Blogs

Understanding Monel Shafts: A Complete Tutorial on Properties and Applications

Overview

Monel shafts, primarily composed of nickel and copper, are distinguished by their exceptional corrosion resistance, high tensile strength, and adaptability, making them ideal for demanding applications in industries such as marine, aerospace, and automotive. The article supports this by detailing their mechanical properties, such as the ability to withstand extreme temperatures and harsh environments, and by emphasizing their versatility in fabrication and performance, which positions them as a preferred choice over materials like stainless steel and titanium.

Introduction

In the realm of advanced materials, Monel alloys stand out for their remarkable properties that cater to the demanding needs of various industries. Composed primarily of nickel and copper, these alloys are engineered to excel in corrosive environments, making them indispensable in sectors ranging from marine engineering to aerospace.

As industries increasingly prioritize durability and performance, understanding the composition, mechanical advantages, and applications of Monel shafts becomes crucial for procurement managers seeking reliable solutions.

This exploration delves into the unique characteristics of Monel, its competitive edge over alternative materials, best practices for sourcing, and the future trends that will shape its usage in an evolving market landscape.

Exploring the Composition and Mechanical Properties of Monel Shafts

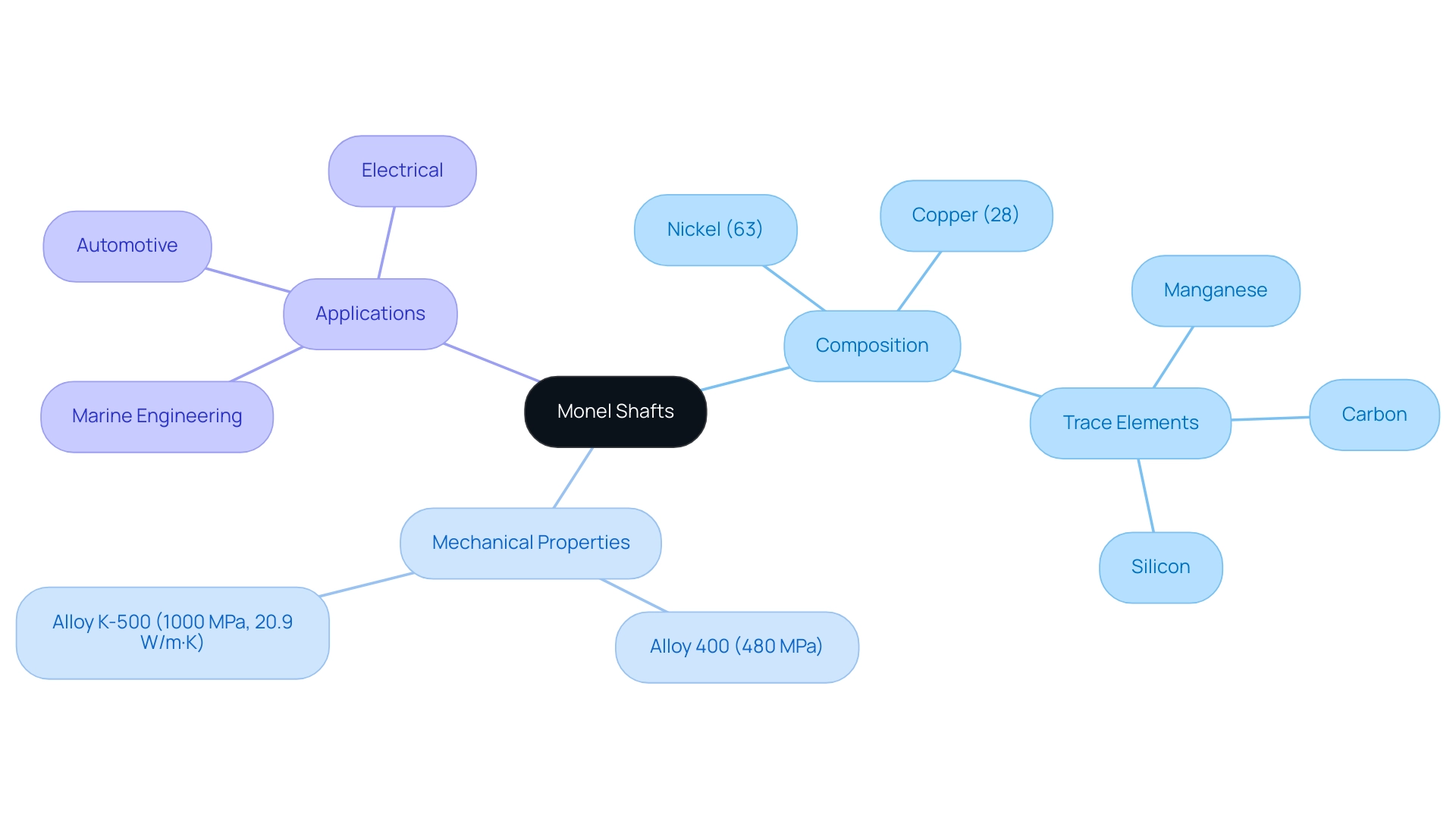

Nickel-copper materials, primarily made up of 63% nickel and 28% copper, are celebrated for their remarkable resistance to corrosion, especially in harsh settings such as seawater and acidic environments. These alloys also contain trace elements such as manganese, carbon, and silicon, which significantly enhance their mechanical properties. For example:

- Alloy 400 boasts a tensile strength of 480 MPa.

- Alloy K-500 can reach an impressive tensile strength of up to 1000 MPa and a thermal conductivity of 20.9 W/m·K, rendering it suitable for various thermal uses.

The high ductility and exceptional resistance to stress corrosion cracking of the monel shaft ensure durability and reliability in extreme conditions. Their capacity to endure temperatures as high as 1000°F (538°C) further highlights the material’s adaptability across various industrial fields, including marine engineering, automotive, and electrical sectors. As emphasized in the case study on the physical characteristics of these metal mixtures, their high strength and adaptability render them a favored material in challenging environments.

As noted by industry expert Huaxiaometal, ‘Versatility: Easily fabricated, welded, and machined, making it a top choice for manufacturers.’ This combination of characteristics positions the monel shaft as an ideal choice for uses necessitating reliability and performance in extreme conditions. At Domadia, we offer a diverse range of copper nickel alloys that cater to these exact needs.

Explore our extensive product catalog to find the perfect solution for your project requirements.

Applications of Monel Shafts in Various Industries

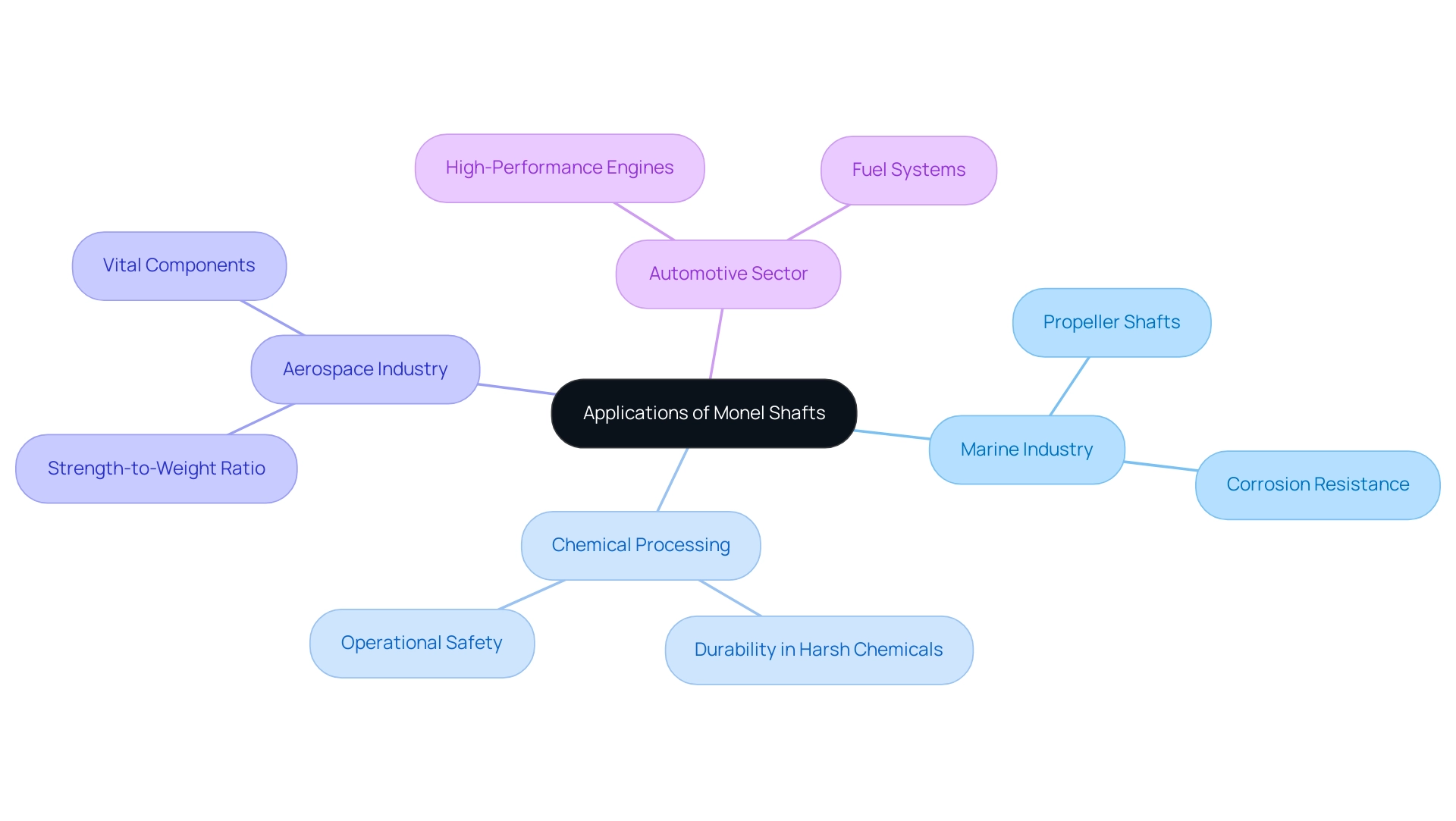

Certain shafts, specifically monel shafts, are extensively employed in marine applications, particularly as propeller shafts, due to their remarkable resistance to seawater corrosion. This characteristic is essential for enhancing the longevity and performance of marine vessels. Alloy 400, with a melting point range of 1300-1350°C, further underscores its suitability for demanding environments.

In the chemical processing sector, this alloy is acknowledged for its durability in components exposed to harsh chemicals, significantly contributing to operational safety and equipment lifespan. As noted by Huaxiao Metal, the material’s versatility allows it to be easily fabricated, welded, and machined, making it a preferred choice. Moreover, in the aerospace industry, nickel-copper alloys play a crucial role in vital components where ideal strength-to-weight ratios are essential.

The automotive sector also utilizes the distinctive characteristics of a specific alloy, employing these components in high-performance engines and fuel systems, which necessitate materials that can endure extreme conditions. Frequent updates and insights into the alloy market, as emphasized in the case study ‘Staying Informed about the Alloy Market,’ are crucial for companies to stay competitive, further highlighting the strategic significance of these components across various challenging applications.

Comparing Monel Shafts with Other Materials

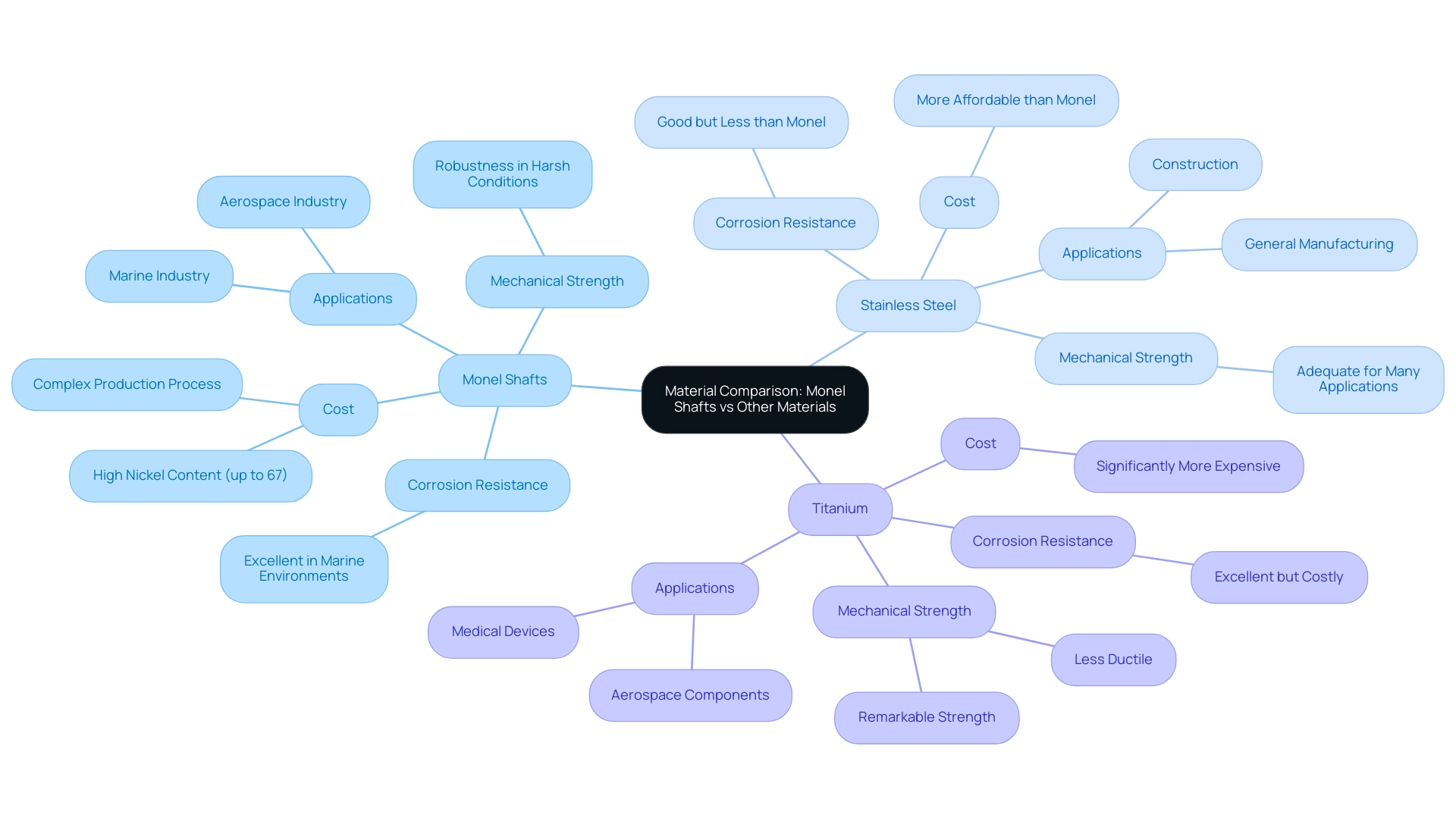

When assessing these shafts relative to stainless steel, it is essential to recognize that this material provides exceptional corrosion resistance, particularly crucial in marine environments where exposure to saline conditions can lead to premature material failure. This alloy is significantly more costly than SS316, primarily due to its high nickel content, which can be as much as 67%. While stainless steel is often favored for its cost-effectiveness and widespread availability, as noted by Kat de Naoum, it typically lacks the robustness required to endure such harsh conditions without succumbing to corrosion.

Furthermore, a case study named ‘Cost and Processing of Monel 400 vs SS316’ emphasizes that the intricate production process and specialized uses of this alloy result in its elevated cost, reinforcing its essential role in crucial uses. Conversely, titanium, recognized for its lightness and remarkable strength, poses its own difficulties; it is significantly pricier and not as ductile as other materials, limiting its adaptability in specific uses. Consequently, these rods effectively achieve a balance between performance, cost, and versatility.

The monel shaft arises as the favored choice in numerous contexts where both mechanical strength and resistance to corrosive environments are paramount, thus reinforcing its essential role in industries such as marine and aerospace.

Best Practices for Sourcing Monel Shafts

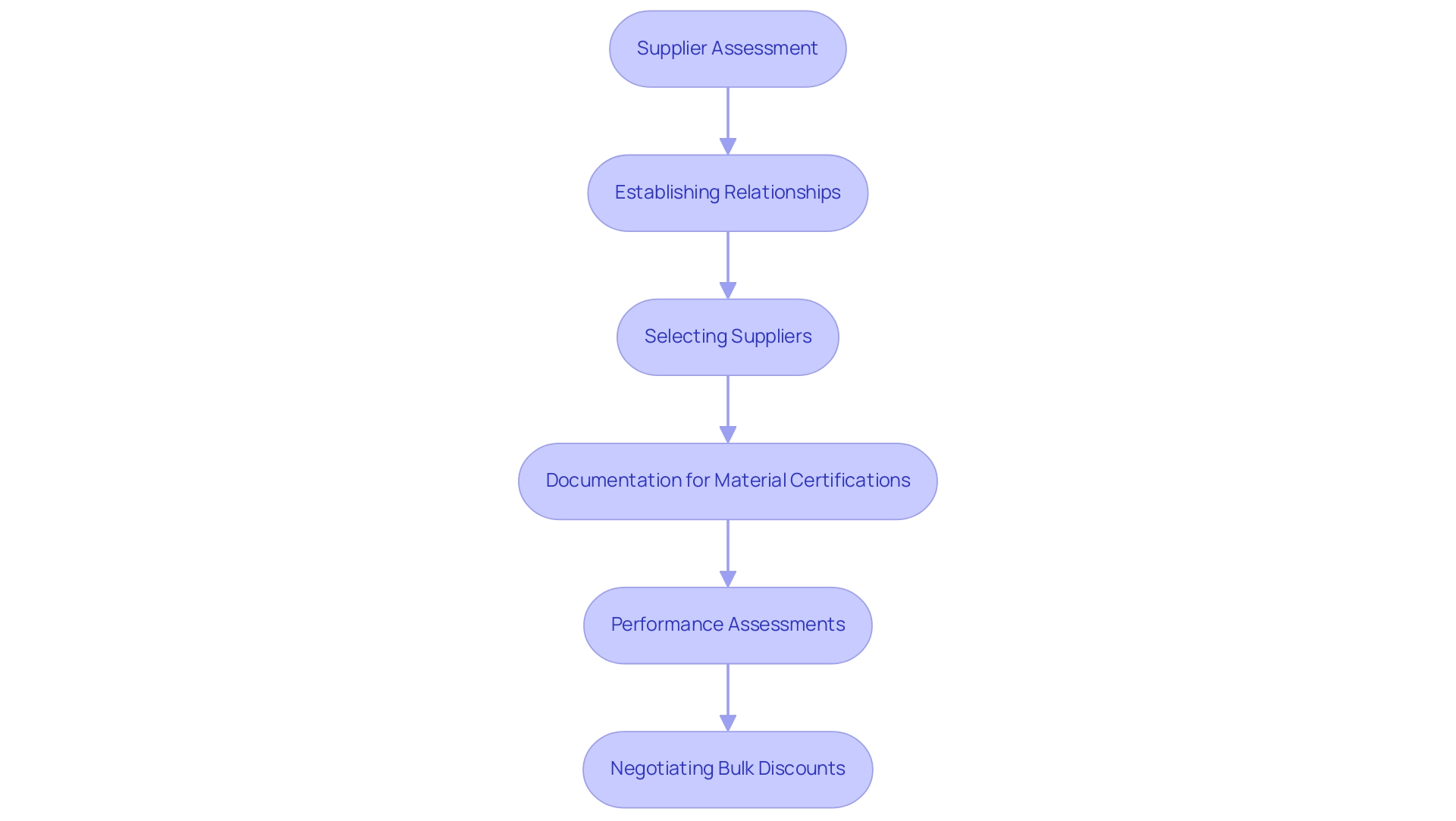

Acquiring specialized metal components necessitates a tactical method focused on supplier assessment and adherence to global standards. Establishing long-term relationships with suppliers who consistently demonstrate reliability in both quality and delivery timelines is crucial. For instance, the Newton Motion Driver Shaft’s compatibility with over 95% of the driver market underscores the importance of selecting suppliers with proven track records in various applications.

Furthermore, using premium mica tape from vendors such as Domadia can greatly improve the insulation characteristics of metal components in high-temperature settings. Domadia’s mica tape is rigorously tested to meet international standards, ensuring that it provides reliable thermal insulation that complements the durability of certain alloys. Negotiating bulk purchasing discounts can further optimize costs, enhancing overall procurement efficiency.

It is essential to ensure that suppliers provide comprehensive documentation for material certifications to facilitate compliance and traceability. As noted in the words of The Club Nut, ‘The differences in your test, which don’t follow what is known, are due to the differences from swing to swing,’ underscoring the need for consistent supplier performance. Regular performance assessments through systematic audits and feedback mechanisms are vital to uphold high-quality standards in your procurement processes.

By implementing these best practices, procurement managers can effectively navigate the complexities of sourcing monel shafts while maintaining a competitive edge in the market.

Future Trends in Monel Shaft Usage

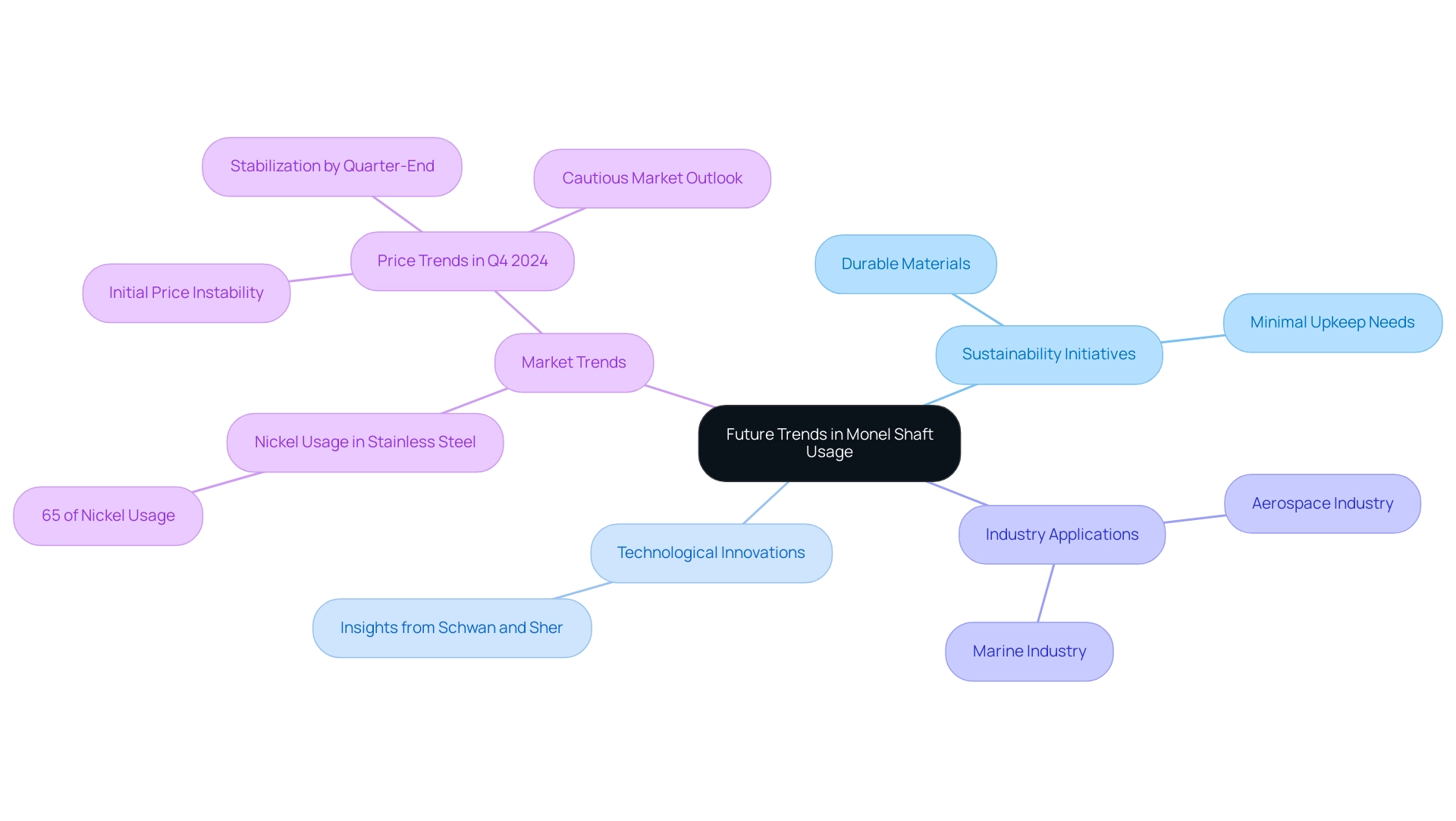

As sustainability initiatives gain traction across various industries, the demand for durable materials such as nickel-copper alloy is anticipated to surge. These materials, recognized for their durability and minimal upkeep needs, are becoming more appealing to industries emphasizing sustainable practices. Significantly, around 65% of total nickel is utilized in producing stainless steel, emphasizing the competitive environment in which these metal mixtures function.

Innovations in alloy technology, including insights from Schwan and Sher who noted that ‘a dielectric particle disturbs the local -field; even in a homogeneous external field there is a local gradient,’ are set to further enhance the properties of these components, positioning them favorably against alternative materials. In particular, the aerospace and marine industries are likely to expand their use of specialized monel shafts, given their established reliability in harsh environments. The recent case study on the Europe Price Trend in Q4 2024 reflects that while prices were initially unstable due to supply chain difficulties, they stabilized by quarter-end, indicating a cautious but positive outlook.

According to industry analysts, this trend signifies a critical opportunity for procurement managers to align their sourcing strategies with the evolving market landscape. Staying abreast of these developments will enable effective decision-making and capitalize on the advantages presented by the monel shaft.

Conclusion

Monel alloys represent a cornerstone in the development of advanced materials, particularly due to their unique composition and mechanical properties. With a high nickel and copper content, Monel shafts deliver exceptional corrosion resistance and mechanical strength, making them invaluable in sectors such as marine engineering, aerospace, and chemical processing. Their ability to withstand extreme temperatures and harsh environments positions them as a superior choice compared to alternative materials like stainless steel and titanium.

The applications of Monel shafts are vast, highlighting their versatility across various industries. From enhancing the performance of marine vessels to ensuring operational safety in chemical processing, Monel’s properties allow for reliable performance in demanding conditions. As industries increasingly prioritize durability and eco-friendliness, the strategic sourcing of Monel shafts becomes paramount. Establishing strong supplier relationships and adhering to best practices in procurement can significantly impact operational efficiency and product reliability.

Looking ahead, the trends in Monel shaft usage indicate a growing demand driven by sustainability initiatives and technological advancements. As industries evolve, procurement managers must remain vigilant and adapt their strategies to harness the full potential of Monel materials. By staying informed of market fluctuations and emerging innovations, organizations can effectively position themselves to leverage Monel’s advantages, ensuring long-term success in their respective fields.