Blogs

Recycling Revolution: Turning E-Waste into Valuable Metals | DOMADIA™

Introduction: From Waste to Wealth

Old phones, discarded laptops, broken chargers—each of them hides something extraordinary: metals more valuable than gold ore.

Welcome to the Recycling Revolution, where the world’s fastest-growing waste stream—electronic waste (e-waste)—is now becoming one of the richest urban mines for precious and rare metals.

At DOMADIA™, we see e-waste not as trash but as an opportunity. Every circuit board, every wire, every microchip carries recoverable metals that can be reintroduced into manufacturing, cutting down on mining, waste, and environmental impact.

This is the story of how e-waste metal recycling is transforming industries, conserving resources, and shaping a cleaner, smarter future.

The Rising Mountain of E-Waste

Globally, over 62 million tonnes of e-waste were produced in 2022, but less than 20 % is properly recycled. The rest ends up in landfills or is informally burned, releasing toxic substances like lead and mercury.

Yet, within this discarded mass lies immense value:

- One tonne of circuit boards contains more gold than one tonne of mined ore.

- Recycling 1 million smartphones can recover 35 kg of gold, 350 kg of silver, and 16,000 kg of copper.

E-waste recycling isn’t just eco-friendly—it’s economically intelligent. Recovering metals from e-waste saves energy, reduces carbon emissions, and protects our planet from mining-intensive extraction.

Chemical Composition: The Hidden Treasure Inside Electronics

Each electronic device is a blend of multiple metallic and non-metallic components. Here’s what typically makes up e-waste:

| Metal / Element | Chemical Symbol | Approx. Composition | Role in Devices |

| Copper | Cu | 15–25 % | Conductors, PCBs, wiring |

| Aluminum | Al | 5–10 % | Casings, frames, heat sinks |

| Iron / Steel | Fe | 10–20 % | Chassis, screws, enclosures |

| Gold | Au | < 0.1 % | Contacts, connectors |

| Silver | Ag | < 0.2 % | Circuit paths, switches |

| Palladium | Pd | trace | Plating, catalysts |

| Tin | Sn | 1–3 % | Soldering |

| Nickel | Ni | 1–2 % | Batteries, coatings |

| Rare Earths (Nd, Dy, Tb, Ce, La) | — | trace | Magnets, screens, motors |

At DOMADIA™, precision analysis ensures selective recovery of high-value metals like gold, copper, palladium, and rare earths, while maintaining safety and zero-leakage standards.

Technical Explanation: How Metals Are Recovered

E-waste metal recycling involves three key steps—each a blend of chemistry, engineering, and sustainability.

1. Mechanical Separation

- Devices are dismantled and shredded.

- Magnetic and eddy-current separators extract ferrous and non-ferrous metals.

- Froth flotation and screening further concentrate metal-rich fractions.

2. Hydrometallurgical Recovery

- Metals are dissolved using controlled acids (H₂SO₄, HCl, HNO₃) or organic leachants.

- Solvent extraction, precipitation, and electrowinning recover metals in pure form.

- Recovery efficiency can reach up to 95 % for gold and copper.

3. Emerging Green Technologies

- Bioleaching: Bacteria like Acidithiobacillus ferrooxidans dissolve metals naturally.

- Graphene and Nano-Adsorbents: Used for selective recovery of gold and rare earths.

- Low-Energy Pyrolysis: Extracts metals with reduced emissions and energy cost.

DOMADIA™ supports these innovations by collaborating with global partners focused on low-impact extraction and eco-design recycling systems.

Properties and Standards of Recovered Metals

Recycled metals meet or exceed industrial standards for purity and performance:

| Property | Specification | Standard |

| Purity (Au, Ag, Cu) | 99.9 % – 99.99 % | ASTM B170 / ISO 11484 |

| Conductivity (Cu) | ≥ 100 % IACS | ASTM B193 |

| Density | As per native metal | ASTM B311 |

| Corrosion Resistance | Equivalent to virgin metals | ISO 9227 |

| Environmental Safety | Zero hazardous leachate | RoHS / WEEE / ISO 14001 |

DOMADIA™ ensures every recycled batch is certified, traceable, and compatible with high-end manufacturing applications—from semiconductors to aerospace components.

Applications of Recycled Metals

Recovered metals from e-waste find use across industries:

1. Electronics & Semiconductors

Gold, copper, and silver re-enter circuit boards, connectors, and microchips.

2. Automotive & Electric Vehicles

Nickel, cobalt, and rare earths power motors, sensors, and battery systems.

3. Aerospace & Defense

High-purity aluminum and nickel alloys are reused in aircraft and defense components.

4. Energy & Renewables

Copper and rare earths support wind turbine magnets and solar inverters.

5. Jewelry & Consumer Goods

Recovered gold and silver are refined for luxury applications, proving recycling doesn’t compromise beauty or quality.

By reusing metals, DOMADIA™ directly contributes to reducing mining demand and cutting carbon emissions in metal production by over 80 %.

Technical Specifications at a Glance

| Parameter | Typical Range (DOMADIA™ Recycled Metals) |

| Gold Recovery Rate | 95–99 % |

| Copper Recovery Rate | 90–98 % |

| Leach Residue Toxicity | < 0.1 mg/L (Safe Standard) |

| Energy Use | 70 % lower than mining |

| Carbon Emissions | Reduced by 80 % per kg of metal |

| Waste Slag Generation | < 2 % of input mass |

| Compliance | RoHS, REACH, ISO 14001 Certified |

DOMADIA™ operates under green chemistry principles, ensuring high yield with minimal environmental impact.

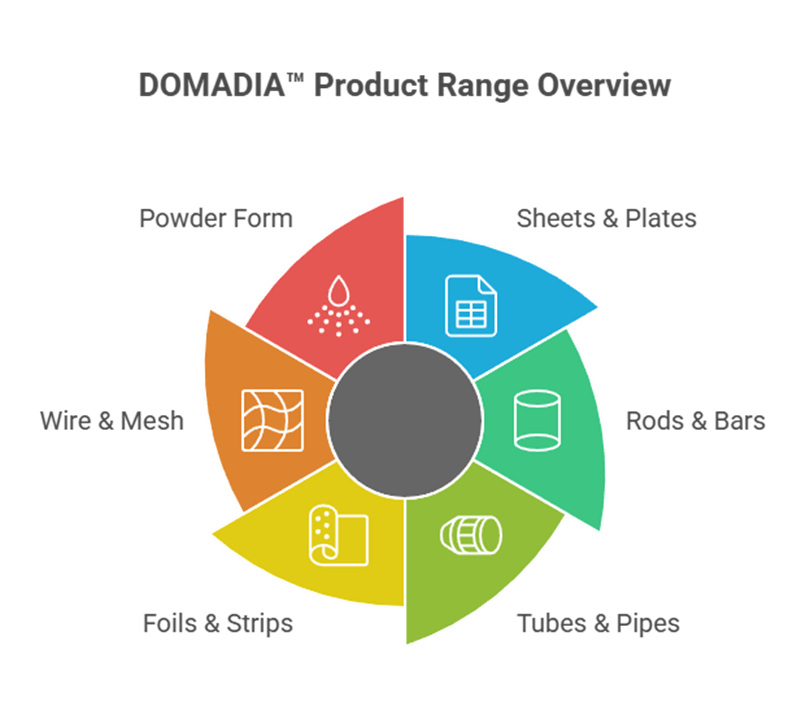

Shapes and Forms of Recycled Metals

Recovered metals are available in various industrial shapes and forms depending on the intended application:

DOMADIA™ supplies recycled metals in these standardized forms for global industrial use.

Environmental & Economic Impact

E-waste recycling isn’t just good business—it’s good stewardship.

- Energy Savings: Recycling copper uses 85 % less energy than mining it.

- Emission Cuts: Each tonne of recycled aluminum saves ~ 9 tons of CO₂.

- Resource Security: Reduces dependence on critical mineral imports.

- Circular Economy: Keeps valuable materials in continuous use.

- Community Safety: Prevents informal, toxic burning of e-waste.

For DOMADIA™, every recycled gram represents a tonne of mining avoided—a genuine step toward a sustainable manufacturing ecosystem.

The Future: Smart Recycling and Circular Innovation

The next frontier lies in AI-driven sorting, robotic disassembly, and design-for-recycling electronics. DOMADIA™ is exploring ways to integrate these smart systems into supply chains—ensuring that every product born today can be responsibly reborn tomorrow.

As nations enforce stricter E-Waste Management Rules and Extended Producer Responsibility (EPR), recycling metals from e-waste will no longer be optional—it will be essential.

Conclusion

E-waste metal recycling is more than a process—it’s a promise.

A promise to reclaim what we once discarded, to turn pollution into progress, and to forge a sustainable tomorrow from yesterday’s technology.

At DOMADIA™, we’re proud to be part of this revolution—where every recovered circuit, chip, and connector helps build a world that’s cleaner, smarter, and endlessly renewable.

Let’s power the Recycling Revolution together.

Because the future of metals isn’t underground—it’s already in your hands.

Join DOMADIA™’s mission to build a circular metal ecosystem.

🔗 Visit domadia.net to explore our sustainability initiatives and e-waste recovery solutions.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#EwasteRecycling #CircularEconomy #SustainableMetals #DOMADIA #RecyclingRevolution #GreenManufacturing #TechSustainability #EwasteIndia #MetalsRecovery