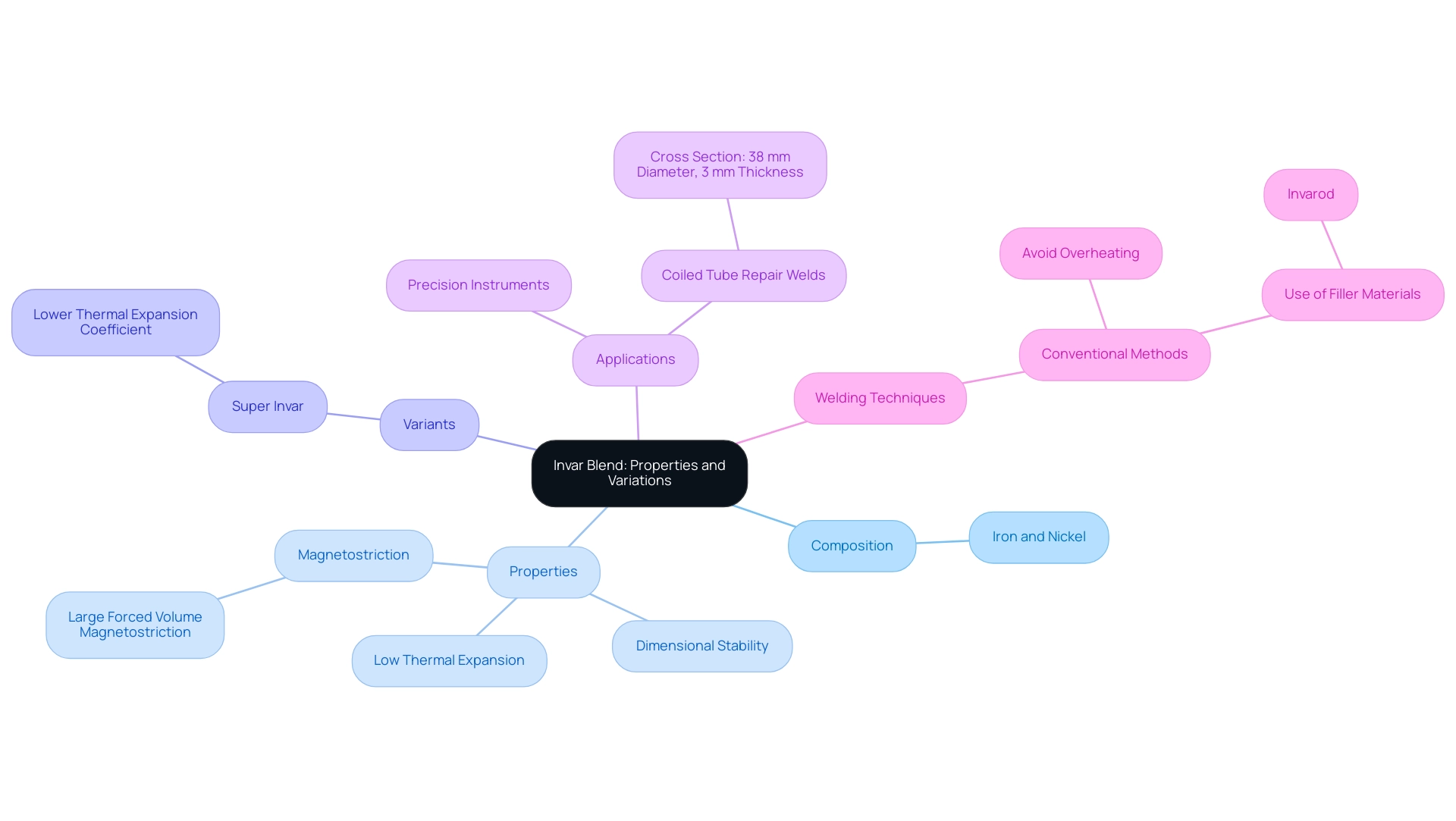

Understanding Invar Blend: Properties and Variations

The invar blend, primarily composed of iron and nickel, is highly esteemed for its remarkable low thermal expansion properties, which are critical in applications that require dimensional stability across fluctuating temperatures. This unique characteristic is particularly advantageous in precision instruments, where even minute alterations in dimensions can lead to significant inaccuracies. For instance, in applications involving Coiled Tube repair welds, the specific details of a cross-section with a diameter of 38 mm and a thickness of 3 mm highlight the precision required in such contexts.

Variants such as Super Invar, which incorporates cobalt, exhibit even lower thermal expansion coefficients, further elevating their performance in high-precision environments. However, as noted by J.C. Peuzin, a drawback of these substances is their very large forced volume magnetostriction, δ ≅10 −10 m A, which can limit their use in high magnetic field environments. For procurement managers, grasping these material properties is essential for making informed decisions regarding the selection of materials that meet stringent accuracy and reliability requirements.

Furthermore, understanding the welding techniques for alloy 36 is crucial, as conventional methods can be employed, but care must be taken to avoid overheating the molten metal to prevent defects such as spattering and pits. The strategic advantages of utilizing invar blend and its variations extend beyond short-term uses, influencing long-term project success and operational efficiency.

Key Applications of Invar Blend in Industry

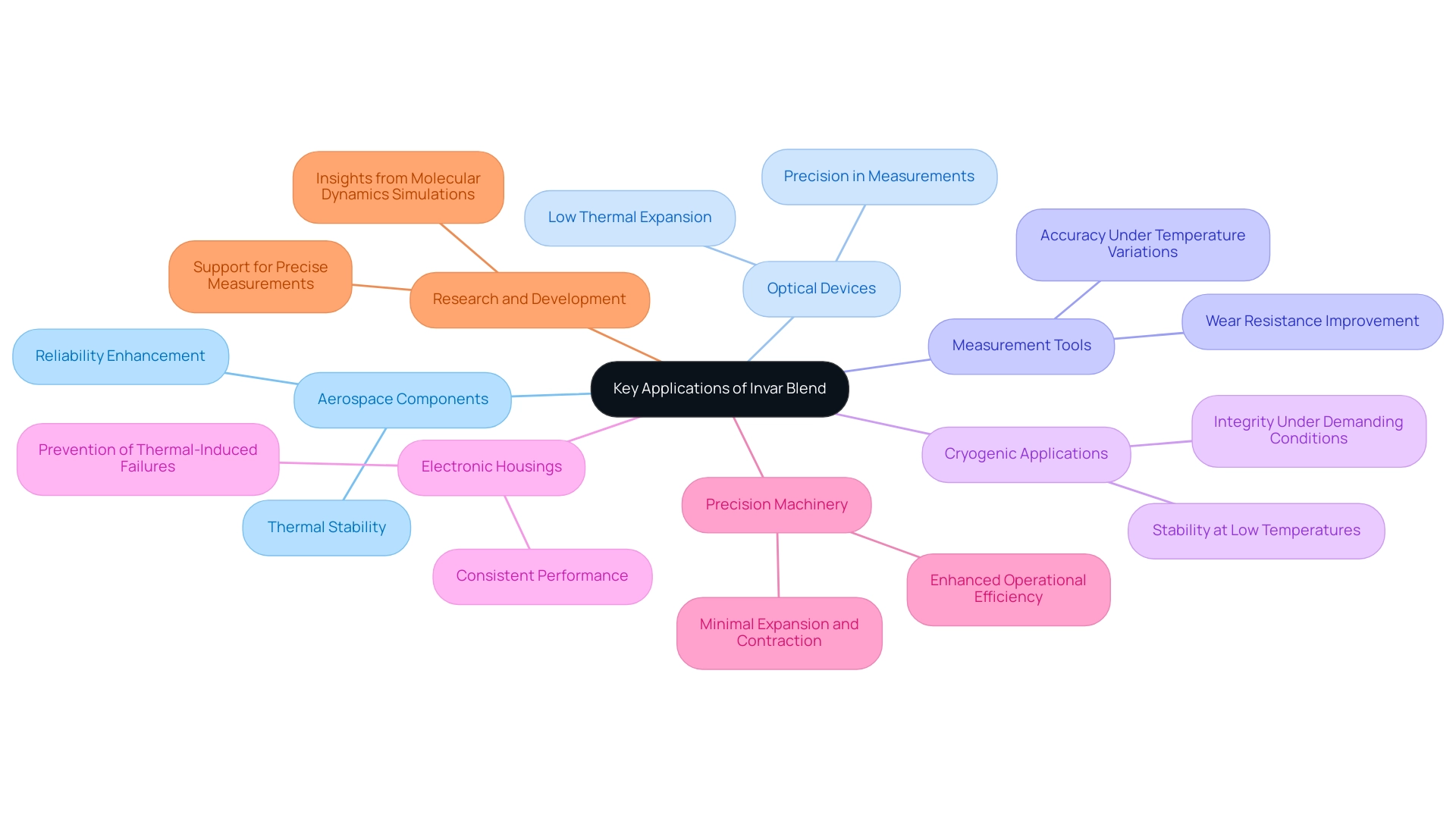

Blend is recognized for its exceptional properties, making it a vital material across multiple industries. Its key applications include:

Aerospace Components: This material is crucial in the manufacturing of precision components for aircraft, where maintaining thermal stability is essential. A recent analysis indicated that the unique properties of this material enhance the reliability of these components, significantly impacting the aerospace sector’s performance in 2024.

Optical Devices: The low thermal expansion of this alloy renders it ideal for optical instruments such as telescopes and cameras. This trait guarantees steady precision in measurements and focus, a requirement highlighted by aerospace engineers who promote its use in high-precision fields.

Measurement Tools: Numerous measurement devices utilize a specific alloy to uphold accuracy under varying temperature conditions. This stability is critical in scientific research, where even minor deviations can lead to significant errors. For example, the NiB-coated sample exhibited a rise in wear resistance by over 15 times compared to ZnAl-coated specimens, highlighting its effectiveness in precision uses.

Cryogenic Applications: Invar’s stability at extremely low temperatures makes it a preferred choice for cryogenic equipment, particularly in applications involving liquefied gases. Its functionality in such environments has been validated through extensive research, demonstrating its ability to maintain integrity under demanding conditions.

Electronic Housings: The alloy’s thermal stability is also advantageous for electronic housings, where consistent performance is paramount. The application of this material in this context ensures that electronic components function optimally without thermal-induced failures.

Precision Machinery: This material plays a significant role in the construction of precision machinery, where minimal expansion and contraction during operation is critical. This characteristic aids in maintaining the accuracy of machinery, thereby enhancing operational efficiency. A case study on the tribological qualities of PAI and PAI composites under various mediums emphasized the significance of substance efficacy in precision applications, paralleling the advantages of a specific alloy.

Research and Development: The invar blend is a favored material in research and development settings, particularly in fields like physics and engineering. Its ability to support precise measurements is invaluable, as highlighted by Din Bandhu, who noted, “By integrating molecular dynamics simulations and experimental techniques, this study provides valuable insights into tailoring glass compositions for enhanced performance on metallic substrates.”

These software solutions highlight the versatility and essential role of the entity in advancing technology across various fields, particularly in aerospace and optical domains, where its unique properties are indispensable.

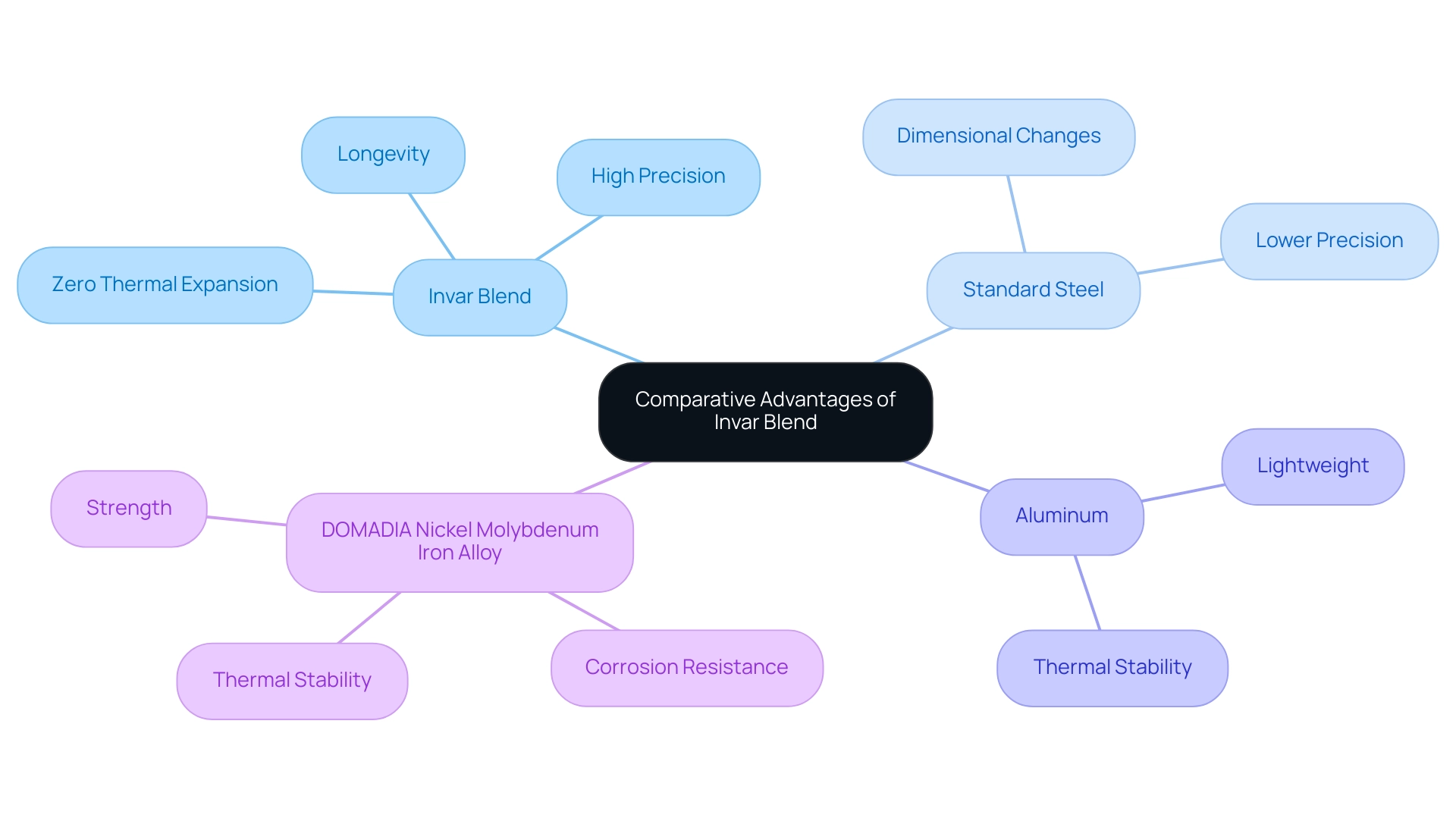

Comparative Advantages of Invar Blend Over Other Alloys

The invar blend is recognized for its unique benefits compared to conventional alloys, particularly in situations where stability and precision are crucial. Notably, this alloy exhibits an almost zero thermal expansion coefficient at room temperature, significantly reducing the risk of dimensional changes that can lead to inaccuracies when compared to standard steel. This characteristic is crucial in sectors that demand high precision.

Additionally, it is essential to clean parts immediately after machining to remove sulfur residues, as this can prevent embrittlement, ensuring the longevity and reliability of the components. In contrast, while aluminum is often favored for its lightweight properties, its superior thermal stability makes it more appropriate for high-precision uses. Moreover, the DOMADIA Nickel Molybdenum Iron Alloy is distinctive because of its remarkable strength, corrosion resistance, and thermal stability, which improves its performance in critical uses across aerospace, automotive, petrochemical, electronics, and renewable energy sectors.

Recent studies indicate that while other alloys may undergo considerable expansion when subjected to heat, this specific alloy’s unique composition allows it to maintain its structural integrity under similar conditions. Moreover, comparative thermal expansion statistics reveal that this alloy outperforms standard steel, making it an even more attractive option for applications requiring tight tolerances. This comparative advantage is essential for procurement managers, as choosing resources with strict quality criteria can significantly affect project results.

The case study on welding techniques for a specific alloy further illustrates this point, demonstrating that, when handled with care, the material can be effectively welded using conventional methods, ensuring strong joints without compromising the alloy’s integrity. Such insights reinforce the strategic importance of the invar blend in conjunction with the DOMADIA Nickel Molybdenum Iron Alloy in the procurement process, where both substances complement each other in providing exceptional performance for critical applications.

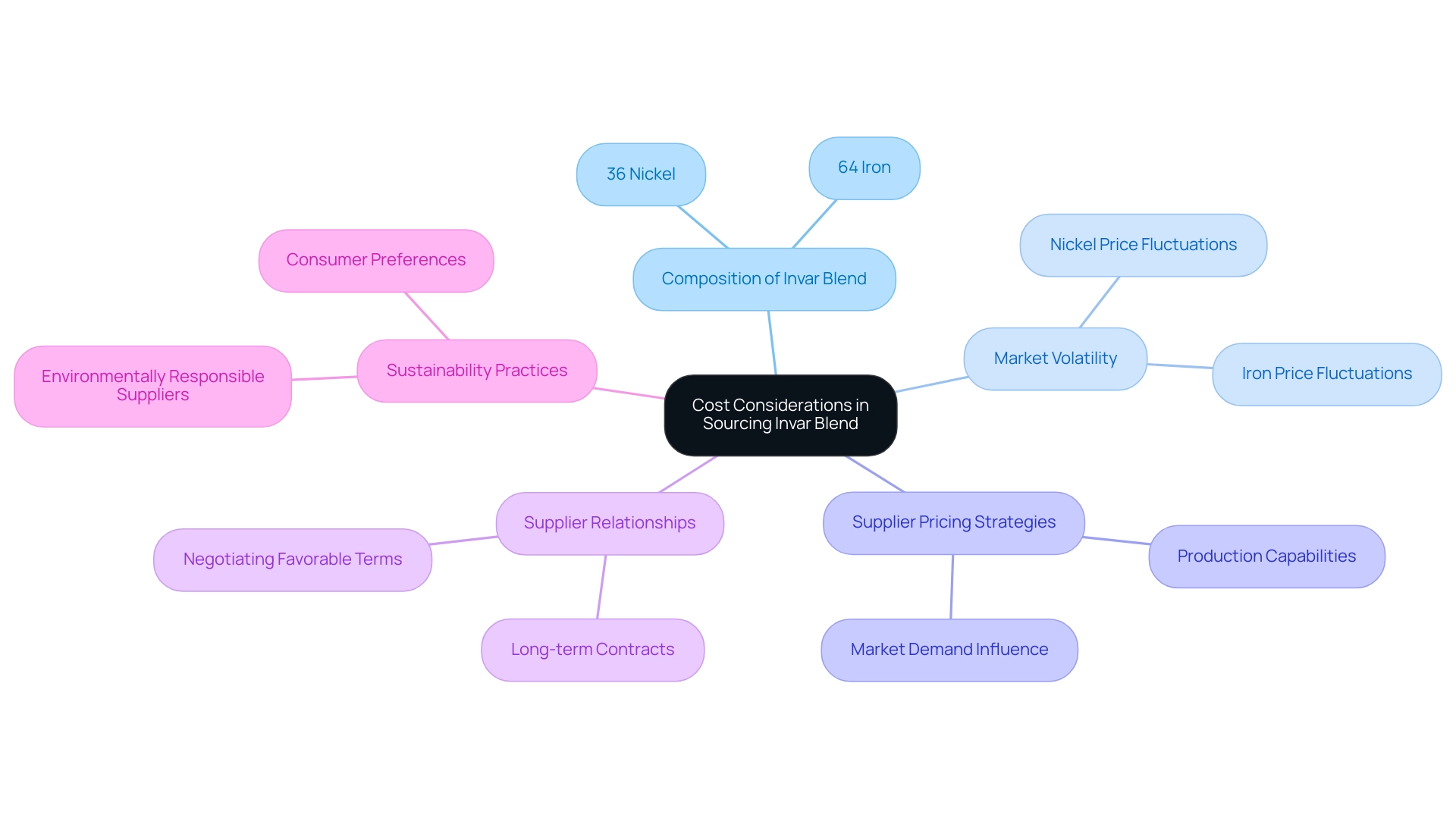

Cost Considerations in Sourcing Invar Blend

When sourcing invar blend, procurement managers must navigate a complex landscape of cost factors that significantly influence pricing. The composition of this alloy, characterized by an invar blend of approximately 36% nickel and 64% iron, is a crucial factor; variations in the costs of these raw materials can result in substantial changes in the overall expense of these alloys. For instance, a rise in nickel prices can directly influence the pricing of certain products, making it imperative for procurement teams to stay informed about these trends.

Current market conditions indicate that both nickel and iron prices are subject to volatility, similar to that of an invar blend. Furthermore, suppliers’ pricing strategies can vary widely, influenced by their production capabilities and the prevailing market demand. Companies such as ThyssenKrupp AG utilize their vast international networks to enhance pricing strategies, employing advanced production facilities to provide competitive rates on steel products.

As noted by a representative from a Global Consulting Firm, “Our company has been working with for some years now and we are very happy with the quality of the reports provided by the company. I, on behalf of my organization, would like to thank you for offering professional reports.” Establishing strong relationships with suppliers is essential for negotiating favorable terms, while using an invar blend in long-term contracts can provide crucial cost stability, facilitating better budget forecasting.

As sustainability practices in production continue to gain traction, aligning procurement strategies with environmentally responsible suppliers may yield long-term cost and reputational benefits, particularly as consumers increasingly favor companies that prioritize sustainability. Understanding these financial dynamics is vital for optimizing procurement strategies without compromising on quality.

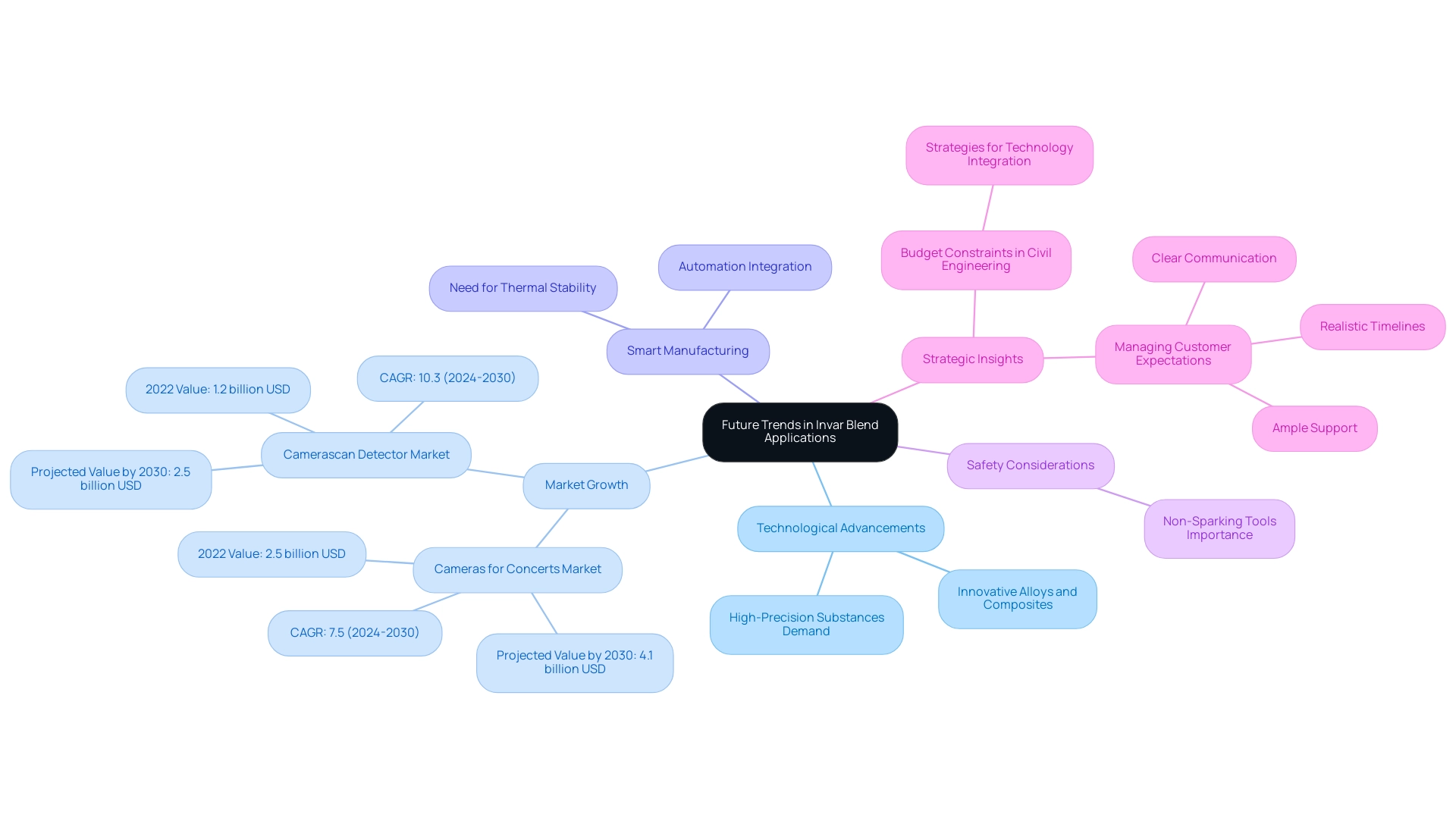

Future Trends in Invar Blend Applications

The future of invar blend applications is increasingly promising, shaped by several key trends across diverse industries. Notably, advancements in technology are projected to elevate the demand for high-precision substances, particularly within the aerospace and electronics sectors. For example, the market for cameras for concerts and live performances was valued at 2.5 billion USD in 2022 and is projected to reach 4.1 billion USD by 2030, emphasizing a notable growth trajectory that highlights the need for precision components in various applications.

The integration of smart manufacturing and automation is set to further amplify the need for substances that offer exceptional thermal stability. According to recent statistics, the market for high-precision materials is expected to expand significantly, driven by these technological innovations. Additionally, ongoing research into new alloys and composites suggests that innovative applications could be found for Invar Blend in previously unfeasible areas.

As noted by an expert, ‘Facing budget constraints in civil engineering? Here are strategies to integrate new technology without overspending.’ This insight is crucial for procurement managers looking to navigate the evolving landscape.

Furthermore, it is important to recognize the role of Non-Sparking Tools in ensuring safety in explosive environments, which is a critical consideration for procurement managers when selecting equipment. The case study on managing customer expectations for new features emphasizes the importance of clear communication and support as industries continue to evolve. It is imperative for procurement managers to remain proactive and adaptable, strategically leveraging these trends to maintain a competitive edge.

Conclusion

Invar Blend emerges as a pivotal material across various high-precision industries, showcasing its exceptional low thermal expansion properties that ensure dimensional stability even under fluctuating temperatures. Its unique composition, primarily of iron and nickel, allows it to excel in critical applications such as:

- Aerospace components

- Optical devices

- Measurement tools

- Cryogenic systems

The comparative advantages of Invar Blend over traditional alloys further solidify its position as the material of choice for procurement managers seeking reliability and accuracy.

As industries evolve, the strategic benefits of Invar Blend extend beyond immediate applications. Understanding the cost implications of sourcing this alloy, particularly in relation to the volatility of raw material prices, is essential for making informed procurement decisions. Establishing strong supplier relationships and aligning with environmentally responsible practices will not only optimize costs but also enhance the reputation of organizations embracing sustainability.

Looking ahead, the demand for Invar Blend is set to rise, driven by technological advancements and the increasing need for precision materials in sectors like aerospace and electronics. As the landscape shifts, procurement managers must remain vigilant and adaptable, leveraging emerging trends to maintain a competitive edge. By prioritizing Invar Blend and its unique properties, organizations can ensure operational efficiency and long-term success in an increasingly competitive market.