Blogs

Ceramic Coatings vs Metallic Coatings: Which Is Right for Your Industry? | DOMADIA™

Introduction: The Invisible Armor Behind Industrial Success

Every machine, engine, and structure fights a hidden battle — against heat, wear, corrosion, and time. The true protector behind their long life? Surface coatings.

At DOMADIA™, one question comes up frequently: “Should I choose ceramic coating or metallic coating?” The answer depends on your operating environment, temperature range, and performance goals. Both materials are powerful, yet their advantages shine in different situations. Let’s uncover which one truly fits your industrial needs.

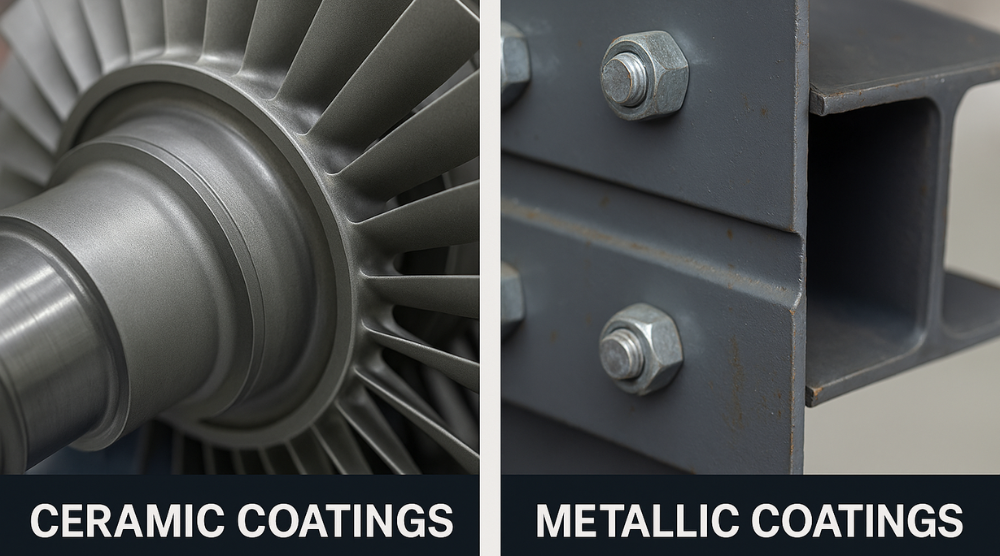

Understanding the Two Titans

Ceramic Coatings

Ceramic coatings are non-metallic, inorganic materials — often made from compounds like silicon carbide, aluminum oxide, or titanium dioxide. These coatings are applied to create a high-temperature, corrosion-resistant shield that can handle the harshest conditions.

Key Properties:

- Withstand temperatures up to 2000°C

- Offer excellent thermal insulation

- Provide chemical and oxidation resistance

- Are electrically insulating

- Deliver exceptional hardness and wear protection

Applications:

- Aerospace turbine blades

- Automotive exhaust components

- Industrial furnaces and kilns

- Energy and power generation systems

Metallic Coatings

Metallic coatings involve applying a thin metal layer — such as zinc, nickel, chromium, or aluminum — to enhance strength, conductivity, and corrosion protection. These coatings combine durability with mechanical flexibility, making them suitable for structural applications.

Key Properties:

- Great electrical and thermal conductivity

- Strong adhesion and ductility

- Reliable corrosion and wear resistance

- Ideal for mechanical reinforcement

Applications:

- Oil and gas pipelines

- Marine and offshore equipment

- Electronic components

- Structural steels and fasteners

Technical Comparison: Ceramic vs Metallic Coatings

| Property | Ceramic Coating | Metallic Coating |

| Base Composition | Non-metallic oxides, carbides, nitrides | Pure metals or metal alloys |

| Temperature Resistance | Up to 2000°C | Typically up to 600°C |

| Electrical Conductivity | Insulating | Conductive |

| Corrosion Resistance | Excellent in extreme conditions | Very good, limited under high heat |

| Durability | Extremely long-lasting | Moderate to high |

| Cost | Higher upfront | More economical |

| Surface Finish | Matte to semi-gloss | Metallic shine |

Choosing the Right Coating for Your Industry

Different industries require different performance levels. Here’s how each coating performs across key sectors:

✅ Aerospace & Defense

In high-altitude and extreme temperature environments, ceramic coatings outperform others by providing exceptional thermal stability and oxidation resistance. They safeguard turbine blades, jet engines, and combustion chambers — ensuring maximum efficiency and extended service life.

✅ Automotive

Within the automotive sector, metallic coatings like zinc and nickel act as a reliable shield against corrosion, keeping chassis and body components intact over time. Meanwhile, ceramic coatings play a crucial role in managing exhaust heat, improving engine performance and durability.

✅ Electronics

Across electronic systems, metallic coatings guarantee consistent electrical conductivity, which is essential for circuit boards, sensors, and connectors. Conversely, ceramic coatings provide the insulation and heat control required to protect sensitive components from thermal overload.

✅ Energy & Power Plants

Ceramic coatings are the go-to solution for turbines and reactors, extending operational lifespan under extreme heat and chemical exposure.

✅ Marine & Offshore

Metallic coatings like aluminum and zinc offer sacrificial corrosion protection against saltwater — essential for rigs, ships, and coastal equipment.

Environmental & Cost Considerations

When it comes to sustainability, longevity plays a critical role.

Metallic coatings are typically cheaper and easier to apply, but they may require frequent maintenance due to corrosion or oxidation. On the other hand, ceramic coatings, while costlier initially, drastically reduce reapplication frequency.

This means fewer replacements, less downtime, and lower environmental waste.

At DOMADIA™, we emphasize coatings that support long-term sustainability. Fewer recoats translate into reduced emissions, lower energy use, and a longer lifecycle for your equipment — all while maintaining superior performance.

DOMADIA™: Your Coating Partner in Performance

Whether you need thermal insulation, corrosion resistance, or electrical optimization, DOMADIA™ delivers coatings designed for your unique industrial goals. Our specialists work with you to analyze conditions, recommend the best material, and ensure precision in application.

From aerospace engines to offshore platforms, our coatings are engineered to outperform — because at DOMADIA™, performance isn’t a promise; it’s proof.

Conclusion

In the comparison of Ceramic Coatings vs Metallic Coatings, there’s no single champion — only the right material for your purpose.

If your priority is high-temperature insulation and corrosion resistance, ceramic coatings are the clear choice. But if you value conductivity, cost-efficiency, and structural reinforcement, metallic coatings are your perfect match.

With DOMADIA™, you gain more than protection — you gain performance, longevity, and sustainability.

Upgrade your equipment’s protection with advanced coatings from DOMADIA™ — where innovation meets endurance.

Explore more at domadia.net

Follow us on LinkedIn: https://www.linkedin.com/in/kairav

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#CeramicCoating #MetallicCoating #IndustrialSolutions #DOMADIA #SurfaceEngineering #Manufacturing #Aerospace #Automotive