Blogs

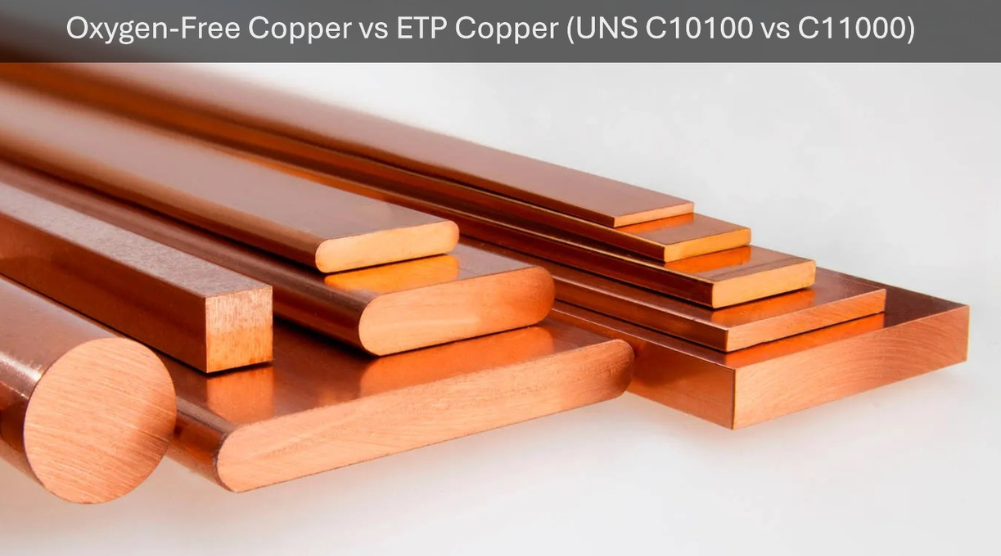

Oxygen-Free Copper vs ETP Copper (UNS C10100 vs C11000): Which One Should You Choose?

Introduction: When Purity Powers Performance

Think copper is just copper? Think again.

From the wires in your walls to the components in a satellite, the type of copper you choose can significantly affect performance, safety, and even long-term costs.

Two of the most commonly used copper types in electrical and high-performance environments are:

- Oxygen-Free Copper (OFC) – UNS C10100/C10200

- ETP Copper (Electrolytic Tough Pitch) – UNS C11000

Let’s break down what they are, how they differ, and where each truly belongs.

What is ETP Copper?

ETP (Electrolytic Tough Pitch) Copper, designated as C11000, is the most widely used grade of copper today.

Composition:

- Contains ~99.9% pure copper

- Includes a small, controlled amount of oxygen: typically, 150–400 ppm (0.02–0.04%)

The oxygen improves conductivity by helping oxidize and eliminate other harmful impurities during refining. However, in certain environments, it becomes a liability.

Properties:

- Excellent electrical conductivity (~100% IACS)

- Good ductility and formability

- Susceptible to hydrogen embrittlement in high-temp + hydrogen-rich environments

- Lower cost and widely available

Common Applications:

- Power cables

- Bus bars

- Electrical wiring for buildings

- Transformers and motor windings

- General industrial uses

What is Oxygen-Free Copper?

Oxygen-Free Copper (OFC) refers to high-purity copper that contains almost no oxygen—typically less than 10 ppm, and often as low as 1–5 ppm. Grades include C10100 and C10200.

Also called OFHC (Oxygen-Free High Conductivity) copper, this material is refined using special processes (like induction melting in an oxygen-free environment) to eliminate all traces of oxygen.

Properties:

- ≥ 99.95–99.99% purity

- Excellent electrical and thermal conductivity

- Superior resistance to hydrogen embrittlement

- High ductility, creep resistance, and vacuum stability

- Easy to weld and shape

- Produces no copper flakes during fabrication

High-Performance Applications:

- Aerospace components

- Particle accelerators

- High-voltage electrodes

- Audio/Visual high-end cables

- Vacuum tubes

- MRI machines

- Semiconductor equipment

Key Differences Between ETP and OFC Copper

| Feature | ETP Copper (C11000) | Oxygen-Free Copper (C10100/C10200) |

| Oxygen Content | 150–400 ppm | <10 ppm (often 1–5 ppm) |

| Purity | ~99.9% | 99.95–99.99% |

| Electrical Conductivity | ~100% IACS | ~100% IACS (with better high-temp stability) |

| Hydrogen Embrittlement | Susceptible in specific environments | Highly resistant |

| Cost | Lower | Higher |

| High-Temp Suitability | Moderate | Excellent |

| Common Applications | Wiring, cables, motors | Aerospace, vacuum systems, audio, medical |

Environmental Impact: Less is More

While ETP copper is cost-effective, it can suffer from shorter lifespans in demanding environments, leading to:

- Frequent replacements

- More scrap and waste

- Increased energy consumption for recycling

On the other hand, oxygen-free copper lasts longer, performs better under stress, and reduces the need for replacement—making it a greener and more sustainable choice over time.

So while it may cost more upfront, its long-term environmental and operational advantages are substantial.

Standards & Availability

Both ETP and oxygen-free copper conduct electricity superbly. But if your application involves:

| Copper Type | UNS Designation | ASTM Standard | Shapes Available |

| ETP Copper | C11000 | ASTM B170 | Rods, wires, busbars, strips, sheets |

| Oxygen-Free Copper | C10100 / C10200 | ASTM B170, B187 | Rods, tubes, wires, strips, custom forms |

Final Takeaway: Don’t Just Conduct, Outperform

- High temperatures

- Hydrogen-rich environments

- Vacuum conditions

- High-precision electronics or scientific instruments

…then oxygen-free copper is not a luxury—it’s a necessity.

For general electrical wiring and infrastructure, ETP copper remains a reliable, cost-effective choice.

🔌 Your system is only as strong as the copper that runs through it. Choose wisely.

Visit our website on https://domadia.net/

Talk to us: Kairav Domadia | Aadil Domadia | Er.Pankaj Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia