Blogs

How to Determine if Beryllium Copper is RoHS Compliant: A Step-by-Step Guide

Overview:

To determine if beryllium copper is RoHS compliant, procurement managers should follow a systematic process that includes identifying reliable vendors, requesting regulatory documentation, and evaluating material specifications. The article emphasizes the importance of maintaining thorough records and conducting laboratory testing when necessary, as well as fostering strong supplier relationships to ensure adherence to RoHS and REACH standards, thereby ensuring that the sourced beryllium copper meets required environmental regulations.

Introduction

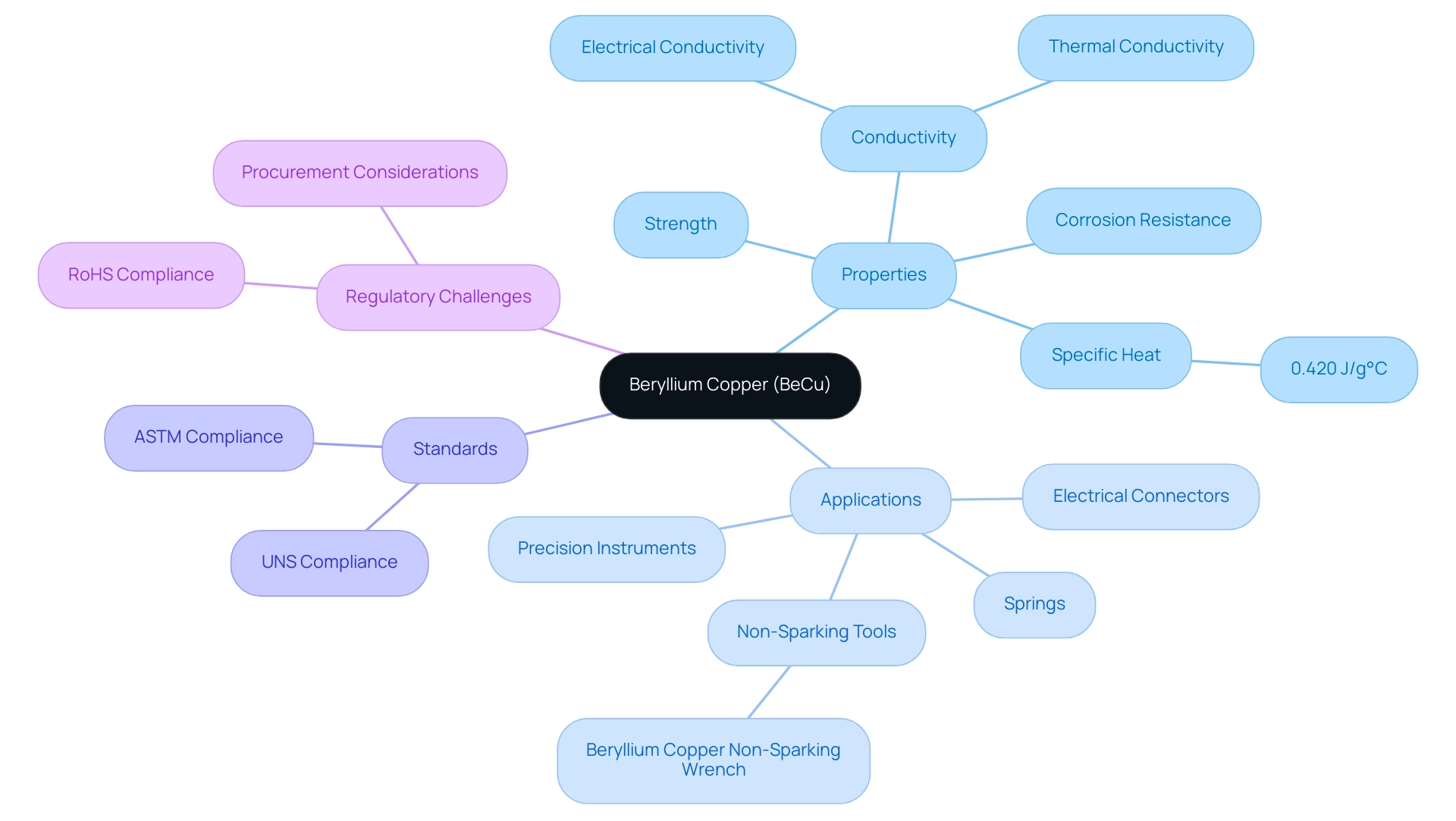

In the realm of advanced materials, beryllium copper stands out as a powerhouse alloy, renowned for its remarkable strength, exceptional conductivity, and resistance to corrosion. As industries increasingly prioritize performance and reliability, understanding the properties and applications of this versatile material becomes essential for procurement managers.

From electrical connectors to safety tools designed for hazardous environments, the implications of selecting beryllium copper extend far beyond mere functionality; they encompass compliance with stringent regulations such as RoHS and REACH.

This article delves into the intricacies of beryllium copper, offering insights into its applications, compliance challenges, and best practices for procurement, ensuring that organizations can make informed decisions while navigating the complexities of material sourcing in today’s dynamic market.

Understanding Beryllium Copper: Properties and Applications

Beryllium copper (BeCu) is a versatile alloy celebrated for its remarkable strength, exceptional electrical and thermal conductivity, and impressive resistance to corrosion. Its specific heat, measured at 0.420 J/g°C, underscores its efficiency in thermal applications. This alloy finds extensive use in critical applications, including:

- Electrical connectors

- Springs

- Precision instruments

where both performance and reliability are paramount.

Significantly, tempered copper alloys like C17510 and C17500 offer outstanding electrical conductivity and wear resistance, further boosting their attractiveness for demanding applications. As procurement managers evaluate resources for their projects, understanding the distinct characteristics of copper alloy, which is beryllium copper RoHS compliant, is crucial; these traits directly affect the performance of the final product and its compliance with environmental regulations. The automotive and electronics sectors particularly benefit from its attributes, making BeCu a preferred choice in manufacturing components that demand durability and efficiency.

In addition to its broad applications, DOMADIA Beryllium Copper complies with international standards, including UNS and ASTM, ensuring that products meet rigorous quality benchmarks.

For instance, the Beryllium Copper Non-Sparking Wrench is designed specifically for safety in potentially hazardous environments. Its non-sparking properties make it an ideal tool for industries such as oil and gas, where avoiding ignition sources is critical. This wrench features a robust construction that enhances its durability and reliability in demanding conditions.

However, it is important to recognize the regulatory challenges posed by the presence of beryllium in the alloy. Under RoHS regulations, which limit hazardous substances in electrical and electronic equipment, procurement managers must navigate these concerns carefully to ensure that the high-performance substance they choose is beryllium copper RoHS compliant while leveraging its benefits. As industries seek to optimize their resources, understanding the pricing and inventory details of Beryllium Copper Strips is crucial for informed procurement decisions.

Furthermore, insights from case studies, like the one involving high-throughput configurable Raman probes, further illustrate the versatility and efficiency of copper in various applications, solidifying its role in modern manufacturing.

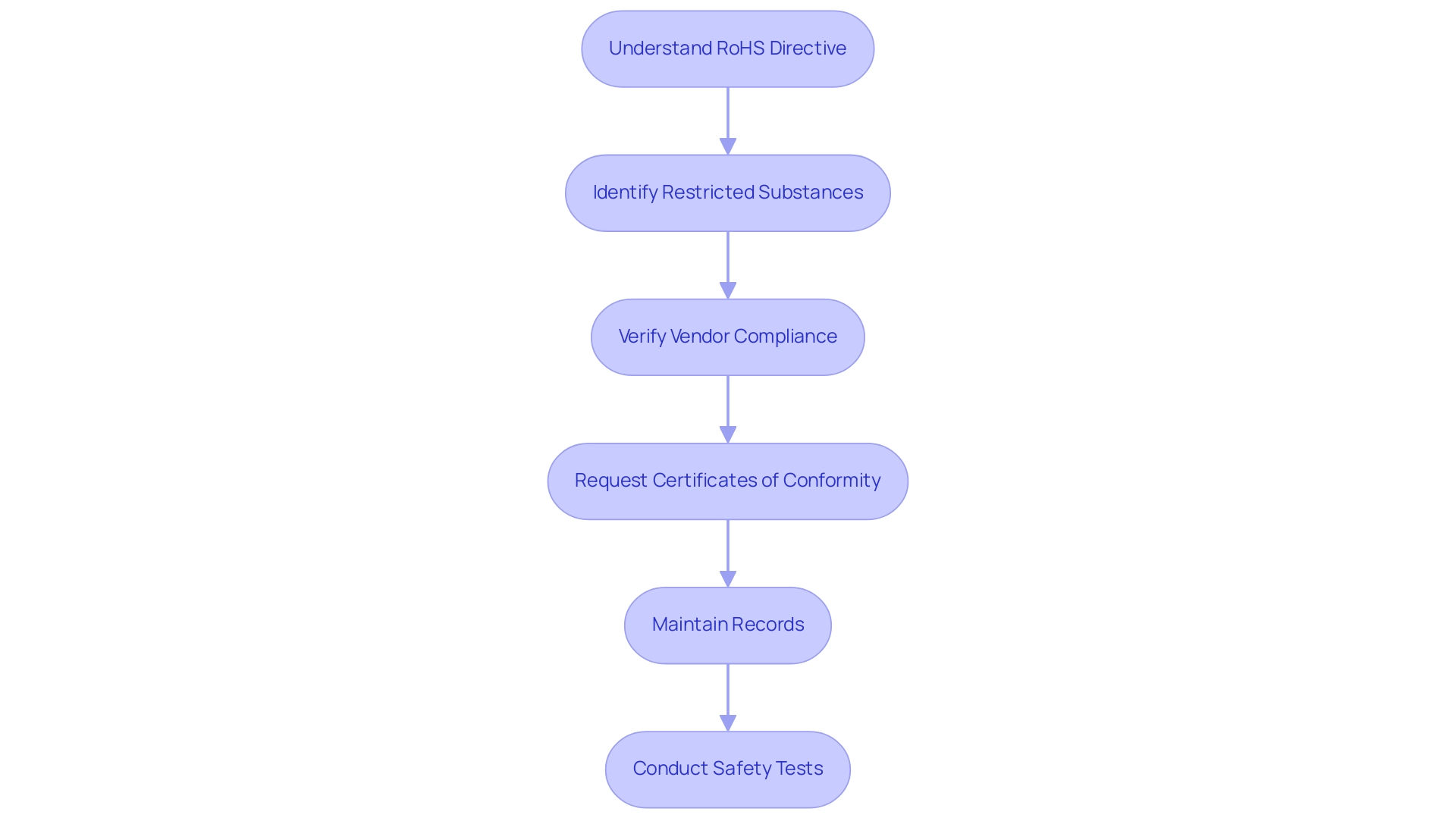

Navigating RoHS Compliance: Key Regulations for Beryllium Copper

The Restriction of Hazardous Substances (RoHS) Directive imposes strict limitations on the use of hazardous materials, including certain substances, in electrical and electronic products. As a classified restricted substance, copper alloy must adhere to specific concentration limits to ensure compliance. According to OSHA, an article is defined as:

- ‘a manufactured item other than a fluid or particle:

(i) which is formed to a specific shape or design during manufacture;

(ii) which has end use function(s) dependent in whole or in part upon its shape or design during end use; and

(iii) which under normal conditions of use does not release more than very small quantities, e.g., minute or trace amounts of a hazardous chemical, and does not pose a physical hazard or health risk to employees.’

This definition highlights the significance of ensuring that copper components, including the Copper Non-Sparking Wrench, are managed appropriately. This wrench is specifically designed for safety in explosive environments, showcasing its non-sparking properties. Procurement managers are advised to diligently verify that vendors, such as Domadia, provide documentation proving their copper components meet these stringent requirements.

Furthermore, under the REACH regulation, substances identified as very high concern (SVHC), including a specific element, must be registered and communicated throughout the supply chain. Domadia’s commitment to safe use is exemplified by its rigorous adherence to regulatory standards, allowing for the continued use of beryllium-containing products while promoting safety and reliability. To enable adherence, it is wise to request certificates of conformity from suppliers and to maintain thorough records of substance specifications and supplier declarations.

Additionally, a successful test for beryllium in air and on surfaces has been developed for workplace safety, emphasizing the importance of monitoring hazardous materials in procurement practices. Domadia offers a wide array of products, including foils, sheets, rods, and wires, which additionally enhances safety in various applications. Consistent adherence to these practices not only aids in regulatory requirements but also enhances the safety and reliability of the components used in explosive environments, highlighting that Beryllium Copper tools, which are known for their non-sparking, corrosion-resistant, and durable properties, are beryllium copper RoHS compliant.

Conducting a Compliance Assessment for Beryllium Copper

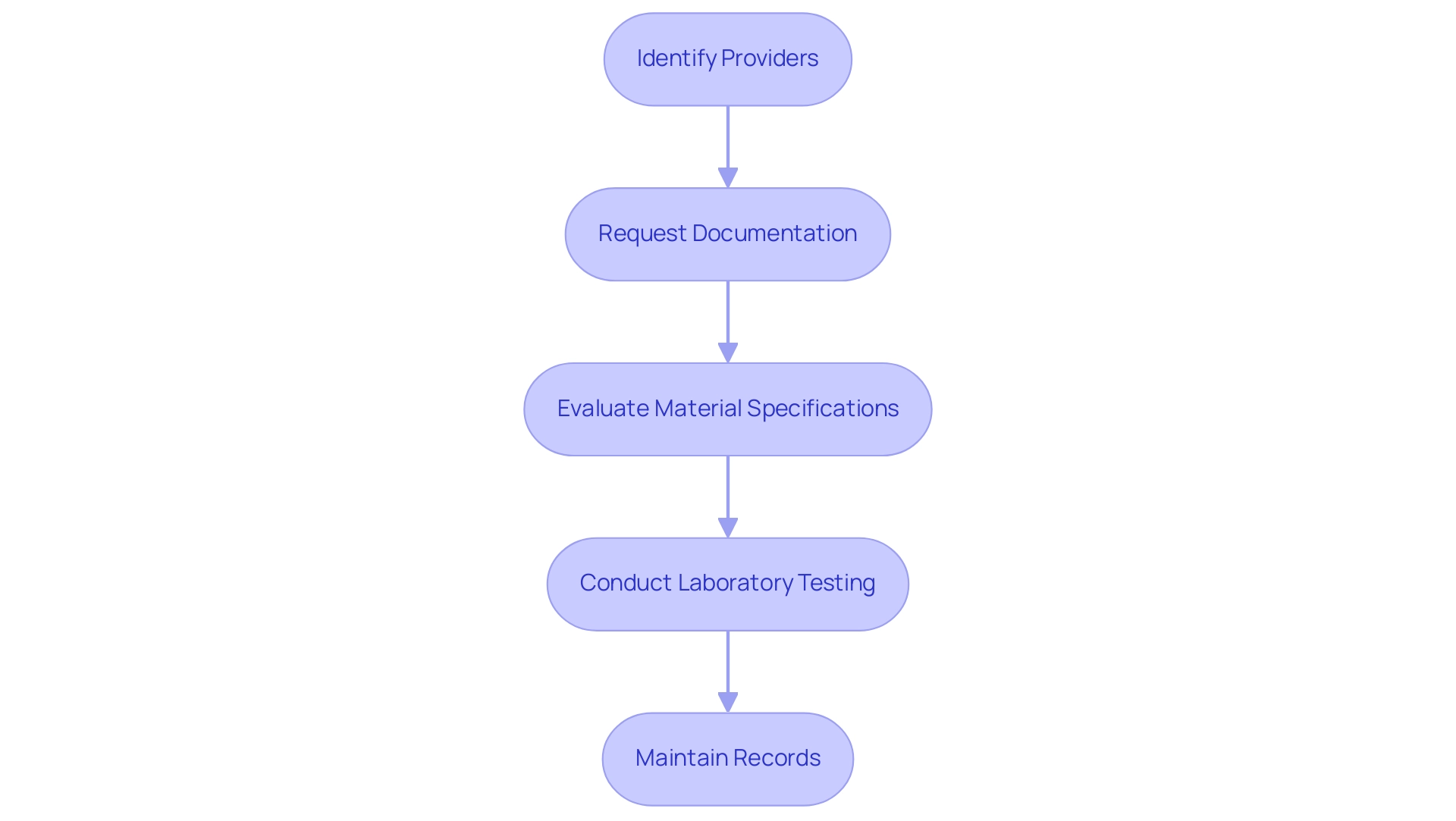

To effectively carry out a regulatory evaluation for copper alloy, procurement managers should follow the subsequent systematic steps:

Identify Providers:

Begin by compiling a comprehensive list of vendors that offer beryllium copper resources, including trusted partners like Domadia, known for their extensive product range that includes foils, sheets, rods, and wires. This initial step is crucial for establishing a reliable supply chain.Request Documentation:

Interact with vendors to acquire necessary regulatory documentation, including certificates that confirm the product is beryllium copper RoHS compliant and adheres to REACH regulations. This documentation is essential for verifying regulatory compliance and ensuring that the resources sourced align with industry standards.Evaluate Material Specifications:

Meticulously review the material specifications provided by the suppliers, ensuring that the content remains within acceptable limits. Recent studies indicate that urinary concentrations of this element in exposed populations correlate with airborne levels, emphasizing the significance of this evaluation.

The mass median aerodynamic diameter (MMAD) of the aerosol, as noted by Cohen et al., ranged from 3 to 6 µm during most sampling periods, underscoring the need for careful assessment.Conduct Laboratory Testing:

In situations where documentation is insufficient, contemplate sending samples for laboratory analysis to precisely verify metal levels. This step is critical, especially in light of findings from the case study on particle-migration control programs, which demonstrated that despite control measures, beryllium exposure continues to occur through skin contact.Maintain Records:

It is essential to keep detailed records of assessment results, vendor communications, and laboratory test outcomes. This documentation will serve as a valuable resource for future audits and regulatory verifications. Additionally, ensure that vendor documentation is beryllium copper RoHS compliant, as this compliance is a key element of adherence. Moreover, refer to user manuals offered by vendors for assistance on product specifications and adherence procedures, which can further aid your sourcing choices.

Lastly, be sure to inquire about pricing and inventory details to ensure that your procurement practices align with budgetary constraints and availability. By adhering to these steps and utilizing the assistance of trustworthy vendors, procurement managers can guarantee that their sourcing practices not only align with regulatory requirements but also effectively reduce potential risk of adherence.

Establishing Supplier Relationships for Compliance Assurance

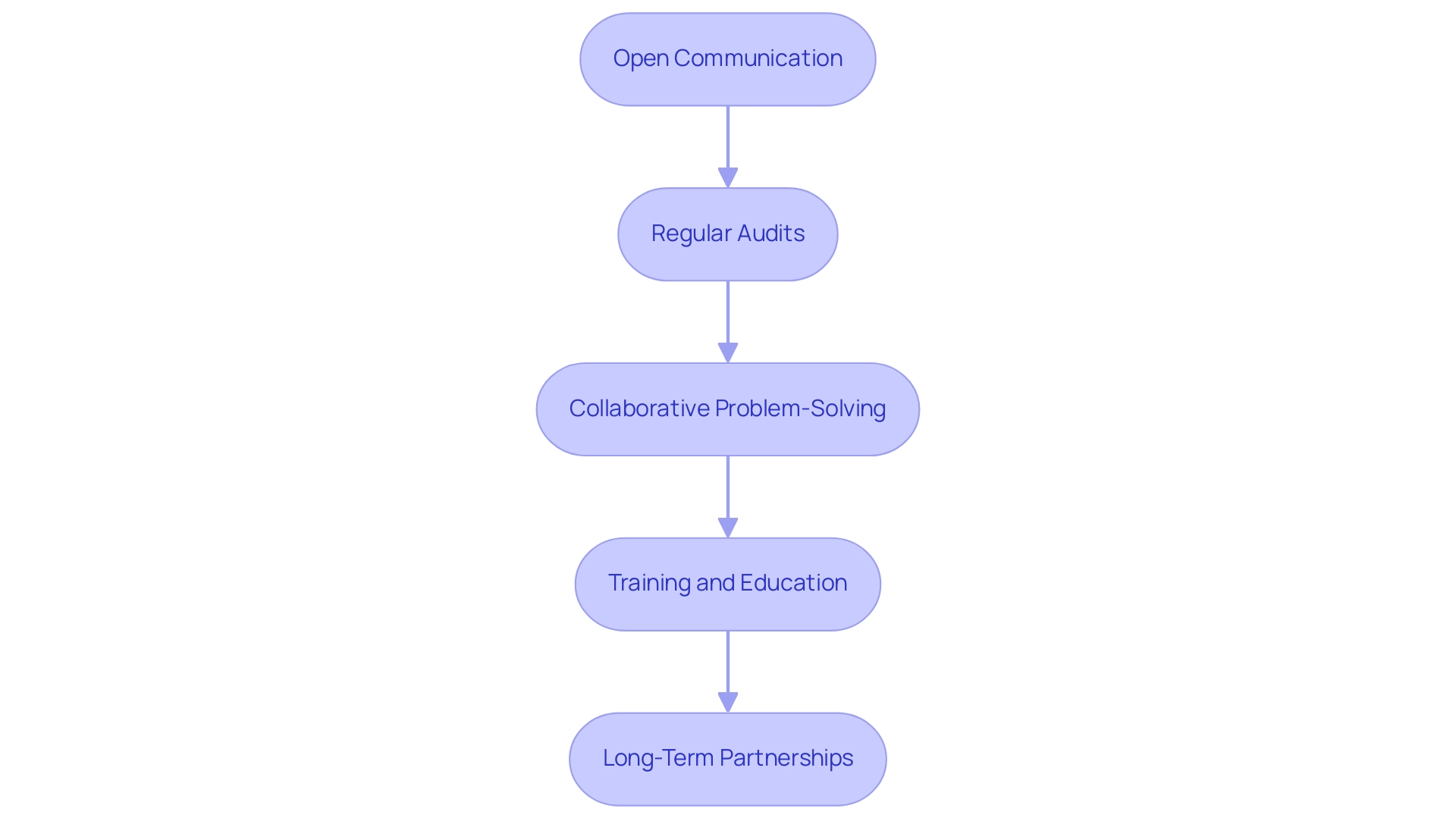

To develop strong vendor connections that guarantee adherence assurance, procurement managers should implement the following strategies:

Open Communication: Establish transparent lines of communication with vendors regarding regulatory requirements and expectations. This clarity fosters trust and facilitates adherence to regulations.

Regular Audits: Carry out systematic assessments of vendors to evaluate their adherence to RoHS and REACH standards. Considering that 27% of security and IT professionals recognize internal audit fatigue as a significant challenge for adherence, regular audits can alleviate this issue by simplifying the process.

The Ponemon Institute highlights that finance and healthcare sectors are particularly at risk, with 58% of financial organizations and 55% of healthcare organizations reporting a third-party data breach in the last year, underscoring the critical need for robust auditing practices.

Collaborative Problem-Solving: Participate in collective problem-solving with vendors to address regulatory challenges. This cooperative approach not only strengthens relationships but also enhances the likelihood of resolving issues effectively.

Training and Education: Provide instructional sessions to vendors on regulatory standards, highlighting the significance of adherence to regulations. This investment in education can substantially enhance adherence rates and overall provider performance. For example, instructing providers on the use of Non-Sparking Tools in explosive settings can improve safety and adherence in these high-risk applications. Furthermore, promoting employee involvement through training programs can create a skilled workforce that is better prepared to address regulatory challenges.

Long-term Partnerships: Prioritize the development of long-term partnerships with suppliers dedicated to adherence and quality. Such enduring relationships can lead to improved reliability in the supply chain and better alignment with regulatory demands.

Moreover, grasping the characteristics and uses of Beryllium Copper C17200, recognized for its high strength and outstanding electrical conductivity, can guide procurement choices and ensure that resources consistently meet regulatory standards. The anticipated talent shortage in mechanical engineering, where 97% of supply chain leaders foresee a growing shortage of suitable talent, is prompting companies to adapt by increasing outsourcing in engineering roles. By adopting these strategies, procurement managers can strengthen their supply chains and ensure that the beryllium copper materials they use is beryllium copper RoHS compliant, safeguarding against potential risks highlighted by industry experts.

Additionally, with 168 countries having ISO members representing them, adherence to global compliance standards is crucial for maintaining supplier relationships.

Conclusion

Beryllium copper emerges as a vital material in modern manufacturing, distinguished by its exceptional strength, electrical conductivity, and corrosion resistance. As highlighted throughout this article, its applications span critical areas such as:

- Electrical connectors

- Safety tools

- Precision instruments

making it indispensable in industries that demand reliability and performance. However, the benefits of beryllium copper come with the complexities of regulatory compliance, particularly concerning RoHS and REACH directives, which necessitate careful consideration by procurement managers.

Navigating compliance challenges is essential to leverage the advantages of this alloy while ensuring adherence to safety regulations. The systematic approach outlined in the article—ranging from supplier selection to maintaining thorough documentation—provides a robust framework for conducting compliance assessments. Establishing strong supplier relationships through open communication and collaboration further enhances the ability to meet regulatory standards, ensuring that beryllium copper components are not only effective but also safe for use in hazardous environments.

In conclusion, understanding the multifaceted properties and applications of beryllium copper is crucial for making informed procurement decisions. By prioritizing compliance and fostering reliable supplier partnerships, organizations can harness the full potential of this remarkable alloy, driving innovation and safety in their operations. The strategic approach to sourcing beryllium copper will ultimately lead to enhanced performance, regulatory adherence, and long-term success in today’s competitive market.