Blogs

High-Efficiency Electrical Busbars: 9 Smart Reasons They Outperform Conventional Wires

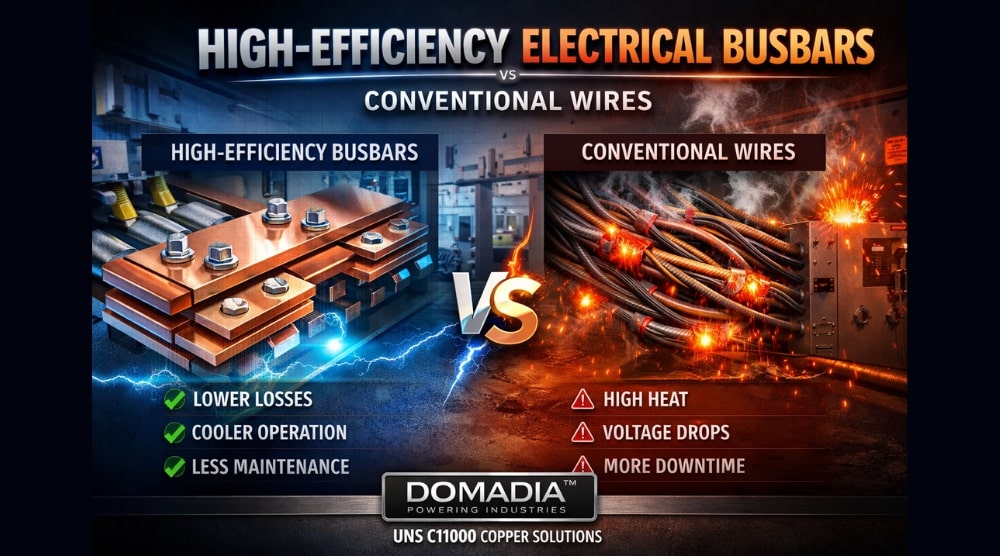

High-Efficiency Electrical Busbars are rarely discussed until something goes wrong—hot panels, unexplained voltage drops, frequent tightening schedules, or sudden downtime just when production peaks.

And that’s the problem.

Power distribution is often designed for installation convenience, not long-term efficiency. As loads increase, machines multiply, and panels get denser, conventional wiring starts showing its limits. This is where High-Efficiency Electrical Busbars quietly change the rules.

A real industrial scenario

A manufacturing plant expanded its automation line. Instead of redesigning the power backbone, they added parallel cables—again and again. Within months, the main panel showed excessive heat rise. Cooling fans ran longer. Maintenance checks increased. Downtime followed.

The solution was not thicker wires.

The solution was a mindset shift.

The mindset shift: from “more cable” to smarter current flow

Conventional wires are excellent for flexibility and routing. But they were never meant to act as high-current highways inside compact panels.

High-Efficiency Electrical Busbars are engineered specifically for this role:

- Shorter current paths

- Uniform current distribution

- Fewer termination points

- Better heat dissipation

Efficiency here is not a buzzword—it is measurable electrical and thermal stability.

Why High-Efficiency Electrical Busbars outperform conventional wires

1. Lower electrical losses

Busbars reduce resistive losses by minimizing unnecessary length and parallel conductor imbalance. The result is lower I²R losses and higher system efficiency.

This is the foundation of High-Efficiency Electrical Busbars.

2. Superior thermal performance

Flat copper busbars offer significantly higher surface area than round wires of equivalent cross-section. Heat spreads faster and escapes more efficiently.

Cooler conductors mean:

- longer service life

- stable insulation performance

- reduced panel derating

3. Reduced voltage drop

Voltage stability becomes critical as loads fluctuate. High-Efficiency Electrical Busbars provide consistent voltage delivery under heavy and dynamic loads, especially in VFDs, UPS systems, and automation panels.

4. Fewer failure points

Multiple cables mean multiple lugs—and every lug is a potential hotspot. Busbars drastically reduce termination points, improving reliability and simplifying inspections.

Lifecycle economics: where High-Efficiency Electrical Busbars really win

While wires may look economical initially, lifecycle cost tells a different story.

With High-Efficiency Electrical Busbars, industries benefit from:

- reduced maintenance hours

- fewer emergency shutdowns

- lower panel cooling energy

- faster expansions and upgrades

- extended conductor lifespan

Downtime costs often exceed material costs—and this is where High-Efficiency Electrical Busbars justify themselves.

Environmental impact: efficiency that reduces recycling cycles

Every replacement cycle has an environmental cost—scrapping, transport, remelting, and emissions.

Because High-Efficiency Electrical Busbars last longer and operate cooler:

- replacement frequency drops

- scrap generation reduces

- energy consumption over lifecycle decreases

This is not a marketing claim. It is operational sustainability—and a practical contribution to environmental responsibility.

Chemical composition: Copper Busbars (UNS C11000)

DOMADIA™ commonly supplies UNS C11000 (ETP Copper) for High-Efficiency Electrical Busbars.

Typical chemical composition:

- Copper (Cu): ≥ 99.90%

- Oxygen (O): ≤ 0.04%

This purity ensures excellent electrical and thermal conductivity—essential for High-Efficiency Electrical Busbars.

Properties that define High-Efficiency Electrical Busbars

- Electrical conductivity: ~100% IACS

- Thermal conductivity: excellent heat dissipation

- Mechanical strength: stable for panel assemblies

- Formability: suitable for flat and formed profiles

- Joinability: excellent bolting and brazing behavior

These properties allow High-Efficiency Electrical Busbars to perform reliably under continuous industrial loads.

Standards followed

High-Efficiency Electrical Busbars are typically manufactured and applied in alignment with:

- ASTM B187 – Copper bus bars and shapes

- ASTM B152 – Copper sheet and strip

- ASTM B284 – Electrical conductor applications

- IEC 61439 – LV switchgear assemblies

- IEC 60204-1 – Electrical equipment of machines

Standards ensure consistency, safety, and scalability.

Technical specifications (typical)

- Material: UNS C11000 Copper

- Thickness: 2 mm to 20+ mm

- Width: 10 mm to 200+ mm

- Finish options: bare, tin-plated, silver-plated, epoxy-coated

- Assembly: bolted joints with controlled torque

- Operating focus: low loss, low heat rise, long service life

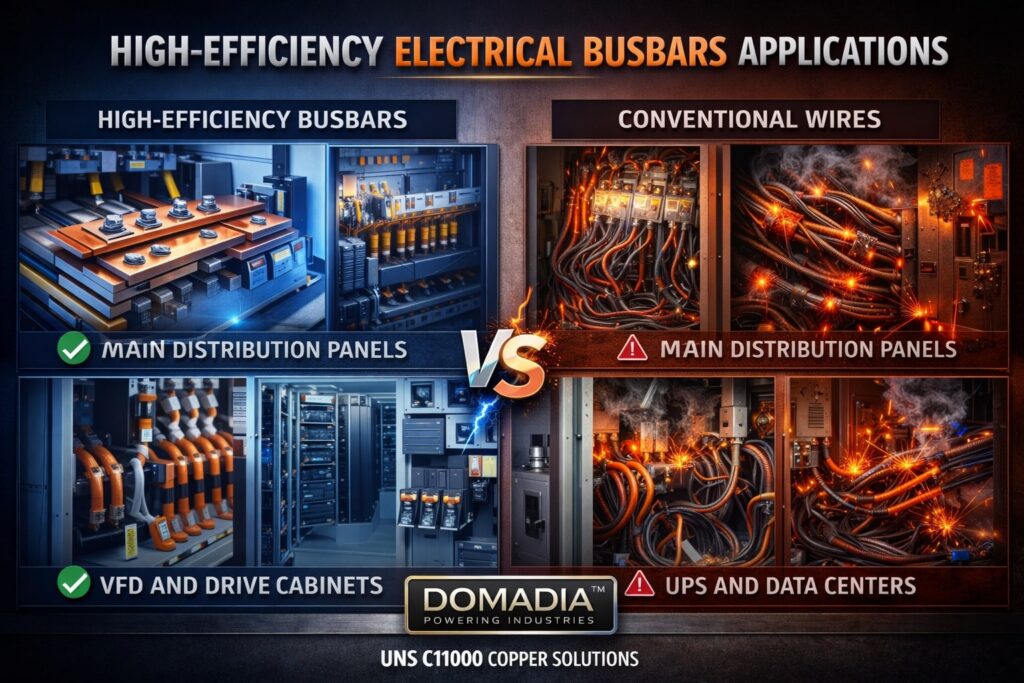

Applications where High-Efficiency Electrical Busbars dominate

1. Main LT & HT Distribution Panels: High-efficiency electrical busbars ensure uniform current flow, reduced I²R losses, and superior thermal stability in LT and HT panels. This improves safety, minimizes hotspots, and supports long-term operational reliability.

2. MCCs and PCCs: In motor and power control centers, busbars handle high current loads with lower voltage drop than conventional cables. This results in stable motor performance, easier maintenance, and reduced downtime.

3. VFD and Drive Cabinets: Busbars provide compact, low-inductance connections that limit heat buildup and electrical noise in VFD systems. This enhances drive efficiency, protects sensitive electronics, and extends equipment life.

4. UPS and Data Centers: High-efficiency electrical busbars support dense power distribution while maintaining low resistance and predictable performance. They help improve energy efficiency, reduce cooling demand, and ensure uninterrupted power delivery.

5. EV Charging and Battery Systems: In EV infrastructure, busbars manage high DC currents safely and efficiently. Their robust design improves charging reliability, reduces thermal stress, and supports fast-charging architectures.

6. Renewable Energy Inverters: Busbars enable efficient power transfer in solar and wind inverters by minimizing losses and improving thermal control. This leads to higher conversion efficiency and longer service life in demanding outdoor environments.

Shapes available from DOMADIA™

- Flat copper busbars

- Edge-rounded busbars

- Punching-ready busbars

- Laminated busbars (low inductance)

- Formed profiles (L, U, Z)

- Flexible copper bus links

- Earthing bars and custom sections

The tangible fix (actionable takeaway)

If your panels are running hot or becoming difficult to maintain:

- Identify high-current paths

- Replace parallel cable bundles with busbars

- Maintain wires only for routing complexity

This simple shift unlocks the real benefits of High-Efficiency Electrical Busbars.

Final takeaway

High-Efficiency Electrical Busbars are not an upgrade for aesthetics—they are an upgrade for reliability, efficiency, and long-term cost control. DOMADIA™ supports engineered copper busbar solutions that help industries distribute power smarter, cooler, and longer.

When current levels rise, conventional wires become a liability—not a solution.

Upgrade to DOMADIA™ High-Efficiency Electrical Busbars designed for lower losses, higher safety, and longer service life.

👉 Contact Us to engineer the right busbar solution for your system.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#HighEfficiencyElectricalBusbars #ElectricalBusbars #BusbarVsWire #CopperBusbars #UNSC11000 #PowerDistribution #IndustrialElectrical #EnergyEfficientDesign #Switchgear #LTPanel #Manufacturing #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We have supplied to Chennai, Coimbatore, Hosur, Tiruchirappalli, and Madurai across Tamil Nadu, Karnataka, Kerala, Andhra Pradesh, and Telangana, with global reach extending to Canada, France, Spain, Australia, and the United Arab Emirates.