Blogs

Metal Powder Guide: Everything You Need to Know About DOMADIA™ Metal Powders-Types, Properties & Industrial Uses

Metal Powder Guide Starts Here: Why UNS R50250 Matters Today

Metal Powder Guide conversations usually begin only when something goes wrong—poor flow, inconsistent density, failed prints, or rejected parts. UNS R50250 titanium powder quietly solves many of these problems before they even appear.

At DOMADIA™, metal powders are not treated as commodities. They are engineered inputs that directly control performance, repeatability, lifecycle cost, and sustainability. This Metal Powder Guide focuses on UNS R50250 (Commercially Pure Titanium) and explains why it is becoming a preferred material across advanced manufacturing sectors.

What Is UNS R50250 Metal Powder?

UNS R50250 is Commercially Pure Titanium (CP Titanium), widely used when corrosion resistance, strength-to-weight ratio, and biocompatibility are more critical than extreme alloy strength.

In powder form, UNS R50250 unlocks design freedom for modern processes such as:

- Additive Manufacturing (AM / 3D Printing)

- Powder Metallurgy (PM)

- Thermal Spray Coatings

DOMADIA™ supplies UNS R50250 metal powders with controlled particle morphology, chemistry, and traceability—key requirements for industrial reliability.

Chemical Composition – UNS R50250

| Element | Typical Content (%) |

| Titanium (Ti) | Balance |

| Oxygen (O) | ≤ 0.25 |

| Iron (Fe) | ≤ 0.30 |

| Carbon (C) | ≤ 0.08 |

| Nitrogen (N) | ≤ 0.03 |

| Hydrogen (H) | ≤ 0.015 |

Low interstitial content is essential. Excess oxygen or nitrogen directly reduces ductility and fatigue life—an area where DOMADIA™ quality control adds measurable value.

Types of DOMADIA™ Metal Powders (UNS R50250)

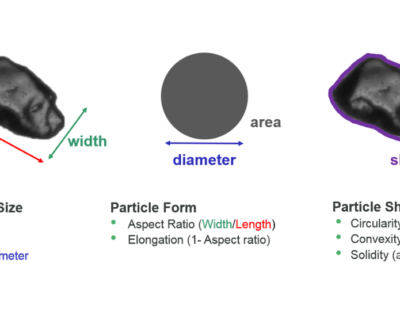

This Metal Powder Guide would be incomplete without explaining powder morphology.

1. Spherical Titanium Powder

- Gas atomized

- High flowability

- Ideal for Additive Manufacturing (SLM / EBM)

2. Irregular / Angular Powder

- HDH or mechanical processing

- Better packing for PM applications

- Cost-effective for large-volume sintering

3. Fine Cut Powders

- Controlled PSD for coatings and specialty builds

- Enhanced surface area for bonding

Key Properties of UNS R50250 Metal Powder

| Property | Performance |

| Density | ~4.51 g/cm³ |

| Melting Point | ~1668°C |

| Corrosion Resistance | Excellent |

| Biocompatibility | Outstanding |

| Strength-to-Weight Ratio | High |

| Thermal Stability | Reliable up to moderate temperatures |

Metal Powder Guide Insight:

For applications exposed to chlorides, moisture, or aggressive chemicals, UNS R50250 outperforms many steels and nickel alloys—without weight penalties.

Technical Specifications (Typical DOMADIA™ Range)

- Particle Size Distribution: 15–45 µm / 45–105 µm (custom cuts available)

- Flowability: Optimized for AM & PM standards

- Apparent Density: Application-specific controlled values

- Oxygen Control: Tight monitoring during production & packaging

- Packaging: Vacuum sealed / inert gas protection

DOMADIA™ powders are supplied with full batch traceability and test certificates.

Applicable Standards

This Metal Powder Guide aligns UNS R50250 with global standards:

- ASTM B348 / B299 – Titanium & Titanium Alloy Products

- ASTM F67 – Medical-grade CP Titanium (application dependent)

- ISO 5832 – Surgical implant materials

- Aerospace & customer-specific AM specifications

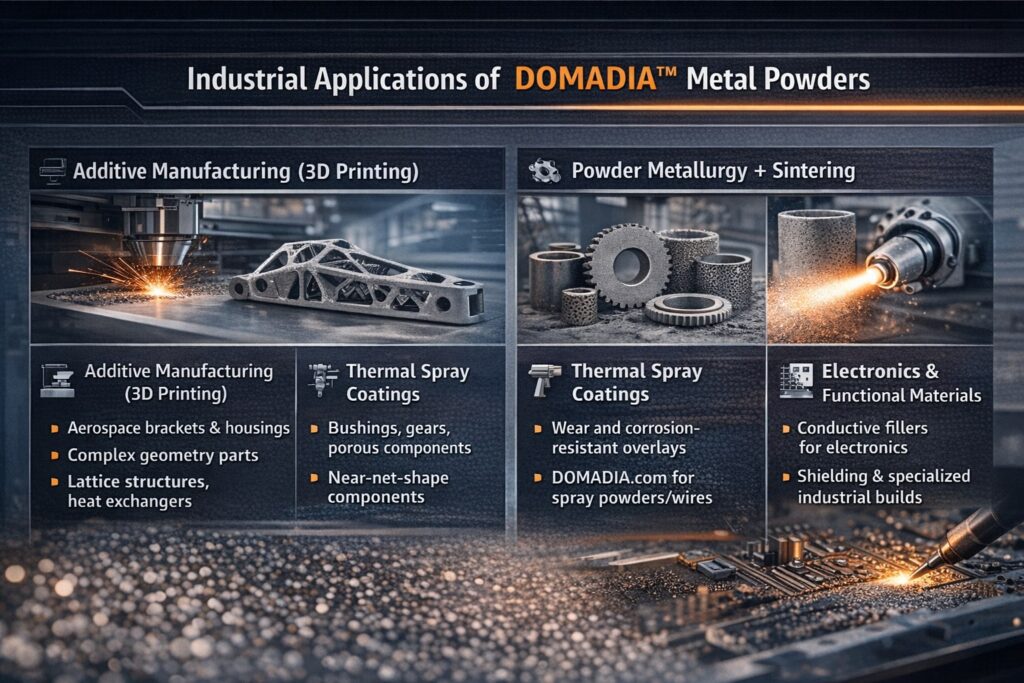

Industrial Applications of UNS R50250 Metal Powder

1. Additive Manufacturing (3D Printing)

- Lightweight aerospace brackets

- Heat exchangers

- Complex lattice structures

- Corrosion-resistant industrial parts

2. Powder Metallurgy & Sintering

- Porous filters

- Bushings and structural components

- Near-net-shape parts with minimal waste

3. Thermal Spray Coatings

- Corrosion protection layers

- Marine and chemical processing equipment

- Wear-resistant overlays

4. Medical & Healthcare (Grade/Standard Dependent)

- Implants

- Surgical instruments

- Prosthetic components

Lifecycle & Environmental Advantage

An often-ignored point in most Metal Powder Guide articles:

Lifecycle matters more than initial cost.

- UNS R50250 lasts longer in corrosive environments

- Fewer failures = fewer replacements

- Less scrap = less recycling

- Lower environmental impact over time

By supplying high-quality, consistent powders, DOMADIA™ contributes to reduced material waste and more sustainable manufacturing cycles.

Why Choose DOMADIA™ Metal Powders?

- Strict chemistry & oxygen control

- Application-driven particle size engineering

- Industrial-grade consistency (not lab-grade assumptions)

- Trusted supply for AM, PM, and coating industries

- Technical support beyond just selling powder

This Metal Powder Guide reflects how DOMADIA™ approaches materials—as performance systems, not catalog items.

Conclusion: Metal Powder Guide Takeaway

Metal Powder Guide discussions are no longer optional for manufacturers working with advanced processes. UNS R50250 titanium powder offers a rare combination of corrosion resistance, weight efficiency, and long-term reliability.

When sourced and controlled correctly—as done by DOMADIA™—it becomes a material that improves uptime, reduces environmental impact, and protects your production economics.

If your application demands consistency, lifecycle value, and engineering-grade powders, UNS R50250 from DOMADIA™ is worth serious consideration.

Explore DOMADIA™ Metal Powders engineered for performance, not guesswork.

Visit now to learn more.

Contact us today to get custom sizes and specifications for your project.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#MetalPowderGuide #UNSR50250 #TitaniumPowder #DOMADIA #AdditiveManufacturing #PowderMetallurgy #IndustrialMaterials

Directly whatsapp us for an Enquiry: https://wa.link/kairav