Blogs

Flexible Wire Performance: Solid Wire vs Flexible Wire with 9 Powerful Failure-Proof Wins

Flexible wire performance is the new reliability currency in automation

At 2:10 a.m., a packaging line stops—again. The PLC cabinet looks fine. The VFD looks fine. The sensors look fine.

But the culprit is tiny: a conductor inside a repeatedly-moving cable has work-hardened, cracked, and gone intermittent.

That’s the modern factory problem.

Robots, gantries, drag chains, moving arms, vibration-prone motors, and fast-cycling actuators punish conductors every minute. And in this world, Flexible wire performance isn’t a “nice-to-have”—it’s the difference between uptime and unplanned downtime.

At DOMADIA™, we see the same pattern across plants: engineers optimize current rating, but forget motion, bend radius, and fatigue life—the exact reasons Flexible wire performance keeps winning in automation-heavy environments.

Real scenario: the failure nobody sees until it’s too late

A maintenance team replaces a “perfectly good” control cable with solid conductor wire because it’s easier to terminate and costs less.

Three weeks later, the same line starts throwing random fault codes.

Why? Micro-cracks form at the termination point and at the first bend. Vibration + repeated flexing turns solid conductor stress into fatigue failure. That’s why Flexible wire performance becomes the quiet hero in moving and vibrating systems.

Mindset shift: Stop selecting wire only by amps and voltage. Start selecting by motion + fatigue + failure mode. That’s where Flexible wire performance becomes measurable—not theoretical.

Flexible vs Solid: what’s actually different?

Flexible wire (stranded conductor)

- Made of many small strands twisted together

- Built to survive repeated bending and vibration

- Typically used in moving equipment, control panels, automation, robotics

This is where Flexible wire performance shines because stress distributes across strands instead of concentrating in one rigid core.

Solid wire (single conductor)

- One continuous metal core

- Holds shape well, easy to terminate

- Better for fixed wiring inside walls, conduits, static panels

Solid wiring can be excellent—until movement or vibration enters the picture. Then Flexible wire performance usually wins on lifespan.

Chemical composition (typical conductor base): Copper UNS C11000 (ETP Copper)

Many industrial flexible/solid copper wires are based on high-conductivity copper such as UNS C11000.

Typical composition (Cu-ETP / UNS C11000):

- Copper (Cu): ~99.90% min

- Oxygen (O): ~0.02–0.04% (typical range)

- Trace impurities: very low, controlled

Why it matters: high copper purity supports conductivity, but conductor geometry determines fatigue life—so Flexible wire performance can outperform solid even when both are the same copper grade.

Properties that decide lifespan (not just datasheet current)

1) Fatigue resistance (the automation killer metric)

Repeated bending creates metal fatigue. Solid conductor concentrates stress at one point. Strands share stress across many wires—this is the backbone of Flexible wire performance.

2) Vibration tolerance

Motors, pumps, compressors, conveyors, and robotics introduce continuous vibration. Stranded conductors resist crack propagation better, improving Flexible wire performance over time.

3) Termination reliability

Solid wire terminates cleanly, but moving systems pull and flex at the lug/ferrule entry point. Stranded + ferrule + correct crimp technique usually delivers better long-run Flexible wire performance.

4) Bend radius and routing

Tight bends destroy conductor integrity faster than most people expect. If routing includes drag chains or frequent motion, Flexible wire performance becomes a design requirement.

Failure risks: what fails first in real plants?

Here’s what field failures commonly look like:

- Intermittent faults (the worst kind): a few strands break or a solid core cracks—signals drop randomly

- Hot spots at terminals: micro-breaks increase resistance → heat → oxidation → more resistance

- Insulation stress cracking: poor cable choice for motion causes jacket fatigue

- Shield failure in moving cables: wrong construction creates noise and false sensor readings

The fastest way to reduce these is to treat Flexible wire performance as a reliability strategy, not a wire type.

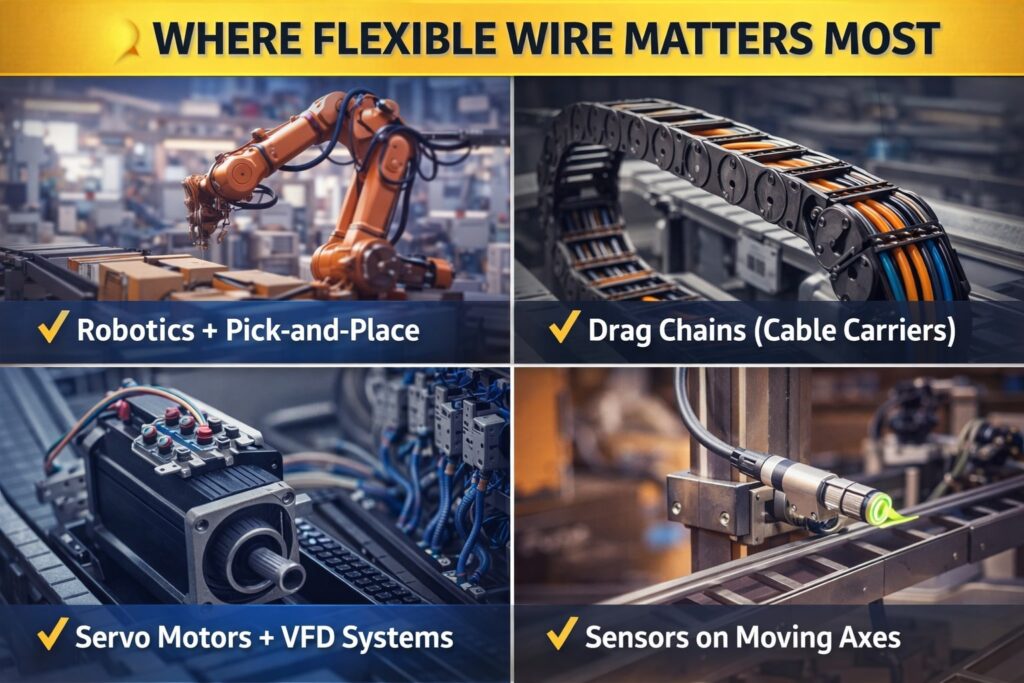

Applications: where flexibility matters more than ever

1) Robotics + pick-and-place arms

Continuous flex cycles + speed + vibration. Solid core failures appear early; Flexible wire performance keeps motion stable.

2) Drag chains (cable carriers)

Repeated bending at controlled radius. Proper stranded construction is the difference between months vs years—classic Flexible wire performance territory.

3) Servo motors + VFD-connected systems

Motion + EMI + heat. Stranded conductors improve mechanical endurance while maintaining electrical stability—another win for Flexible wire performance.

4) Sensors, encoders, limit switches on moving axes

Small signals hate intermittency. Flexible wire performance reduces false trips and phantom faults.

5) Vibrating equipment (pumps, compressors, mixers, crushers)

Even if the cable doesn’t “move,” vibration flexes it microscopically. Flexible wire performance prevents those hidden fatigue breaks.

Standards to know (selection + compliance)

When specifying industrial wire/cable, common references include:

- IEC 60228 (conductor classes—solid vs stranded vs flexible)

- IEC 60332 (flame tests)

- IEC 60502 / IEC 60227 / IEC 60245 (depending on voltage and application)

- UL styles (where UL compliance is required for machinery/export)

- RoHS / REACH (material compliance depending on region)

In automation environments, conductor class selection is central—because Flexible wire performance depends on strand class and construction, not only copper purity.

Technical specifications engineers should actually specify

If your spec only says “copper, 1.5 sq mm,” you’re leaving reliability on the table.

Use this checklist to lock in Flexible wire performance:

- Conductor type: solid / stranded / extra-flexible (IEC class)

- Stranding construction: number of strands + strand diameter

- Bend radius requirement: static vs dynamic bend radius

- Flex cycle expectation: low/medium/high cycle motion

- Temperature rating: ambient + enclosure heat + load

- Insulation/jacket material: PVC / XLPE / PUR / TPE (motion + oil + abrasion)

- Shielding (if needed): braid/foil and drain wire type

- Termination method: ferrules, crimp lugs, spring clamp compatibility

This is how you “design in” Flexible wire performance instead of “hoping for it.”

Shapes available (what DOMADIA™ can support)

For industrial conductor supply and custom needs, DOMADIA™ commonly supports:

- Solid wire (single core conductor)

- Stranded wire (standard flexible)

- Extra-flexible stranded (fine-strand constructions)

- Bunched / rope lay constructions (for dynamic motion applications)

- Tinned copper variants (where corrosion resistance is critical)

- Custom cut lengths, coils, and harness-ready formats (application dependent)

When uptime matters, choosing the right construction is choosing Flexible wire performance.

The simple rule: when should you pick what?

Choose solid wire when:

- Wiring is fixed in conduits/trunking

- There’s minimal vibration and zero repeated movement

- You need rigid routing and simple terminations

Choose flexible wire when:

- There’s motion, flexing, dragging, bending, or vibration

- You need long life under cyclic stress

- You want fewer intermittent faults and reduced downtime

In these cases, Flexible wire performance is the safer default.

6 Immediate Actions to Reduce Electrical Wire Failures

- Define dynamic vs static sections in your cable routes

- Set a minimum bend radius in drawings and现场 installation checks

- Use ferrules for stranded conductors in control panels

- Add strain relief within 150–300 mm of terminations (as routing allows)

- Match jacket material to oils/abrasion if cables move

- Standardize a “motion cable” BOM category so Flexible wire performance becomes repeatable.

Conclusion: performance, lifespan, and failure risk—one decision

Solid wire isn’t “bad.” It’s just honest—it performs best when nothing moves.

But automation-heavy plants are built on motion, vibration, and continuous cycles. That’s why Flexible wire performance keeps outperforming solid wire on lifespan and failure risk in real-world operations.

If your line can’t afford intermittent faults, unplanned shutdowns, and midnight troubleshooting, build your wiring strategy around Flexible wire performance—and let DOMADIA™ help you specify the right construction from day one.

Engineering reliability starts with the right conductor choice.

Flexible wiring solutions from DOMADIA™ are built for automation, motion, and long-term performance.

Build automation systems that last with the right flexible wiring — Contact Us — with DOMADIA™

#FlexibleWire #SolidWire #Automation #IndustrialWiring #DragChain #Robotics #ElectricalMaintenance #PlantReliability

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.