Blogs

High Performance Crucible Alloys Power Aerospace, Defense & Foundry Excellence

Introduction: Where Failure Is Not an Option

High Performance Crucible Alloys are not selected for convenience—they are chosen because failure is unacceptable. In aerospace, defense, and foundry environments, materials face relentless extremes: temperatures exceeding 1,000°C, cyclic mechanical stress, corrosive atmospheres, and zero tolerance for defects. In such conditions, ordinary materials degrade quickly, risking safety, performance, and costly downtime.

This is why High Performance Crucible Alloys sit at the heart of mission-critical manufacturing. At DOMADIA™, these alloys are not treated as commodities; they are engineered solutions designed to deliver consistency, purity, and durability when operating margins disappear.

What Makes High Performance Crucible Alloys Different

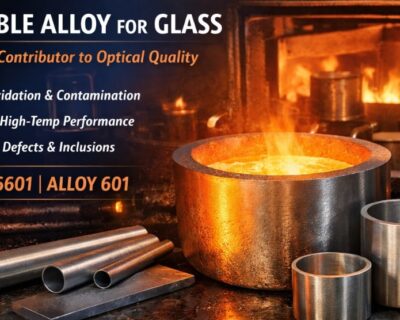

High Performance Crucible Alloys are advanced metallic systems melted and refined in refractory crucibles that withstand extreme thermal and chemical stress. The crucible itself—often made from graphite, silicon carbide, alumina, molybdenum, or tungsten—plays a decisive role in final alloy quality.

Together, crucible and alloy ensure:

- Thermal stability at ultra-high temperatures

- Chemical inertness to prevent contamination

- Structural integrity during repeated thermal cycling

This controlled environment is what allows High Performance Crucible Alloys to achieve precise chemistry, clean microstructures, and predictable mechanical properties.

Aerospace Applications: Performance Above the Clouds

In aerospace, materials are constantly pushed beyond conventional limits. Jet engines, turbines, and propulsion systems rely on High Performance Crucible Alloys to survive conditions that would rapidly destroy standard metals.

Extreme Temperature Resistance

Nickel-based and cobalt-based superalloys processed using High Performance Crucible Alloys retain strength and resist oxidation even under prolonged exposure to intense heat. These alloys are essential for:

- Turbine blades

- Combustion chambers

- Afterburner assemblies

- Rocket and hypersonic propulsion components

Without High Performance Crucible Alloys, modern aerospace propulsion systems would simply not function reliably.

Strength Without Excess Weight

Weight reduction directly impacts fuel efficiency and payload capacity. Titanium and advanced aluminum systems refined as High Performance Crucible Alloys deliver exceptional strength-to-weight ratios. Controlled melting ensures uniform microstructure—critical for airframes, landing gear, and structural reinforcements.

At DOMADIA™, these materials are supplied with strict metallurgical control to maintain batch-to-batch consistency and reliable mechanical performance.

Defense Systems: Reliability Under Fire

Defense applications demand materials that perform under shock, vibration, electromagnetic exposure, and extreme environments. High Performance Crucible Alloys enable this reliability.

Key defense advantages include:

- Magnetic stability for radar and sensor housings

- Controlled electrical conductivity for communication systems

- Dimensional stability under vibration and impact

These properties are only achievable through precise alloy chemistry and clean melting—both hallmarks of High Performance Crucible Alloys.

Foundry Operations: Where Quality Begins

In foundries, quality is determined at the melting stage. High Performance Crucible Alloys ensure that castings start with purity and consistency.

Purity and Contamination Control

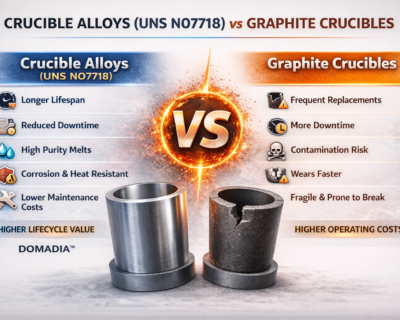

Graphite, silicon carbide, and alumina crucibles used with High Performance Crucible Alloys resist chemical attack from molten aluminum, copper, brass, bronze, and specialty alloys. This prevents unwanted inclusions that can compromise mechanical performance.

Thermal Shock Resistance

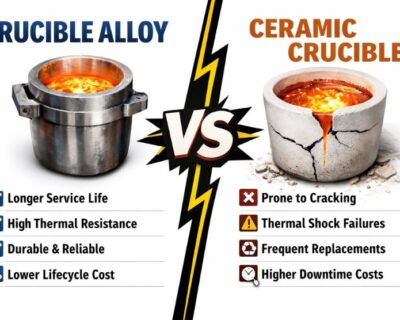

Repeated heating and cooling cycles are unavoidable in foundry operations. High Performance Crucible Alloys, paired with robust crucible materials, withstand thermal shock without cracking—reducing downtime and extending service life.

Flexibility for Modern Production

Foundries increasingly require short production runs and specialty alloys. High Performance Crucible Alloys allow efficient switching between melts, making them ideal for R&D, prototyping, and custom alloy development.

Properties That Define High Performance Crucible Alloys

Across industries, High Performance Crucible Alloys are valued for a consistent set of properties:

- High-temperature mechanical strength

- Excellent oxidation and corrosion resistance

- Controlled grain structure and chemistry

- Resistance to creep and fatigue

- Long operational life under cyclic stress

These properties translate directly into safer operations and lower total lifecycle cost.

Standards and Technical Expectations

High Performance Crucible Alloys are commonly produced to meet stringent aerospace, defense, and industrial standards, including ASTM, AMS, ISO, and customer-specific specifications. DOMADIA™ supports compliance through controlled sourcing, traceability, and metallurgical expertise.

Lifecycle Cost and Sustainability Advantage

While High Performance Crucible Alloys may have a higher initial cost, their long service life changes the economics completely. Fewer replacements mean:

- Reduced downtime

- Lower maintenance frequency

- Less scrap and recycling

From an environmental perspective, this longevity matters. Every replacement cycle consumes energy and increases emissions. By lasting longer, these alloys reduce material turnover—aligning performance with sustainability. This is not marketing; it is responsible engineering.

Why High Performance Crucible Alloys Remain Essential

Across aerospace, defense, and foundry sectors, the same reality applies: downtime is expensive, and failure can be catastrophic. High Performance Crucible Alloys deliver reliability where safety, purity, and durability cannot be compromised.

At DOMADIA™, these alloys are supplied with a deep understanding of application stress, processing demands, and long-term performance expectations. When environments are extreme and margins are zero, High Performance Crucible Alloys make the difference between success and failure.

Ready to Engineer Reliability Where Failure Is Not an Option?

Crucible alloys play known, mission-critical roles in aerospace, defense, and foundry environments—where extreme heat, purity, and lifecycle performance decide success or shutdown.

DOMADIA™ supports industries with high-performance crucible alloy solutions engineered for consistency, longevity, and reduced downtime.

From aerospace metallurgy to heavy-duty foundry operations,Contact Usto secure crucible alloys engineered to last longer.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#CrucibleAlloysPerformance #AerospaceMaterials #DefenseAlloys #FoundryTechnology #HighTemperatureAlloys #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve delivered to Bengaluru, Mysuru, Mangaluru, Hubballi, and Belagavi—covering Karnataka, Telangana, Tamil Nadu, Kerala, and Andhra Pradesh, with exports to Australia, New Zealand, Singapore, Malaysia, and Indonesia.