Blogs

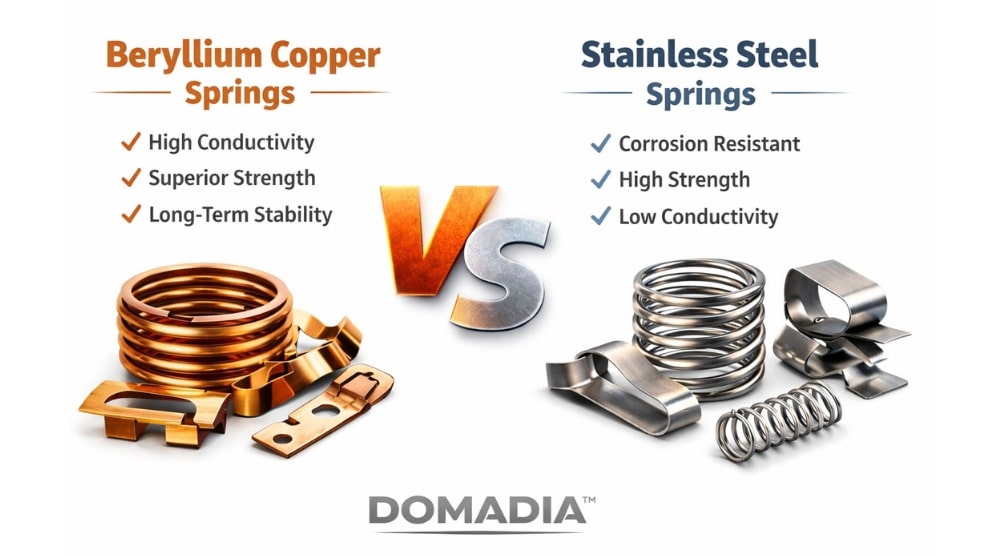

Beryllium Copper Springs vs Stainless Steel Springs: Strength, Conductivity & Longevity Compared

Beryllium Copper Springs are often the reason some products perform flawlessly for years—while others fail quietly, slowly, and expensively.

At DOMADIA™, we once worked with a manufacturer facing a puzzling issue. Their electrical connector passed inspection, assembly was perfect, and initial performance checks were green. Yet, after months in service, failures began appearing. The root cause wasn’t design, tolerance, or assembly. It was the spring material choice. A stainless steel spring was expected to act as both a mechanical force element and an electrical contact. That combination exposed a limitation stainless steel simply isn’t designed to overcome.

This is why the comparison between Beryllium Copper Springs vs Stainless Steel Springs must go deeper than price or availability. The real comparison lies in strength stability, electrical conductivity, fatigue resistance, and long-term reliability.

Beryllium Copper Springs vs Stainless Steel Springs: the mindset shift

Many engineers still view springs as purely mechanical components. Under that mindset, stainless steel often appears sufficient.

But the moment a spring must also:

- carry electrical current

- maintain stable contact pressure

- resist stress relaxation

- perform across thousands or millions of cycles

…the rules change.

This is where Beryllium Copper Springs transition from being seen as “premium” to being recognized as problem-solving materials.

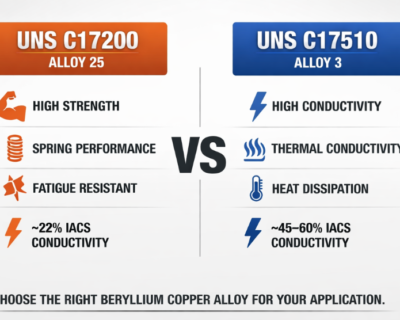

Chemical composition

Beryllium Copper Springs (UNS C17200)

UNS C17200, commonly known as Alloy 25, is a copper-based alloy strengthened through precipitation hardening. It contains approximately 1.8–2.0% beryllium, with copper as the balance and tightly controlled trace elements. This composition allows the alloy to combine high strength, elasticity, and electrical conductivity—a rare combination in spring materials.

Stainless Steel Springs (UNS S30100)

UNS S30100 is an austenitic stainless steel alloy strengthened primarily through cold working. Its composition typically includes chromium (16–18%) and nickel (6–8%), providing corrosion resistance and mechanical strength but limited electrical conductivity.

Key takeaway: Stainless steel is mechanically reliable and corrosion resistant, while Beryllium Copper Springs deliver mechanical performance plus electrical functionality.

Properties that define real-world performance

1) Strength and spring force retention

Both materials can achieve high tensile strength, but strength alone does not define spring performance.

- Beryllium Copper Springs achieve very high tensile strength after heat treatment while retaining excellent elasticity. More importantly, they maintain spring force over time.

- Stainless steel springs can reach comparable tensile strength through cold working, but they are more prone to stress relaxation, especially when exposed to heat, vibration, or continuous load.

In long-term service, force retention is often more critical than initial strength—and this is where Beryllium Copper Springs consistently outperform.

2) Electrical conductivity: the decisive factor

Electrical conductivity is where the difference becomes impossible to ignore.

- Beryllium Copper Springs offer roughly 22% IACS conductivity.

- Stainless steel springs provide only about 2–3% IACS conductivity.

This massive gap directly impacts:

- resistive heating

- signal stability

- contact reliability

- component miniaturization

When springs are part of the electrical path, Beryllium Copper Springs reduce heat buildup and ensure consistent performance.

3) Longevity, fatigue life & stress relaxation

Fatigue resistance determines how long a spring lasts under repeated loading.

- Stainless steel performs well in many mechanical-only applications.

- Beryllium Copper Springs, however, show exceptional fatigue resistance while maintaining electrical and mechanical stability.

In contact springs, connector pins, and spring fingers, stainless steel may slowly lose force, leading to intermittent failures. Beryllium Copper Springs stay springy longer, reducing field failures and warranty returns.

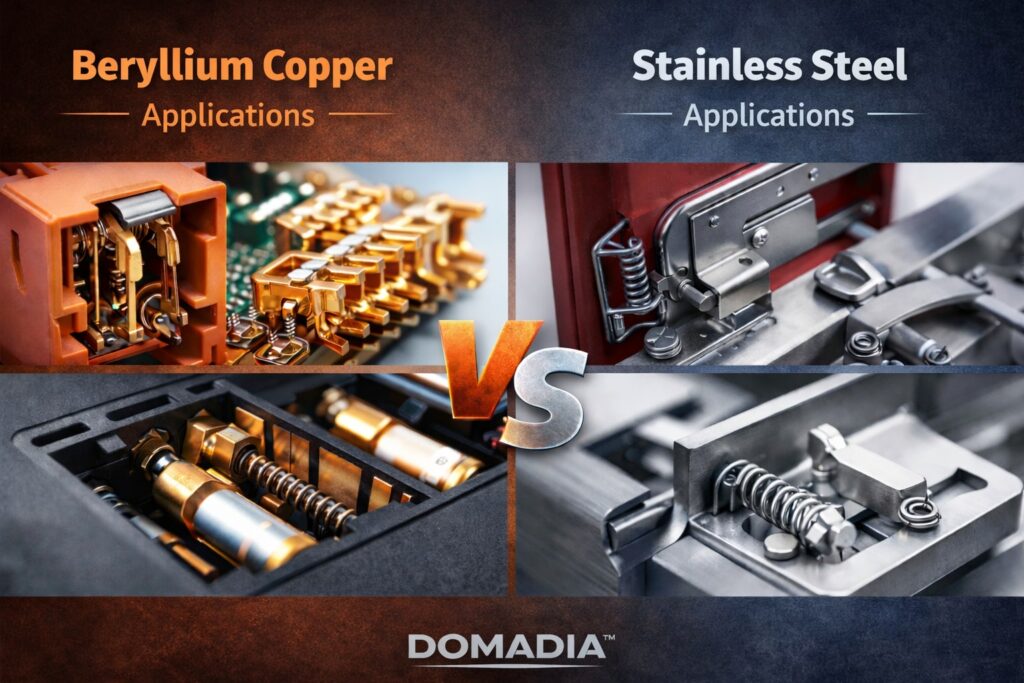

Applications: choosing the right material

Applications best suited for Beryllium Copper Springs

Beryllium Copper Springs are widely used in:

- electrical connectors and terminals

- relays, switches, and fuse clips

- battery contacts and charging pins

- EMI shielding spring fingers

- precision electronic and aerospace components

These applications demand both conductivity and long-term force stability—a combination stainless steel cannot reliably deliver.

Applications best suited for stainless steel springs

Stainless steel springs are ideal when:

- corrosion resistance is the primary concern

- electrical conductivity is not required

- springs are purely mechanical components

- cost sensitivity outweighs lifecycle considerations

DOMADIA™ frequently helps customers differentiate between these use cases, preventing overdesign or premature failures.

Standards and material specifications

Beryllium Copper Springs

- Commonly specified under UNS C17200

- Widely governed by copper alloy standards for strip, wire, rod, and plate

- Supplied in multiple tempers optimized for spring performance

Stainless Steel Springs

- Commonly specified under UNS S30100

- Governed by stainless steel strip and spring wire standards

- Strength achieved primarily through cold working

Understanding standards ensures consistent quality, repeatability, and predictable performance.

Technical specifications overview

Beryllium Copper Springs (UNS C17200)

- Electrical conductivity: ~22% IACS

- Tensile strength (spring tempers): ~190–210+ ksi

- Excellent fatigue resistance

- Low stress relaxation

- Combines mechanical and electrical functionality

Stainless Steel Springs (UNS S30100)

- Electrical conductivity: ~2–3% IACS

- Tensile strength (full hard): up to ~210 ksi

- Good corrosion resistance

- Primarily mechanical performance

Shapes and forms available at DOMADIA™

DOMADIA™ supplies Beryllium Copper Springs and stainless spring materials in a wide range of forms:

- wire (round and shaped)

- strip and coil

- sheet and plate

- rods and bars

- precision blanks

- custom-formed spring components

For compact, high-reliability electrical designs, Beryllium Copper Springs in strip or coil form are often the most effective solution.

Lifecycle cost: where the real savings appear

Stainless steel springs may appear cheaper at purchase—but failures are expensive.

Hidden costs include:

- frequent replacements

- downtime and rework

- warranty claims

- customer dissatisfaction

Because Beryllium Copper Springs last longer and perform more consistently, the cost per year of service is often significantly lower, even with a higher initial material price.

Environmental impact: durability equals sustainability

Every replacement cycle consumes energy, generates scrap, and increases environmental load.

By lasting longer in critical applications, Beryllium Copper Springs reduce replacement frequency, which means:

- less scrap

- lower recycling energy

- reduced logistics and packaging waste

This longevity-driven sustainability aligns with DOMADIA™’s commitment to responsible material selection and long-term performance.

Conclusion: the actionable decision

If your spring:

- carries current

- ensures signal integrity

- maintains contact pressure

- defines reliability

then Beryllium Copper Springs (UNS C17200) are often the smarter engineering choice.

If your spring is strictly mechanical and corrosion resistance is the priority, stainless steel remains a dependable option.

At DOMADIA™, we help engineers and buyers choose materials that prevent failure—before it happens.

Stop spring failures before they reach the field.

Connect with DOMADIA™ to select the right spring material—Beryllium Copper or Stainless Steel—based on performance, lifecycle, and reliability.

Choosing the right spring material defines reliability, lifecycle cost, and system performance.

Contact DOMADIA™ for spring solutions designed for durability, conductivity, and consistent performance.

Talk to a DOMADIA™ Material Expert Today.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#BerylliumCopperSprings #UNSC17200 #UNSS30100 #SpringMaterials #ElectricalContacts #ConnectorDesign #Conductivity #MetalSprings #ReliabilityEngineering #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav

Our reach includes Surat, Vapi, Ankleshwar, Bharuch, and Silvassa across Gujarat, Maharashtra, Dadra & Nagar Haveli, Rajasthan, and MP, with exports to China, Taiwan, Hong Kong, Macau, and Mongolia.