Blogs

UNS C17200 Beryllium Copper Alloys: A Deep Dive with DOMADIA™

C17200 Beryllium Copper is not the alloy engineers notice first.

It’s the alloy they respect later—after everything else fails.

In high-performance manufacturing, breakdowns rarely announce themselves loudly. They start quietly. A spring loses force. A contact heats up. A precision part no longer returns to its original shape. The design looks correct. The assembly is perfect. Yet performance slips.

This is where DOMADIA™ repeatedly sees one material stand apart: UNS C17200 Beryllium Copper—an alloy engineered for strength, endurance, and reliability under continuous stress.

What Is C17200 Beryllium Copper?

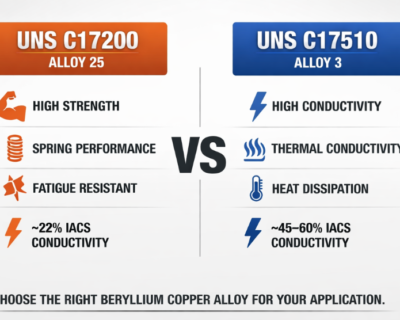

UNS C17200, often referred to as Alloy 25, is a high-strength copper alloy strengthened through precipitation hardening. Unlike conventional copper alloys that rely mainly on cold work, C17200 develops its exceptional properties through a controlled heat-treatment process.

The result is a rare balance:

- Mechanical strength close to certain steels

- Retained elasticity for spring applications

- Useful electrical and thermal conductivity

- Long service life under cyclic loading

This balance is exactly why C17200 appears in demanding electrical, aerospace, tooling, and precision engineering applications.

Chemical Composition of UNS C17200

The performance of C17200 Beryllium Copper comes from its carefully controlled chemistry:

- Copper (Cu): Balance

- Beryllium (Be): Approximately 1.8–2.0%

- Cobalt (Co) / Nickel-Cobalt additions: Used to enhance precipitation hardening response

Each element plays a role in achieving high strength while preserving copper’s inherent conductivity and corrosion resistance.

At DOMADIA™, composition control is treated as a performance requirement—not just a chemical specification.

Unique Properties That Define C17200

1. Exceptional Strength with Elastic Recovery

C17200 can achieve very high tensile and yield strengths while maintaining elasticity. This makes it ideal for components that must repeatedly flex and return to shape without permanent deformation.

2. High Fatigue Resistance

In cyclic applications—where parts bend, compress, or vibrate thousands or millions of times—fatigue failure is the real enemy. C17200 is widely chosen because it maintains performance over long duty cycles.

3. Electrical Conductivity That Still Works

While not as conductive as pure copper, C17200 provides sufficient electrical conductivity for contacts, connectors, and current-carrying springs—applications where steel or other high-strength alloys fail functionally.

4. Corrosion Resistance

C17200 performs well in many industrial and atmospheric environments, helping components retain mechanical and electrical stability over time.

5. Dimensional Stability

After proper heat treatment, the alloy maintains tight tolerances—critical for precision components and repeatable assemblies.

Key Physical & Mechanical Characteristics (Typical)

(Exact values depend on product form and temper)

- High tensile and yield strength after age hardening

- Good elastic limit for spring performance

- Electrical conductivity suitable for functional electrical parts

- Stable performance across temperature variations

- Long operational life with reduced maintenance needs

These characteristics explain why engineers often move to C17200 after experiencing failures with phosphor bronze, brass, or standard copper alloys.

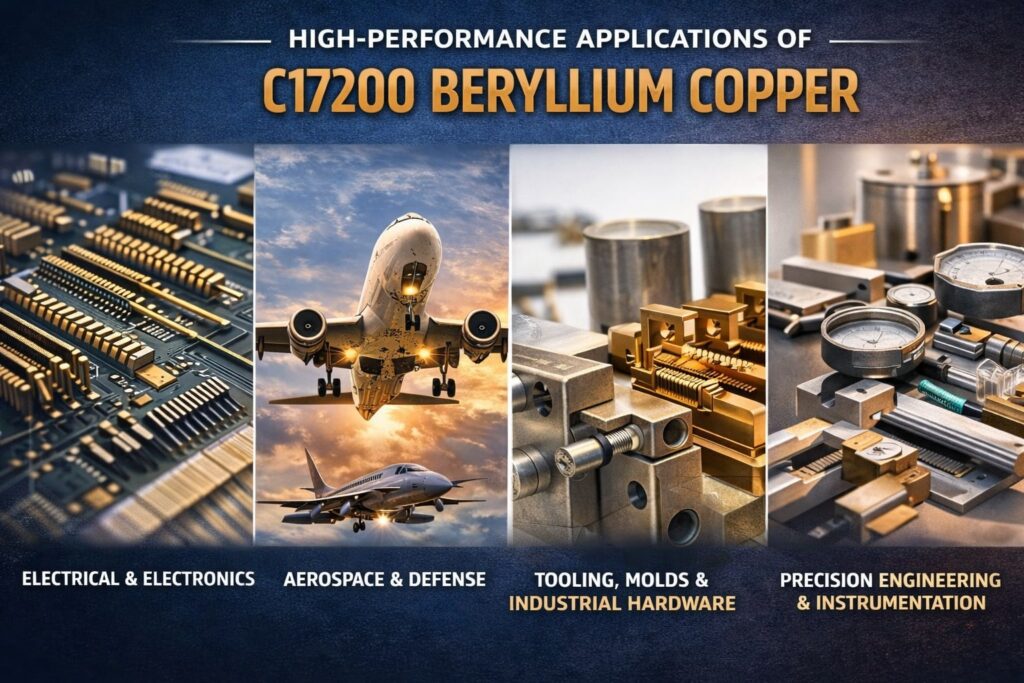

High-Performance Applications of C17200 Beryllium Copper

Electrical & Electronics

- Spring contacts

- Connector pins and contact fingers

- Switch components

- Precision electrical springs

C17200 ensures consistent contact force and conductivity even after repeated engagement cycles.

Aerospace & Defense

- Components exposed to vibration and cyclic stress

- Precision mechanisms requiring stable spring force

- Electrical systems where failure is not an option

Reliability and fatigue life are more important than raw material cost in these environments.

Tooling, Molds & Industrial Hardware

- Mold components and inserts

- Precision mechanical parts

- Wear-resistant components requiring strength and thermal stability

The alloy’s combination of strength and conductivity can also help manage heat in tooling environments.

Precision Engineering & Instrumentation

- Measurement devices

- Calibration components

- Mechanisms requiring repeatable motion

Standards Commonly Associated with C17200

UNS C17200 is supplied according to recognized industry standards depending on form and application. These standards define chemistry, mechanical properties, and acceptable tolerances.

DOMADIA™ recommendation:

Always specify:

- UNS number (C17200)

- Product form (sheet, strip, rod, wire, etc.)

- Temper or heat-treatment condition

This ensures the alloy delivered performs exactly as intended in service.

Technical Specifications to Define Clearly

To avoid premature failure or inconsistent performance, technical specifications should include:

- Alloy designation: UNS C17200

- Required temper or condition

- Mechanical property targets

- Electrical conductivity requirements (if applicable)

- Dimensional tolerances

- Surface finish and edge condition

At DOMADIA™, these details are treated as functional requirements—not paperwork.

Shapes Available from DOMADIA™

C17200 Beryllium Copper is commonly supplied in:

- Sheets & Plates

- Strips & Coils (ideal for spring and contact applications)

- Rods & Bars

- Wires

Each form supports different manufacturing processes and performance needs.

Safety & Responsible Use

Like all beryllium-containing materials, C17200 must be processed responsibly—especially during machining, grinding, or cutting operations. Proper workplace controls ensure safe and compliant use.

Using the alloy correctly delivers long-term performance benefits without compromise.

Final Thoughts

C17200 Beryllium Copper is not chosen for being the cheapest option.

It is chosen because it reduces failures, extends service life, and protects performance where it matters most.

At DOMADIA™, we see this alloy as more than a material—it’s a solution for engineers who value reliability over shortcuts.

When performance must remain stable under stress, cycles, and time,

UNS C17200 Beryllium Copper remains the benchmark.

Power Your Critical Applications with C17200 Beryllium Copper

Contact DOMADIA™ for Technical Support & Supply

📩 Contact us today to get custom sizes and specifications for your project.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#DOMADIA #BerylliumCopper #C17200 #CopperAlloys #ElectricalEngineering #AerospaceMaterials #SpringMaterials #HighPerformanceMaterials #Manufacturing #Tooling

Directly whatsapp us for an Enquiry: https://wa.link/kairav