Blogs

Titanium Powder vs Nickel Powder: Choosing the Right Powder for Your Application

Titanium Powder vs Nickel decisions usually look simple—until a batch fails flow checks, a sintered part cracks, or a coating peels in service.

A real-world scenario we hear often:

A team finalizes a powder-based process (PM / MIM / thermal spray / AM). The pilot runs fine. Then production starts… and suddenly:

- Layer spreading becomes inconsistent

- Density fluctuates

- Corrosion shows up earlier than expected

- Or the component distorts after thermal cycling

The culprit is rarely “powder quality” alone. It’s often the wrong powder family for the job conditions.

This blog breaks down Titanium Powder vs Nickel in a practical, application-first way—so you can choose confidently (and avoid expensive do-overs).

Titanium Powder vs Nickel: The Mindset Shift

Stop asking: “Which metal is better?”

Start asking: “Which failure mode am I designing against?”

- If your enemy is weight + corrosion → Titanium often wins.

- If your enemy is heat + oxidation + creep + harsh chemistry → Nickel (and nickel alloys) often wins.

That single shift prevents most mismatches.

What These Powders Really “Mean”

- Titanium Powder (commonly aligned with CP Titanium, e.g., UNS R50250)

Commercially pure titanium Grade 1 is known for high ductility/formability and corrosion resistance.

In powder form, titanium is widely used in:

- lightweight structural parts

- biomedical components (depending on grade/standard)

- corrosion-resistant PM parts

- AM and thermal spray (often as CP Ti or Ti alloys depending on need)

- Nickel Powder (commonly aligned with Nickel 200, UNS N02200)

Nickel 200 is commercially pure nickel valued for corrosion resistance and strong thermal/electrical conductivity.

In powder form, nickel is widely used in:

- chemical processing environments

- electronic/EMI-related applications

- coatings and wear/corrosion systems

- PM parts requiring toughness and conductivity

Chemical Composition (What You’re Actually Buying)

Titanium (Grade 1 reference chemistry — UNS R50250)

Typical limits commonly referenced for CP Ti Grade 1 include:

- C 0.08% max

- N 0.03% max

- O 0.18% max

- H 0.015% max

- Fe 0.20% max

- Ti balance

Nickel 200 chemistry — UNS N02200

Nickel 200 is typically specified as ~99.2% minimum Ni (commercially pure nickel), with tight controls on impurities depending on the governing spec.

Practical takeaway:

If your application is sensitive to interstitials (like O/N in titanium affecting ductility), titanium chemistry control matters a lot. For nickel, impurity control can influence hot workability, conductivity, and corrosion performance.

Properties Comparison Titanium Powder vs Nickel (How They Behave in the Real World)

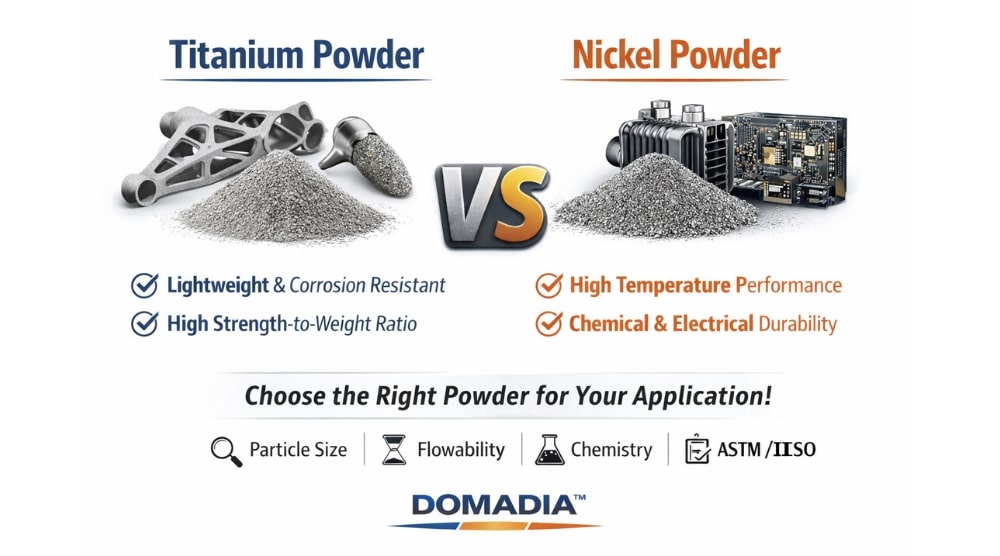

Titanium Powder—what it’s best known for

- Low density (lightweight advantage)

- Excellent corrosion resistance in many environments

- Great biocompatibility (grade-dependent + standards-dependent)

- High strength-to-weight potential (especially in alloys)

- Reactive powder handling needs care (oxidation sensitivity)

Nickel Powder—what it’s best known for

- High thermal stability and strong high-temperature performance (especially nickel alloys)

- Excellent corrosion resistance in many chemical environments

- Good thermal & electrical conductivity

- Typically heavier (density penalty vs titanium)

- Strong candidate for hot zones, heaters, corrosive media, and plating/coatings

Choosing by Applications (Use-Case Lens): Titanium Powder vs Nickel

When evaluating Titanium Powder vs Nickel, the correct choice depends less on price and more on how the material performs under real operating conditions. Below is a clear application-based breakdown to guide material selection.

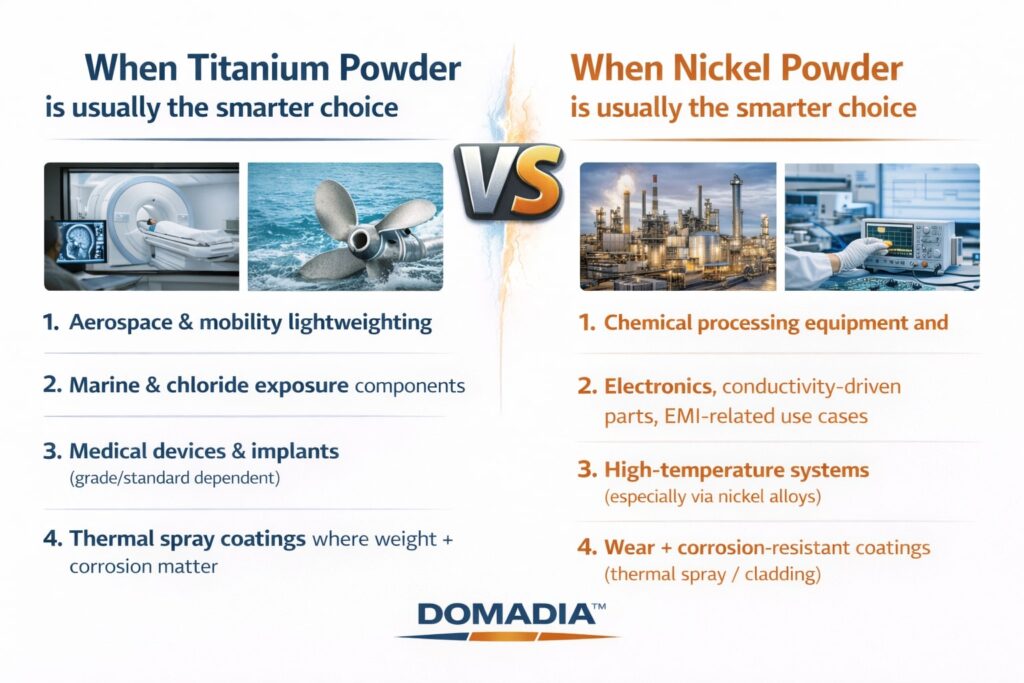

When Titanium Powder is usually the smarter choice

In the Titanium Powder vs Nickel decision, titanium becomes the preferred option when weight reduction and corrosion resistance are critical.

Aerospace & Mobility Lightweighting

In applications where every gram counts, titanium’s superior strength-to-weight advantage delivers long-term performance benefits across the component lifecycle.

Marine & Chloride Exposure Components

Titanium’s exceptional resistance to chloride-rich and saltwater environments makes it a reliable choice for marine-facing systems and coastal installations.

Medical Devices & Implants (Grade/Standard Dependent)

Commercially pure titanium is widely referenced for medical applications. Proper grade selection and compliance with biocompatibility standards are essential for success.

Thermal Spray Coatings Where Weight + Corrosion Matter

Titanium-based coatings are frequently selected where corrosion resistance must be achieved without adding unnecessary weight.

When Nickel Powder is usually the smarter choice

In the Titanium Powder vs Nickel comparison, nickel stands out in environments demanding thermal stability, conductivity, and chemical durability.

Chemical Processing Equipment and Components

Nickel’s corrosion resistance and mechanical robustness perform well in aggressive chemical and industrial processing environments.

Electronics, Conductivity-Driven Parts & EMI-Related Use Cases

Nickel’s electrical and thermal conductivity, along with application-dependent magnetic behavior, supports a wide range of electronic and EMI-sensitive systems.

High-Temperature Systems (Especially via Nickel Alloys)

For prolonged exposure to elevated temperatures, nickel-family materials consistently outperform many alternatives.

Wear + Corrosion-Resistant Coatings (Thermal Spray / Cladding)

Nickel powders are commonly used as base materials for durable coating systems where wear resistance and corrosion protection must coexist.

Standards & Compliance (Don’t Skip This Part)

For material designation and baseline alloy control

- Titanium Grade 1 UNS R50250 is widely referenced in industry supply chains.

- Nickel 200 UNS N02200 appears in ASTM specifications such as ASTM B160 (forms like rod/bar in that spec).

For additive manufacturing (AM) component specifications (powder-bed fusion)

If you’re using powders for AM, relevant standards often specify component requirements + feedstock expectations:

- ASTM F3049: guide for characterizing metal powders used for AM processes

- ISO 4497: particle size distribution by dry sieving (where applicable)

- ISO also highlights ISO/ASTM standards for AM feedstock characterization and qualification, including ISO/ASTM 52907 among others.

DOMADIA™ practical note: When comparing quotes, ask suppliers what they provide for:

- PSD report method (and standard used)

- flowability metrics

- chemistry COA with heat/lot traceability

- oxygen/nitrogen controls (especially for titanium powders)

Technical Specifications (What to Specify on Your PO)

Because “powder” is not one thing, here’s what serious buyers define—whether it’s DOMADIA™ Titanium Powder or DOMADIA™ Nickel Powder:

A) Particle Size Distribution (PSD)

Typical purchasing ranges are application-driven, for example:

- AM/PBF: fine, controlled distributions

- Thermal spray: often coarser ranges

- PM pressing: optimized for packing + sintering

Specify: D10 / D50 / D90 (or sieve cut), plus the test method (ASTM/ISO route).

B) Morphology

- Spherical (often preferred for flow and layer spreading in AM)

- Irregular (can be OK for pressing/sintering depending on design)

C) Chemistry Limits

- Titanium: oxygen/nitrogen/hydrogen limits are crucial for ductility and consistency

- Nickel: purity/impurity control and consistency are key

D) Flowability & Apparent Density

Important for:

- consistent feeding

- stable build quality

- predictable packing density

(Referenced within powder characterization guidance for AM).

E) Packaging & Handling

Especially relevant for titanium powders due to oxidation sensitivity.

Shapes Available (Beyond “Powder”)

Even when the starting requirement is powder, projects often evolve into hybrid sourcing.

DOMADIA™ can support (availability depends on grade and requirement):

- Powder (custom PSD ranges)

- Granules

- Compacts / briquettes (where applicable)

- Plus related formats for project continuity (sheet/strip/rod/plate in many metal programs)

If you tell us your process (AM / thermal spray / PM / MIM), we align the powder characteristics accordingly.

Quick Decision Checklist

Use this checklist before you lock your material:

Choose Titanium Powder if you need:

- weight reduction without sacrificing corrosion resistance

- ductility/formability in CP titanium use cases

- biomedical compatibility (with the correct grade/standard)

Choose Nickel Powder if you need:

- toughness + corrosion resistance in chemical environments

- conductivity-driven performance

- better fit for hot-zone duty (especially with nickel alloys)

Conclusion

Titanium Powder vs Nickel is not a “which is premium?” debate. It’s a service-condition match.

- Titanium often wins on weight + corrosion + biocompatibility paths.

- Nickel often wins on chemical resistance + conductivity + thermal resilience paths.

If you want the safest selection, don’t just compare datasheets—compare:

failure modes, standards, powder characterization, and lifecycle cost.

Choose DOMADIA™ when you want powder that’s specified like an engineer buys it—by application, standards, and measurable properties.

Need help choosing the right metal powder for your application?

Connect with DOMADIA™ for application-matched Titanium and Nickel powders—specified by particle size, chemistry, and standards.

Contact us today to get custom sizes and specifications for your project.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#TitaniumPowder #NickelPowder #MetalPowders #AdditiveManufacturing #PowderMetallurgy #ThermalSpray #Manufacturing #EngineeringMaterials #DOMADIA #UNSR50250

Directly whatsapp us for an Enquiry: https://wa.link/kairav