Blogs

Cerium Oxide SOFC Applications: 7 Advanced Breakthroughs in Solid Oxide Fuel Cells | DOMADIA™

Introduction: Why Cerium Oxide Is Quietly Powering the Hydrogen Economy

Cerium Oxide SOFC technology rarely makes headlines—but it sits at the heart of one of the world’s most promising clean energy systems.

In a recent pilot SOFC installation at an industrial microgrid, engineers faced a familiar problem: excellent theoretical efficiency, but rapid performance drop under real operating conditions. The electrolyte survived. The electrodes didn’t. Redox cycling, thermal stress, and interface instability slowly eroded output.

The turning point came with advanced ceria-based materials engineered for high-performance fuel cell systems.

Not as a replacement—but as a strategic enabler.

At DOMADIA™, we see this pattern repeatedly: when Cerium Oxide SOFC components are engineered correctly, SOFC systems stop behaving like lab experiments and start behaving like power assets.

Understanding Cerium Oxide in SOFC Systems

These advanced ceria-based materials are primarily composed of cerium oxide (CeO₂), often doped with rare earth elements such as gadolinium or samarium to enhance ionic conductivity.

Unlike conventional zirconia-only systems, they exhibit mixed ionic–electronic conductivity, making them exceptionally valuable in next-generation fuel cell architectures.

Why this matters:

- Faster oxygen ion transport

- Lower operating temperatures

- Improved redox stability

- Reduced degradation during cycling

In short, these advanced ceria-based materials expand the operating window of SOFC systems beyond fragile, narrow lab conditions.

Chemical Composition of Cerium Oxide SOFC Materials

Typical Cerium Oxide SOFC compositions include:

| Component | Typical Range |

| Cerium Oxide (CeO₂) | 80–95% |

| Gadolinium Oxide (Gd₂O₃) or Samarium Oxide (Sm₂O₃) | 5–20% |

| Trace stabilizers | <1% |

Doping introduces oxygen vacancies, which dramatically improves ionic mobility—one of the defining advantages of Cerium Oxide SOFC systems.

Key Properties of Advanced Ceria-Based Fuel Cell Materials

These advanced ceria-based materials are selected not just for chemistry, but for their performance under extreme operational stress.

Core Properties:

- High oxygen ion conductivity at intermediate temperatures

- Excellent redox reversibility

- Strong resistance to carbon deposition

- Thermal expansion compatibility with SOFC stacks

- Enhanced catalytic activity

These properties allow Cerium Oxide SOFC components to perform reliably where conventional ceramics fail.

Technical Specifications (Typical Ranges)

| Parameter | Value |

| Operating Temperature | 500°C – 800°C |

| Ionic Conductivity | Up to 0.1 S/cm |

| Density | 6.8–7.2 g/cm³ |

| Melting Point | ~2400°C |

| Oxygen Storage Capacity | High |

At DOMADIA™, Cerium Oxide SOFC specifications are customized based on cell architecture—not generalized datasheets.

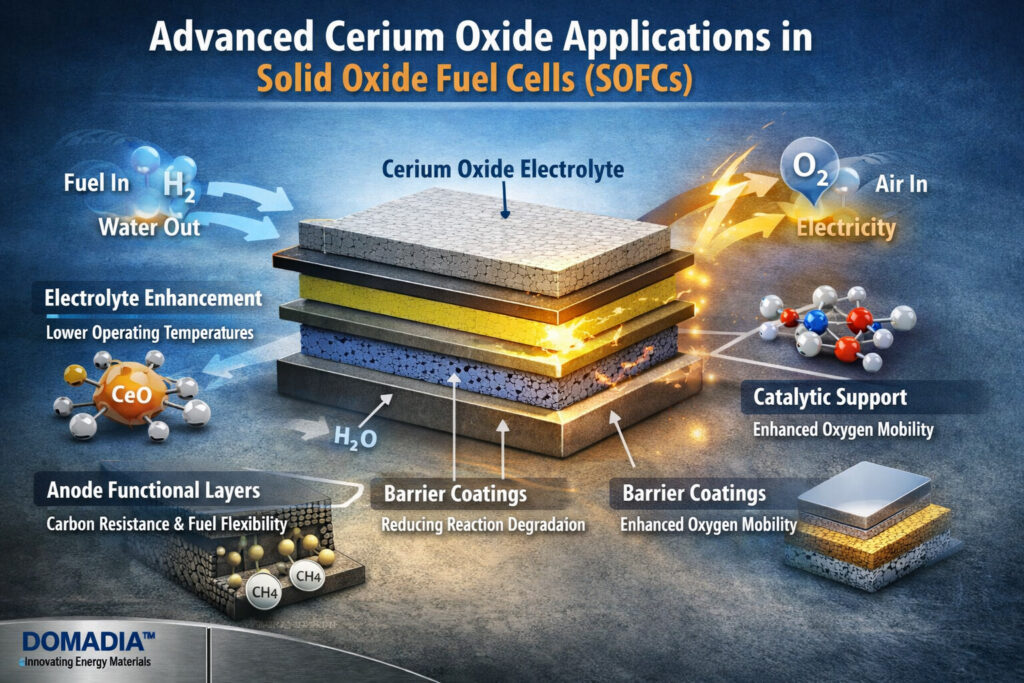

Applications of Cerium Oxide SOFC Technology

1. Electrolyte Enhancement

Cerium Oxide SOFC materials enable lower-temperature operation, improving efficiency and extending stack life.

2. Anode Functional Layers

Mixed conductivity helps suppress carbon fouling and improves fuel flexibility.

3. Interlayers & Barrier Coatings

Cerium Oxide SOFC interlayers reduce chemical interaction between electrodes and electrolytes.

4. Catalytic Support Structures

Enhanced oxygen mobility improves reaction kinetics in reforming and oxidation zones.

Across all these uses, Cerium Oxide SOFC materials reduce degradation rates—often the single biggest cost driver in SOFC ownership.

Standards & Quality Expectations

While Cerium Oxide SOFC materials are application-specific, they typically align with:

- ASTM standards for advanced ceramics

- ISO purity and trace element controls

- SOFC OEM internal qualification protocols

DOMADIA™ works closely with system designers to ensure Cerium Oxide SOFC materials meet both regulatory and operational expectations.

Shapes & Forms Available from DOMADIA™

These advanced ceria-based materials are not a one-size-fits-all solution.

Available forms include:

- Fine powders (controlled particle size)

- Granules for tape casting

- Pellets and discs

- Coatings and slurries

- Custom-processed shapes

The wrong form can undermine even the best Cerium Oxide SOFC chemistry—something we actively help customers avoid.

The Mindset Shift: Materials Are Not Commodities

Many SOFC failures are blamed on “design limitations.”

In reality, they’re often material-interface problems.

Cerium Oxide SOFC performance depends on:

- Particle size distribution

- Dopant uniformity

- Sintering behavior

- Thermal compatibility

At DOMADIA™, we position Cerium Oxide SOFC materials as performance variables, not line items.

The Tangible Fix: Engineering for Lifecycle, Not Just Efficiency

Higher-purity Cerium Oxide SOFC materials may appear costlier upfront. But frequent stack replacement, downtime, and recycling quickly dwarf initial savings.

Longer-lasting Cerium Oxide SOFC components:

- Reduce replacement frequency

- Lower recycling impact

- Cut lifecycle emissions

- Improve system ROI

This is not just cost control—it’s environmental responsibility built into materials engineering.

Conclusion: A Strategic Energy Material for Next-Generation SOFC Systems

Cerium Oxide SOFC materials are no longer experimental additives. They are foundational to scalable, reliable, and commercially viable SOFC systems.

When engineered correctly, Cerium Oxide SOFC solutions unlock:

- Lower operating temperatures

- Longer system life

- Broader fuel flexibility

- Reduced environmental impact

At DOMADIA™, we don’t just supply Cerium Oxide SOFC materials—we help define how they perform in the real world.

Power Your Performance with High-Purity Cerium Oxide

From precision polishing to advanced fuel cell systems, Cerium Oxide Powder plays a critical role in high-performance industrial applications.

At DOMADIA™, we supply controlled-purity, application-ready Cerium Oxide engineered for consistency, stability, and reliability.

Let’s discuss your specifications Contact Us and deliver material solutions that perform under real-world conditions.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#CeriumOxideSOFC #SOFCMaterials #CleanEnergyTech #AdvancedCeramics #FuelCellTechnology #DOMADIA™

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.