Blogs

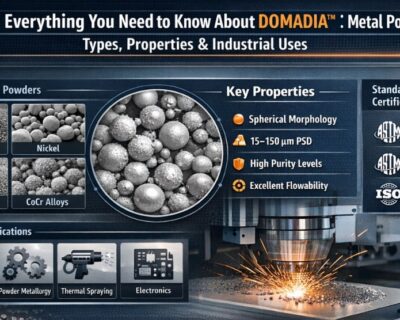

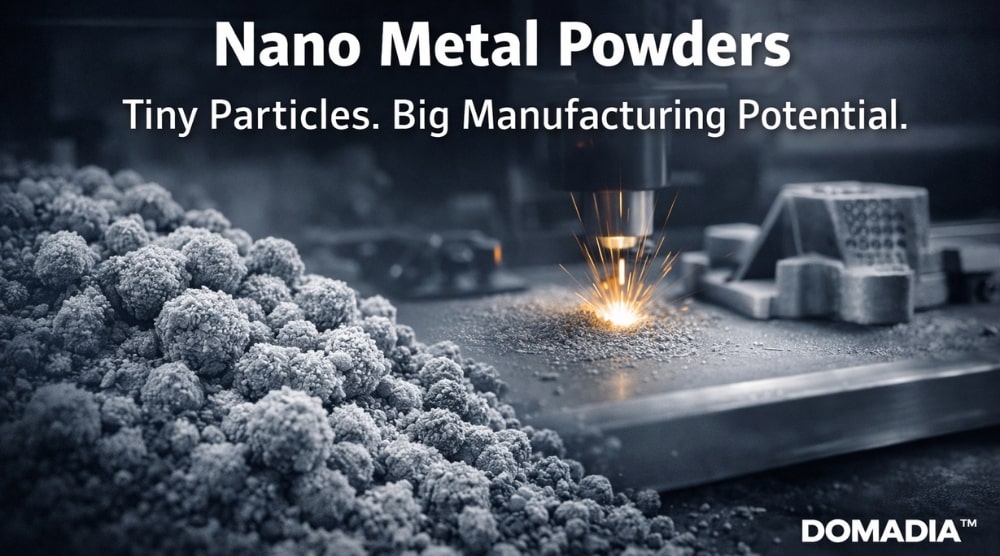

Nano Metal Powders : Tiny Particles, Big Manufacturing Potential | DOMADIA™

Nano Metal Powders: When Size Stops Limiting Performance

The first time a production line failed at a high-end electronics plant, the issue wasn’t software, machining, or design.

It was material behavior at the micro level.

Traditional metal powders performed well—until tighter tolerances, higher conductivity, and extreme miniaturization pushed them beyond their limits. That’s when nano metal powders entered the conversation. And once manufacturers experienced the difference, there was no going back.

This is not about making metals smaller.

This is about unlocking performance traditional materials physically cannot deliver.

What Are Nano Metal Powders?

Nano metal powders are metallic particles typically sized below 100 nanometers (nm). To put that into perspective, a human hair is about 80,000–100,000 nm thick.

At this scale, metals behave differently:

- Surface area increases exponentially

- Atomic diffusion accelerates

- Electrical, thermal, and mechanical properties intensify

DOMADIA™ supplies nano metal powders engineered for controlled particle size distribution, high purity, and repeatable industrial performance—not laboratory-only novelty materials.

Why Nano Metal Powders Change Manufacturing Rules

1. Surface Area Becomes a Performance Multiplier

Nano metal powders offer massive surface area relative to volume. This enables:

- Faster sintering at lower temperatures

- Stronger inter-particle bonding

- Improved coating adhesion

In powder metallurgy and additive manufacturing, this means denser, stronger parts with less energy input.

2. Lower Temperature, Higher Precision

Nano powders enable sintering and consolidation at temperatures significantly lower than conventional powders. This allows:

- Reduced thermal distortion

- Compatibility with sensitive substrates

- Integration into electronics and functional layers

Lower heat, higher control—an engineer’s ideal equation.

3. Electrical & Thermal Conductivity Enhancement

In electronics, conductivity isn’t just about material choice—it’s about particle morphology and contact efficiency.

Nano metal powders improve:

- Conductive pathways

- Signal reliability

- Heat dissipation in compact designs

This is why nano powders are accelerating adoption in next-generation electronics and energy systems.

Chemical Composition Control at Nano Scale

DOMADIA™ nano metal powders are produced with tight elemental control, ensuring:

- Ultra-low impurity levels

- Consistent stoichiometry

- Application-specific alloying

Whether it’s nano copper, nickel, silver, iron, or alloyed nano systems, chemical consistency is what ensures repeatable production—not experimental variability.

Key Properties of Nano Metal Powders

- Particle Size: <100 nm (customized ranges available)

- High Reactivity: Enhanced diffusion and bonding

- Improved Mechanical Strength: Due to grain refinement

- Superior Conductivity: Electrical and thermal

- Uniform Packing Behavior: Critical for thin layers and coatings

These properties are why nano metal powders are no longer confined to R&D labs—they’re entering commercial production lines.

Applications: Where Nano Metal Powders Hit First

Additive Manufacturing (Micro & Precision Builds)

Nano powders enable:

- Finer resolution printing

- Stronger micro-lattice structures

- Functional surface layers

Especially useful in electronics-integrated AM components.

Electronics & Functional Materials

Used in:

- Conductive inks and pastes

- EMI shielding layers

- Sensors and micro-connectors

Miniaturization demands nano-scale control.

Advanced Coatings & Thermal Spray

Nano powders improve:

- Coating density

- Adhesion strength

- Wear and corrosion resistance

Thinner coatings, longer service life.

Energy Storage & Catalytic Systems

High surface area makes nano powders ideal for:

- Battery electrodes

- Fuel cells

- Catalytic reactions

Efficiency rises as particle size falls.

Standards & Quality Expectations

While nano materials often exceed traditional standards, DOMADIA™ aligns nano powder production with:

- Controlled batch documentation

- Particle size validation

- Application-specific compliance

Nano powders are supplied fit-for-purpose, not generic.

Technical Specifications (Typical Range)

- Particle Size Distribution: 20–100 nm (customizable)

- Purity: ≥99.5% (metal dependent)

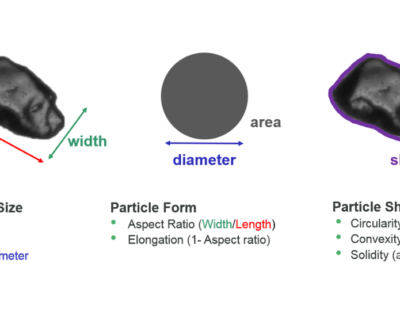

- Morphology: Spherical / near-spherical / engineered

- Bulk Density: Application-dependent

- Packaging: Controlled atmosphere options available

Shapes Available

DOMADIA™ nano metal powders are available in:

- Spherical nano particles

- Engineered agglomerates

- Custom morphology for conductivity or packing behavior

Shape matters as much as size—especially at the nano scale.

Mindset Shift: Smaller Materials, Bigger Thinking

Nano metal powders aren’t a cost addition.

They’re a performance multiplier.

Manufacturers shifting to nano powders often discover:

- Reduced material usage

- Lower processing temperatures

- Longer component lifespan

- Fewer redesign cycles

In high-value manufacturing, downtime and redesign cost far more than material upgrades.

Environmental Impact: Less Scrap, Less Recycling

Frequent part replacement increases:

- Scrap generation

- Energy-intensive recycling

- Environmental footprint

Nano metal powders enable longer-lasting, more efficient components, reducing replacement frequency. Fewer cycles mean lower environmental damage—a small particle making a large sustainability contribution.

This is not marketing.

This is materials engineering with responsibility.

The DOMADIA™ Takeaway

Nano Metal Powders are not the future—they’re already reshaping manufacturing today.

When precision, conductivity, and performance matter at the smallest scales, DOMADIA™ nano metal powders deliver industrial reliability—not experimental uncertainty.

Choose materials that scale with innovation.

Choose performance that lasts.

Choose DOMADIA™ Nano Metal Powders.

Reduce Size. Increase Performance. Build Smarter.

Learn how DOMADIA™ nano metal powders enable next-generation components.

Contact Us to Upgrade Your Manufacturing Performance

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#NanoMetalPowders #AdvancedManufacturing #MetalPowders #Nanotechnology #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav