Blogs

Unlocking the Power of CMSX-4 Powder (UNS N06602): Applications That Fuel High-Temperature Industries

Introduction

Imagine a fighter jet soaring through blistering heat where temperatures surpass 1,100 °C—yet its turbine blades remain unfazed, delivering relentless performance. That’s the magic of CMSX-4 Powder (UNS N06602). Forget one-size-fits-all materials; when failure isn’t an option, CMSX-4is engineered to outperform—even under the harshest thermal stress.

What Is CMSX-4 Powder?

CMSX-4 Powder is a high-performance, nickel-based single-crystal superalloy renowned for its exceptional creep strength, oxidation resistance, and thermal fatigue resilience—making it indispensable in aerospace, power generation, and advanced manufacturing.

Applications

CMSX-4 Powder shines in scenarios where heat, stress, and precision collide:

- Aerospace: Turbine blades and jet engine components that endure extreme heat.

- Power Generation & Gas Turbines: Critical parts like vanes, combustion chambers, and heat exchangers.

- Additive Manufacturing (3D Printing): Ideal for LPBF, EBM, DED—producing complex, high-precision parts.

- Coatings & Spraying: Forms protective layers via thermal spray, enhancing durability against oxidation and wear.

- Défense & Automotive: Jet propulsion parts, racing turbochargers, and components needing both heat resistance and reliability.

Industrial & Marine: High-temperature furnace parts, marine heat exchangers, downhole tools—applications where both stress and corrosion matter.

Why CMSX-4 Powder Works Where Others Fail

1. Single‑crystal structure eliminates grain boundaries that typically invite creep and fatigue.

2. Superior mechanical strength at high temperatures (even up to ~1,200 °C).

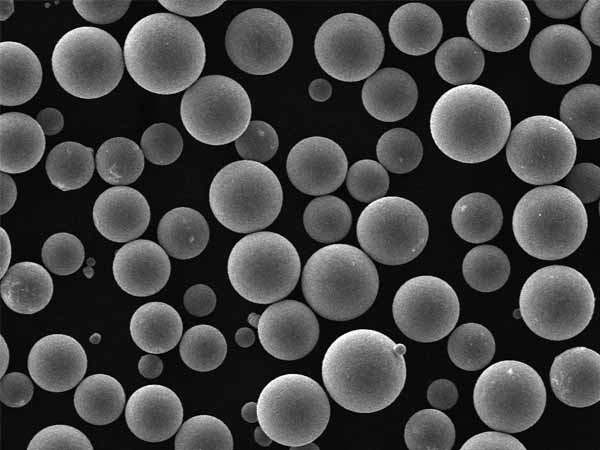

3. Oxidation & corrosion resistance, thanks to chromium, aluminum, cobalt, and other alloying elements. 4. Excellent flowability and purity, especially in spherical, gas-atomized form—critical for additive manufacturing.

Standards, Sizes & Specs

- Particle sizes typically range between 15–150 µm depending on processing method and application.

Relevant standards include ASTM F3055‑14a (AM), AMS 4138D (aerospace), AMS 5382, AMS 5385

Conclusion

When precision, endurance, and reliability under extreme heat are non-negotiable, CMSX-4 Powder (UNS N06602) delivers unmatched performance. From aerospace and power generation to cutting-edge 3D printing, it’s the go-to material where failure simply isn’t an option.

Contact our experts today!

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#CMSX4Powder #NickelAlloy #HighTemperatureAlloys #GasTurbines #JetEngines #AdvancedManufacturing #MetalPowders #AerospaceEngineering #TurbineBlades #HeatResistance #MaterialsScience #PowderMetallurgy #EnergySolutions #MarineEngineering #DefenseTechnology #AutomotiveEngineering