Blogs

Tungsten Powder (UNS W7400) vs Molybdenum Powder (UNS R07005): Key Differences You Must Know

When it comes to high-performance metals for extreme conditions, Tungsten and Molybdenum often stand side by side in engineering conversations. Both are refractory metals, sitting next to each other in the periodic table, and both boast exceptional resistance to heat and wear. But here’s the catch — while they share a lot, the differences between tungsten powder and molybdenum powder can mean the difference between over-engineering your project or saving significant costs without compromising performance.

At DOMADIA™, we help industries make smarter material choices. Let’s break down the similarities, differences, and when each one wins the crown.

Understanding Refractory Metal Powders

What Is Tungsten Powder (UNS W7400)

Tungsten powder is a gray-black metallic powder with a metallic luster and a body-centered cubic crystal structure. Known for:

- Density: ~19.3 g/cm³ (one of the heaviest metals)

- Melting Point: 3410°C — the highest among all metals

- Hardness: Extremely high, making it ideal for wear resistance

- Primary Uses: Cutting tools, armor-piercing ammunition, radiation shielding, aerospace parts

Chemical Composition: Pure tungsten (W ≥ 99.95%), with trace amounts of Fe, O, and C.

What Is Molybdenum Powder (UNS R07005)

Molybdenum powder is a dark gray metallic powder produced by reducing molybdenum trioxide (MoO₃) with hydrogen. It’s valued for:

- Density: ~10.2 g/cm³ (much lighter than tungsten)

- Melting Point: 2620°C

- Chemical Stability: Outstanding corrosion resistance, especially in acids

- Primary Uses: Furnace components, glass melting electrodes, thermal spray coatings, electronics

Chemical Composition: Pure molybdenum (Mo ≥ 99.95%), with trace O, C, and Si.

Similarities Between Tungsten and Molybdenum Powder

Both powders are:

- Refractory metals: High melting points, stable under extreme heat

- Excellent conductors of heat (W ~173 W/m·K, Mo ~138 W/m·K)

- Mechanically strong with excellent wear resistance

- Good in powder metallurgy for complex shapes and sintered parts

Key Differences — Where Each Excels

| Property | Tungsten Powder (UNS W7400) | Molybdenum Powder (UNS R07005) |

| Density | 19.3 g/cm³ (very heavy) | 10.2 g/cm³ (lighter) |

| Melting Point | 3410°C | 2620°C |

| Hardness | Extremely high | Lower, more machinable |

| Strength | Exceptional at high temp | Strong, with better ductility |

| Conductivity | Lower electrical conductivity | Higher electrical conductivity |

| Corrosion Resistance | Lower in acids | Excellent in acidic media |

| Cost | Higher | More economical |

Applications at a Glance

Tungsten Powder Applications:

Aerospace Turbine Blades – Tungsten powder is used in high-performance alloys for turbine blades, where its high melting point and strength help withstand extreme temperatures and mechanical stress.

Radiation Shielding & X-ray Collimators – Due to its very high density, tungsten powder is pressed and sintered into parts that absorb harmful radiation, protecting medical staff, patients, and sensitive instruments.

Armor-Piercing Ammunition – Tungsten powder is compacted into penetrator cores, delivering exceptional hardness and density that allow projectiles to pierce armored vehicles and reinforced targets.

Cutting Tools & Wear Parts – Blended with cobalt or other binders, tungsten carbide powders form cutting tools and wear-resistant components that last longer under high friction, pressure, and heat.

Molybdenum Powder Applications:

Furnace Heating Elements – Molybdenum powder is processed into rods and wires for high-temperature furnaces, offering excellent strength and stability even beyond 1,700 °C.

Glass Melting Electrodes – With its resistance to molten glass corrosion, molybdenum powder forms dense electrodes that ensure long-lasting performance in glass manufacturing.

Thermal Spray Coatings – Molybdenum powder is used in plasma and flame spray processes to create wear- and corrosion-resistant coatings on machine parts and automotive components.

Semiconductor Components – Its high purity and thermal conductivity make molybdenum powder essential for thin films, contacts, and substrates in semiconductor and electronics industries.

Tungsten-Molybdenum Alloy Powder: Combines tungsten’s strength & melting point with molybdenum’s light weight & corrosion resistance. Ideal for aerospace, electronics, and high-temperature tooling.

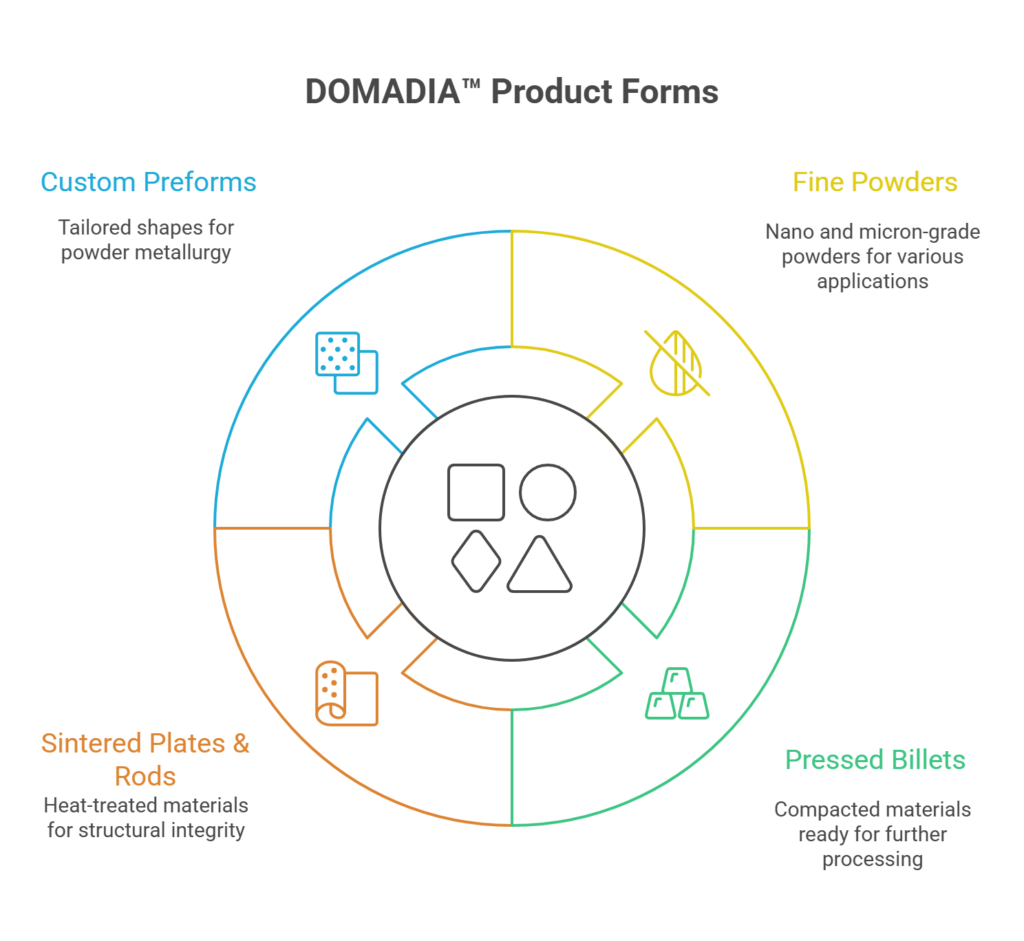

Available Shapes & Forms at DOMADIA™

Technical Specifications

| Parameter | Tungsten Powder | Molybdenum Powder |

| Purity (%) | ≥ 99.95% | ≥ 99.95% |

| Particle Size | 1–15 μm | 1–10 μm |

| Crystal Structure | BCC | BCC |

| Thermal Conductivity | 173 W/m·K | 138 W/m·K |

| Coefficient of Expansion | 4.5 μm/m·K | 4.8 μm/m·K |

Standards

- Tungsten: ASTM B777, ISO 6848

- Molybdenum: ASTM B387, ISO 6848

Environmental Impact — Why the Right Choice Matters

Choosing the right metal powder is more than a cost decision — it’s an environmental one.

Tungsten’s longer wear life means less frequent replacements in extreme environments, while molybdenum’s lighter weight reduces overall material consumption in large-scale applications. Fewer replacements mean less scrap metal recycling, which translates to lower CO₂ emissions from manufacturing and refining. By picking the right powder for your application, you’re not just saving money — you’re contributing to a greener planet.

Conclusion

Both Tungsten Powder (UNS W7400) and Molybdenum Powder (UNS R07005) have their place in high-performance engineering. Tungsten dominates in ultra-high temperature and density-critical applications, while molybdenum offers a cost-effective, corrosion-resistant solution for mid-to-high temperature uses.

At DOMADIA™, we supply both powders — along with tungsten-molybdenum alloys — to help you get the best of both worlds.

Reach out to Domadia’s team for recommendations or any sort of help.

Visit our website: Domadia.com

Email: sales@domadia.com

Call/WhatsApp: +91-9594066275

Follow us on LinkedIn: https://www.linkedin.com/in/kairav

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia

#Tungsten #Molybdenum #RefractoryMetals #PowderMetallurgy #DOMADIA #MetalPowders #EngineeringMaterials