Blogs

Rare Earth Magnets in EV Motors: How Compact Power Is Redefining Efficiency | DOMADIA™

Introduction: Small Component. Massive Impact.

Rare Earth Magnets EV technology is quietly reshaping how electric vehicles perform, travel farther, and last longer.

When consumers talk about EVs, they talk about range, acceleration, charging time, and efficiency. What rarely enters the conversation is the component that makes all of this possible inside the motor—high-performance rare earth magnets.

At DOMADIA™, we see this shift every day. EV manufacturers are no longer chasing bigger motors. They are chasing smarter power density, and that journey starts with rare earth magnets.

Why Rare Earth Magnets EV Motors Depend On Compact Power

Traditional motor designs relied on size to generate torque. EV platforms changed that rule.

Rare Earth Magnets EV motors use neodymium-based magnetic systems that deliver extremely high magnetic strength in very small volumes. This allows engineers to design motors that are:

- Smaller and lighter

- More energy-efficient

- Capable of higher torque at lower speeds

- Optimized for extended driving range

This is why Rare Earth Magnets EV solutions dominate modern traction motors.

The Real-World EV Scenario: Where Efficiency Is Won or Lost

A mid-sized electric car operating in urban traffic stops and starts hundreds of times a day. Each acceleration demands instant torque. Each deceleration demands controlled energy recovery.

Motors using conventional magnetic materials lose energy as heat and inefficiency. Motors built around Rare Earth Magnets EV architectures deliver rapid magnetic response with minimal losses.

The result is tangible:

- Faster acceleration

- Improved regenerative braking

- Reduced battery drain

- Lower thermal stress on motor components

Efficiency here is not theoreticality directly translates into extra kilometers per charge.

Chemical Composition of Rare Earth Magnets Used in EV Motors

The most common Rare Earth Magnets EV motors use are Neodymium Iron Boron (NdFeB) magnets.

Typical Composition:

- Neodymium (Nd): 25–32%

- Iron (Fe): Balance

- Boron (B): ~1%

- Additives: Dysprosium (Dy), Terbium (Tb) for high-temperature stability

DOMADIA™ supplies rare earth magnet grades optimized to balance magnetic strength with thermal endurance—critical for EV motor longevity.

Properties That Make Rare Earth Magnets EV-Ready

Rare Earth Magnets EV applications demand more than just strength.

Key Properties:

- Extremely high magnetic energy density

- Excellent torque-to-weight ratio

- Stable magnetic performance over long duty cycles

- Resistance to demagnetization under load

- Compact geometry compatibility

These properties enable EV motors to stay smaller while delivering higher output—one of the biggest engineering wins in electric mobility.

Technical Specifications (Typical for EV Motor Grades)

| Parameter | Typical Range |

| Maximum Energy Product (BHmax) | 35–52 MGOe |

| Operating Temperature | Up to 180–220°C (grade dependent) |

| Coercivity | High (for demagnetization resistance) |

| Magnetic Flux Density | Very high |

| Density | ~7.4–7.6 g/cm³ |

DOMADIA™ Rare Earth Magnets EV grades are supplied with tight tolerance control to ensure consistent motor behavior across production batches.

Standards Followed in EV Magnet Manufacturing

Rare Earth Magnets EV components must comply with strict global standards:

- ISO 9001 – Quality management

- ISO 14001 – Environmental management

- RoHS & REACH compliance

- Automotive-grade material traceability standards

DOMADIA™ aligns magnet sourcing and processing with automotive OEM and Tier-1 expectations.

Applications of Rare Earth Magnets EV Systems

Rare Earth Magnets EV solutions extend far beyond traction motors, enabling compact, efficient, and reliable performance across multiple vehicle systems:

Traction motors for electric cars, buses, and two-wheelers

High magnetic strength allows motors to deliver instant torque, smoother acceleration, and higher power density while keeping motor size and weight low.

Integrated starter-generator systems

Rare earth magnets support rapid start-stop functionality with minimal energy loss, improving overall drivetrain efficiency and responsiveness.

Electric power steering motors

Compact magnetic designs ensure precise steering control, faster response, and reduced power consumption compared to conventional systems.

Regenerative braking systems

Strong and stable magnetic fields enable efficient energy recovery during braking, converting kinetic energy back into usable electrical power.

Cooling and auxiliary motor assemblies

Smaller, efficient motors driven by rare earth magnets improve thermal management, cabin comfort, and system reliability without increasing battery load.

Each application benefits from compact size, high efficiency, and predictable magnetic performance—key factors in advancing modern EV design.

Shapes Available for EV Motor Integration

To support modern motor architectures, DOMADIA™ offers Rare Earth Magnets EV formats in:

- Arc segments (for rotor assemblies)

- Blocks and rectangles

- Rings and discs

- Custom geometries for OEM motor designs

Precision shaping ensures optimal magnetic flux alignment and minimal losses.

The Mindset Shift: Bigger Motors Are Not Better Motors

The EV industry has moved past brute-force engineering.

The real breakthrough came when engineers realized:

Efficiency is not about size. It is about magnetic intelligence.

Rare Earth Magnets EV motors deliver more power per kilogram, allowing lighter vehicles, better handling, and longer battery life.

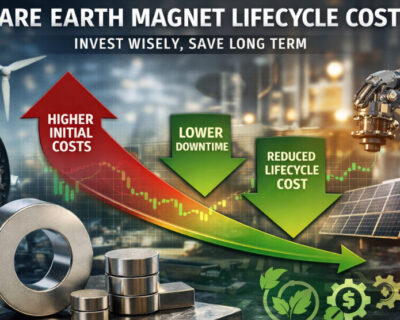

The Tangible Fix: Designing for Efficiency, Not Just Cost

Yes, Rare Earth Magnets EV solutions cost more upfront than ferrite alternatives.

But the math changes when you account for:

- Smaller motor size

- Lower energy consumption

- Reduced thermal management costs

- Longer service life

- Fewer replacements and less recycling

At DOMADIA™, we position rare earth magnets as efficiency enablers, not cost centers.

Environmental Impact: Efficiency That Lasts Longer

Frequent replacement increases scrap, recycling energy, and emissions. Rare Earth Magnets EV systems last significantly longer due to their magnetic stability.

Less replacement means:

- Lower material turnover

- Reduced recycling cycles

- Smaller environmental footprint

This longevity is a quiet but meaningful contribution to sustainable mobility—and one DOMADIA™ proudly supports.

Conclusion: Compact Power Is the Future of EV Motors

Rare Earth Magnets EV technology proves that the smallest components often create the biggest performance shifts.

From higher torque density to extended range and lower environmental impact, rare earth magnets are redefining how electric vehicles move, perform, and last.

At DOMADIA™, we support this evolution by supplying magnet solutions engineered for efficiency, reliability, and long-term value—because the future of mobility demands nothing less.

Efficiency in EV motors starts with the right magnetic foundation.

Choose DOMADIA™ for engineered Rare Earth Magnet solutions—Contact Us to power smarter, lighter, and more efficient EV designs.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#RareEarthMagnetsEV #ElectricVehicleMotors #EVEfficiency #NeodymiumMagnets #CompactPower #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.