Blogs

Top 7 Alloys Every Aerospace Engineer Should Know in 2025 | DOMADIA™

Introduction — A Suspense Start

A few months ago, an aerospace team approached DOMADIA™ with a critical issue:

Their high-precision component — designed for extreme temperature zones in the engine — kept failing after only 200 flight hours. Every failure grounded the aircraft, delayed timelines, and triggered massive maintenance costs.

The surprising twist?

The part wasn’t failing because of machining errors or operational misuse.

It simply wasn’t made from the right aerospace alloy.

That’s when the entire project shifted from “What went wrong?” to

“Which aerospace alloys deliver the highest performance under extreme conditions?”

This blog reveals the Top 7 Alloys every aerospace engineer must know in 2025 — the metals powering jet engines, spacecraft, turbomachinery, and next-generation propulsion systems.

Throughout this post, you’ll repeatedly see why aerospace alloys for high performance are the difference between mission success and catastrophic failure.

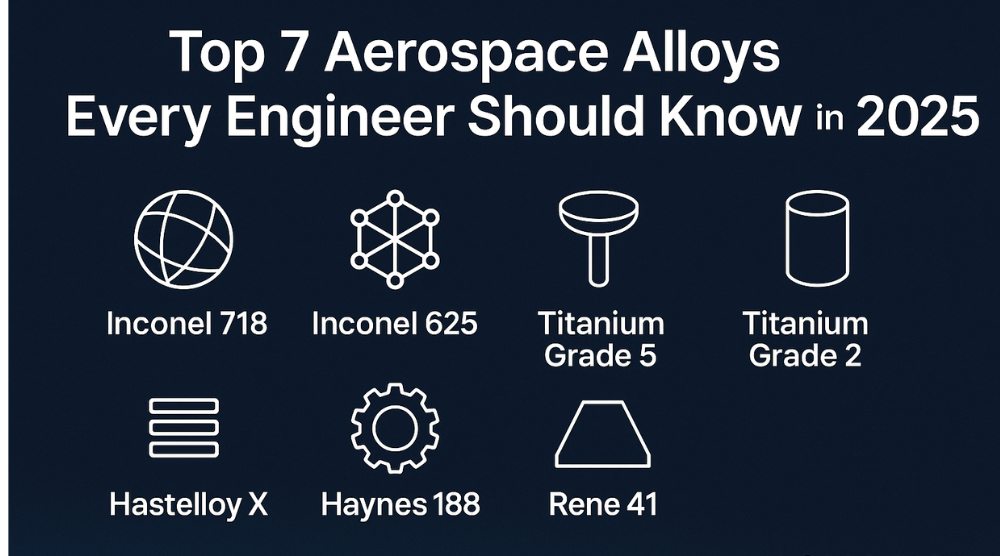

The Top 7 Aerospace Alloys Of 2025 — Powered By Domadia™

1️⃣ Inconel® 718 (Uns N07718)

Why Aerospace Engineers Love It

- Outstanding high-temperature strength

- Incredible fatigue resistance

- Perfect for cryogenic conditions

- Weldable and stable at 700°C

Where DOMADIA™ Supplies It:

- Turbine discs

- Jet engine compressors

- Rocket motor components

- Fasteners

Why It Matters for High Performance

No other alloy offers the same blend of heat resistance + mechanical stability for aerospace duty cycles.

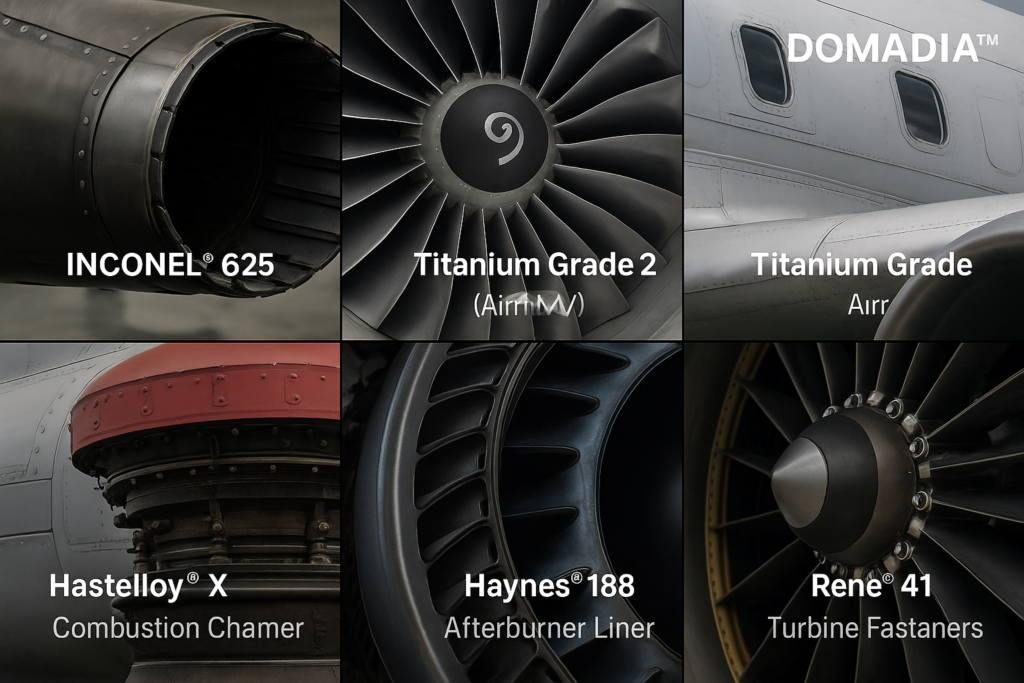

2️⃣ Inconel® 625 (Uns N06625)

Key Properties

- Exceptional corrosion resistance

- Flawless oxidation stability

- High strength at 1000°C

Applications

- Exhaust systems

- Bellows & expansion joints

- Engine hot-zone ducting

Aerospace Advantage

Perfect for components exposed to aggressive gases and heat loads.

3️⃣ Titanium Grade 5 (Ti-6al-4v)

Why It Dominates Aerospace

- 4x stronger than pure titanium

- 45% lighter than steel

- Excellent fatigue strength

- Bi-phase α-β structure

Used In:

- Landing gear

- Fan blades

- Structural frames

- Fasteners

Why DOMADIA™ Recommends It

The ultimate lightweight aerospace alloy with unmatched strength-to-weight ratio.

4️⃣ Titanium Grade 2 (Commercially Pure Ti)

Properties

- High ductility

- Amazing corrosion resistance

- Lower cost vs Ti-6Al-4V

Applications

- Airframe components

- Fuel tanks

- Heat exchangers

A High-Performance Choice When Weight Matters

When engineers need both corrosion resistance and formability — Grade 2 wins.

5️⃣ Hastelloy® X (Uns N06002)

What Makes It Stand Out

- Superb oxidation resistance

- Stable at 1200°C

- Exceptional creep strength

Applications

- Afterburner parts

- Combustion chambers

- Gas turbine hot sections

Why It Matters

Heat doesn’t scare Hastelloy X.

6️⃣ Haynes® 188 (Uns R30188)

Performance Highlights

- High strength above 1100°C

- Outstanding oxidation resistance

- Great thermal stability

Applications

- Afterburner liners

- Transition ducts

- Flame holders

High Performance Category

Chosen for aerospace projects where failure is not an option.

7️⃣ Rene® 41 (Uns N07041)

The Superalloy Built for Extremes

- High tensile strength up to 980°C

- Superb creep resistance

- Precipitation-hardened

Aerospace Use Cases

- Turbine casings

- Jet engine fasteners

- Afterburner components

Why Engineers Trust It

Designed specifically for high-pressure, high-temperature aerospace zones.

The Future Of Aerospace Alloys In 2025 & Beyond

From next-gen propulsion systems to reusable space vehicles, aerospace engineers are shifting toward:

- Higher-temperature resistant alloys

- Corrosion-resistant nickel superalloys

- Lightweight titanium structures

- Materials with longer fatigue life cycles

This is why the demand for superalloys is rising globally.

Manufacturers now prioritize aerospace alloys for high performance that deliver safety, reliability, and long-term stability.

And DOMADIA™ is at the forefront of supplying these mission-critical materials.

Conclusion — Why These 7 Alloys Matter

The difference between a 100-hour part and a 10,000-hour part often comes down to choosing the right alloy.

From Inconel to Titanium to Haynes, these aerospace alloys for high performance ensure:

- 🚀 Higher engine efficiency

- 🌡️ Improved heat tolerance

- 🛡️ Better corrosion & oxidation resistance

- 🔧 Longer life cycles

- 💸 Reduced downtime & maintenance

In aerospace, failure is expensive — precision alloys are priceless.

DOMADIA™ continues to power global aerospace programs with certified, high-specification alloys that deliver reliability where it matters most.

Upgrade your material selection with the alloys that power modern aerospace.

Explore the blog today.

👉 Contact DOMADIA™Today

📩 Contact us today to get custom sizes and specifications for your project.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#AerospaceAlloys #Inconel #TitaniumAlloys #HaynesAlloys #Superalloys #HighTemperatureMaterials #DOMADIA #AerospaceEngineering

Directly whatsapp us for an Enquiry: https://wa.link/kairav