Blogs

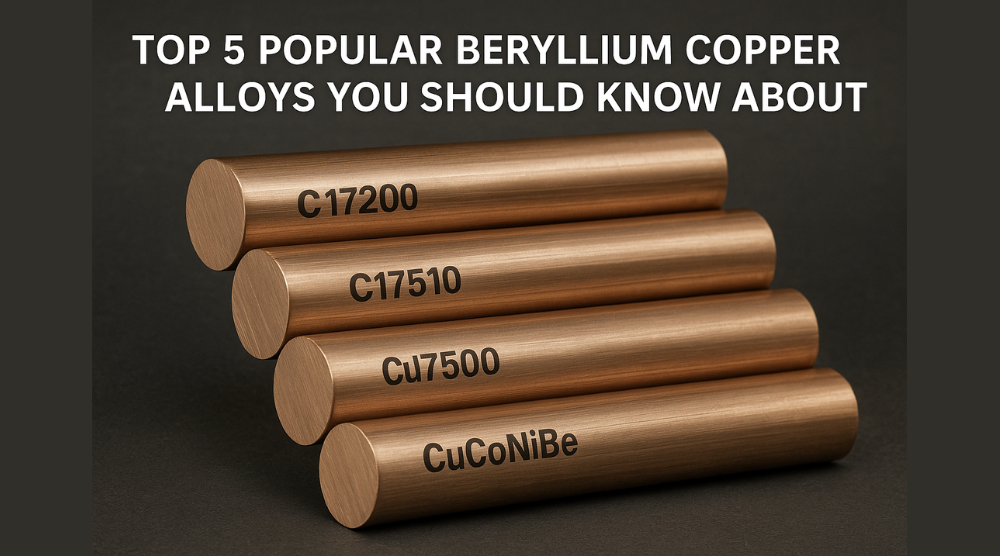

Top 5 Popular Beryllium Copper Alloys You Should Know About

Beryllium copper alloys continue to stand out in the world of high-performance metals — thanks to their exceptional strength, conductivity, corrosion resistance, and fatigue endurance. These unique advantages make BeCu indispensable across aerospace, electronics, defense, tooling, and precision engineering.

Below is a detailed breakdown of the top 5 most popular beryllium copper alloys — C17200, C17510, C17500, CuCoNiBe, and C17300 — along with what sets each one apart.

1. C17200 — Top Beryllium Copper Alloys

C17200 is the most widely used and widely recognized beryllium copper alloy. Containing 1.8–2.0% beryllium, it offers:

- The highest strength among all BeCu grades (tensile strength above 200,000 psi)

- Rockwell hardness comparable to steel

- Excellent fatigue strength, wear resistance, and corrosion resistance

Applications:

Aerospace components, precision molds, electrical connectors, high-stress mechanical parts.

2. C17510 — The Strength + Conductivity Balance

C17510 is engineered for applications requiring a balance between high electrical conductivity and mechanical durability. Its refined composition gives it remarkable:

- Good tensile strength

- Improved conductivity

- Stability under continuous stress or vibration

Applications:

High-reliability springs, electrical connectors, relays, and switch components.

3. C17500 — Tough, Workable, and Heat-Resistant

With 0.4–0.7% beryllium and 2.4–2.7% cobalt, C17500 is formulated for exceptional hot and cold workability. It offers:

- High thermal resistance

- Good toughness and durability

- Superior formability

Applications:

Tooling, cast or molded components, welding tools, and other applications requiring dimensional stability under heat.

4. CuCoNiBe — Advanced Strength for Extreme Environments

CuCoNiBe combines cobalt, nickel, and beryllium, resulting in one of the most advanced BeCu variants. This alloy is known for:

- Exceptional mechanical strength

- Excellent corrosion resistance

- High stability in extreme environments

Applications:

Aerospace systems, defense components, high-performance instrumentation.

5. C17300 — The Machinability Star

C17300 includes 0.2–0.6% lead, significantly enhancing its machinability without compromising performance. It retains much of the strength of C17200 while offering:

- Faster, cleaner machining

- Improved precision

- Great dimensional stability

Applications:

Electronic connectors, switches, fasteners, and components demanding both accuracy and durability.

Need high-performance beryllium copper alloys?

DOMADIA™ supplies premium C17200, C17510, C17500, CuCoNiBe & C17300 for aerospace, electronics, and precision tooling.

✔ High strength

✔ Superior conductivity

✔ Reliable, certified quality

👉 Contact DOMADIA™Today

📩 Contact us today to get custom sizes and specifications for your project.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#BerylliumCopper #BeCu #CopperAlloys #HighPerformanceAlloys #C17200 #C17510 #C17500 #CuCoNiBe #C17300 #AerospaceMaterials #EngineeringMaterials #IndustrialMetals #PrecisionAlloys #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav