Blogs

How Nickel Alloys Are Powering the Future of Green Technologies | DOMADIA™

The Silent Revolution Behind Clean Energy

What if the metals we mine today are shaping the clean world of tomorrow?

As the world races toward net-zero emissions, much of the spotlight shines on solar panels, electric vehicles, and wind turbines. But beneath these innovations lies an unsung hero — Nickel Alloys.

At DOMADIA™, we’ve seen how these powerful materials are redefining sustainability — from hydrogen fuel cells to geothermal systems and next-gen batteries.

Let’s uncover how Nickel Alloys are quietly powering the green revolution — one atom at a time.

The Science of Strength: Chemical Composition

Nickel alloys are a blend of nickel with elements like chromium, molybdenum, iron, cobalt, or copper.

This fusion creates materials with extraordinary corrosion resistance, high-temperature stability, and mechanical strength.

Typical Nickel Alloy Composition:

| Element | Function |

| Nickel (Ni) | Base element providing toughness and oxidation resistance |

| Chromium (Cr) | Adds corrosion and scaling resistance |

| Molybdenum (Mo) | Enhances strength and resistance to pitting/crevice corrosion |

| Iron (Fe) | Improves ductility and reduces cost |

| Cobalt (Co) | Maintains strength at elevated temperatures |

| Copper (Cu) | Enhances thermal conductivity and corrosion resistance |

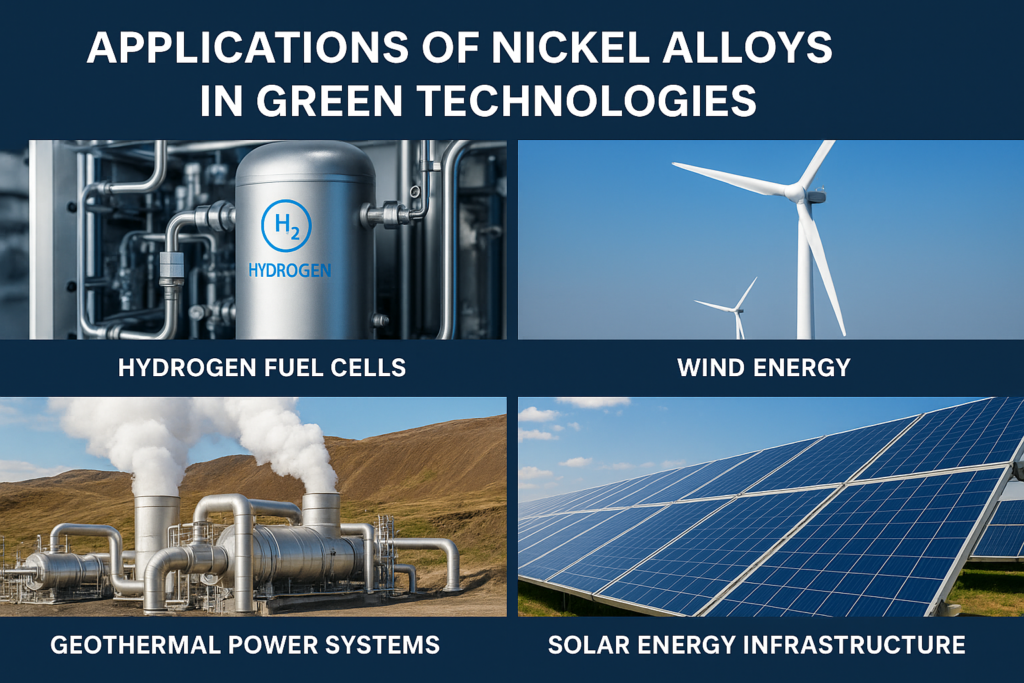

Applications of Nickel Alloys in Green Technologies

1. Hydrogen Fuel Cells

Nickel alloys are essential in the production, storage, and transport of hydrogen. Their ability to resist hydrogen embrittlement and high temperatures makes them ideal for electrolyzers and fuel cell stacks — the heart of hydrogen-powered systems.

2. Wind Energy

Nickel-based components strengthen gearboxes, shafts, and fasteners in offshore wind turbines, ensuring they withstand harsh marine environments while maintaining high mechanical integrity.

3. Geothermal Power Systems

In geothermal energy, where temperatures and pressures are extreme, Nickel-Chromium-Molybdenum alloys prevent corrosion and scaling — extending the life of pipelines and heat exchangers.

4. Solar Energy Infrastructure

Nickel alloys form durable mounting systems, solar panel frames, and connectors that resist weathering and thermal expansion — vital for long-term solar installations.

5. Electric Vehicles (EVs) and Batteries

The growing EV industry depends heavily on Nickel-rich batteries (like NMC – Nickel Manganese Cobalt) and structural components made of nickel alloys for improved energy density and lifecycle.

Key Properties and Technical Specifications

| Property | Description |

| Melting Point | 1300–1450°C |

| Density | 8.0–8.9 g/cm³ |

| Thermal Conductivity | 10–90 W/m·K |

| Tensile Strength | Up to 1000 MPa |

| Corrosion Resistance | Excellent in acids, alkalis, and marine environments |

| Magnetic Properties | Can be tailored (non-magnetic to magnetic) based on alloy composition |

These characteristics make nickel alloys the perfect candidate for sustainable energy systems that demand both performance and longevity.

Standards and Grades

Nickel alloys are standardized globally to ensure safety and consistency:

| Standard | Common Grades | Application |

| UNS N06625 (Inconel 625) | Aerospace, Geothermal | |

| UNS N08825 (Incoloy 825) | Chemical Processing, Heat Exchangers | |

| UNS N07718 (Inconel 718) | Turbines, Hydrogen Systems | |

| UNS N06002 (Hastelloy X) | Solar Furnaces, Jet Engines |

DOMADIA™ ensures all nickel alloys conform to ASTM, ASME, and ISO specifications for industrial and renewable applications.

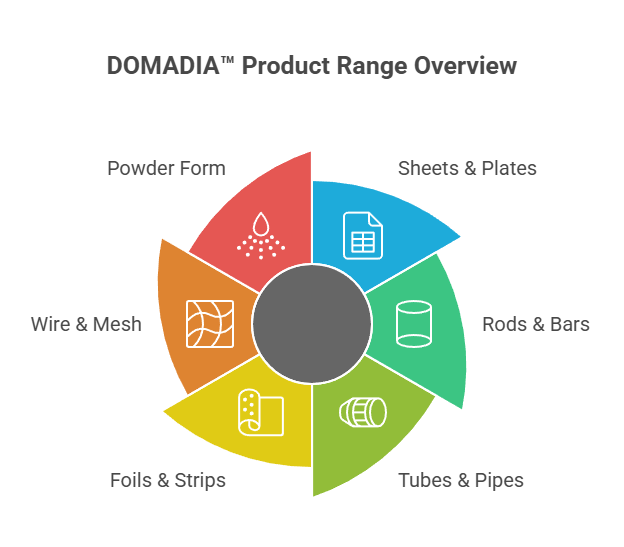

Shapes and Forms Available at DOMADIA™

Each form is engineered for specific performance goals — from lightweight 3D-printed hydrogen valves to high-strength offshore components.

Environmental Impact: The Longer It Lasts, The Greener It Gets

Every time a part fails, it needs to be replaced, remade, and recycled — all of which consume energy and resources.

Nickel alloys last significantly longer than conventional materials, reducing waste, emissions, and operational downtime.

By choosing DOMADIA™ Nickel Alloys, industries not only gain reliability but also contribute to a cleaner planet.

Less replacement. Less recycling. More sustainability.

The Future Is Nickel-Shaped

As renewable technologies scale up, the demand for materials that can withstand heat, corrosion, and time is soaring.

Nickel alloys are proving themselves not just as materials of choice, but as materials of the future. At DOMADIA™, we believe that innovation isn’t just about invention — it’s about endurance.

And when it comes to endurance, Nickel Alloys will continue to be the backbone of the green energy revolution.

Conclusion

Nickel Alloys in Green Technologies are more than industrial materials — they’re the invisible backbone of sustainability.

From powering hydrogen fuel cells to supporting offshore turbines, they enable the world to move cleaner, faster, and longer.

Choose DOMADIA™ Nickel Alloys — where durability meets sustainability.

Ready to power your green innovation?

Explore our Nickel Alloy Solutions at DOMADIA™ — built for performance, designed for the planet.

Talk to us: Kairav Domadia | Aadil Domadia | Er.Pankaj Domadia | Pragati Sanap | Pooja N N

#NickelAlloys #GreenEnergy #Sustainability #HydrogenFuel #RenewableInnovation #DOMADIA #CleanTech