Blogs

Crucible Alloy vs Ceramic Crucibles – Which Lasts Longer in Industrial Use?

Crucible Alloy vs Ceramic Crucibles – The Question Every Foundry Eventually Faces

Crucible Alloy vs Ceramic Crucibles is not just a purchasing decision—it’s a reliability decision. In industrial environments, crucibles don’t fail politely. They crack mid-cycle, contaminate melts, halt production, and quietly inflate operational costs.

At DOMADIA™, this question often comes from engineers who have already experienced downtime and want answers backed by performance, not assumptions.

So, which truly lasts longer in industrial use? Let’s break it down.

Understanding Crucible Alloy and Ceramic Crucibles

Crucible Alloy Explained

Crucible alloys are engineered metallic materials—often nickel-based or special high-temperature alloys—designed to withstand extreme heat, thermal cycling, and chemical exposure. Unlike brittle materials, alloys rely on metallurgical stability and ductility.

DOMADIA™ Crucible Alloys are selected for:

- High-temperature strength

- Resistance to thermal shock

- Chemical stability with molten metals

- Long lifecycle under continuous operation

Ceramic Crucibles Explained

Ceramic crucibles are typically made from alumina, silicon carbide, or graphite-based composites. They are widely used due to their initial affordability and good high-temperature resistance.

They perform well in:

- Laboratory environments

- Low-volume melts

- Controlled heating cycles

However, industrial reality often exposes their limitations.

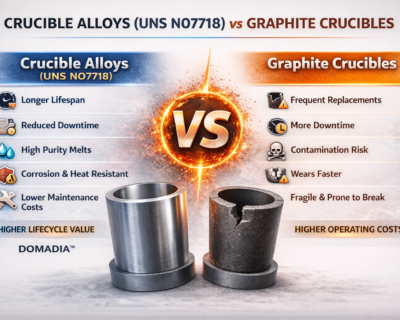

Crucible Alloy vs Ceramic Crucibles: Lifecycle Comparison

Lifecycle is where the real difference emerges.

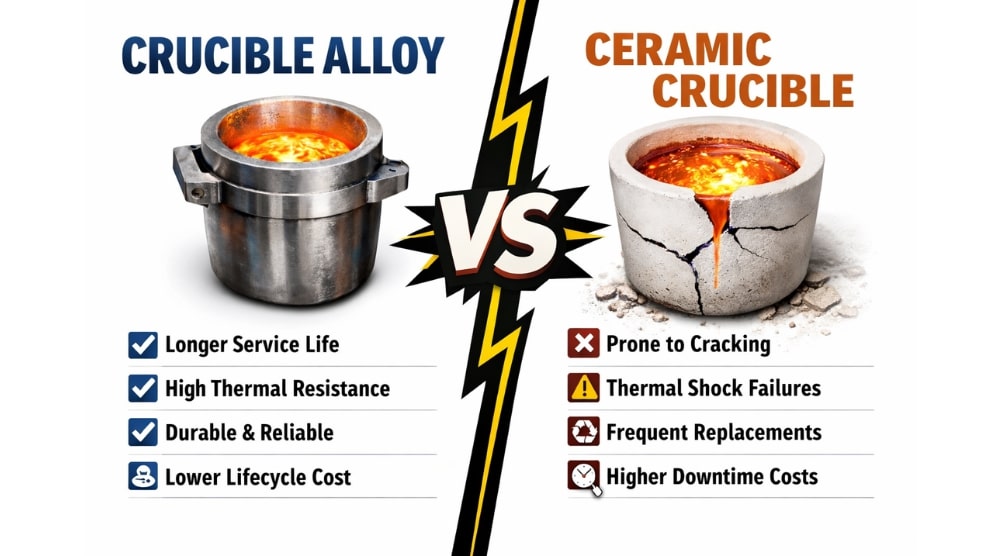

Thermal Shock Resistance

Industrial operations rarely heat slowly and cool gently.

- Ceramic Crucibles:

Ceramics are inherently brittle. Repeated heating and cooling create micro-cracks that grow silently until sudden failure. - Crucible Alloys:

Metallic alloys absorb thermal stress through controlled expansion. This flexibility dramatically improves lifespan.

Winner: Crucible Alloy vs Ceramic Crucibles → Crucible Alloy

Mechanical Strength Under Load

Molten metal is heavy. Add vibration, handling, and thermal expansion.

- Ceramic Crucibles:

High compressive strength but poor tensile strength. Once cracked, replacement is unavoidable. - Crucible Alloys:

Maintain structural integrity even under mechanical and thermal stress.

Winner: Crucible Alloy vs Ceramic Crucibles → Crucible Alloy

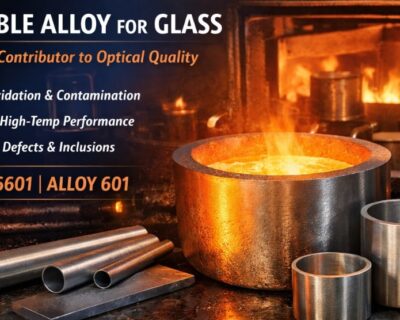

Chemical Compatibility and Melt Purity

Purity is profit in industrial melting.

- Ceramic Crucibles:

Can react with aggressive melts or fluxes, especially during extended runs. - Crucible Alloys:

Engineered for chemical resistance, minimizing contamination risks.

DOMADIA™ crucible alloys are chosen specifically to protect melt chemistry across aluminum, copper, brass, bronze, and specialty alloys.

Winner: Crucible Alloy vs Ceramic Crucibles → Crucible Alloy

Downtime: The Hidden Cost Most Buyers Miss

At first glance, ceramic crucibles appear cheaper.

But industrial math tells a different story.

Ceramic crucibles often require:

- More frequent replacement

- Unplanned shutdowns

- Production interruptions

- Higher scrap rates

Crucible alloys, while higher in initial cost, deliver:

- Longer service life

- Predictable performance

- Fewer shutdowns

- Lower total cost of ownership

This is where Crucible Alloy vs Ceramic Crucibles becomes a strategic decision—not a price comparison.

Environmental Impact: Performance Equals Sustainability

Every failed crucible creates waste.

- More replacements = more scrapping

- More recycling = higher energy consumption

- More downtime = inefficient energy use

Because crucible alloys last significantly longer, they reduce:

- Scrap generation

- Recycling frequency

- Environmental footprint

At DOMADIA™, longevity is sustainability. Choosing crucible alloys is not just an operational decision—it’s an environmental one.

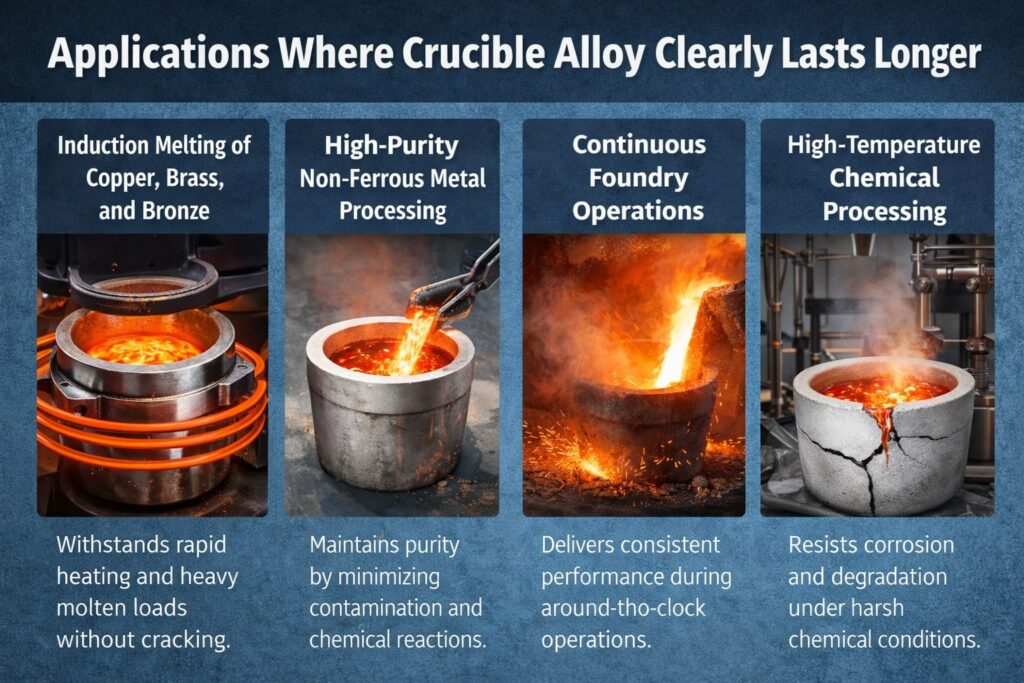

Applications Where Crucible Alloy Clearly Lasts Longer

In real-world industrial environments, the difference between Crucible Alloy vs Ceramic Crucibles becomes unmistakable. When heat, cycles, and uptime demands increase, performance—not price—defines success.

Induction Melting of Copper, Brass, and Bronze

Induction melting subjects crucibles to rapid heating, high electromagnetic stress, and heavy molten loads. Crucible alloys withstand repeated thermal cycling without cracking, while ceramic crucibles often fail due to thermal shock and mechanical stress.

High-Purity Non-Ferrous Metal Processing

Crucible alloy vs ceramic crucibles becomes a critical decision when purity matters in non-ferrous metal processing. Crucible alloys offer superior chemical stability, reducing the risk of contamination and unwanted reactions with molten metals—an area where ceramic crucibles often struggle during extended production runs.

Continuous Foundry Operations

Foundries operating 24/7 cannot afford unexpected stoppages. Crucible alloys provide consistent performance over long service periods, minimizing replacements and ensuring predictable production schedules compared to ceramic alternatives.

High-Temperature Chemical Processing

Aggressive chemical environments and elevated temperatures demand materials that resist corrosion and structural degradation. Crucible alloys maintain integrity under these harsh conditions, where ceramic crucibles may degrade or fracture.

Operations Where Downtime Is Unacceptable

In industries where every minute of downtime equals lost revenue, crucible failure is not an option. The longer service life and mechanical reliability of crucible alloys make them the safer choice over ceramic crucibles.

Where Ceramic Crucibles Still Fit

Ceramic crucibles continue to serve well in laboratory settings, low-volume melts, and controlled heating applications. However, when industrial reliability, longevity, and uptime matter most, Crucible Alloys are the clear choice.Top of FormBottom of Form

Standards and Quality Control

Crucible alloys supplied by DOMADIA™ align with internationally recognized alloy standards and undergo strict quality control for:

- Chemical composition

- Grain stability

- Thermal performance

- Dimensional consistency

Consistency is what keeps production lines running.

Final Verdict: Which Lasts Longer in Industrial Use?

When evaluated through:

- Lifecycle cost

- Thermal shock resistance

- Mechanical strength

- Chemical stability

- Downtime impact

- Environmental responsibility

The answer is clear.

Crucible Alloy vs Ceramic Crucibles → Crucible Alloys last longer in industrial use.

At DOMADIA™, we don’t just supply crucible materials—we help industries choose performance that lasts, protects processes, and reduces long-term risk.

Looking to upgrade from frequent crucible failures to long-term reliability?

Connect with DOMADIA™ and choose crucible alloys engineered for industrial endurance.

Reduce crucible failures, downtime, and replacement costs—Contact us to choose between crucible alloys and ceramic crucibles based on lifecycle performance, thermal reliability, and real industrial operating conditions.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#CrucibleAlloyVsCeramicCrucibles #CrucibleAlloys #CeramicCrucibles #IndustrialMelting #FoundryTechnology #HighTemperatureMaterials #DOMADIA™

Directly whatsapp us for an Enquiry: https://wa.link/kairav

Our reach includes Surat, Vapi, Ankleshwar, Bharuch, and Silvassa across Gujarat, Maharashtra, Dadra & Nagar Haveli, Rajasthan, and MP, with exports to China, Taiwan, Hong Kong, Macau, and Mongolia.