Blogs

Understanding Monel Tanks: An In-Depth Tutorial on Properties and Applications

Overview

Monel tanks are increasingly recognized for their exceptional durability and corrosion resistance, making them a preferred choice in various industries such as marine engineering, chemical processing, and aerospace. The article supports this by detailing their unique properties, including high strength, weldability, and formability, which enhance their performance in challenging environments, ultimately leading to lower life-cycle costs and compliance with industry standards.

Introduction

In the ever-evolving landscape of industrial materials, Monel stands out as a formidable contender, particularly for procurement managers seeking reliable and high-performance solutions. This nickel-copper alloy, renowned for its exceptional corrosion resistance and mechanical properties, is increasingly adopted across diverse sectors, from marine engineering to chemical processing.

As industries face the dual challenges of stringent regulations and the demand for sustainable practices, understanding the unique attributes and applications of Monel becomes imperative. This article delves into the composition, advantages, and compliance standards of Monel tanks, while also exploring future trends that underscore their strategic importance in modern applications.

By leveraging insights into Monel’s capabilities, procurement professionals can make informed decisions that enhance operational efficiency and ensure long-term investment value.

Introduction to Monel: Composition and Unique Properties

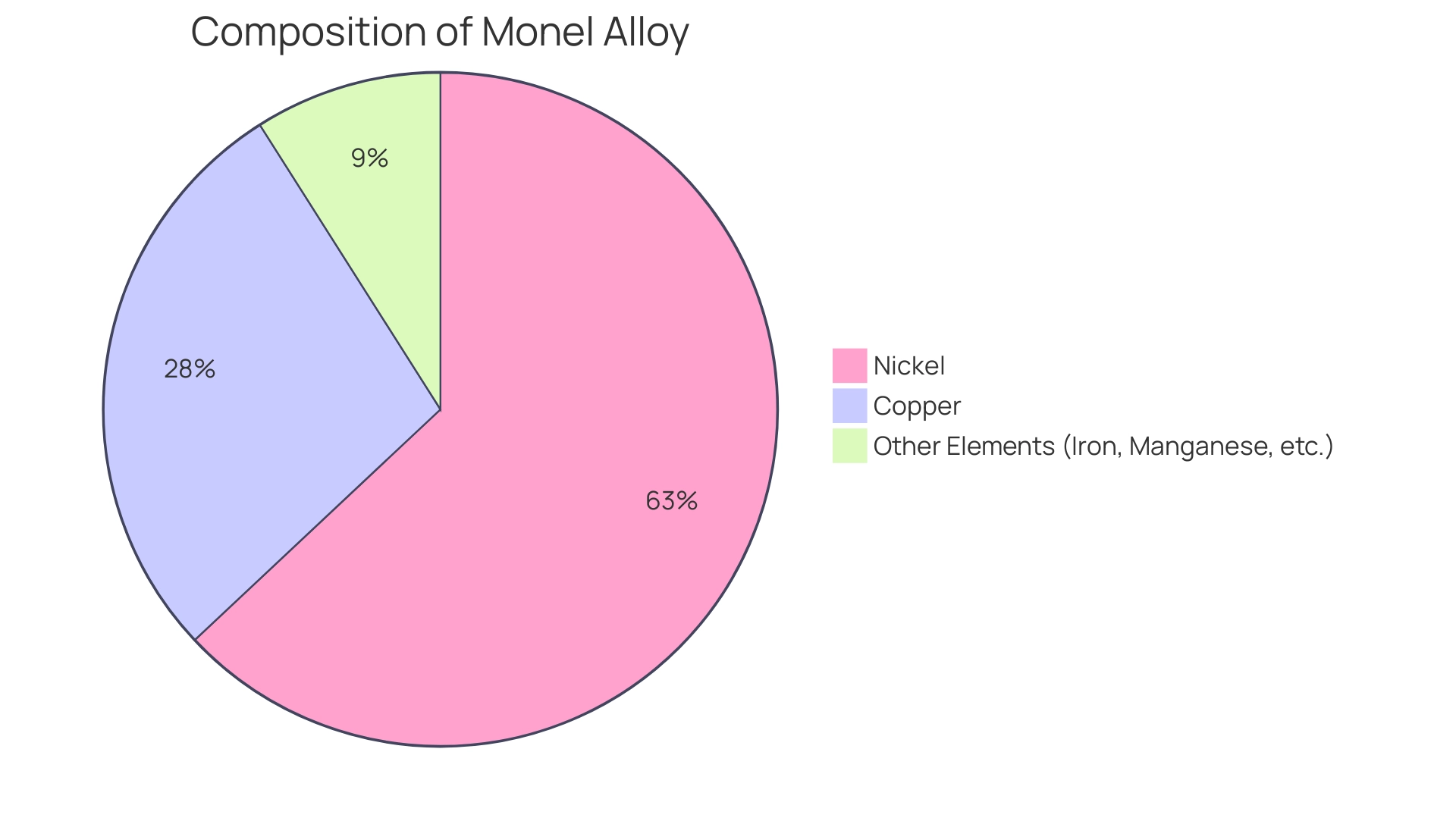

This nickel-copper mixture primarily composed of around 63% nickel and 28% copper is part of Domadia’s diverse selection of copper nickel compositions, which are designed for various applications, including marine engineering and electronics. This mixture demonstrates remarkable corrosion resistance, particularly in challenging environments like marine settings. Its composition, which includes small amounts of iron and manganese, enhances its robust performance against corrosive elements.

The distinctive characteristics of this material, including high strength and toughness at elevated temperatures, exceptional weldability, and formability, make it a versatile choice across industries. The alloy’s inherent ability to withstand stress and resist pitting is particularly advantageous in applications requiring durability and reliability. Consequently, this metal is increasingly being recognized as a superior alternative to stainless steel, especially in scenarios demanding resistance to seawater and acidic conditions.

On average, this material costs around $2.05 per pound, providing a concrete economic perspective on its use. Domadia provides a comprehensive product catalog showcasing copper nickel materials, ensuring a solution for every project requirement. Recent advancements in nickel-copper alloys have further underscored the strategic importance of this material in contemporary uses, reinforcing its reputation in sectors such as semiconductor technology and battery composition.

As noted by Mansoor Ahmed, ‘Nice information,’ which reflects the growing acknowledgment of the entity’s importance and the quality of Domadia’s offerings. Additionally, the case study titled ‘Reimagining Electrode Loading Analysis’ illustrates the material’s application in semiconductor markets and battery technology, showcasing its relevance in addressing current challenges in chip technology and battery composition.

Applications of Monel Tanks Across Industries

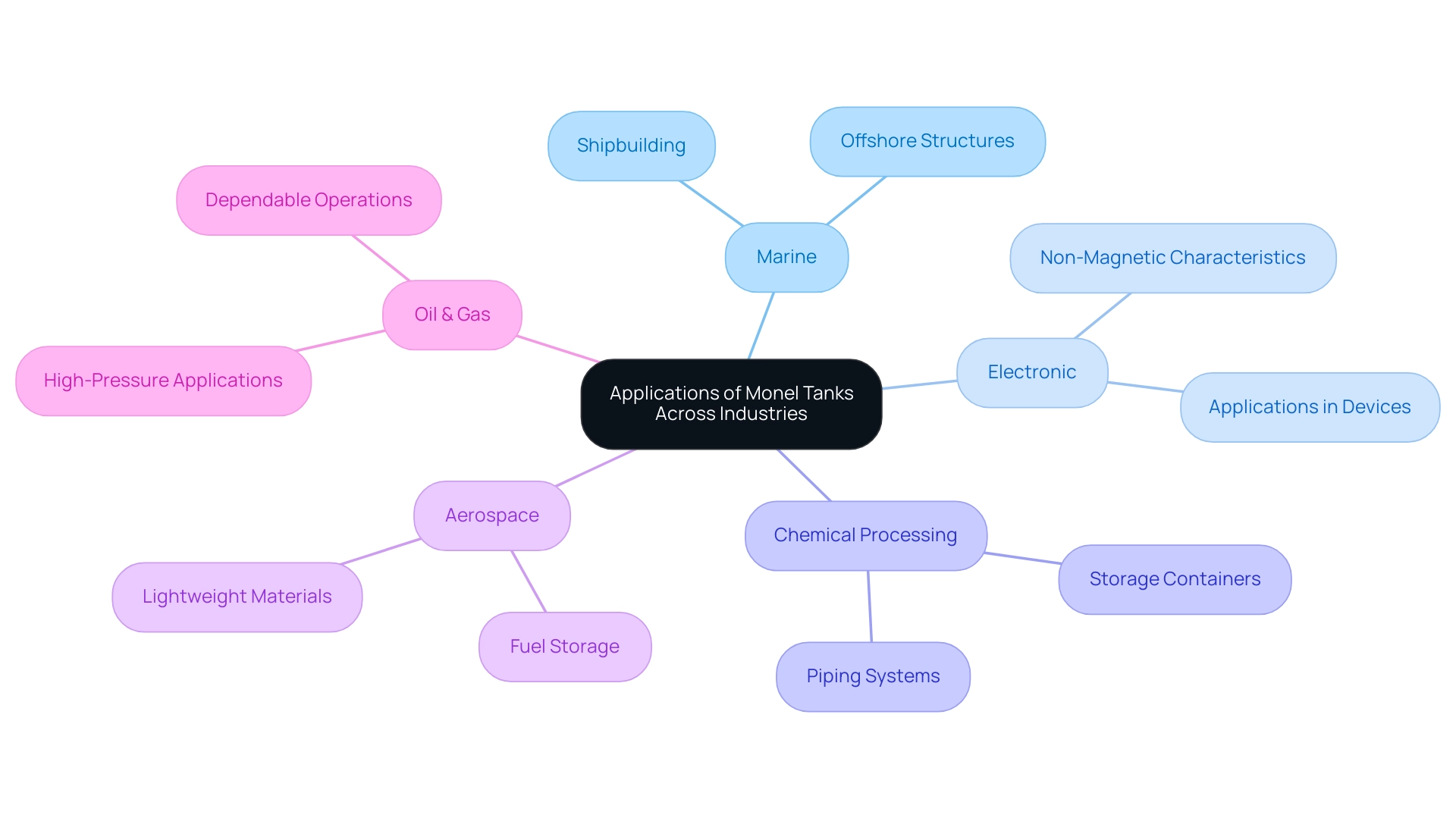

Alloy containers are increasingly acknowledged for their exceptional durability and efficiency across various sectors. In the marine sector, monel tanks serve as essential components in shipbuilding and offshore structures, demonstrating exceptional durability against the corrosive effects of seawater. Recent insights from industry specialists emphasize that certain alloys, recognized for their non-magnetic characteristics, are especially beneficial in electronic devices and maritime uses, even though they display slight magnetism under certain conditions.

Selecting the appropriate substance, like titanium, can greatly influence performance and durability in industrial uses, highlighting the significance of material choice in procurement strategies. Furthermore, in chemical processing, this remarkable resistance to both acids and alkalis positions it as a preferred material for storage containers and piping systems. The ongoing growth in stainless steel production, which saw a notable annual increase of 10.6% to reach 56.3 million metric tons in 2021, reflects a broader industry trend towards materials that enhance safety and efficiency.

The IMARC Team states, ‘The report is excellent and has a good amount of data and our team is extremely happy with the information provided,’ underscoring the reliability of the data presented. Furthermore, a case study on the resistance of nickel alloys to aqueous environments demonstrates that these alloys, such as monel tanks, are recognized for their corrosion resistance in distilled and seawater, with specific alloys being suggested for essential uses, including those in marine and chemical processing contexts. The aerospace industry also gains advantages from these containers, employing them for fuel storage and other uses where lightweight yet durable materials are essential.

The material’s ability to endure high-pressure settings makes it appropriate for oil and gas uses, guaranteeing dependable and efficient operations. The varied uses of these containers highlight their crucial function in enhancing safety and operational effectiveness in multiple sectors.

Advantages of Using Monel Tanks

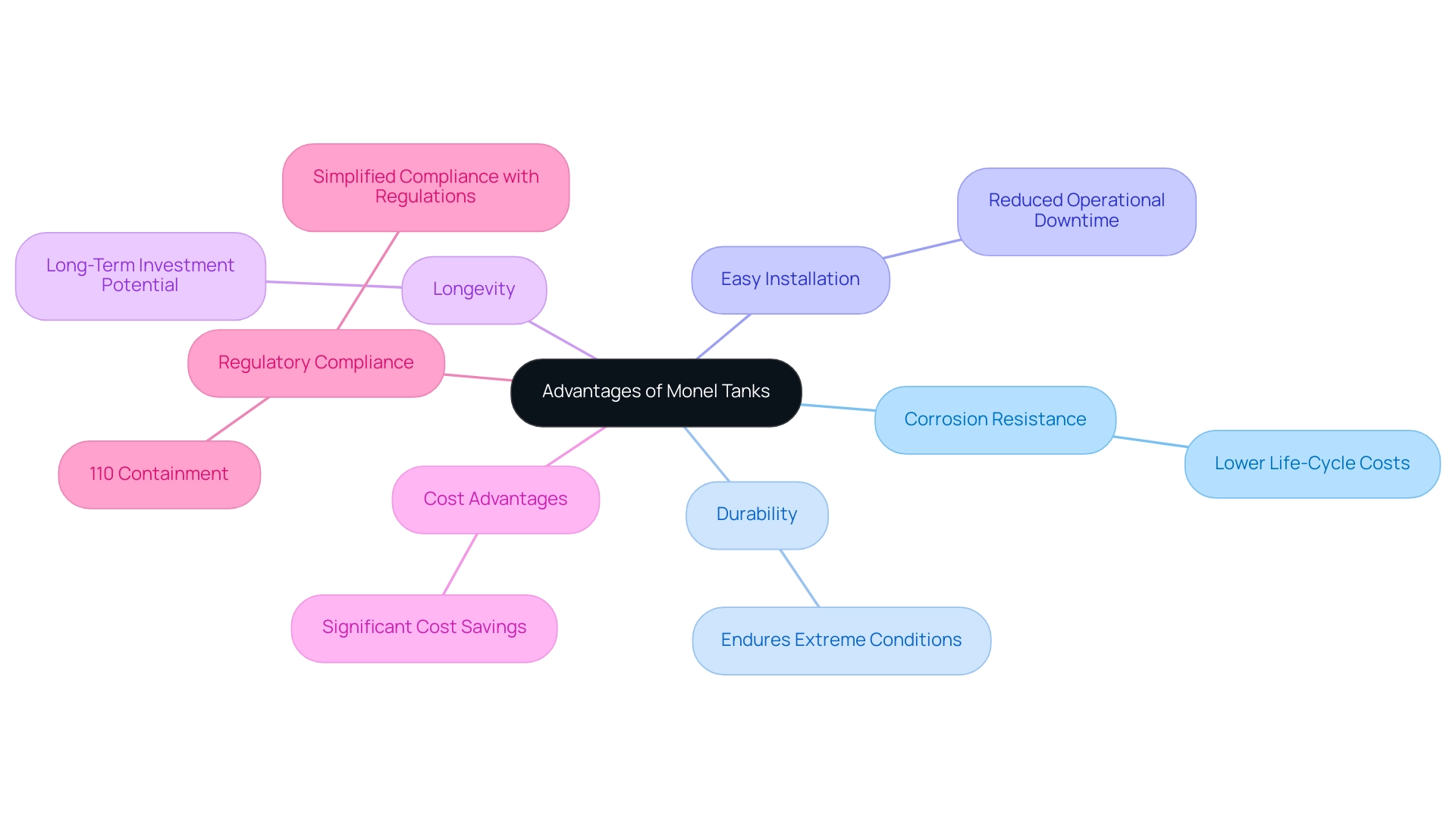

Monel tanks provide a compelling range of benefits that make them a premier option for industrial uses. Their remarkable corrosion resistance dramatically decreases the frequency of replacements, resulting in significantly lower life-cycle costs. This durability is further supported by the strength of monel tanks, allowing them to endure extreme environmental conditions without compromising structural integrity.

The fabrication properties of this alloy facilitate straightforward installation and maintenance, reducing operational downtime. Moreover, the longevity and reliability of monel tanks are enhanced by their compatibility with a range of media—including seawater and aggressive chemicals. As procurement managers aim to embrace sustainable practices, investing in monel tanks emerges as a strategic choice, promising strong performance and significant cost advantages, particularly in corrosive settings.

Significantly, industry specialists, including Admiral Mike, emphasize the worth of these vessels, stating,

I talk to Tad Jones and Dyer, and he said those vessels should outlast the boat. He said not to get rid of them no matter what.

This reinforces the long-term investment potential of these materials in various applications.

Furthermore, the incorporation of double-walled vessel designs with built-in secondary containment eliminates the need for separate systems, simplifying compliance with environmental regulations and reducing maintenance costs. With Western Global double-walled containers featuring 110% containment, procurement managers can confidently consider the economic and environmental benefits of specialized materials. Staying informed about market trends and regulatory changes is paramount for making strategic sourcing decisions that leverage the advantages of specific alloys.

Compliance and Standards for Monel Tanks

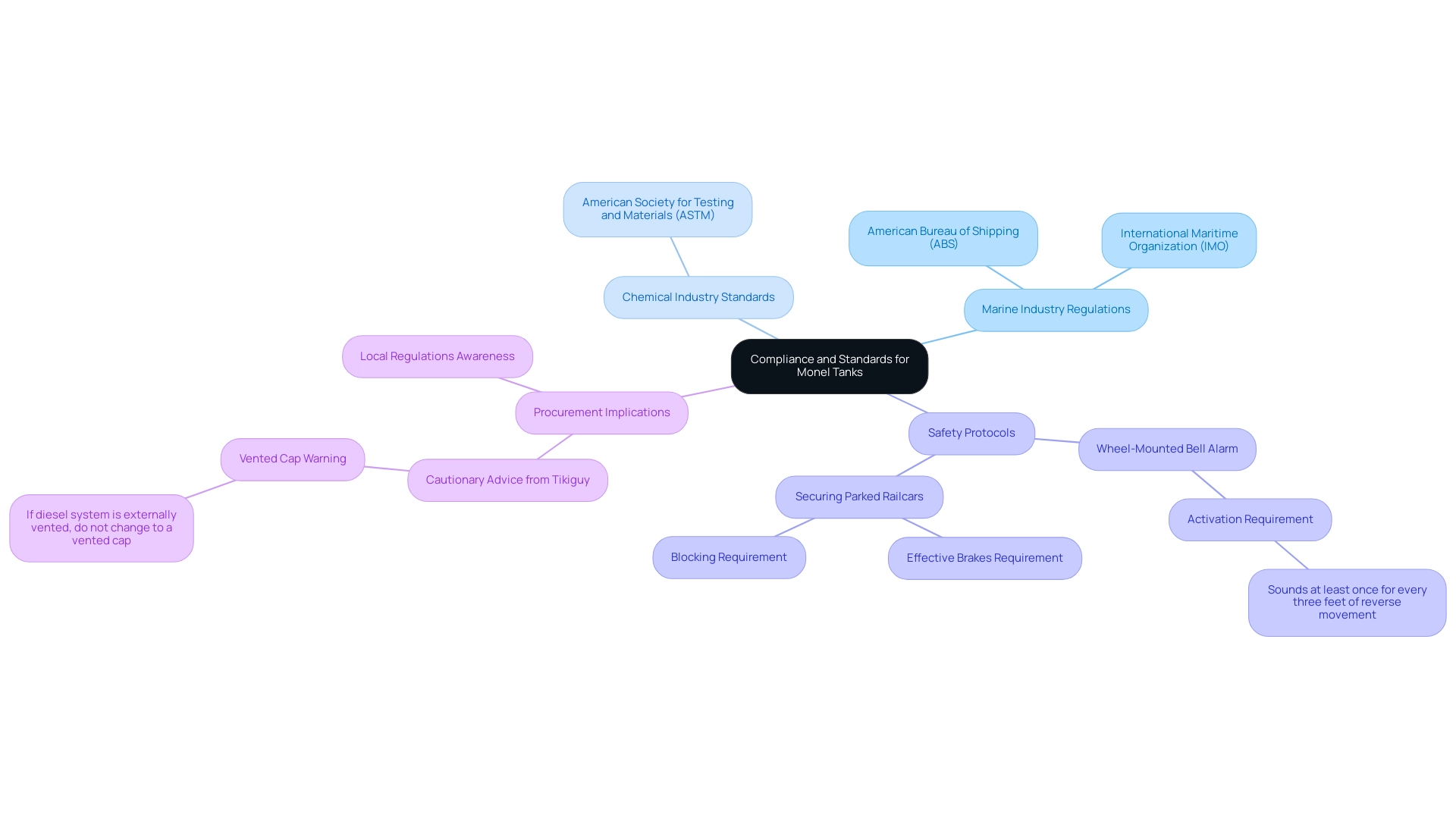

Alloy containers are subject to stringent industry standards that are critical for ensuring both safety and operational effectiveness. In the marine industry, adherence to the American Bureau of Shipping (ABS) and International Maritime Organization (IMO) regulations is not just recommended; it is essential for compliance and safety in marine environments. Likewise, in the chemical industry, the American Society for Testing and Materials (ASTM) standards play a crucial role in certifying that these containers are capable of safely holding a diverse range of chemicals.

For example, self-propelled mobile machinery must be equipped with a wheel-mounted bell alarm that activates at least once for every three feet of backward movement, highlighting the significance of safety protocols in settings where specialized containers are used. Additionally, procurement managers should heed the cautionary advice from Tikiguy:

- ‘Beware!!! If your diesel system is externally vented (no through the cap) then DO NOT change to a vented cap.’

This highlights the critical nature of compliance in operational settings. Additionally, the case study named ‘Securing Parked Railcars‘ demonstrates the necessity of compliance standards in preventing unintended movement, emphasizing the significance of such measures in ensuring the safety of specific containers. It is equally important for procurement managers to remain vigilant regarding local regulations that may influence the design and installation of specialized containers.

A comprehensive understanding of these compliance requirements empowers procurement professionals to make informed decisions, ensuring that the materials selected not only meet industry expectations but also adhere to the necessary safety protocols.

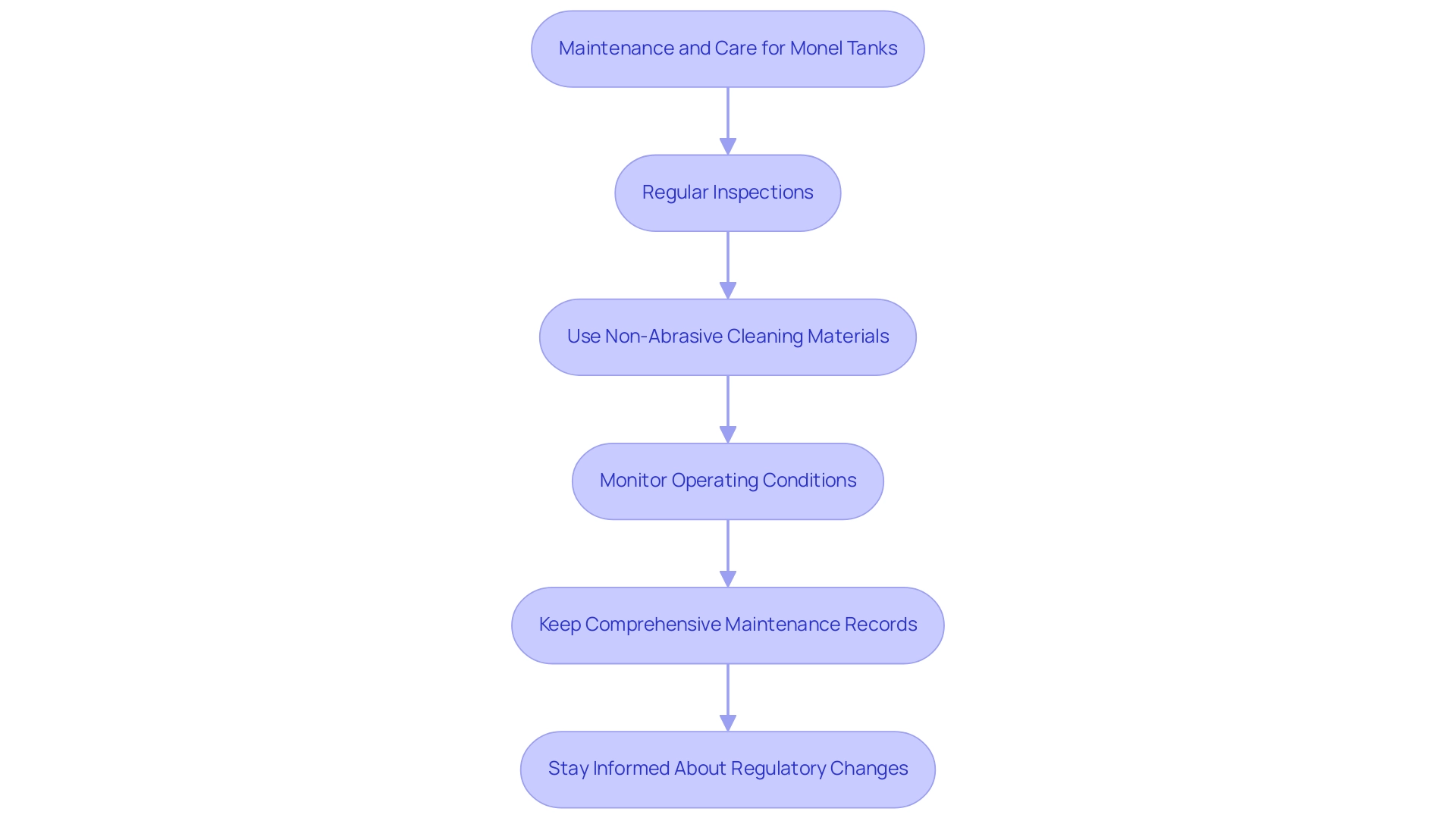

Maintenance and Care for Monel Tanks

To ensure the longevity and operational efficiency of monel tanks, implementing a rigorous maintenance schedule is paramount. Regular inspections are crucial for detecting early signs of corrosion and damage, particularly at welds and joints, which are often susceptible to stress-induced failures. It is advisable to utilize non-abrasive cleaning materials along with suitable cleaning agents that maintain the integrity of the alloy without introducing additional vulnerabilities.

Furthermore, actively monitoring operating conditions—such as temperature and pressure—is essential to mitigate undue stress on the containers. Comprehensive maintenance records should be meticulously kept, as they are invaluable for identifying trends that may signal underlying issues. This proactive approach not only enhances safety but also promotes sustained efficiency in operations.

Notably, the accountability proportion for metal removal rate stands at 13.2, highlighting the significance of precise maintenance practices. Additionally, as demonstrated in the case study titled “Experimental Setup for Alloy 400 Machining,” the assessment of machining performance under different conditions can guide maintenance strategies. Staying informed about updates in the eCFR is also critical, as regulatory changes may impact maintenance practices specifically for monel tanks.

As noted by Sanjay Chintakindi from the Industrial Engineering Department at King Saud University,

This research work would be a better attempt to improve the optimization and behavior of machining for high-strength metals in the industry and to identify and introduce the most significant parameters,

underscoring the critical evaluation of maintenance practices in relation to material behavior.

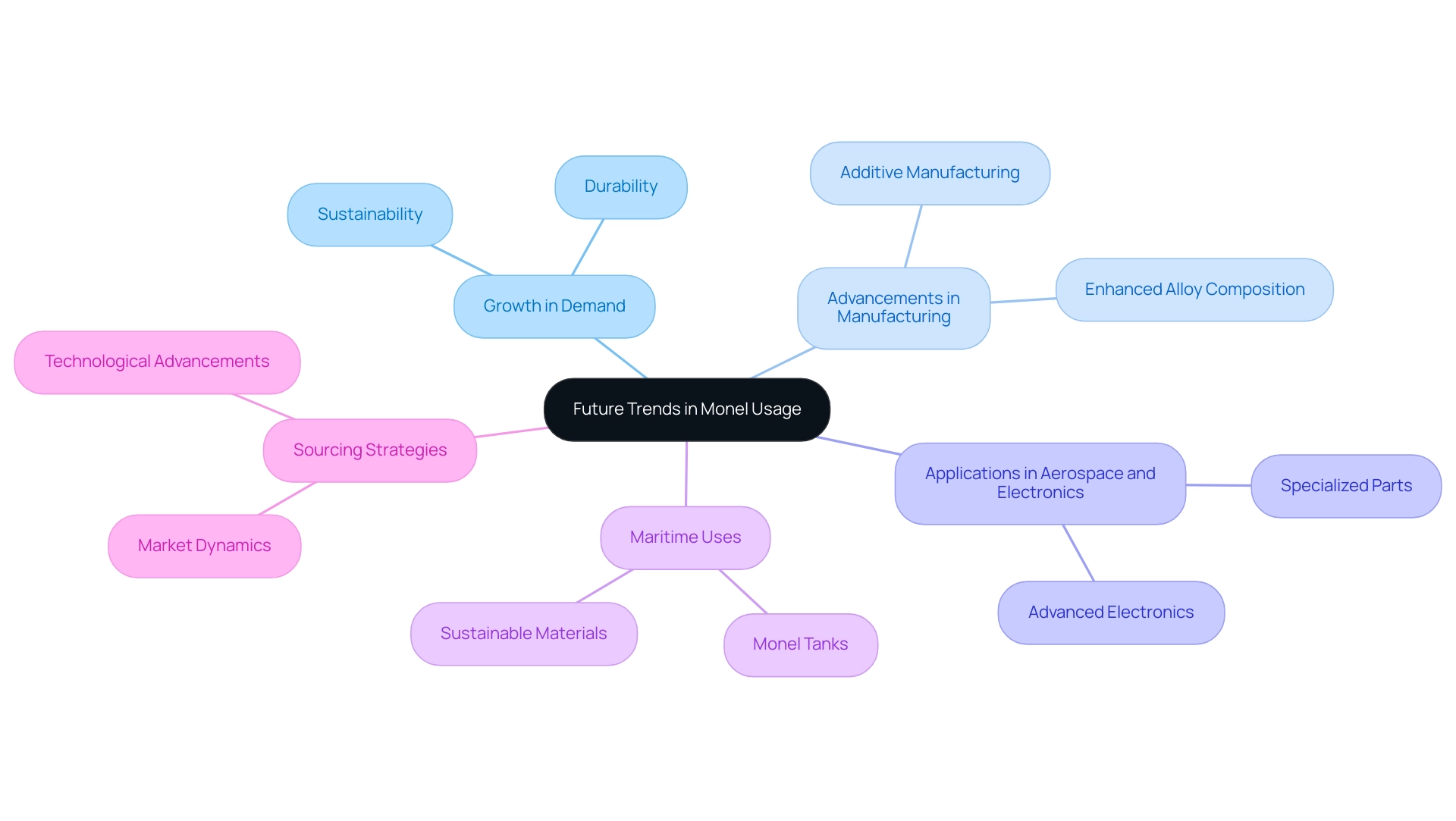

Future Trends in Monel Usage

As industries continue to evolve, the demand for these metal mixtures is poised for significant growth, largely attributed to their exceptional properties. Significantly, advancements in manufacturing techniques, especially additive manufacturing, are poised to expand the uses of this alloy in cutting-edge fields, including specialized parts for aerospace and advanced electronics. A recent case study emphasizes an increasing need for specific metals, particularly monel tanks, in maritime uses, indicating a transition towards sustainability and the requirement for durable materials that ensure longevity while reducing ecological footprint.

Additionally, advancements in alloy composition are enhancing the properties of this metal, making it increasingly suitable for various applications. According to Procurement Resource, the price of Monel is projected to experience a mixed trend in the upcoming quarter, which underscores the necessity for procurement managers to remain vigilant about technological advancements and market dynamics. By adapting sourcing strategies in line with these trends, procurement professionals can ensure their operations remain competitive and compliant with future industry standards.

Conclusion

Monel’s unique composition and outstanding properties position it as a vital material across a spectrum of industries. Its exceptional corrosion resistance, mechanical strength, and versatility make it a preferred choice for applications in:

- Marine engineering

- Chemical processing

- Aerospace

- Beyond

The advantages of Monel tanks, including:

- Lower life-cycle costs

- Straightforward maintenance

- Compliance with stringent industry standards

further bolster their appeal to procurement managers looking for reliable and sustainable solutions.

As industries face increasing pressure to meet regulatory requirements and embrace sustainable practices, the role of Monel becomes even more critical. The insights gained from case studies and expert opinions reinforce the strategic importance of this alloy in addressing contemporary challenges, particularly in high-stress environments. Moreover, staying informed about future trends and advancements in alloy technology will empower procurement professionals to make proactive sourcing decisions that align with evolving market demands.

In conclusion, investing in Monel tanks not only enhances operational efficiency but also ensures long-term value and compliance. By understanding the unique advantages and applications of Monel, procurement managers can confidently navigate the complexities of material selection, ultimately driving success in their respective industries. Embracing Monel as a core component of procurement strategies is a forward-thinking approach that promises to yield significant benefits in both performance and sustainability.